なぜCNCの機械加工はさまざまな業界で非常に重要なのですか? それがもたらすからです 一貫性. 最初のピースから百万まで, CNCマシンは同一になります, 高品質の結果. そして、航空宇宙やヘルスケアのような産業が完璧を要求する場合(単一のエラーが何百万もの費用がかかったり、寿命がかかる可能性がある場合、CNCの機械加工はゴールドスタンダードとして上昇します.

この記事で探求します 30 CNC加工が不可欠な産業. 表面レベルの説明を超えて、CNCが演じる特定の役割に深く潜ります, 生成するコンポーネントの種類, そして、なぜそれが世界中のメーカーにとって好ましい選択であり続けているのか. 最後まで, CNCの機械加工が飛行機から宝石まですべてをどのように促進するかを明確に描くことができます.

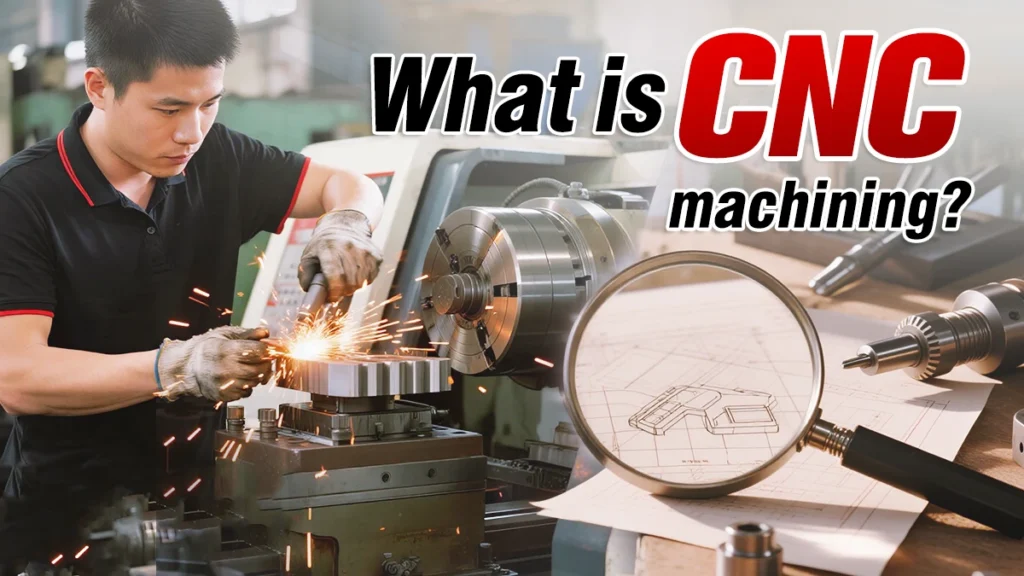

CNC加工とは?

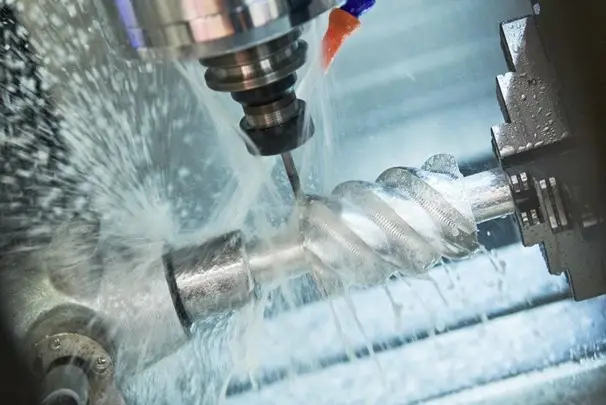

その中心に, CNC加工 の結婚です コンピューターと機械的ツール. 旋盤を手動で制御する代わりに, 工場, ドリル, またはグラインダー, コンピューターが引き継ぎます. エンジニアは、通常、CADの形でデジタルデザインを供給します (コンピュータ支援設計) ファイル - CNCシステムに, そして、マシンはそれを正確な動きに解釈します. 結果? 完璧な部品カット, ドリル, または、設計どおりに形作られています.

CNCマシンにはいくつかのタイプがあります:

CNCフライス盤 - カットに使用されます, ドリル, 固体材料を形作ります.

CNC旋盤 - シャフトやネジなどの対称オブジェクトを作成するのに最適です.

CNCルーター - 木材のような柔らかい素材を切るのに最適です, プラスチック, および複合材料.

CNCグラインダー - 超滑らかな仕上げが必要なときに使用されます.

従来の機械加工とは異なります, ここで、ヒューマンエラーは常にリスクです, CNCの機械加工が繁栄します 自動化と再現性. デザインがアップロードされると, マシンは数百または数千回同じ精度でそれを再現できます. これは生産をスピードアップするだけでなく、廃棄物とコストを劇的に削減します.

もう1つの重要な違いは、処理する能力です 複雑なジオメトリ. 従来のツールは、複雑なパターンや湾曲したデザインに苦しむかもしれません, しかし、CNCマシンは彫ることができます, ミル, または外科的精度でドリルします. 例えば, のようなコンポーネント 航空機タービンブレード または カスタム医療インプラント そのような正確さで手作業で作ることはほとんど不可能です.

要するに, CNC加工は単なるツール以上のものです 製造革命. それは想像力と生産の間のギャップを橋渡しします, デジタルの青写真を、比類のない精度で物理的現実に変える.

