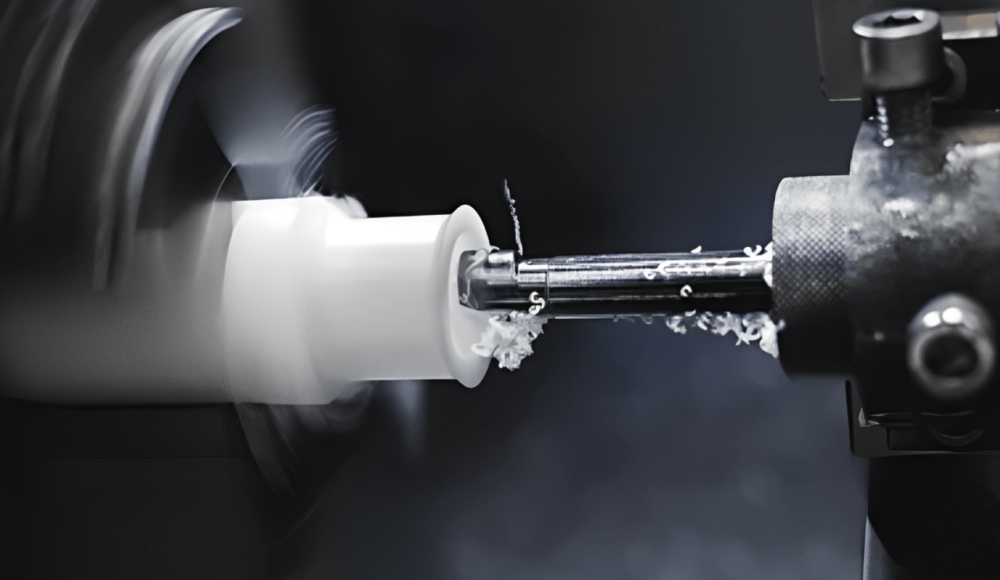

Lavorazione CNC è popolare per la sua funzionalità di automazione. Non solo accelera la velocità. Ma promuovono anche alta precisione e accuratezza. oltre a questo, è utilizzato in molte applicazioni in molti settori. COSÌ, quando parliamo di lavorazione CNC e dei suoi prodotti in uscita. Consideriamo anche i materiali che utilizziamo per il processo di lavorazione CNC. In questo articolo, Esploreremo i diversi materiali ideali per la lavorazione a CNC, i fattori da considerare quando si selezionano i materiali, e suggerimenti per ottimizzare le scelte di materiale per i tuoi progetti.

Diverse categorie di materiale nella lavorazione del CNC

La lavorazione a CNC è un processo versatile in grado di lavorare con una vasta gamma di materiali. Mentre il metallo e la plastica sono i materiali più comunemente usati, La lavorazione a CNC può anche ospitare materiali come la ceramica, legna, e materiali compositi. Ogni categoria materiale presenta vantaggi e sfide distinte, che rende importante scegliere quello giusto a seconda dell'applicazione.

Categorie di Materiali per la lavorazione CNC:

- Metalli- comunemente usato in settori come l'aerospaziale, settore automobilistico, e dispositivi medici a causa della loro durata e forza.

- Plastica- Popolare nei beni di consumo e nelle industrie mediche, dove leggero, Sono necessarie parti resistenti alla corrosione.

- Compositi- Utilizzato in industrie specializzate come la produzione di attrezzature aerospaziali e sportive, Offrire rapporti elevati di forza a peso.

- Legno e ceramica-Utilizzato per la produzione specializzata e a basso volume, in genere per prodotti artistici o unici.

