1. Preparazione del materiale

Selezioniamo materiali in gomma premium: fogli, aste, o blocchi, basati su durezza e applicazione. La qualità costante garantisce un'eccellente stabilità dimensionale e prestazioni.

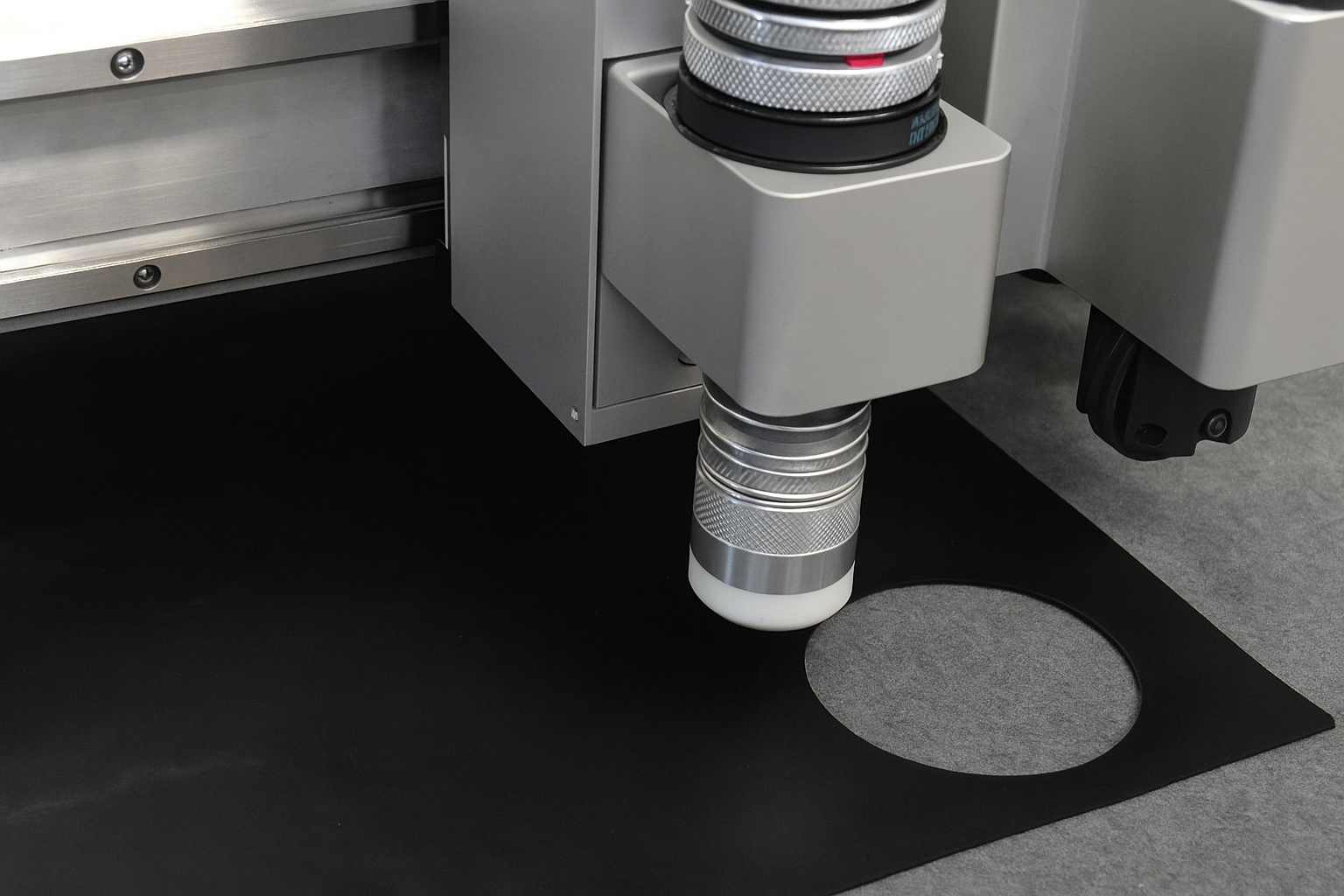

