Alluminio è uno dei materiali tecnici più versatili grazie alla sua forza leggera, resistenza alla corrosione, e alta conduttività. È ampiamente utilizzato nel settore aerospaziale, settore automobilistico, elettronica di consumo, dispositivi medici, e architettura. Tuttavia, le superfici in alluminio grezzo o lavorato spesso richiedono finitura superficiale per migliorare le prestazioni, durabilità, e appello visivo.

La finitura superficiale non è solo una questione estetica. Può migliorare notevolmente la resistenza dell’alluminio alla corrosione, abrasione, e attacco chimico, garantendo allo stesso tempo che i componenti si incontrino tolleranze strette e requisiti funzionali. Se hai bisogno di un pannello in alluminio lucidato a specchio, una parte aerospaziale resistente alla corrosione, o un involucro durevole di un prodotto di consumo, il giusto metodo di finitura è fondamentale.

Questa guida esplora perché la finitura superficiale dell’alluminio è importante, IL 10 metodi di finitura più comuni, diversi effetti e stili di superficie, e come scegliere quello giusto per la tua applicazione.

Perché i prodotti in alluminio necessitano di finitura superficiale?

La finitura superficiale dell'alluminio serve a entrambi funzionale E estetico scopi. Di seguito sono riportati i motivi principali per cui è essenziale:

Resistenza alla corrosione: L'alluminio forma naturalmente una sottile pellicola di ossido, ma in ambienti difficili, rifiniture aggiuntive (per esempio., anodizzazione o film chimico) garantisce una protezione a lungo termine.

Resistenza all'usura: Molte parti in alluminio sono esposte ad attrito o sollecitazioni meccaniche. I rivestimenti duri migliorano la resistenza ai graffi e la durata.

Proprietà elettriche e termiche: Alcune finiture migliorano la conduttività (per esempio., pellicola chimica), mentre altri migliorano l'isolamento (per esempio., anodizzazione).

Attrito ridotto & Contaminazione: Le finiture lisce riducono l'attrito e impediscono l'accumulo di sporco o umidità nelle fessure.

Appello estetico: Finiture come la lucidatura, spazzolatura, e la verniciatura a polvere offrono stili diversi, dalla lucentezza a specchio alle texture satinate o opache.

In breve, la finitura dell’alluminio influenza direttamente quella di un prodotto durata, prestazione, e valore del marchio.

10 Tipi comuni di finiture in alluminio

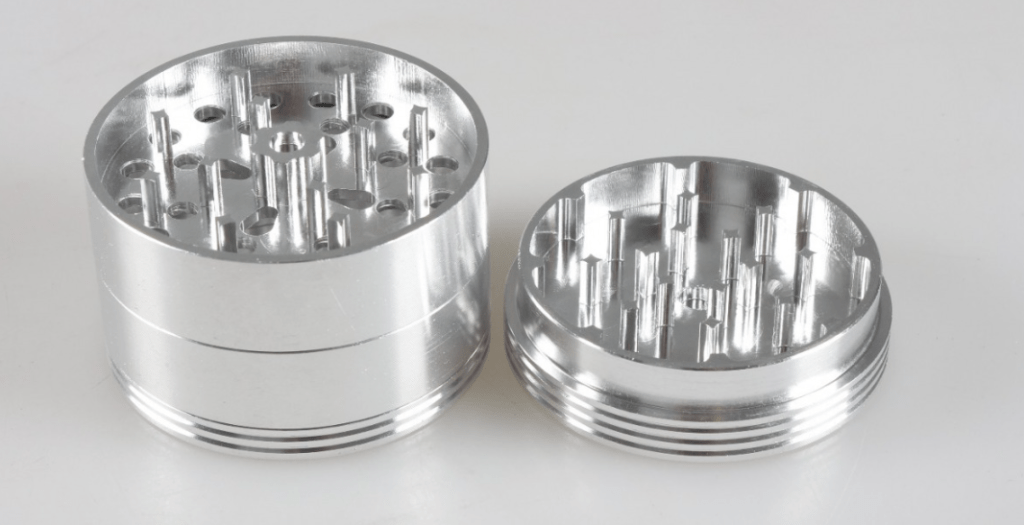

1. Finitura as-machined

Processi: La parte è lasciata allo stato grezzo, stato lavorato.

Rugosità superficiale: Tipicamente Ra 0.2 – 3.2 µm, a seconda dei parametri di lavorazione.