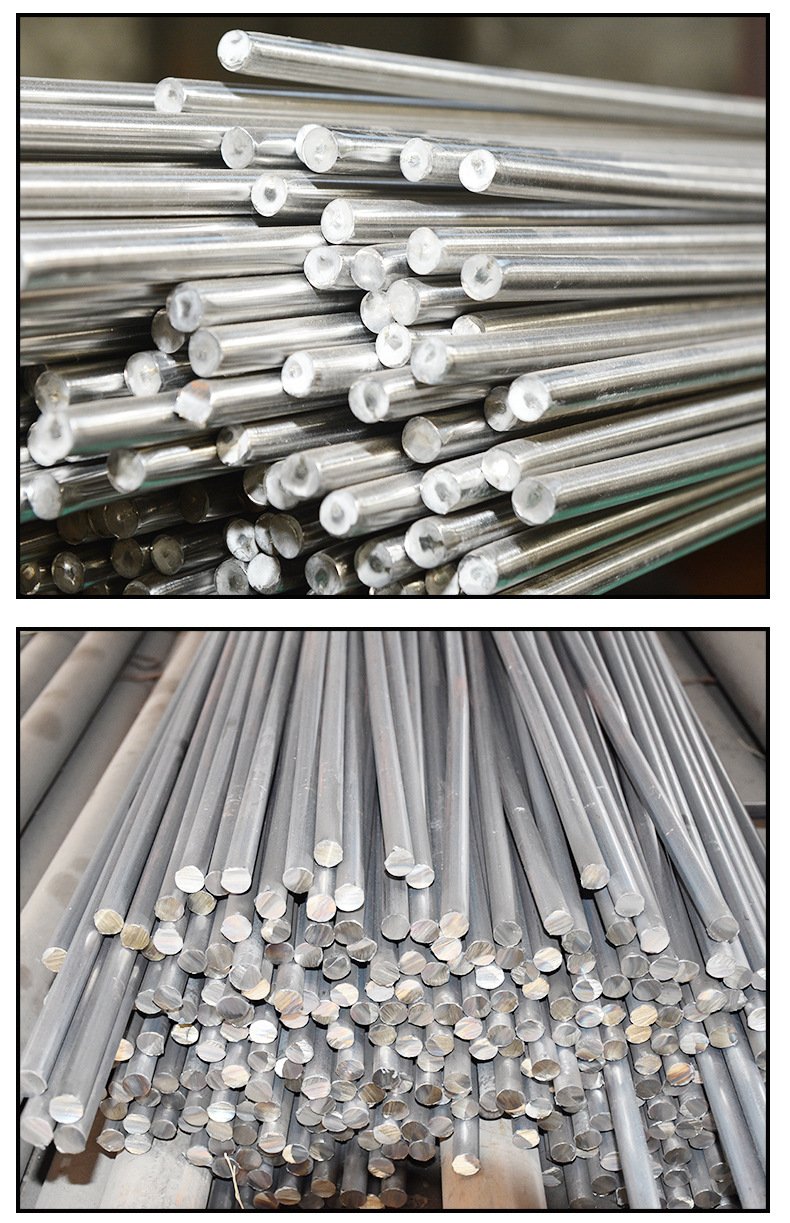

Tipi di materiali metallici per la lavorazione a CNC ed esempi

I metalli sono il materiale di riferimento per la maggior parte delle operazioni di lavorazione a CNC a causa della loro forza, resistenza al calore, e capacità di sopportare carichi pesanti. Sotto, Esploriamo i metalli più comunemente usati nella lavorazione del CNC.

Alluminio

L'alluminio è uno dei metalli più comunemente usati nella lavorazione del CNC. I suoi vantaggi includono una bassa densità, elevato rapporto resistenza/peso, e eccellente macchinabilità. Leghe di alluminio, ad esempio 6061 E 7075, sono ampiamente utilizzati nelle industrie che richiedono materiali leggeri ma forti, come aerospaziale, settore automobilistico, ed elettronica di consumo. È resistente alla corrosione e offre eccellenti finiture superficiali, rendendolo adatto per parti sia funzionali che estetiche.

Acciaio inossidabile

L'acciaio inossidabile è noto per la sua resistenza alla corrosione, tenacità, e alta forza. È spesso usato nei dispositivi medici, aerospaziale, e applicazioni marine. Mentre l'acciaio inossidabile ha una resistenza superiore alla corrosione, La sua durezza può rendere difficile la macchina. I gradi comuni di acciaio inossidabile utilizzati nella lavorazione a mezzi CNC includono 303, 304, E 316.

Acciaio al carbonio e le sue leghe

L'acciaio al carbonio è ampiamente utilizzato grazie alla sua eccellente macchinabilità, forza, e convenienza. È particolarmente favorito per applicazioni che richiedono robuste proprietà meccaniche come i componenti strutturali, ingranaggi, e dispositivi di fissaggio. Tuttavia, La mancanza di resistenza alla corrosione dell'acciaio di carbonio limita le sue applicazioni in ambienti difficili se non rivestiti.

Rame e le sue leghe

Il rame è scelto per la sua alta conducibilità termica ed elettrica. È spesso usato in componenti elettrici come cablaggio e connettori, così come nei sistemi di raffreddamento. Ottone E bronzo, leghe di rame, Offrire una migliore macchinabilità e resistenza alla corrosione, rendendoli ideali per la produzione di componenti di precisione come gli ingranaggi, cuscinetti, e connettori.

Titanio

Il titanio offre un'eccezionale combinazione di forza e proprietà leggere. È ampiamente utilizzato nelle industrie ad alte prestazioni, tra cui impianti aerospaziali e medici. Tuttavia, Il titanio è difficile da macchiare a causa della sua tenacia, Sono necessari processi di utensili e lavorazione specializzati.

Magnesio

Il magnesio è uno dei metalli più leggeri, rendendolo una scelta adatta per le applicazioni che richiedono un peso ridotto, come automobilistico e aerospaziale. Le proprietà di Magnesio lo rendono anche eccellente per le applicazioni ad alta temperatura. Tuttavia, La sua infiammabilità durante la lavorazione rappresenta una sfida.

