CNC machining configures materials with exact measurements. These machines use computerized controls to design intricate geometries. De plus, modern CNC machines allow the application of CAD (computer-aided design) to facilitate the production of detailed complex designs by reducing material wastage. De plus, automation has significantly increased productivity and mitigated operators’ dependency.

Dans cet article, we will discuss the primary benefits of CNC machining in detail.

Importance of CNC Machining

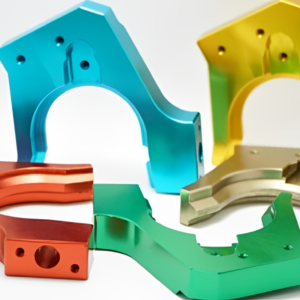

It’s crucial to pinpoint that Usinage CNC has become a meticulous contemporary fabrication. It offers the benefits of high dimensional accuracy, excellent stability, and scale economy. The technique makes it possible to create simpler parts that conventional fabrications can not turn into reality. Par exemple, it boasts the production of telecommunication equipment including heat sinks, microwave tower parts, and amplifier enclosures. En outre, the process enables the reproduction of highly detailed mechanical parts and simultaneously, conforms to technical and geometrical requirements.

How to choose the right CNC Machine

When choosing a CNC machine, a few parameters are important to consider. Consider the following tips:

- Project Objectives: Set out the project goals onset. If you’re going to work with wood, then a CNC router is optimal for your application. For metalworking, a CNC plasma cutter can be a good option.

- Budget Considerations: Do not forget about the general cost. This comprises the initial machine cost to labor cost & maintenance throughout its use by the CNC factory.

- Machine Weight: Determine the weight-carrying capacity of the CNC machine. Housing, par exemple, involves heavy duties because of the forces involved. Thus the cast iron construction while a light duty might use a different lighter machine.

- Power Requirements: It’s suggested to assess the power rating of the equipment being used. Because it influences your cost breakdown and therefore should coincide with the electrical capacity of your facility.

10 Benefits of CNC Machining

1. CNC Machining Reduces Material Wastage On Floor

CNC machining is an effective process in terms of minimizing wasted material. When designing parts, the faulty cuts are likely to be minimal. Accuracy leads to less likelihood of having several faulty products, therefore optimizing the material usage. This technology makes it possible to make appropriate cuts without having to produce unnecessary waste.

2. CNC Machining Offers Good Precision and Accuracy

The CNC machines work on set computer programs, and hence, give out similar results. High accuracy is required for many parts and the physical models compare well with the digital models. The automation eliminates laborious operations while minimizing human error in the production lines.

3. CNC Machining Guarantees High Speed and High Quality of Products

The processes of CNC machining are fast and effective. These machines can manufacture components at a faster rate than is possible through conventional techniques. In the current models, there are possibilities of loading and unloading the materials without much operator interference. Automation results in better efficiency and a considerable reduction in costs.

4. CNC Machining Makes Assembly Easier

Parts produced by CNC machining make assembly tasks easier. Due to the high level of precision in production, the components of a product are well-fitted in the production line. Reduced time for processing results in a shorter turnaround to wait for the completion of the part. Donc, when body kits are developed accurately, assembly only needs slight modifications hence reducing costs.

5. CNC Machining Helps Increasing Safety at Workplace

CNC machining has been found to greatly minimize safety hazards in the manufacturing environment. Automation means dangers inherent in manual activities are reduced to the barest minimum. Usually sealed off, these machines even more shield the operators from possible injuries.

6. CNC Machining is Energy Efficient

Compared to conventional modes of parts fabrication, CNC machining consumes much less energy. Indications show that the process consumes approximately one-seventh of the power of conventional machining. Efficiency is derived from short cycle times and low power consumption per minute hence lower electric consumption.

7. CNC Machining Reduces Cost of Production

Comme discuté plus tôt, CNC machining is an efficient and accurate parts-making process. The machines utilize more raw materials than conventional methods hence they use fewer materials. De plus, the use of CNC technology in the production process minimizes costs through the elimination of mistakes and increases profitability.

Initialement, CNC milling machines were used only for complex operations. They work with different kinds of materials such as metal, verre, plastique, et même du bois. As equipped with various functions, they form complicated patterns, carve patterns, and inscribe writings. Originally costly, current CNC machines are relatively cheap and thus suitable for both recreational users and experts.

9. CNC Machining Maintains Consistent Quality and Design Integrity

CNC machining ensures part and input parameters are consistent during manufacturing and design. When several cycles are executed, the final products are equally uniform in terms of quality. The only way to break this consistency is by intentionality. Such accuracy is desirable in applications that demand high accuracy and the ability to reproduce a given result multiple times.

10. Digital Simulations as a Tool for Virtual Prototyping

CNC machining enables the creation of actual models where the actual product can be simulated on the computer. Manufacturers can examine the results of their programs before a full-scale implementation of it. These simulations will assist in pointing out problems prior that may be experienced in the future. Donc, refining designs enables waste reduction and increases manufacturing effectiveness.

Is CNC Machining better than Traditional Machining?

If you’re contemplating the integration of CNC machines into your production process, you can expect the following benefits:

- Minimal Skill Requirement: CNC machining services do not require a lot of technical training or experience in the operation of the equipment.

- High Replication Capacity: Large quantity production is possible and quality is not compromised because products can be produced in 1000s of volume.

- Reduced Labor Needs: The CNC machinery operation entails less effort as compared to traditional systems.

- Versatile Production Options: CNC software also increases flexibility which is an important aspect of manufacturing.

- No Need for Prototypes: In CNC machining, there is no need for developing models as a practice that is identical to conventional production modes.

- Modern Workforce Compatibility: CNC machining is compatible with the skills of modern employees.

- Superior Finish Quality: Oil-based coolants lead to improved surface finishes when used.

- Lighter and Stronger Parts: Through CNC machining you can create complex geometries and thus make highly rigid components.

En général, CNC machining has several advantages over traditional manufacturing methods. Some of these advantages include; higher design flexibility, improved precision, and the production of intricate details.

Conclusion

CNC machining is an innovative manufacturing technique that involves the use of computers. These are accurate, controlled, and highly efficient. Parts produced by CNC machining are of higher quality when compared with parts being made manually. En outre, these advantages enable the companies to gain competitive benefits and foster success in most manufacturing fields.

Précision au sommet provides enhanced CNC Machining solutions to enable your business to achieve higher standards and function for improvement. Whether it’s one part or many, Tops Precision has a fast delivery, within 10 days turnaround. Explore how Tops Precision brings your ideas into focus with efficiency, précision, and economy. Contact us and start your project today!