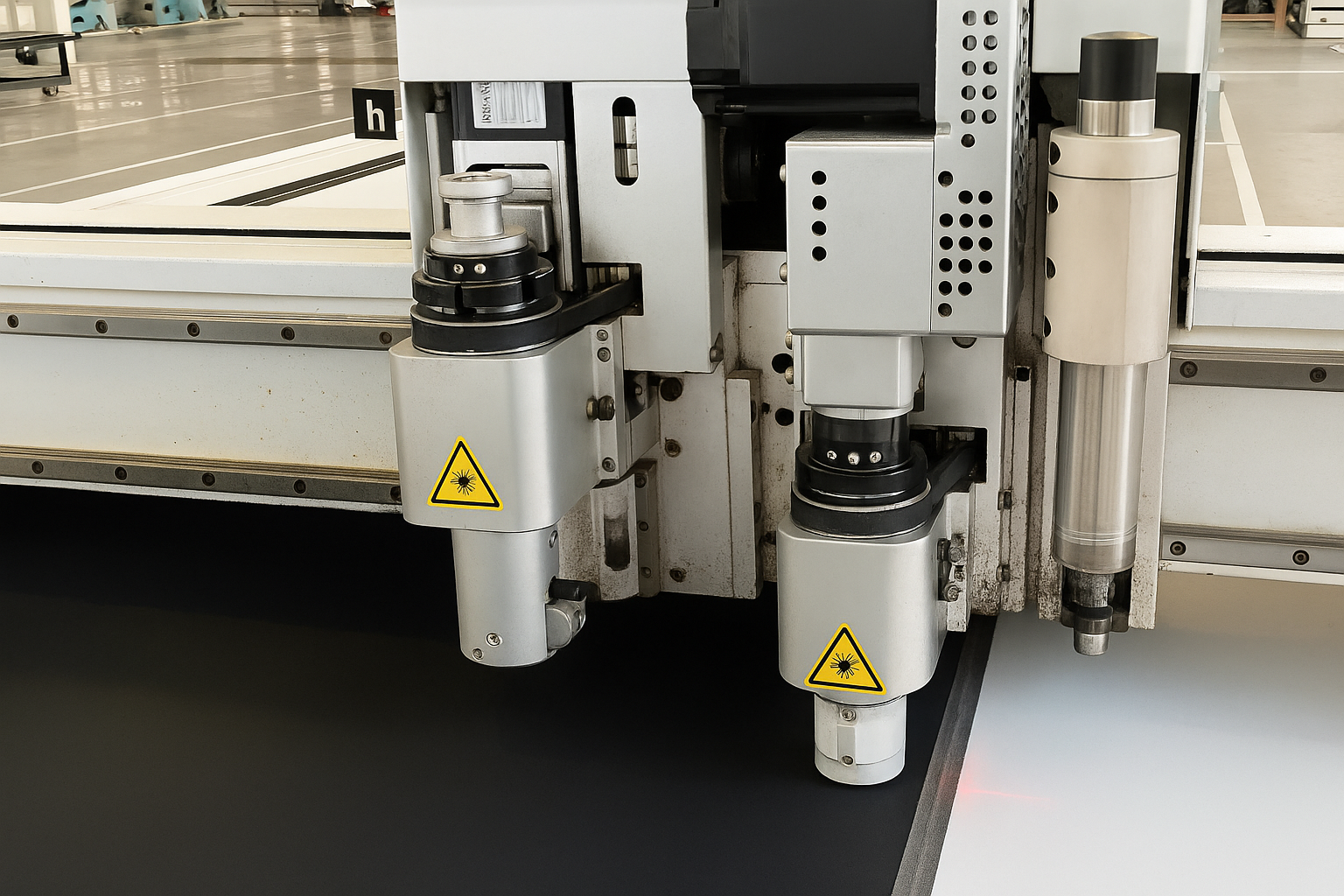

2. Setup CNC

Le nostre macchine usano le mascelle morbide, strumenti personalizzati, e montaggi di smorzamento delle vibrazioni per contenere in gomma flessibile saldamente e prevenire la distorsione durante la lavorazione.