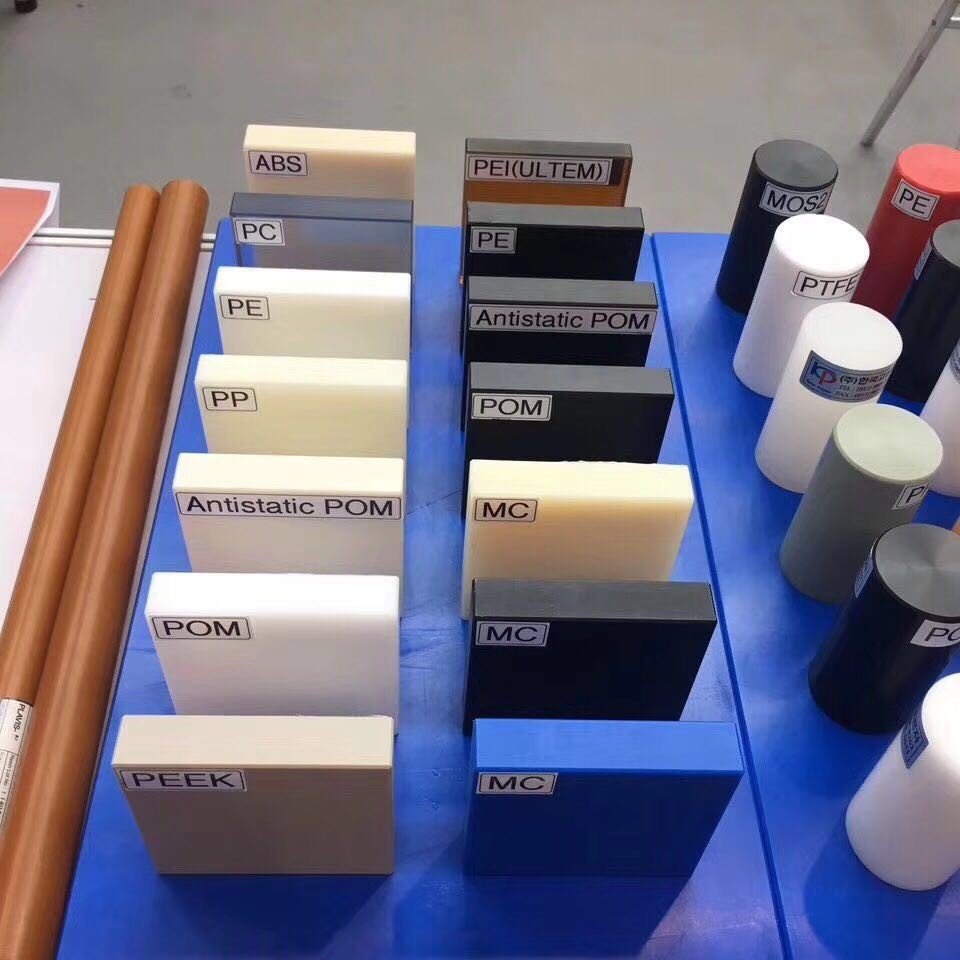

Tipi di materiali plastici per la lavorazione a CNC ed esempi

Mentre i metalli dominano la lavorazione a CNC, le materie plastiche stanno guadagnando trazione, soprattutto per le applicazioni in cui leggero, durabilità, e la flessibilità è necessaria. Le seguenti materie plastiche sono spesso utilizzate nella lavorazione del CNC:

Acrilico (PMMA)

Acrilico, o PMMA, è ampiamente usato per la sua chiarezza ottica e rigidità. Viene spesso usato come sostituto del vetro in applicazioni come Windows, display, e segnaletica. L'acrilico è versatile ma incline a cracking, Soprattutto sotto lo stress elevato, che deve essere considerato durante la lavorazione.

Polipropilene (PP)

Il polipropilene è noto per la sua resistenza chimica e resistenza alla fatica. È comunemente usato in applicazioni mediche e beni di consumo. Tuttavia, la sua tendenza ad ammorbidirsi ad alte temperature rende difficile la macchina in alcuni casi.

Acetale (POM/Delrin)

Acetal è noto per la sua forza superiore, Resistenza all'umidità, e eccellente macchinabilità. È spesso usato in componenti di precisione come ingranaggi e cuscinetti a causa della sua capacità di mantenere la sua forma anche sotto carichi pesanti.

Nylon

Il nylon è un forte, durevole, e materiale resistente all'impatto utilizzato in numerose applicazioni, compresi i cuscinetti, ingranaggi, e componenti elettrici. Ha anche un basso attrito, rendendolo una scelta comune per le parti esposte all'usura.

addominali

ABS è una plastica a prezzi accessibili con una buona machinabilità, resistenza alla trazione, e resistenza all'impatto. È usato per produrre parti automobilistiche, recinti protettivi, e prototipi. Anche gli addominali sono altamente colorabili, rendendolo una buona scelta per le applicazioni estetiche.

UHMW-PE

Polietilene ultra-alt-molecolare (UHMW-PE) è altamente resistente all'usura e all'abrasione, rendendolo adatto per applicazioni come cuscinetti, ingranaggi, e superfici scorrevoli. Anche se può essere difficile da macchina, Le sue proprietà eccezionali lo rendono un materiale prezioso per gli ambienti ad alto stress.

Policarbonato (computer)

Il policarbonato è noto per la sua eccellente resistenza all'impatto e chiarezza ottica. È spesso usato in applicazioni ad alta temperatura, così come nella produzione di componenti elettronici, dispositivi medici, e parti automobilistiche.

Politherethetone (SBIRCIARE)

La sbirciatina è una plastica ad alte prestazioni con eccezionale resistenza chimica, resistenza meccanica, e stabilità dimensionale, rendendolo ideale per l'uso in ambienti estremi come l'aerospaziale, lavorazione degli alimenti, e petrolio e gas.

Cloruro di polivinile (PVC)

Il PVC è una plastica a basso costo con eccellente macchinabilità. Viene utilizzato nelle applicazioni che richiedono resistenza alle sostanze chimiche e ad alto impatto, come i sistemi idraulici, raccordi elettrici, e componenti automobilistici.