CNC加工の利点

業界全体でのCNCマシニングの成功は、その産業に由来しています 多数の利点. 不可欠な重要な利点を分析しましょう:

精度と精度

CNCマシンは数ミクロンと同じくらいタイトな許容範囲を実現します. 航空宇宙やヘルスケアなどの業界向け, 最小のエラーでさえ壊滅的な結果につながる可能性がある場合, このレベルの精度は命を救います.

速度と効率

プログラムされたら, CNCマシンは機能します 24/7 疲労なし. 以前は数週間かかっていたことは数日で、あるいは数時間で行うことができます. 自動化により、メーカーは品質を犠牲にすることなく厳しい締め切りを満たすことができます.

スケーラビリティと再現性

単一のプロトタイプが必要です? CNCはそれを行うことができます. 必要 10,000 同一の部品? CNCもそれを行うことができます - 一貫性を失うことなく. これにより、プロトタイピングと大量生産の両方に理想的な選択肢になります.

材料の汎用性

CNCマシンは、幅広い材料を処理します, から アルミニウムのような金属, 鋼鉄, そしてチタン に プラスチック, 複合材, 木材, 陶器でさえ. この柔軟性は、航空宇宙から宝石までの産業がすべて同じ技術から利益を得ることができることを意味します.

費用対効果

CNCマシンにはかなりの前払い投資が必要です, 彼らは廃棄物を削減することで長期コストを削減します, 生産をスピードアップします, そして、人間の誤りを最小限に抑えます. 時間とともに, これにより、CNC加工が行われます 経済的に無敵.

複雑さはシンプルになりました

最新のCNCマシン, 特に 5-軸モデル, かつて不可能だったと思われるデザインを処理できます. ソリッドチタンから彫刻を刻むことを想像してください。CNCは、このような複雑な仕事を実行可能かつ効率的にします.

これらの利点は、CNCの機械加工がなぜになったのかを説明しています 現代製造の基礎, 航空宇宙と同じように多様な産業を動かしています, 自動車, そしてエンターテイメントさえ.

航空宇宙産業

航空宇宙ほど精度を必要とする産業はほとんどありません. 単一の飛行機が構成されています 何百万もの部品, そして、最も小さな欠陥でさえ、災害を引き起こす可能性があります. そのため、CNCの機械加工は単に有用ではありません ミッションクリティカル 航空宇宙用.

生成された重要なコンポーネント

エンジン部品: タービンブレード, 燃料システム, とノズル

着陸装置: 極端なストレスに耐える高強度成分

機体構造: 機体, 翼, サポートブラケット

キャビンと内部の部品: 座席, コックピット楽器, ストレージビン

これらの部分は通常、から作られています アルミニウム, チタン, および複合材料, 彼らのために選ばれました 強度と重量の比率. CNCマシンは、これらの丈夫な材料を簡単に処理できます, 軽量でありながら耐久性のあるコンポーネントを生成します.

CNCが航空宇宙に不可欠である理由

安全基準: 精度は交渉できません; 公差はかみそりの薄いです.

耐久性: 航空宇宙部品は極端な温度と圧力に直面しています.

カスタマイズ: プロトタイプと新しいデザインは、CNCを使用して迅速にテストされます.

例えば, 作成 ジェットタービンブレード 機械加工曲線が必要です, 穴, および複雑なジオメトリ. 手動のアプローチには数ヶ月かかりますが、それでも欠陥があります. CNCマシンは、完璧な精度で数時間でこの課題を処理します.

要するに, CNCの機械加工はです 航空と宇宙旅行の名のないヒーロー, 近代的なフライトを可能にします.