3. Taglio dell'esecuzione

Con HSS affilato e strumenti in carburo, Mulliamo, giro, e scanalature di parti di gomma come O-ring e guarnizioni. I mangimi ottimizzati assicurano tagli puliti senza strappare o deformazioni.

4. Rimozione del truciolo / Raffreddamento

I trucioli di gomma vengono evacuati usando aspirapolvere e aria, nessun refrigerante liquido - preservando l'elasticità e la purezza del materiale.

5. Ispezione e finitura

Tutte le parti vengono ispezionate per tolleranze strette. La post-elaborazione include debuster e condizionamento termico per ripristinare la resistenza e la flessibilità.

Proprietà diverse della gomma

COSÌ, Le seguenti sono le diverse proprietà della gomma:

1. Elasticità

Ideale per sigilli e smorzatori, Le nostre parti di gomma mantengono flessibilità con una precisione ad alta dimensione.

2. Resistenza alla trazione

Machiamo le gomme forti come NBR per gestire carichi dinamici senza lacerare.

3. Resistenza a lacrime

I nostri componenti resistono alla strappa e alla fatica flessibile, Garantire una durata di servizio più lunga.

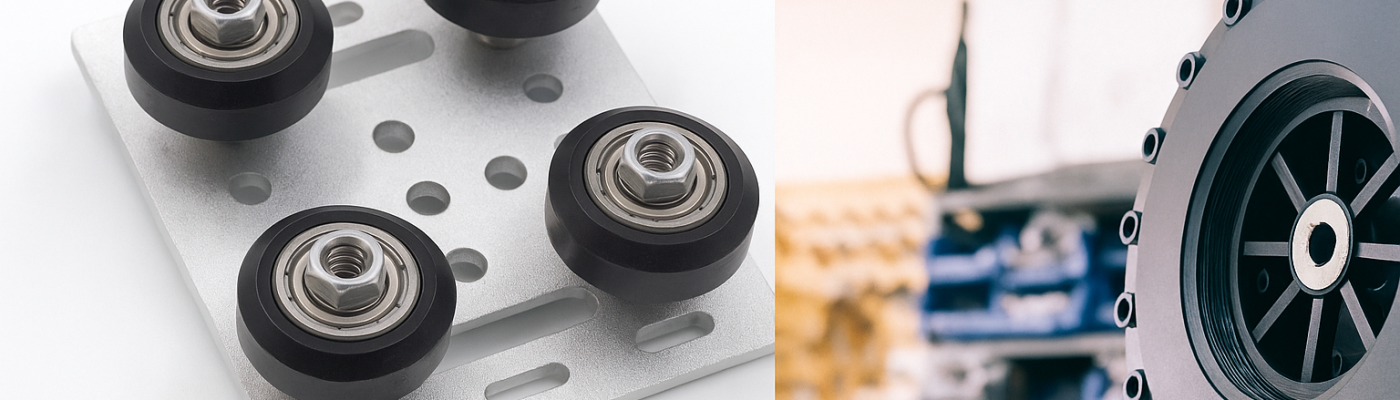

4. Resistenza all'abrasione

Produciamo rulli e cuscinetti resistenti all'usura usando composti duri come il neoprene e la PU.

5. Resistenza chimica

EPDM, Faston, e altre gomme sono lavorate con precisione per ambienti chimici difficili.

6. Stabilità termica

Parti di silicone e FKM resistono a 250 ° C, Perfetto per applicazioni ad alto calore.

7. Isolamento elettrico

Machiamo le gomme dielettriche per la cassaforte, parti accurate nei sistemi elettronici e soggetti a umidità.

8. Tempo atmosferico & Resistenza all'ozono

Le parti EPDM sono UV-, ozono-, e resistente all'umidità: Ideale per uso esterno e HVAC.

9. Resistenza al set di compressione

Le nostre foche mantengono la forma e la funzione sotto pressione a lungo termine e calore.