Vista rapida: Grafico dei materiali di lavorazione a CNC

Ecco una rapida panoramica dei materiali CNC comuni, le loro proprietà chiave, e alcuni esempi di dove vengono utilizzati.

| tipo di materiale | Materiale | Proprietà chiave | Applicazioni comuni | Voti & Codici |

| Metallo | Alluminio | Leggero, resistente alla corrosione, eccellente macchinabilità | Cornici aerospaziali, parti automobilistiche, elettronica, costruzione | Al 1050, Al 6061, Al 7075 |

| Acciaio inossidabile | Forte, resistente alla corrosione, resistente al calore | Attrezzatura medica, marino, recinti esterni | Ss 303, Ss 304, Ss 316 | |

| Acciaio al carbonio | Molta forza, eccellente macchinabilità | Dispositivi di fissaggio meccanici, componenti strutturali | 1018, 4130, 4140 | |

| Rame | Ottima conduttività termica/elettrica, malleabile, resistente alla corrosione | Filo elettrico, dispositivi magnetici, gioielleria | Cu, Cu + Zn, Cu + Essere | |

| Titanio | Elevato rapporto resistenza/peso, resistente alla corrosione | Aerospaziale, militare, parti biomediche | Costruisci 1, Costruisci 2 | |

| Magnesio | Leggero, eccellenti proprietà termiche | Componenti del motore, settore automobilistico, aerospaziale | Mg, Lega di magnesio | |

| Plastica | Acrilico (PMMA) | Alta chiarezza ottica, rigido, durevole | Segnaletica, lampade, parti automobilistiche, beni di consumo | Pmma-acrilico, Temp di PMMA-High |

| Nylon (PA6) | Forte, durevole, resistente all'impatto, Buono per resistenza all'usura | Ingranaggi, cuscinetti, parti automobilistiche | PA6, PA66, Nylon 6-6 | |

| Policarbonato (computer) | Resistente alla frantuma, resistente al calore, chiarezza ottica | Dispositivi medici, parti automobilistiche, Componenti elettronici | computer, computer + Riempimento di vetro | |

| SBIRCIARE | Elevata resistenza chimica, mantiene la rigidità ad alte temperature | Aerospaziale, dispositivi medici, Componenti a semiconduttore | SBIRCIARE | |

| addominali | Buona lavorabilità, resistente all'impatto, resistenza alla trazione | Recinti, prototipazione rapida, parti automobilistiche | addominali, Temp ad alta alta temperatura | |

| Composito | Fibra di carbonio | Molta forza, leggero, alta rigidità | Aerospaziale, settore automobilistico, attrezzatura sportiva | CFRP, CRP, Cfrtp |

Qual è il materiale di lavorazione più usato?

Quando si tratta di lavorazione a CNC, metallo e plastica sono i materiali più comunemente usati. Tuttavia, Se dovessimo sceglierne uno, alluminio Prende il primo posto.

Perché l'alluminio è così popolare?

- Facile da lavorare- taglia senza intoppi senza un'usura eccessiva sugli strumenti.

- Leggero ma forte- Ideale per industrie come aerospaziale e automobilistico.

- Resistente alla corrosione-Ottimo per applicazioni all'aperto e ad alta misurazione.

- Conveniente- Rispetto al titanio o all'acciaio inossidabile, L'alluminio è economico.

- Riciclabile-ecologico e ampiamente disponibile.

Altri materiali popolari per la lavorazione a CNC:

- Acciaio- Forte, durevole, e utilizzato in applicazioni pesanti.

- Ottone- Eccellente per parti di precisione e componenti elettrici.

- Plastica (addominali, POM, Nylon)- leggero, conveniente, e ottimo per i prototipi.

Quale materiale è più facile da macchina?

Se stai cercando un materiale che tagli come il burro, ottone è uno dei più facili da macchina.

Perché l'ottone è così facile da macchina?

- Morbido e liscio- Taglia in modo pulito senza scheggiare.

- Bassa frizione- Riduce l'accumulo di calore, Quindi non danneggia gli strumenti.

- Grande finitura superficiale-ha bisogno di poco o nessun post-elaborazione.

- Non è in sospeso- A differenza dell'acciaio inossidabile, L'ottone rimane facile da macchina.

Altri materiali facili da macchina:

- Alluminio- Quasi facile come l'ottone ma più forte.

- Plastica (addominali, POM, Nylon)- Questi tagliano rapidamente e non si oppongono agli strumenti.

- Acciaio dolce- più morbido dell'acciaio inossidabile e più facile da tagliare.

Quale materiale è difficile da macchiare?

Alcuni materiali Mangia utensili da taglio, causare calore eccessivo, o richiedono tecniche speciali a macchina. IL più impegnativo I materiali con cui lavorare includono titanio, Inconel, e acciaio indurito.

Perché questi materiali sono difficili da macchina?

- Titanio-Rapporto elevato di forza-peso lo rende difficile, Ma genera anche molto calore, causando usura degli utensili.

- Inconel (Lega di nichel)-Utilizzato nelle applicazioni aerospaziali e ad alto calore, Questo metallo è estremamente duro e resiste a tagliare.

- Acciaio temprato- È ottimo per la durata ma richiede velocità lente, strumenti speciali, e refrigerante per la macchina efficacemente.

- Fibra di carbonio & Compositi- Questi possono sfilare, crepa, o produrre polvere dannosa quando è lavorato.

Suggerimenti per la lavorazione dei materiali duri:

✔ Usa Strumenti in carburo o rivestiti di diamanti Per una durata degli strumenti più lunga.

✔ Applicare refrigerante per evitare il surriscaldamento.

✔ Usa velocità lente e velocità di alimentazione adeguate Per ridurre l'usura degli utensili.

✔ Considera Macchine a CNC specializzate Progettato per metalli duri.

