- Acciaio,

- Acciaio inossidabile,

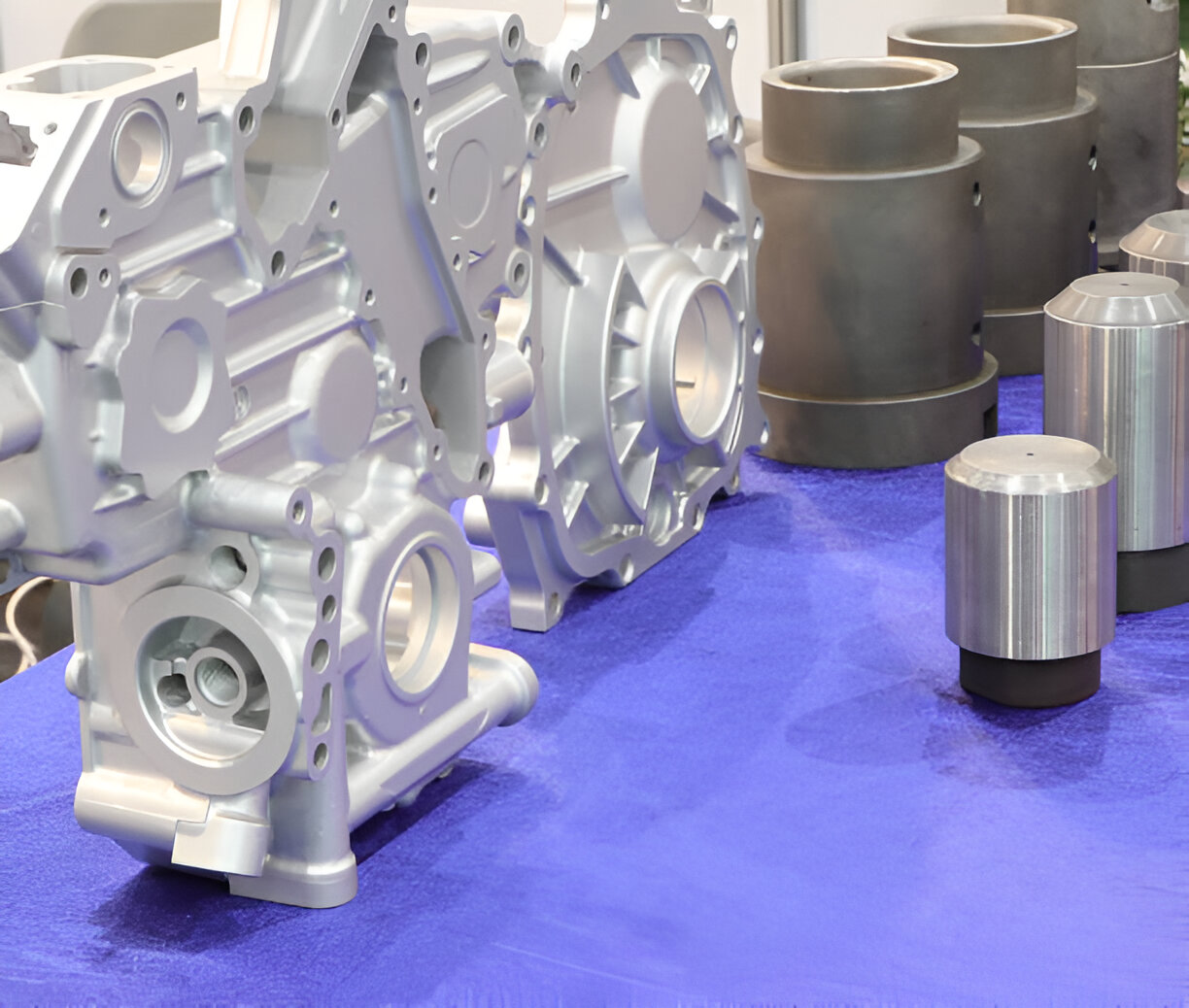

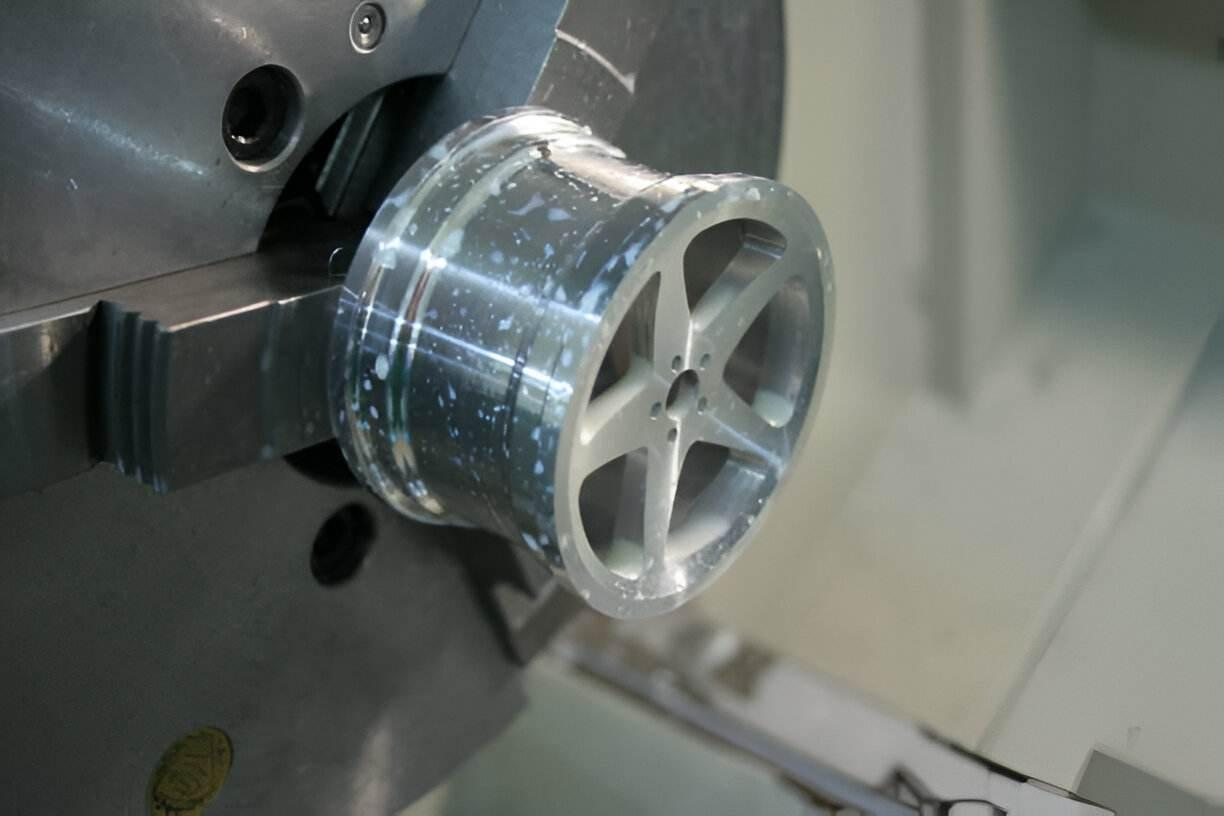

- Alluminio, E

- Titanio,

- Inconel.

- addominali,

- Nylon,

- Delrin,

- ANIMALE DOMESTICO.