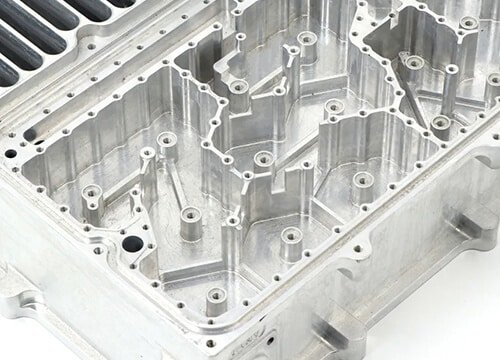

自動車産業

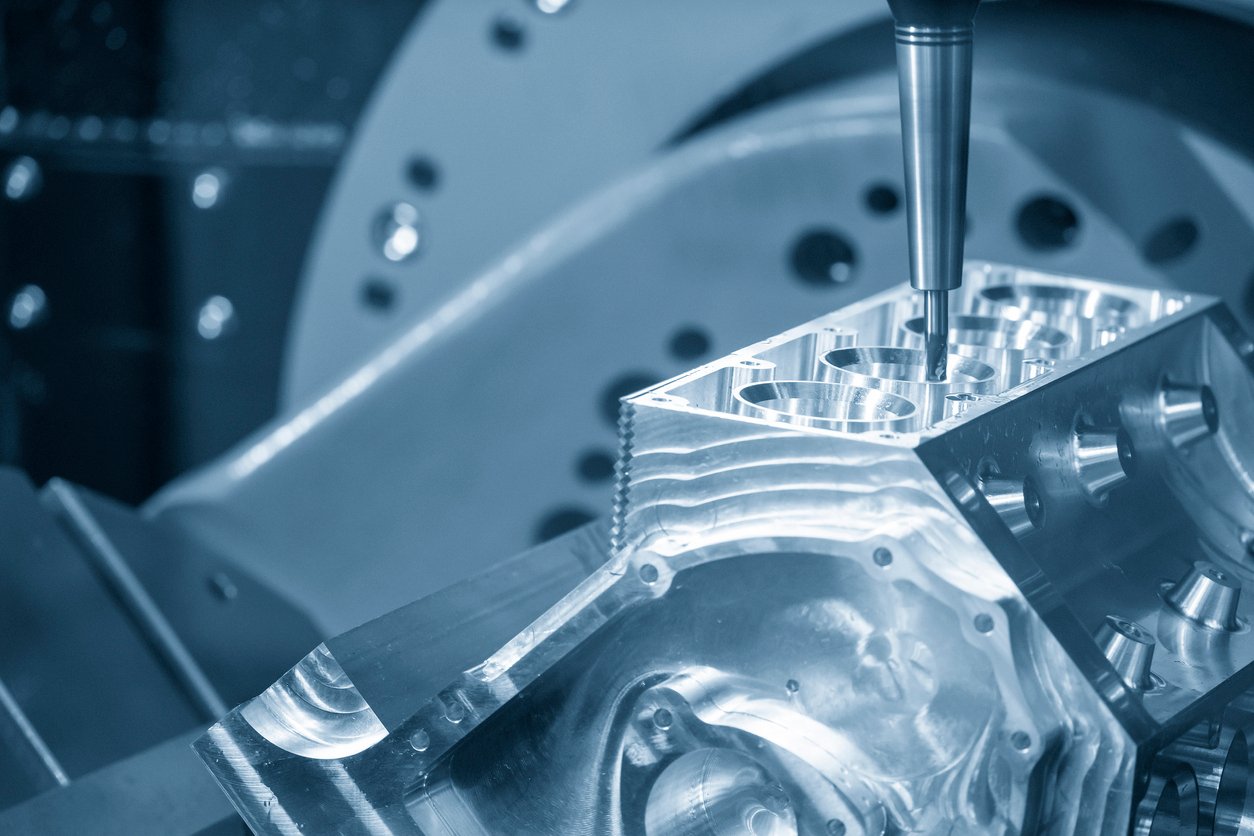

V8エンジンシリンダーブロックを切断する5軸機械加工センター. アルミニウムシリンダーブロックの製造プロセスを切断する5軸フライス機械.

自動車セクターは別です CNC加工のヘビーユーザー. なめらかなスポーツカーの設計から、毎日の通勤車両の生産まで, CNCは、車をより速くする上で重要な役割を果たします, より安全, より信頼性が高くなります.

主要な自動車アプリケーション

エンジンコンポーネント: ピストン, シリンダーヘッド, およびバルブブロック

トランスミッションとギアボックス: 精密ギアとケーシング

サスペンションとステアリング: ショックアブソーバー, ステアリングラック, およびジョイント.Alloy Wheels: Lightweight alloy wheels that require tight tolerances for safety, バランス, そしてパフォーマンス

プロトタイピング: 大量生産前のコンセプトカーの設計とテスト部品

体と内部の部品: ダッシュボード, ドアパネル, およびステアリングホイール

CNC加工により、各パーツが完全に適合するようになります, これは不可欠です 車両の安全性とパフォーマンス. 少し離れているピストンを想像してみてください。エンジン全体を妥協する可能性があります.

なぜ自動車でCNCが重要なのか

量産: CNCは、何百万もの同一のコンポーネントを有効にします.

プロトタイピング速度: デザイナーは概念を迅速にテストできます.

耐久性: CNCマシンの金属は熱に耐えます, 摩擦, とストレス.

カスタマイズ: 高級自動車メーカーは、パーソナライズされた機能にCNCを使用します.

例えば, テスラやBMWのような企業が新しい車両をプロトタイプするとき, CNCの機械加工により、デザインからテストに記録的な時期に移動できます. その間, トヨタのようなメーカーはCNCに依存しています 大規模な生産, 組立ラインから転がるすべての車が厳格な基準を満たすことを保証する.

簡単に言えば, CNC加工 自動車の世界を動かし続けます, 大量生産とイノベーションのバランスをとる.

医療産業

精度と信頼性を必要とする産業はほとんどありません 医療セクター. ここ, 成功と失敗の違いは、人間の生活で測定できます. CNC加工は、生産を可能にすることにより、医療製造に革命をもたらしました 非常に正確です, 滅菌, および複雑な部品 厳しいヘルスケア基準を満たしています.

医学のアプリケーション

手術器具: メス, 鉗子, クランプ, 骨鋸には微視的な精度が必要です.

整形外科インプラント: チタン股関節, 膝の交換, 歯科インプラントは患者に完全に適合する必要があります.

診断機器: MRIスキャナー, CTスキャナ, また、超音波マシンには、CNCマシンのハウジングとコンポーネントが含まれています.

マイクロデバイス: ペースメーカーハウジングと整形外科手術のための小さなネジは、しばしばCNC生産されます.

CNCが不可欠である理由

患者の安全性の精度: 数分のミリメートルでさえ、インプラントが適切に統合されるかどうかを判断できます.

滅菌生産: CNCマシンは動作できます 医療グレード材料 ステンレス鋼のように, チタン, および生体適合性プラスチック.

カスタマイズ: 多くの場合、患者はパーソナライズされたインプラントが必要です, また、CNC加工により、カスタムデザインが実現可能になります.

明確な例は、生産です 歯科インプラント. 各患者の顎骨構造はユニークです, CNC加工により、個人の正確な測定に合わせて調整されたインプラントの作成が可能になります. このカスタマイズは、従来の機械加工では非現実的です.

確保することによって 正確さ, 再現性, および生体適合性, CNCの機械加工は、現代のヘルスケアの基礎となっています, より長い寿命とより良い治療結果を可能にします.