Se il tuo progetto richiede ultra durevole parti, Questi materiali valgono la sfida, Ma Preparati per tempi di lavorazione più lunghi e costi più elevati.

Fattori chiave per la selezione dei materiali di lavorazione a CNC

Come ti assicuri di scegliere il materiale migliore? Ci sono diversi fattori importanti da considerare, e capire questi può aiutarti a prendere decisioni più informate.

Applicazioni in parte

La prima cosa a cui pensare è ciò per cui la tua parte verrà effettivamente usata. Materiali diversi sono più adatti a diverse applicazioni. Per esempio, Se stai creando parti per l'industria aerospaziale, Avrai bisogno di materiali leggeri ma forti, Piace titanio O alluminio. D'altra parte, Se stai facendo parti per un sistema di trasformazione alimentare, Potresti aver bisogno di un materiale resistente alle alte temperature e alle sostanze chimiche aggressive, ad esempio acciaio inossidabile O SBIRCIARE plastica.

Ogni materiale ha i suoi punti di forza e di debolezza, E vuoi abbinare le proprietà del materiale alle esigenze dell'applicazione. Comprendere l'ambiente in cui funzionerà la tua parte, sia che dovrà affrontare un'alta pressione, temperature estreme, o usura costante: può guidarti alla scelta del materiale giusto.

Peso della parte

Il peso della tua parte svolge un ruolo significativo nella selezione dei materiali. Per parti che devono essere leggere e facili da gestire (come i componenti in settore automobilistico O aerospaziale industrie), Avrai bisogno di materiali a bassa densità, ad esempio alluminio O titanio. Questi materiali non sono solo leggeri ma anche resistenti e forti.

In contrasto, Se la tua parte dovrà supportare carichi pesanti, vorrai un materiale più denso e più forte, ad esempio acciaio. Comprendere i requisiti di peso della tua parte aiuta a garantire che funzioni come previsto senza costi di materiale non necessari o tempo di elaborazione.

Parte di precisione e tolleranza

La precisione è spesso uno degli aspetti più critici quando si sceglie un materiale. Alcuni materiali sono più facili da macchina per dimensioni precise rispetto ad altri. Per esempio, alluminio è generalmente più facile da macchina per le tolleranze strette rispetto ai materiali più duri come titanio O acciaio al carbonio. Più è difficile un materiale, Maggiore è il costo e il tempo che ci vorranno per raggiungere la precisione desiderata.

Se la tua parte richiede un'elevata precisione e tolleranze strette, Preparati a lavorare con materiali più difficili da macchina o che potrebbero richiedere ulteriori processi (come il trattamento termico o gli strumenti specializzati). Assicurati di tener conto del livello di precisione richiesto quando si sceglie un materiale, poiché influenzerà direttamente i costi di lavorazione e le tempistiche.

Proprietà in parte

Pensa alle proprietà che la tua parte deve avere. Per esempio:

- Forza: La tua parte deve resistere a carichi pesanti? Materiali come acciaioO titanio fornire un'eccellente resistenza.

- Resistenza alla corrosione: La tua parte sarà esposta all'umidità o ai prodotti chimici? Considerare acciaio inossidabileO alluminio.

- Stabilità termica: La tua parte sarà esposta ad alte temperature? CeramicaE titanio sono ottimi per la resistenza al calore.

Ogni materiale ha proprietà specifiche che lo rendono ideale per ambienti e usi particolari. Quando si seleziona un materiale, Considera come queste proprietà aiuteranno bene la tua parte nella sua applicazione prevista.

Estetica del prodotto

A volte, Il modo in cui una parte appare è importante quanto il modo in cui si comporta. Per esempio, In beni di consumo O elettronica, L'apparizione della parte può svolgere un ruolo importante nell'accettazione dei consumatori. Materiali come plastica (per esempio., addominali O policarbonato) Può essere facilmente modellato e colorato per soddisfare le specifiche di progettazione.

D'altra parte, metalli Piace acciaio inossidabile E alluminio può anche fornire un elegante, look moderno. Se l'estetica è una grande preoccupazione, Assicurati di scegliere materiali che possano essere facilmente rifiniti o che hai già l'aspetto a cui mi puni.

Opzioni di finitura superficiale

Quando si lavora una parte, La finitura superficiale è importante sia per il suo aspetto che per la funzionalità. Alcuni materiali, Piace alluminio O acciaio inossidabile, sono più facili da lucidare e finire, mentre altri, Piace acciaio al carbonio o alcune plastiche, può richiedere ulteriori passaggi di finitura per ottenere l'aspetto o la morbidezza desiderati.

Anche le finiture superficiali svolgono un ruolo nelle prestazioni della parte. Per esempio, parti che verranno utilizzate in ambienti ad alta attrezzatura (come ingranaggi o cuscinetti) avrà bisogno di una finitura che riduca l'usura, Mentre le parti utilizzate in applicazioni mediche o aerospaziali possono richiedere un liscio, superficie lucida per funzionalità e ragioni estetiche.

Lavorabilità

Alcuni materiali sono più facili da macchina rispetto ad altri, che può influire sia sul costo che il tempo necessario per produrre la parte. Materiali più morbidi come alluminio E plastica sono più facili da macchina e possono ridurre l'usura degli utensili e il tempo di produzione complessivo. D'altra parte, Materiali più duri come titanio O tungsteno sono più difficili da macchiare, richiedere strumenti specializzati, tempo aggiuntivo, e costi potenzialmente più alti.