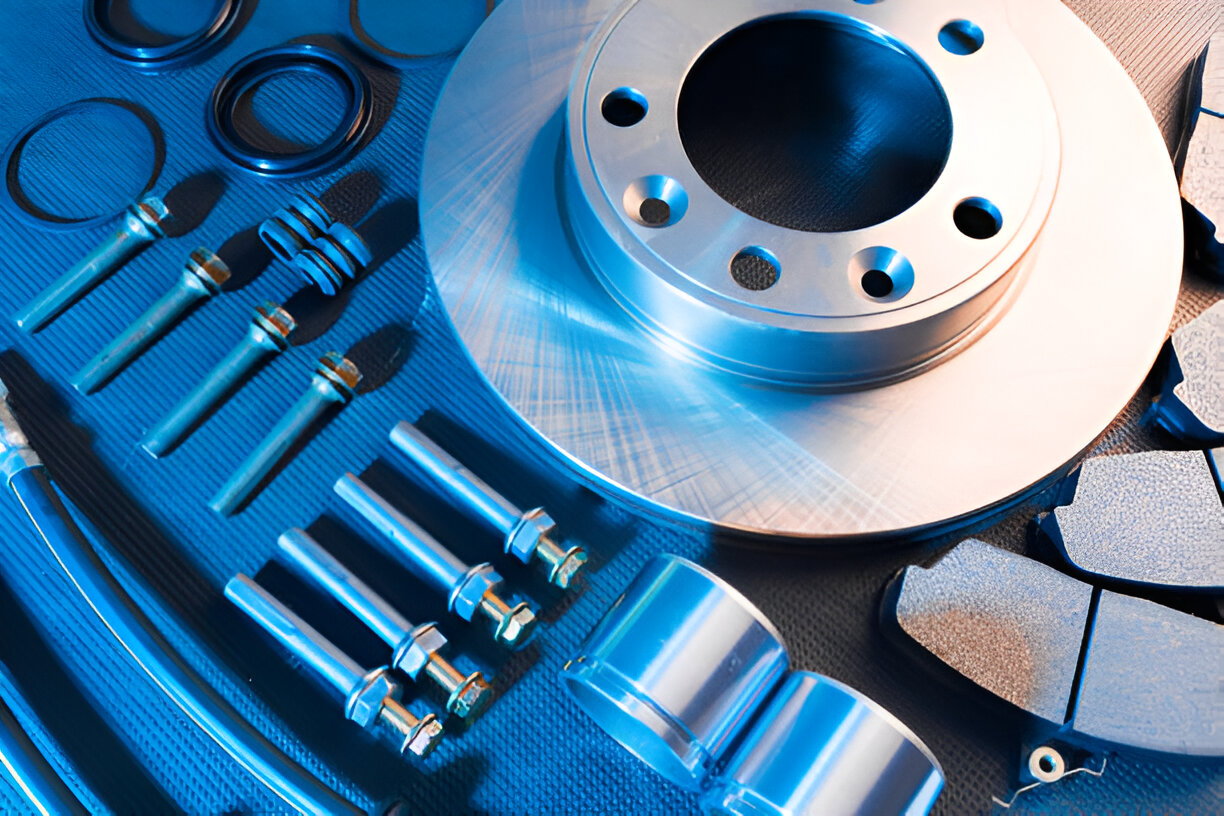

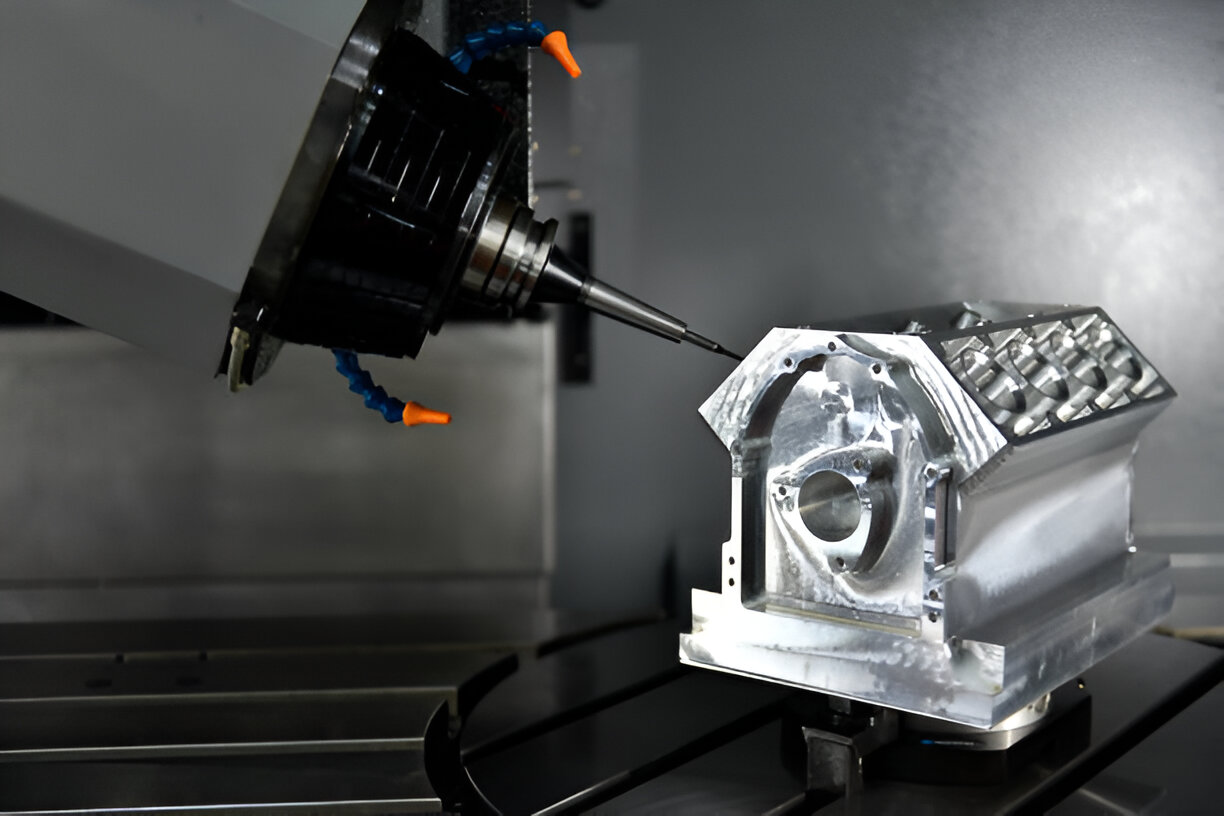

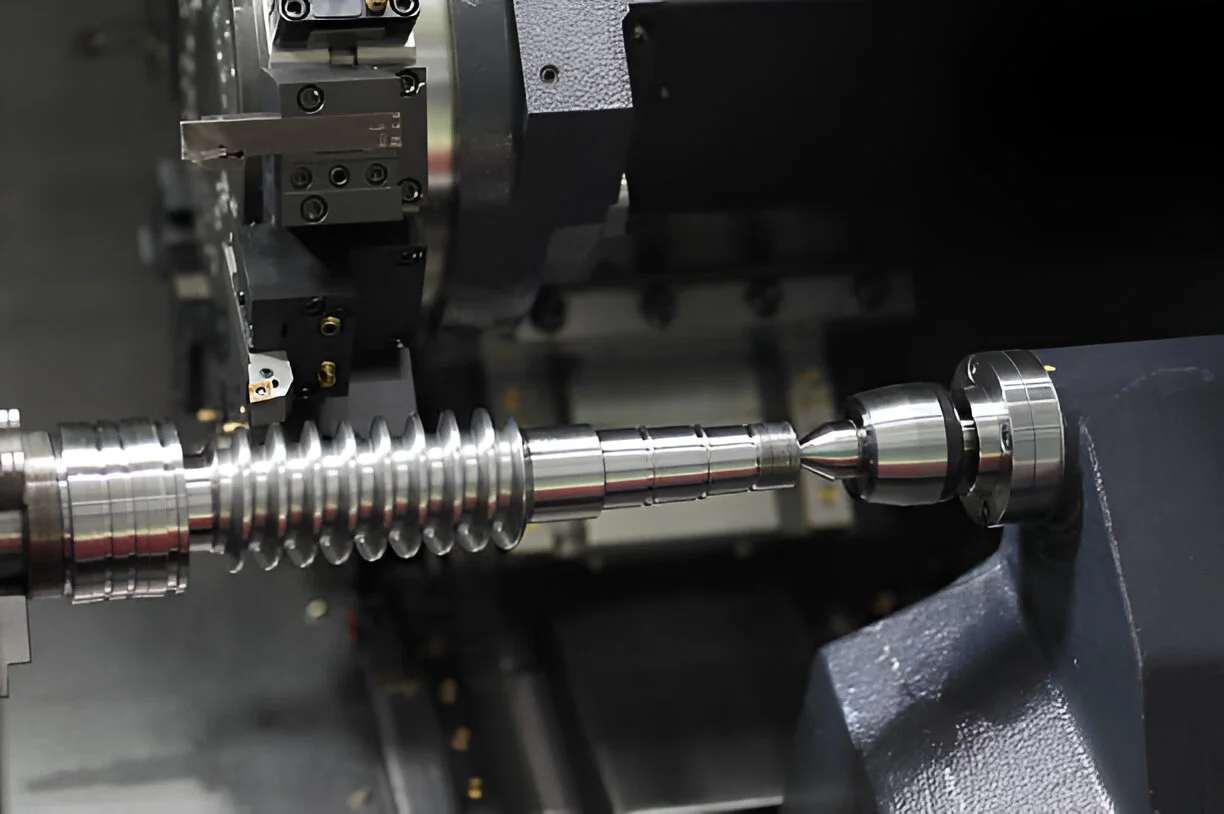