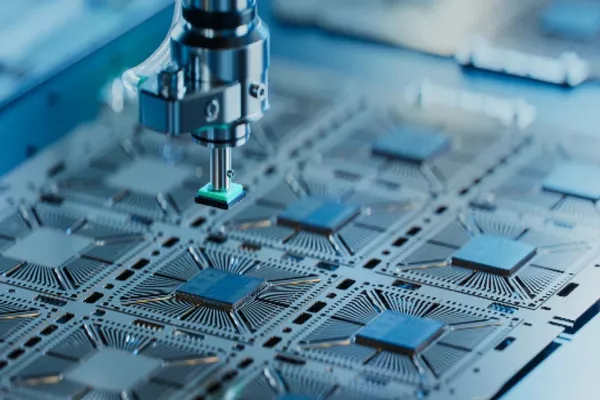

エレクトロニクス産業

の エレクトロニクスセクター 繁栄します 小型化と精度 - CNCの機械加工が優れている2つの品質. スマートフォンから高度な通信システムまで, CNCテクノロジーは、繊細なコンポーネントがピンポイントの精度で製造されることを保証します.

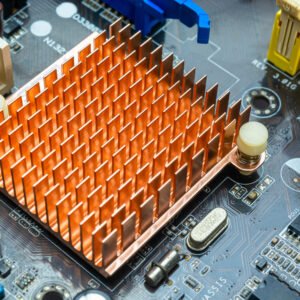

電子機器のアプリケーション

プリント基板 (PCB): CNCルーターとミルは、マイクロホールとシェーピングボードの掘削に使用されます.

エンクロージャーとケーシング: ラップトップの保護カバー, 電話, とルーター.

ヒートシンク: CNCマシンは、効率的な熱管理のために溝とフィンを切断します.

RFコンポーネント: コネクタ, アンテナハウジング, および導波管.

CNCがエレクトロニクスで重要である理由

マイクロサイジョン: 多くの電子部品は爪よりも小さいですが、正確なフィットが必要です.

材料の多様性: CNCはプラスチックを機械加工できます, アルミニウム, 銅, および複合材料 - すべてエレクトロニクスで広く使用されています.

スケーラビリティ: 電子機器の製造はしばしば関与します 量産 小さい, 複雑な部品.

革新: CNCマシンを使用すると、新しいガジェットのプロトタイピングが速くなります.

例としてスマートフォンを取ります. iPhoneまたはSamsungデバイスの洗練されたアルミニウムボディは、完璧にCNCにマシンされています, ガラスパネルや内部コンポーネントにシームレスなフィットを確保する. 同様に, CPUのヒートシンク 効率的な冷却のために正確な寸法を維持するためにCNCに依存する.

エレクトロニクスがより小さく、より強力になっている世界では, CNC加工が提供されます 精度と一貫性 消費者の需要に追いつくため.

軍事と防衛

の 防衛産業 耐えなければならないコンポーネントを生産するためのCNC加工に依存しています 極端な条件-熱, プレッシャー, 腐食, そしてインパクト. ここ, 失敗はオプションではありません, CNCテクノロジーを防衛製造の重要な部分にします.

軍事および防衛の申請

武器システム: 樽, 発射メカニズム, および精度スコープ.

車両と航空機: 装甲車両, ドローン, ヘリコプターには多数のCNCマシンパーツが含まれています.

通信機器: 安全な無線, レーダーハウジング, および衛星コンポーネント.

保護具: ヘルメット, 鎧のプレート, および戦術機器ハウジング.

CNCが不可欠である理由

ストレス下での信頼性: CNCマシンパーツは、戦闘環境に耐えることができます.

精密ターゲティング: 武器の精度は、完璧なコンポーネントに依存します.

ラピッドプロトタイピング: 防衛請負業者は、新しい設計を迅速にテストできます.

セキュリティ基準: 防衛部品は満たさなければなりません 最高品質の認定.

例えば, 戦闘機のコンポーネント - タービンブレードからコックピットハウジングまで - CNCが緊密な許容範囲でマシドされています. 同様に, ガイド付きミサイルシステムのような高度な武器は、完璧なパフォーマンスを確保するためにCNC部品に依存しています.

防衛部門は、CNCの機械加工を組み合わせているため、信頼しています 精度, 耐久性, およびスケーラビリティ, 国が強く維持できるようにする, 信頼できる防衛能力.

石油およびガス産業

の 石油およびガス産業 地球上の最も厳しい環境のいくつかで動作します - 深い海, 砂漠, 北極地域. ここの機器は処理する必要があります 極度の圧力, 熱, および腐食状態, CNCの機械加工を必要とする.

石油とガスの用途

掘削ツール: ドリルビット, パイプ, およびカップリング.

バルブとフィッティング: 流体の流れを調節する高圧成分.

ポンプとコンプレッサー: 精密化されたハウジングとインペラ.

海底機器: 塩水環境での腐食に抵抗するように設計されたコンポーネント.

CNCが重要な理由

材料強度: CNCの機械加工は、硬化鋼で動作します, チタン, エキゾチックな合金.

信頼性: 障害は壊滅的な油流出やガスの漏れにつながる可能性があります.

効率: CNCは、交換部品のより速い生産を可能にします, ダウンタイムを最小化します.

カスタマイズ: 異なる石油掘削装置には、CNCが生産できる特殊な部品が必要です.

Aを考慮してください 深海掘削操作: すべての部分, ドリルヘッドからバルブシステムまで, 押しつぶしの圧力と腐食性の海水に耐えなければなりません. CNC加工により、これらのコンポーネントが業界の厳しい基準を満たしていることが保証されます.

提供することによって 強さ, 精度, そして耐久性, CNC加工により、エネルギーセクターはスムーズに動作し続けます。.