Se il tuo progetto ha scadenze rigorose o vincoli di bilancio, È importante considerare la lavorabilità del materiale, Come scegliere un materiale troppo difficile da macchina può aumentare significativamente il tempo e il costo della produzione.

Costo

Il costo è sempre un fattore nella selezione dei materiali. Mentre è allettante andare per il materiale per la massima prestazione, Potrebbe non essere sempre la scelta più economica. Materiali come alluminio sono generalmente più convenienti e offrono un buon equilibrio tra macchinabilità, forza, e durata, rendendoli una scelta popolare. Tuttavia, Materiali ad alte prestazioni come titanio O SBIRCIARE Può essere molto più costoso, sia in termini di costi materiali che di tempo di lavorazione.

Prima di decidere un materiale, Assicurati di bilanciare le prestazioni con il costo. A volte, Un materiale meno costoso funzionerà altrettanto bene per la tua applicazione, permettendoti di risparmiare sui costi materiali e sulle spese di lavorazione.

Suggerimenti Quando si utilizzano processi CNC per macchiare materiali diversi

Scegli gli strumenti giusti per il lavoro

Non tutti gli strumenti di taglio sono creati uguali. Materiali diversi richiedono diversi tipi di strumenti per ottenere i migliori risultati. Per esempio, metalli più duri come titanio E acciaio inossidabile avranno bisogno di strumenti in carburo o ceramica perché possono resistere al calore e allo stress del taglio di materiali più duri. Per materiali più morbidi come alluminio O plastica, Spesso puoi cavartela utilizzando strumenti in acciaio ad alta velocità.

- Mancia: Abbina sempre il materiale dello strumento al materiale che stai lavorando. Questo aiuta a ridurre l'usura dello strumento e garantisce tagli più fluidi.

Controllare la velocità di taglio e la velocità di alimentazione

Il taglio della velocità e della velocità di alimentazione sono fondamentali per raggiungere i risultati desiderati. Se la velocità di taglio è troppo veloce per un determinato materiale, Può far sì che lo strumento si lisca più velocemente, surriscaldare, o addirittura rompere. D'altra parte, Se la velocità di alimentazione è troppo lenta, Può portare a una lavorazione inefficiente e un aumento dei tempi di produzione.

- Mancia: Per materiali più morbidi come alluminio, Utilizzare velocità di taglio più veloci e velocità di alimentazione più elevate. Per materiali più duri come titanio O acciaio, Ridurre la velocità di taglio e la velocità di avanzamento per evitare l'accumulo di calore eccessivo e l'usura degli utensili.

Usa il refrigerante giusto

L'uso del refrigerante durante la lavorazione a CNC è essenziale per ridurre l'accumulo di calore e prevenire danni sia allo strumento che al pezzo. Materiali diversi generano diversi livelli di calore, Quindi il tipo di refrigerante e la quantità utilizzata possono variare.

- Mancia: Utilizzo refrigeranti a base d'acqua Per materiali più morbidi come alluminio E plastica, poiché possono aiutare a prevenire il danno termico. Per materiali più duri come acciaio inossidabile E titanio, potresti voler usare refrigeranti a base di olio Per un migliore raffreddamento e lubrificazione.

Presta attenzione allo spessore del materiale

Lo spessore del materiale che stai lavorando influisce su quanto velocemente ed efficiente la macchina CNC può tagliarla. Materiali più spessi, Soprattutto i metalli come acciaio al carbonio E acciaio inossidabile, richiederà macchine più potenti e strumenti più forti per superarle. D'altra parte, Materiali più sottili come plastica O fogli di alluminio richiederà meno energia e può essere lavorata più rapidamente.

- Mancia: Regola sempre la profondità di taglio e i percorsi degli utensili in base allo spessore del materiale. Per materiali più spessi, Ridurre la profondità di ogni taglio per evitare di sforzare la macchina e gli utensili.

Prendi in considerazione le proprietà dei materiali prima di scegliere una strategia di lavorazione

Ogni materiale ha il proprio set di caratteristiche: alcuni sono più fragili, Altri sono più flessibili, e alcuni possono espandersi o contrarsi se esposti al calore. Comprendere queste proprietà ti aiuterà a determinare la migliore strategia di lavorazione per il materiale.

- Mancia: Per materiali soggetti a deformazioni, ad esempio plastica Piace PVC O acetale, Usa velocità di taglio più basse ed evita tagli profondi per ridurre al minimo il movimento del materiale. Per materiali come titanio, che si espandono a causa del calore, Usa una velocità di alimentazione più lenta e assicurati che la macchina sia ben calibrata per evitare eventuali distorsioni.

Garantire una corretta proprietà di lavoro

Tenere il materiale saldamente in atto è fondamentale, Soprattutto quando si lavora a forme complesse. Se il pezzo non viene mantenuto correttamente, Può muoversi durante la lavorazione, portando a povere tolleranze, Imperfezioni di superficie, o addirittura parti danneggiate. Alcuni materiali sono più inclini a deformazione o spostamento, Quindi hanno bisogno di cure extra.

- Mancia: Usa forte e affidabile infissi sul lavoro, ad esempio morsetti O Sistemi di Chuck a vuoto, per tenere le parti in posizione saldamente. Per materiali più morbidi come plastica, Utilizzare metodi più morbidi per evitare di danneggiare la parte.