Professionisti: Basso costo, mantenute tolleranze accurate.

Contro: Segni di utensili visibili, protezione limitata dalla corrosione.

Applicazioni: Componenti interni, prototipi, parti non decorative.

2. Anodizzazione

Processi: Trattamento elettrochimico che forma uno strato di ossido controllato.

Spessore: 5–25 μm per decorativi, fino a 50 μm per l'anodizzazione dura.

Benefici:

Eccellente resistenza alla corrosione e all'usura.

Ampia gamma di opzioni di colore.

Superficie non conduttiva per l'isolamento elettrico.

Applicazioni: Pannelli aerospaziali, elettronica di consumo, dispositivi medici.

3. Verniciatura a polvere

Processi: Spruzzatura elettrostatica di particelle di polvere, stagionato a caldo.

Superficie: Protettivo, decorativo, finitura leggermente strutturata.

Benefici:

Senza solventi → ecologico.

Eccellente varietà di colori.

Forte adesione e durata.

Applicazioni: Ruote automobilistiche, mobilia, recinti esterni.

4. Alodino (Film chimico)

Processi: Immersione in un bagno chimico che forma un rivestimento di conversione.

Benefici:

Resistenza alla corrosione economicamente vantaggiosa.

Mantiene conduttività elettrica (a differenza dell'anodizzazione).

Ideale per parti che richiedono la verniciatura successiva.

Applicazioni: Strutture aerospaziali, custodie elettroniche.

5. Sabbiatura delle perle

Processi: Sfere abrasive di vetro o acciaio sabbiate sotto pressione.

Superficie: Liscio, Texture in raso.

Benefici:

Pulisce le impurità.

Crea un aspetto opaco uniforme.

Applicazioni: Beni di consumo, hardware decorativo, interni automobilistici.

6. Galvanotecnica

Processi: Deposizione di metalli come il nichel, oro, argento, o cromo su alluminio tramite elettrolisi.

Benefici:

Conduttività migliorata, resistenza all'usura, e riflettività.

Aggiunge un'estetica di lusso (placcatura oro/argento).

Applicazioni: Elettronica, Connettori aerospaziali, prodotti di consumo di lusso.

7. Lucidatura

Processi: Lucidatura meccanica o chimica per una superficie riflettente.

Benefici:

Migliora la luminosità e l'estetica.

Riduce l'ossidazione levigando i pori.

Applicazioni: Pannelli decorativi, attrezzature mediche, parti di visualizzazione.

8. Spazzolatura

Processi: Le spazzole abrasive creano bene, trama lineare.

Superficie: Aspetto satinato o metallico, riduce i graffi visibili.

Applicazioni: Elettrodomestici da cucina, finiture automobilistiche, pannelli architettonici.

9. Incisione laser

Processi: Il raggio laser focalizzato incide segni o testi permanenti.

Benefici:

Alta precisione e ripetibilità.

Identificazione o marchio permanente.

Applicazioni: Componenti aerospaziali, dispositivi medici, strumenti industriali.

10. Immersione brillante

Processi: Immersione chimica in acido per una lucentezza a specchio.

Benefici:

Crea altamente riflettente, superficie lucida.

Ideale per parti decorative.

Limitazioni: Non compatibile con tutte le leghe (meglio con 6463).

Applicazioni: Cibo & attrezzature per bevande, profili decorativi.

Diversi effetti di superficie & Stili per finiture in alluminio

La finitura non è solo una questione di protezione, ma definisce anche l'aspetto e la sensazione dell'alluminio.

Alta brillantezza (Brillante, Riflessivo): Ottenuto tramite lucidatura, immersione brillante, o anodizzazione con lucentezza. Comune nell'elettronica, finiture automobilistiche, e oggetti di lusso.

Raso (Bagliore morbido, 72 Lucentezza GU): Ottenuto tramite spazzolatura o sabbiatura. Bilancia estetica e durata, nasconde le imperfezioni.

Opaco (Non riflettente, 30 Lucentezza GU): Ottenuto tramite anodizzazione o verniciatura a polvere. Resistente alle impronte digitali e richiede poca manutenzione.

Metallico (Aspetto di lusso): Ottenuto tramite anodizzazione, spazzolatura, o galvanica. Può imitare l'ottone, rame, oro, o finiture in acciaio inox.