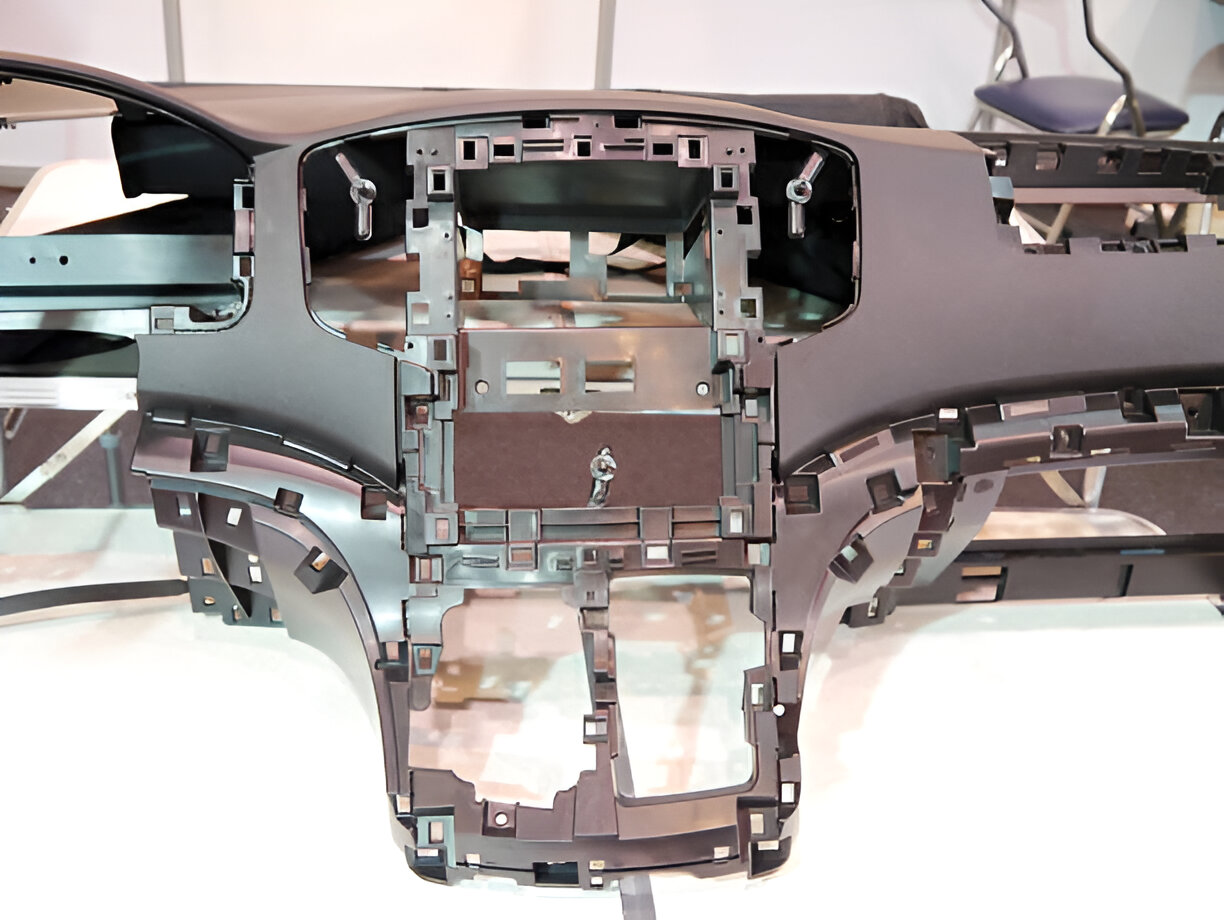

Tutte le parti che produciamo mantengono la completa tracciabilità e una documentazione dettagliata. Se hai bisogno di prototipi in piccoli volumi o stai cercando la produzione completa, diamo precisione su ogni lavoro.