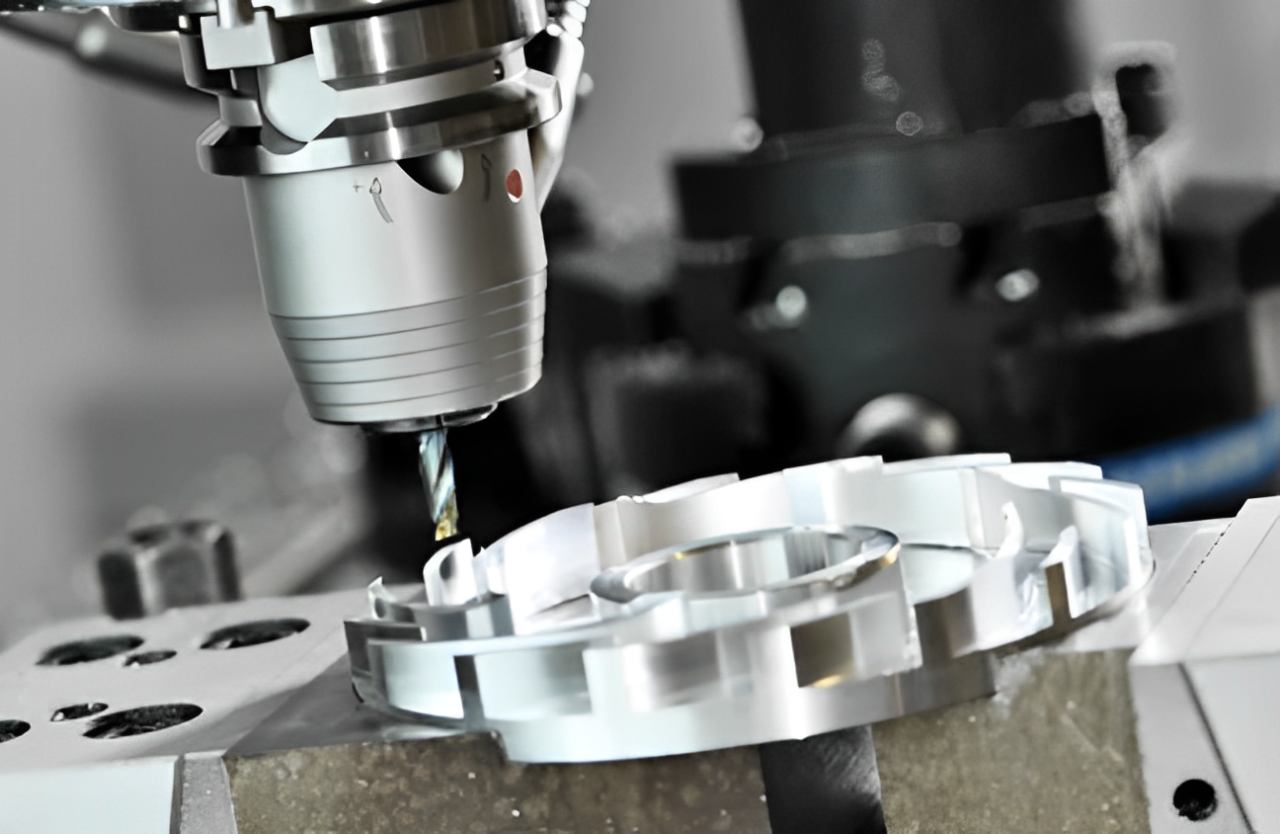

Scegli la macchina CNC giusta

Non tutte le macchine CNC sono adatte a ogni materiale. Materiali più morbidi, Piace alluminio, Può essere facilmente lavorato con macchine CNC a 3 assi standard. Tuttavia, Materiali più duri, ad esempio titanio O acciaio, può richiedere 5-Macchine CNC assi per una maggiore flessibilità e una migliore precisione.

- Mancia: Per tagli intricati o altamente dettagliati in materiali difficili, Prendi in considerazione l'uso 5-Asse Machining CNC. Questo tipo di macchina consentirà più angoli di attacco e un migliore controllo del processo di taglio.

La finitura superficiale conta

La finitura sulla superficie della tua parte lavorata può fare un'enorme differenza, entrambi in termini di estetica e funzionalità. Alcuni materiali, Piace alluminio E acciaio inossidabile, avrà una finitura superficiale naturalmente liscia dopo la lavorazione, mentre altri, Piace plastica O titanio, può richiedere ulteriori processi di post-lavorazione come lucidatura O anodizzazione Per ottenere la finitura desiderata.

- Mancia: Tieni sempre a mente la finitura superficiale desiderata quando si seleziona un materiale. Se è necessaria una finitura lucida o liscia, Assicurati che il materiale che scegli sia favorevole a quel tipo di finitura. Alcuni materiali, Piace ottone O acciaio inossidabile, può essere lucidato facilmente, mentre altri, Piace bronzo, potrebbe richiedere passaggi extra.

Contestare i costi e la disponibilità dei materiali

Il costo del materiale è sempre una considerazione chiave. Titanio E acciaio inossidabile, sebbene eccellente per determinate applicazioni, può essere molto più costoso dei materiali come alluminio O ottone. Inoltre, Alcuni materiali sono più prontamente disponibili di altri, che potrebbe influire sui tempi di consegna.

- Mancia: Scegli i materiali che si adattano al budget del progetto. Se acciaio inossidabile è oltre il tuo budget, considerare alluminio O acciaio al carbonio come alternative per parti meno critiche.