Fattori da considerare quando si sceglie una finitura superficiale dell'alluminio

Quando si sceglie la finitura giusta, ingegneri e progettisti devono considerare:

Ambiente applicativo: Interni vs. uso esterno, Esposizione ai raggi UV, prodotti chimici corrosivi, o abrasione.

Requisiti estetici: Colore, lucentezza, struttura, coerenza del marchio.

Costo: Costo di elaborazione iniziale + spese di manutenzione o sostituzione a lungo termine.

Durabilità: Durata prevista della finitura, resistenza all'usura e agli agenti atmosferici.

Funzionalità: Conduttività vs. isolamento, considerazioni sul peso, attrito superficiale.

Applicazioni industriali delle finiture in alluminio

Le finiture in alluminio non servono solo a conferire al metallo un bell'aspetto, ma rendono anche le parti più resistenti, più duraturo, e più affidabile in ambienti difficili. A seconda della finitura, l'alluminio può essere utilizzato quasi ovunque, dagli aerei agli smartphone.

Aerospaziale

Le parti degli aerei devono resistere a sollecitazioni elevate, variazioni di temperatura, ed esposizione all'umidità. Finisce come anodizzazione E pellicola chimica (alodino) sono ampiamente utilizzati perché migliorano la resistenza alla corrosione senza aggiungere troppo peso. L'incisione laser è comune anche per la marcatura permanente delle parti, che è importante per la sicurezza e la tracciabilità.

Settore automobilistico

Auto, camion, e le motociclette si affidano a finiture in alluminio per entrambi protezione e stile. Sulle ruote vengono utilizzate la verniciatura a polvere e l'anodizzazione, finiture, e parti del motore per la protezione dal sale stradale, Calore, e indossare. Anche le finiture lucide e spazzolate sono apprezzate per conferire ai veicoli un aspetto elegante, look moderno.

Elettronica di consumo

Il liscio, involucro lucido sul tuo smartphone o laptop spesso proviene dall'anodizzazione o dalla sabbiatura. Queste finiture conferiscono al dispositivo un aspetto premium proteggendolo allo stesso tempo da graffi e impronte digitali.

Dispositivi medici

Nella sanità, i materiali devono essere sicuro, facile da pulire, e resistente alla corrosione. Le parti in alluminio anodizzato e lucidato sono spesso utilizzate negli strumenti chirurgici, attrezzature ospedaliere, e persino componenti dell'impianto. Queste finiture mantengono le superfici lisce, sterile, e durevole.

Architettura e costruzione

Da infissi per facciate di edifici, l’alluminio è ovunque nell’architettura moderna. La verniciatura a polvere è particolarmente apprezzata qui perché può fornire una protezione duratura e un'ampia gamma di colori per soddisfare le esigenze di progettazione. Le finiture spazzolate o metalliche aggiungono anche un aspetto esclusivo agli elementi interni come mobili e apparecchi di illuminazione.

Macchinario industriale

Le macchine per carichi pesanti utilizzano spesso componenti in alluminio anodizzato o elettrolitico per una maggiore resistenza all'usura e migliori prestazioni elettriche. Ciò garantisce che le parti possano resistere ad ambienti difficili senza rompersi rapidamente.

Conclusione

La finitura dell'alluminio è un passaggio cruciale per garantire che le parti soddisfino entrambi esigenze funzionali ed estetiche. Con opzioni che vanno dalla pellicola chimica economica alla immersione lucida decorativa e all'anodizzazione ad alte prestazioni, ogni finitura offre vantaggi unici per diverse applicazioni.

Considerando attentamente ambiente applicativo, esigenze di durabilità, costo, e l'aspetto desiderato, i produttori possono selezionare la giusta finitura superficiale dell'alluminio per migliorare sia il prestazioni e durata dei loro prodotti.

Domande frequenti

- Qual è la finitura in alluminio più resistente?

L'anodizzazione, in particolare l'anodizzazione dura, offre una resistenza superiore all'usura e alla corrosione, rendendolo una delle finiture più durevoli. - Quale finitura previene meglio la corrosione?

L'anodizzazione e l'alodine sono entrambi efficaci, con l'anodizzazione che offre una migliore resistenza a lungo termine. - Qual è il trattamento superficiale dell'alluminio più conveniente??

Pellicola chimica (alodino) è relativamente economico pur garantendo una forte resistenza alla corrosione e adesione della vernice.