再生可能エネルギー産業

世界がに向かってシフトするにつれて 持続可能なエネルギー, CNCの機械加工は、風のためのインフラストラクチャを構築する上で中心的な役割を果たしています, 太陽, と水力. 多くの場合、再生可能エネルギーコンポーネントが必要です 大きい, 複雑な, そして正確な部品, どのCNC加工が効率をもたらします.

再生可能エネルギーのアプリケーション

風力タービン: ローターハブ, シャフト, およびギアボックスコンポーネント.

太陽光発電: アルミニウムフレーム, マウント, and tracking systems.There are many solar panel suppliers that rely on precision-made metal parts, のような HBOWA.

水力発電: タービンブレードとハウジングパーツ.

エネルギー貯蔵: バッテリーシステム用のCNCマシンケーシング.

CNCが重要な理由

スケーラビリティ: 再生可能プロジェクトは、多くの場合、大規模な生産を必要とします.

耐久性: コンポーネントは、屋外環境で何十年も続く必要があります.

素材の柔軟性: CNCマシンは複合材料で動作します, 金属, および合金.

イノベーションに優しい: 再生可能技術が進化するにつれて, CNCはプロトタイピングとカスタムパーツをサポートしています.

例えば, 風力タービンギアボックス 大規模ですが、確実に機能するために顕微鏡的許容耐性で機械加工する必要があります 20+ 年. 同様に, CNC加工は、太陽への絶え間ない曝露に耐えることができるソーラーパネルマウントを作成するために使用されます, 風, と雨.

再生可能エネルギーインフラストラクチャにバックボーンを提供することにより, CNC加工は、グローバルなシフトの力を維持するのに役立ちます 環境に優しい未来.

消費財業界

の 消費財セクター 広大です, 家電製品からおもちゃやパーソナルエレクトロニクスに至るまですべてに及ぶ. それらを結びつけるのは必要性です 費用対効果の高い, 耐久性のある, そして、審美的に魅力的な製品 - そして、CNCの機械加工はそれらを提供する上で大きな役割を果たします.

消費財のアプリケーション

アプライアンス: 洗濯機のドラム, ブレンダーブレード, およびコーヒーマシンパーツ.

エレクトロニクス: ノートパソコンの筐体, スピーカーエンクロージャー, ゲームコンソール.

おもちゃとガジェット: 可動部品用の精密プラスチックまたは金属成分.

高級品: ハイエンド時計, デザイナーアクセサリー, およびカスタムツール.

CNCが消費者製品で重要な理由

一貫性: 消費者は、すべてのアイテムが同じように見えることを期待しています.

カスタマイズ: パーソナライズされた電話ケース, 刻まれたアイテム, または、テーラードガジェットはCNCフレンドリーです.

耐久性: CNCの機械加工により、大量に成形されたプラスチックと比較して、長持ちする部品が保証されます.

設計の柔軟性: CNCを使用すると、デザイナーは複雑なフォームを実験できます.

の例を見てください ハイエンドヘッドフォン. スピーカーの周りのアルミニウムハウジングは美学だけではありません。繊細な電子機器を保護し、適切な音質を確保します. CNC加工は、パフォーマンスとスタイルの両方に必要な正確な寸法を提供します.

本質的に, CNCマシンは、メーカーが提供できるようにします 信頼性のある, スタイリッシュ, そして手頃な価格の商品 今日のペースの速い市場での消費者の期待に応えています.

鉄道産業

の 鉄道産業 耐えることができる部品に依存します 重い負荷, 一定の摩擦, と屋外の状態. 列車が何十年も走るので, 耐久性と安全性は交渉できません. CNC加工が提供されます 精度と強度 現代の鉄道システムが必要です.

鉄道のアプリケーション

エンジン: シリンダー, ハウジング, とピストン.

ブレーキシステム: 高い耐性を必要とするブレーキディスクとパッド.

コンポーネントを追跡します: スイッチ, 固定システム, およびレールジョイント.

車のインテリア: 座席構造, パネル, と付属品.

CNCが鉄道の鍵である理由

長寿: 列車の部品は、最小限の摩耗で長年にわたってなければなりません.

安全基準: わずかな欠陥でさえ、脱線を引き起こす可能性があります.

カスタマイズ: 各鉄道システムには、独自のインフラストラクチャのニーズがあります.

スケーラビリティ: CNCは、フリート全体の大規模なバッチ生産を可能にします.

例えば, ブレーキシステム 大量の負荷で確実に機能する必要があります. CNC加工により、ブレーキが均一に関与するように正確な許容範囲を保証する, 事故のリスクを減らす. 同様に, 鉄道ジョイントの精密機械加工により、より滑らかな乗り物と両方の列車とトラックでの摩耗が少なくなります.

結局のところ, CNCの機械加工は、鉄道産業が提供するのに役立ちます 安全, 信頼性のある, 長期にわたる輸送システム.

ロボット業界

の ロボットセクター 今日の最も急成長しているフィールドの1つです, そして、CNCの機械加工は中心です. ロボットが必要です 複雑な, 軽量, 非常に正確なコンポーネント, CNCの製造のための頼りになる方法を機械加工する.

ロボット工学のアプリケーション

フレームとシャーシ: 産業およびサービスロボットの構造的な骨格.

ギアとアクチュエーター: 高精度の動きの部分.

電子ハウジング: センサーとプロセッサ用のエンクロージャー.

プロトタイピング: カスタムロボットアーム, ジョイント, および添付ファイル.

CNCがロボット工学を供給する理由

厳しい公差: ロボットは、繰り返し可能な動きに精度が必要です.