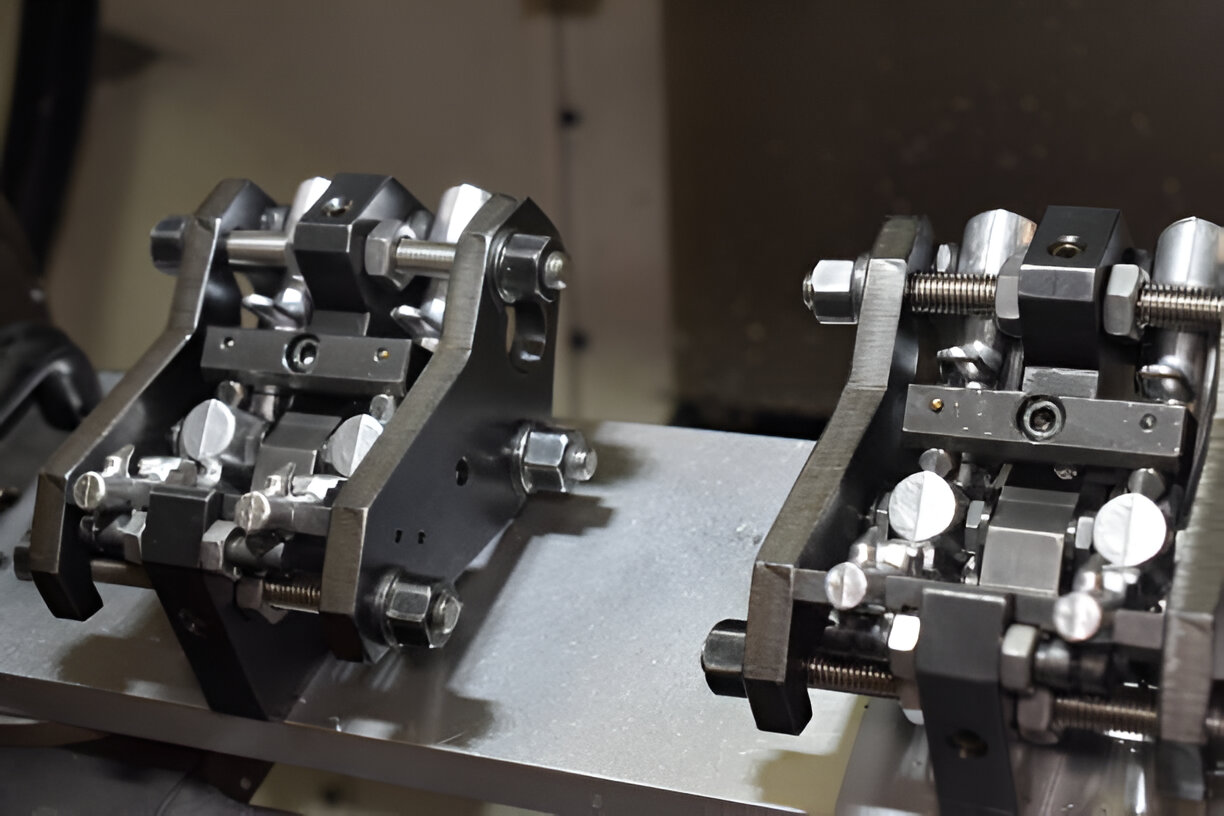

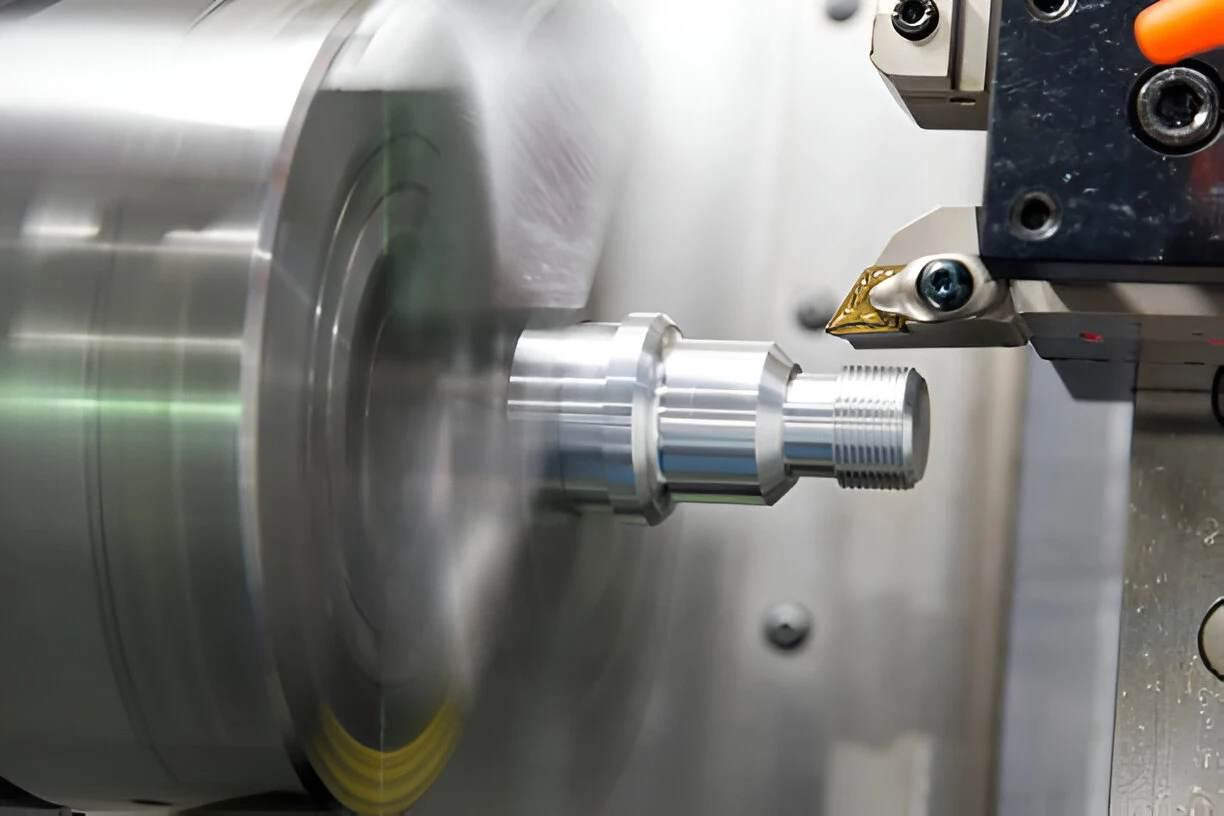

La nostra massima priorità è la qualità. Severi controlli in-process vengono effettuati su ogni parte utilizzando test manuali e misurazioni della macchina CMM. Misuriamo:

- Dimensioni

- Discussioni

- Finitura superficiale

- Tolleranza

Possiamo mantenere una precisione rigorosa fino a ± 0,005 mm. Tutti i dettagli vengono controllati prima della spedizione. Le nostre macchine sono state calibrate regolarmente. Tutti gli strumenti sono mantenuti a standard elevati. Ciò che ricevi sono finiture pulite e una vestibilità pulita. L'uniformità è fornita con ogni lotto. Non sacrifichiamo la qualità e i dettagli.

Quando contrai con Massima precisione, ottieni più delle parti. Ottieni affidabilità. Abbiamo una risposta rapida e orari flessibili. Tecnici qualificati ti assistono sempre, quindi tra gli schizzi iniziali e la consegna finale, le cose sono facili e semplificate. Non sono previsti ritardi o rilavorazioni.