Comprendi l'impatto ambientale

Alcuni materiali hanno un impatto ambientale significativo, o attraverso il mining, in lavorazione, o smaltimento. Materiali come plastica, Se non riciclato correttamente, può contribuire ai rifiuti. Tuttavia, metalli come alluminio E acciaio inossidabile sono spesso altamente riciclabili.

- Mancia: Quando possibile, Scegli materiali riciclabili o hanno un impatto ambientale minimo. Alluminio, ad esempio, è ampiamente riciclato e ha un'impronta ambientale inferiore rispetto ai materiali come plastica.

Ottieni il materiale di lavorazione CNC giusto per i tuoi progetti

Scegliere il materiale giusto è cruciale per il tuo progetto di lavorazione a CNC. Se non sei sicuro di quale materiale sia più adatto alle tue esigenze, Prendi in considerazione la ricerca di consulenza professionale da fornitori di servizi di lavorazione a CNC che offrono ampie opzioni e competenze materiali.

Quali sono le implicazioni dei costi dei diversi materiali di lavorazione?

Scegliere il materiale giusto per la lavorazione a CNC non riguarda solo la forza e le prestazioni, ma anche influisce sul tuo budget. Alcuni materiali sono economici e facili da macchina, mentre altri sono costosi e richiedono strumenti speciali o tempi di elaborazione extra.

Ciò che guida il costo delle materiali di lavorazione?

- Prezzo delle materie prime- Alcuni materiali, Come l'alluminio, sono ampiamente disponibili e convenienti, mentre altri, Come il titanio, sono molto più costosi.

- Lavorabilità- Materiali più morbidi (come ottone e alluminio) macchina più veloce, Ridurre il lavoro e l'abbigliamento degli strumenti. Materiali duri (Come l'acciaio inossidabile o l'incontro) Richiede strumenti di lavorazione e speciali più lenti e speciali, Aumentando i costi.

- Usura degli strumenti- Alcuni materiali di taglio opaco rapidamente, portando a costi di utensili più elevati.

- Rottami e rifiuti- Materiali più duri possono comportare più rifiuti a causa di rotture dell'utensile o errori di lavorazione.

- Requisiti di finitura- Alcuni metalli, Come l'ottone, Naturalmente sembra fantastico, mentre altri, Come l'acciaio al carbonio, richiedono rivestimenti o lucidatura, Aggiunta di costi extra.

Confronto dei costi di materiali di lavorazione comuni

| Materiale | Costo delle materie prime | Costo di lavorazione | Impatto totale dei costi | Migliori casi d'uso |

| Alluminio | Basso | Basso | $$ | Aerospaziale, settore automobilistico, elettronica |

| Ottone | Medio | Molto basso | $$ | Parti di precisione, idraulico, elettrico |

| Acciaio inossidabile | Medio | Alto | $$$ | Medico, lavorazione degli alimenti, Parti resistenti alla corrosione |

| Titanio | Molto alto | Molto alto | $$$$$ | Aerospaziale, impianti medici |

| Acciaio al carbonio | Basso | Medio | $$ | Parti strutturali, utensili |

| Plastica (addominali, POM, Nylon) | Basso | Molto basso | $ | Prototipi, Componenti leggeri |

| Inconel (Lega di nichel) | Estremamente alto | Estremamente alto | $$$$$$ | Motori a reazione, applicazioni di calore estremo |

Come bilanciare i costi e le prestazioni

✅ Andare per alluminio o ottone se vuoi conveniente, Materiali facili da macchina.

✅ Usa la plastica per prototipi a basso costo che non hanno bisogno di alta resistenza.

✅ Prendi in considerazione l'acciaio inossidabile Quando La resistenza alla corrosione è cruciale, ma preparati a costi di lavorazione più elevati.

✅ Titanio e Inconel Sono Materiali premium—Ulii Solo quando assolutamente necessario A causa del loro alto prezzo e difficoltà di lavorazione.

💡 Suggerimento professionale: Se la tua parte non ha bisogno di resistenza estrema o resistenza al calore, Attacca con alluminio o acciaio dolce per risparmiare sui costi di materiale e di lavorazione.

Conclusione

La lavorazione a CNC è un processo di produzione incredibilmente versatile che ospita una vasta gamma di materiali. Sia che tu stia lavorando con i metalli, plastica, o compositi, La chiave per il successo è selezionare il materiale giusto in base all'applicazione della parte, proprietà, e requisiti di lavorazione. Comprendendo le proprietà materiali e le sfide di lavorazione, È possibile ottimizzare il processo di selezione dei materiali, ridurre i costi, e ottenere parti di alta qualità.

Domande frequenti

- Quali sono i fattori da considerare quando si seleziona un materiale CNC?

Prendi in considerazione l'applicazione in parte, peso, precisione, proprietà, e costo.

- Quale lega di alluminio è la migliore per la lavorazione del CNC?

L'alluminio 6061-T6 è comunemente usato per la lavorazione del CNC grazie alla sua eccellente lavorabilità e resistenza.

- Quali materie plastiche sono più macchinabili?

Acetale, SBIRCIARE, e il PVC offre una grande stabilità di macchinabilità e dimensionali.

- Qual è il metallo più difficile da Mill?

Il titanio è uno dei metalli più difficili da mulini, spesso richiede strumenti e tecniche specializzate.

1 pensato a “Materiali per la lavorazione CNC, Tutto quello che devi sapere”