材料の多様性: ロボット工学は金属を使用します, プラスチック, および複合材料.

カスタマイズ: CNCは、特殊なロボット用のユニークなビルドを有効にします.

革新: 迅速なプロトタイピングは、新しいデザインをサポートしています.

例えば, 車の組立ラインで使用される産業用ロボットが必要です マイクロメーターの精度で機械加工されたギア ストレスの下で一貫したパフォーマンスを確保するため. その間, ドローンのようなサービスロボットは、CNCマシンの軽量アルミニウムまたは炭素繊維部品を使用して効率を最大化します.

簡単に言えば, CNCの機械加工により、ロボット工学を提供します 精度と適応性 この最先端の業界に必要です.

鉱業

の 鉱業 機械で困難な環境で動作します - dust, 摩耗, 水分, そして絶え間ない摩耗. CNC加工が提供されます 頑丈, 耐久性のある, 信頼できる部品 これにより、コストのかかる故障なしに採掘操作を継続することができます.

マイニングのアプリケーション

掘削機器: ドリルヘッド, ロッド, およびカップリング.

発掘機械: バケツ, 歯車, および構造コンポーネント.

粉砕システム: クラッシャーと粉砕機の精密部品.

コンベアシステム: ローラー, シャフト, そしてサポート.

CNCがマイニングに不可欠である理由

耐久性: CNC部品は、研磨材の摩耗に抵抗します.

材料強度: CNC加工は、硬化鋼と合金を処理できます.

信頼性: マイニングのダウンタイムは費用がかかります。術は障害を減らします.

規模: 重機用の大きなコンポーネントは効率的に機械加工できます.

取る ロッククラッシャー 例として. そのギアは、すぐに消耗せずに一定の研削に耐える必要があります. CNC加工により、ギアは耐久性があるだけでなく、故障を最小限に抑えるために正確に一致することを保証します.

要するに, CNC加工により、鉱業の機械が残ることが保証されます 信頼性のある, 強い, そして生産的 最も厳しい環境でさえ.

光学業界

の 光学業界 要求 顕微鏡精度, CNC加工はまさにそれを提供します. 製造カメラレンズから望遠鏡アセンブリまで, CNCマシンは、光学的透明度に必要な完璧な精度を提供します.

光学系のアプリケーション

レンズ型: ガラスまたはプラスチックレンズ用の精密金型.

マウントとハウジング: 顕微鏡と望遠鏡の構造フレーム.

マイクロオプティック: 内視鏡とレーザーシステムの小さなコンポーネント.

光学ベンチ: 科学研究のための複雑な集会.

CNCが光学系に優れている理由

ミクロンレベルの精度: クリアイメージングに不可欠です.

滑らかな仕上げ: CNC研削により、完璧な光学表面が保証されます.

カスタマイズ: CNCは、一意のレンズ構成を有効にします.

マテリアルハンドリング: ガラス, プラスチック, そして、金属製の住宅はすべて利点があります.

例えば, 医療内視鏡で, 小さな光学コンポーネントは、医師が人体の内部ではっきりと見るために完全に整列する必要があります. CNC加工により、これらのアラインメントが一貫性があり信頼性が保証されます.

本質的に, CNCの機械加工は、カメラから望遠鏡までの光学デバイスが希釈者である理由です シャープ, 信頼性のある, そして正確なビジョン.

食品加工業界

食品加工機械はそうでなければなりません サニタリー, 耐久性のある, そして効率的です. CNCの機械加工は、耐えることができる食品に安全な機器の生産に重要な役割を果たします 一定のクリーニング, 切断, およびパッケージング操作.

食品加工のアプリケーション

刃を切る: パンをスライスするための精密ブレード, 肉, または野菜.

型と死: クッキーの形状, パスタ, またはチョコレート.

コンベアシステム: ローラー, シャフト, および機械部品.

包装機器: 顎, シーリングコンポーネント, チューブの形成.

CNCが食品産業で重要な理由

衛生基準: CNCマシンは、細菌に抵抗する滑らかな表面を生成します.

耐久性: ステンレス鋼および食品グレードのプラスチックは、洗浄化学物質に耐えます.

効率: CNC加工により、長期にわたって保証されます, 鋭い切削工具.

カスタマイズ: さまざまな食品には、カスタマイズされた型とツールが必要です.

例えば, パスタ型 CNCが正確な形状にマキシドされています, 毎回均一な製品を確保します. 同様に, 食品包装装置は、CNC部品に依存してバッグや箱を迅速かつ確実に密封します.

CNC加工なし, 食料生産は遅くなります, 衛生が少ない, そして、はるかに効率が低い.

繊維産業

の テキスタイル産業 CNC加工を使用して強化します 生地の生産, 刺繍, と織り. しばしば見落とされています, CNCは、最新の繊維機械の精度と耐久性に貢献しています.

テキスタイルのアプリケーション

刺繍機: 精密ステッチ用のCNC製造コンポーネント.

織り機: 織機部品, 紡錘, とボビンズ.

切削工具: 布の切断のための刃.

パターン作成: 複雑なテキスタイルデザインを作成するためのCNCルーター.

CNCがテキスタイルをサポートする理由

一貫性: 欠陥のないスムーズな生産を保証します.

耐久性: 繊維機械は継続的に動作します。CNC部品は寿命を延ばします.

カスタマイズ: ユニークなテキスタイルパターンには、精密ツールが必要です.

効率: CNCは、高品質でダウンタイムを短縮します, 長期にわたる部品.

例えば, 織物の紡錘 生地が均等に織り込むには、完璧に回転する必要があります. CNC加工により、この精度が保証されます, テキスタイル製造におけるエラーと廃棄物の削減.

これにより、CNCの機械加工は目に見えないが不可欠なパートナーになります 服, ファブリック, ファッションアクセサリーと 世界中.

エンターテインメント業界

の エンターテインメント業界 創造性で繁栄します - そしてCNC加工は想像力を実現するのに役立ちます. ステージセットから映画の小道具まで, CNCは、複雑なデザインを実用的で繰り返し可能にします.

エンターテインメントのアプリケーション

小道具とモデル: 兵器, 衣装, 映画のレプリカ.

ステージセット: CNC彫刻パネル, フレームワーク, そして風景の作品.

楽器: ギターの首, バイオリンの体, とドラムシェル.

テーマパーク: 乗車コンポーネントと装飾構造.

CNCが創造性を促進する理由

複雑なデザイン: CNCマシンは、複雑な形状を手作業で不可能にします.

再現性: プロデュースとセットピースは、プロダクション用に複製できます.

耐久性: CNCは強力に保証されます, 繰り返し使用するための長期にわたる部品.

カスタマイズ: すべての創造的なプロジェクトには、ユニークなデザインが必要です.

例えば, ハリウッド映画で, 現実的です SF小道具 武器やヘルメットのように、正確さと耐久性のためにCNCマシン化されています. その間, 楽器メーカーはCNCを使用して、一貫した音質で木材を彫ります.

CNC加工により、可能になります ファンタジーを現実に変えます, エンジニアリングの精度でクリエイティブ産業をサポートします.

通信業界

の 通信業界 グローバルコミュニケーションのための物理インフラストラクチャを作成するために、CNCの機械加工に依存しています. スマートフォンかどうか, 衛星, またはアンテナタワー, CNCは耐久性と精度を保証します.

通信のアプリケーション

コネクタ: 精密にマシンされたプラグとソケット.

アンテナコンポーネント: ベース, 括弧, およびハウジング.

エンクロージャー: 通信機器の保護ケーシング.

熱管理: 5Gシステムのヒートシンク.

CNCがテレコムで重要な理由

精度: テレコムは、高周波信号の正確な適合に依存しています.

耐久性: 屋外のアンテナは、極端な天候に耐えなければなりません.

カスタマイズ: 一意のインストールにはカスタムブラケットが必要です.

スケーラビリティ: CNCは、標準化された部品の大量生産をサポートしています.

考えてみてください 5Gインフラストラクチャ - アントエナは、完璧なパフォーマンスのためにCNCに加入されたハウジングとマウントを必要とします. CNC精度なし, 接続性は信頼できません.

これにより、世界を維持する上でCNCの機械加工が不可欠になります 接続と通信.

研究 & 発達 (R&D)

の R&Dセクター イノベーションで繁栄します, CNC加工は最も強力なツールの1つです. コンセプトモデルから実験デバイスまで, CNCはアイデアを具体的にします.

rのアプリケーション&D

プロトタイピング: テスト可能な部品の迅速な作成.

テスト機器: 精密ハウジングと備品.

カスタムコンポーネント: 実験用の1回限りのデザイン.

教育モデル: 大学や研究室での教師.

CNCがrを強化する理由&D

スピード: アイデアを素早く物理的なプロトタイプに変えます.

柔軟性: 多様なデザインと素材を処理します.

正確さ: 部品エラーを排除することにより、信頼できるテスト結果を提供します.

革新: 技術の境界を推進する産業を支援します.

例えば, バイオテクノロジーの研究者は、DNAシーケンスのためのカスタム機器を設計するかもしれません. CNC加工により、それらを可能にします プロトタイプと改良 長い遅延のないこのツール.

本質的に, CNCの機械加工はです 想像力と革新の間の橋渡し, 科学者とエンジニアが自分のアイデアをテストし、完璧にすることを可能にする.

家具製造業

の 家具産業 増大する需要を満たすためにCNC加工を受け入れました カスタムデザイン, 耐久性, および大量生産効率. 手作りの家具が唯一の選択肢だった時代は過ぎ去りました - トーダイ, CNCマシンは、芸術性とスケーラビリティの両方を実現することを可能にします.

家具のアプリケーション

フレームワーク: 椅子, テーブル, とベッドフレーム.

装飾的な要素: 複雑な彫刻と彫刻.

カスタム家具: クライアントのニーズに合わせたオーダーメイドのデザイン.

キャビネットとパネル: キッチンとオフィスの家具部品.

なぜ家具でCNCが重要なのか

設計精度: CNCは、詳細な彫刻を一貫して再現できます.

カスタマイズ: 顧客はパーソナライズされた形状やパターンを要求できます.

素材の柔軟性: 木材で動作します, 複合材, 金属, とプラスチック.

効率: 品質を維持しながら大量生産を高速化します.

例えば, ある 豪華なダイニングテーブル その端に沿って華やかな彫刻を特徴とするかもしれません. CNCマシンは、これらの複雑なデザインを完璧に複製します, 何百時間もの手労働を必要とせずに、すべてのユニットが同一に見えるようにしてください.

要するに, CNC加工が組み合わされます テクノロジーとの職人技, 家具業界が創造性と効率の両方を提供できるようにする.

製薬業界

医薬品で, 精度と衛生 不可欠です. CNC加工により、薬物製造に使用される機器が保証されます, 梱包, テストは、業界の厳格な安全基準を満たしています.

医薬品のアプリケーション

生産機器: ミキサー, カプセル化マシン, タブレットプレス.

包装機械: 形成ダイ, シーリングジョー, および充填システム.

実験装置: 実験とテスト用のカスタムツール.

CNCが不可欠である理由

滅菌基準: CNCの機械加工は滑らかになります, 細菌耐性表面.

耐久性: マシンはしばしば実行されます 24/7 信頼できる部品が必要です.

精度: 正確な投与とパッケージングは、完璧な機械に依存します.

カスタマイズ: ユニークな研究プロジェクトには、特殊なコンポーネントが必要です.

例えば, ピルプレス すべてのタブレットが形状と投与量が同一であることを保証するCNCマシンダイに依存しています. この一貫性なし, 薬物の安全性が損なわれる可能性があります.

CNCの機械加工は、保証する上で隠されたが重要な役割を果たします 安全, 効果的, 信頼できる薬 世界中の患者に到達します.

バイオテクノロジー産業

の バイオテクノロジーセクター 科学の境界を押し広げます, 多くの場合、必要です 個性的, 複雑な, およびミニチュアコンポーネント. CNC加工は、これらの高度に専門化されたツールを生産するための頼りになるテクノロジーです.

バイオテクノロジーのアプリケーション

医療機器: DNAシーケンサー, 顕微鏡, ラボインスツルメンツ.

研究機器: 特殊なハウジングと精密部品.

カスタムコンポーネント: 実験的研究のために1回限りの構築.

CNCがバイオテクノロジーをサポートする理由

ミクロンの精度: マイクロスケールデバイスに不可欠です.

材質の適合性: ステンレス鋼で動作します, チタン, および生体適合性プラスチック.

ラピッドプロトタイピング: 研究者が新しいデザインを迅速にテストするのに役立ちます.

革新: ユニークなソリューションを提供することにより、ブレークスルーを有効にします.

例えば, ある DNAシーケンスマシン CNCマシンのハウジングに依存して、光学部品と電子コンポーネントを極端に整列させます. CNCなし, このような複雑なアセンブリは不可能です.

有効にすることによって 最先端の科学研究, CNC加工は、バイオテクノロジーの急速な進歩の基礎です.

スポーツ用品業界

の スポーツ用品セクター パフォーマンスを耐久性とブレンドします, また、CNC加工により、機器がこれらの要求を満たすことが保証されます. 自転車から野球のバットまで, CNCがもたらします 一貫性とカスタマイズ スポーツ用品に.

スポーツのアプリケーション

自転車: フレーム, 歯車, およびブレーキシステム.

ゴルフクラブ: カスタムヘッドとシャフト.

屋外ギア: ナイフ, スケートボード, キャンプツール.

保護装置: ヘルメットとサポート構造.

スポーツでCNCが重要な理由

パフォーマンスの精度: 小さな違いは、運動能力に影響を与える可能性があります.

カスタマイズ: アスリートは、多くの場合、自分のスタイルに合わせたギアが必要です.

耐久性: CNCマシンの金属と複合材料は長持ちします.

量産: CNCは、製品ライン全体で同じ品質を保証します.

例えば, プロのゴルファー 多くの場合、スイングスタイルに完全に一致するCNCマシンのカスタムクラブを使用します. 同様に, 高性能の自転車は、安全性と速度のためにCNCにマシンされたギアとブレーキシステムに依存しています.

CNC加工により、スポーツ用品がよく見えるだけでなく、 フィールドで一流のパフォーマンスを提供します.

宇宙技術産業

それが来たら 宇宙探査, 賭け金は高くなることはありません. 空間での単一のコンポーネントの障害は、ミッションの失敗を意味する可能性があります。. CNC加工により、部品が構築されます 最も要求の厳しい基準 地球上.

スペースのアプリケーション

衛星部品: アンテナ, ハウジング, と括弧.

ロケットコンポーネント: エンジン, ケーシング, および燃料システム.

宇宙船アセンブリ: 科学機器ハウジング, パネル, およびコネクタ.

CNCが宇宙技術で重要である理由

超高精度: スペースコンポーネントは完全にフィットする必要があります.

材料の耐久性: 極端な条件に耐えるCNC機械のチタンと合金.

信頼性: 宇宙ミッションで失敗する余地はありません.

革新: CNCは、次世代宇宙船のプロトタイプを有効にします.

例えば, ロケットエンジンハウジング 打ち上げ中に極端な熱と圧力に耐えるには、完璧な機械加工が必要です. CNC加工により、比類のない一貫性でこれを可能にします.

簡単に言えば, CNCの機械加工はです 宇宙探査のバックボーン, サイエンスフィクションを科学的現実に変えます.

化学処理産業

の 化学工業 耐えることができる機械が必要です 腐食性の材料と高温. CNCの機械加工は、これらの要求の厳しい条件を乗り切るのに十分なタフな部品を提供します.

化学処理のアプリケーション

原子炉: 化学反応のための精密化された血管.

ポンプとバルブ: 攻撃的な液体を処理するように設計された部品.

熱交換器: 正確な許容範囲を必要とするコンポーネント.

CNCが不可欠である理由

耐食性: 化学物質に耐性のあるエキゾチックな合金.

精度: 化学プロセスの正確な制御を保証します.

耐久性: 厳しい環境で機器の寿命を延長します.

安全性: 漏れや事故のリスクを減らします.

例えば, バルブコンポーネント 化学プラントでは、危険な化学物質の漏れを防ぐために完全にフィットする必要があります. CNC加工により、必要な精度が保証されます.

CNC加工なし, 化学プラントは維持に苦労します 安全性と信頼性 彼らの操作で必要です.

教育セクター

教育でさえ、CNC加工から利益を得ることができます. 学校, 大学, トレーニング機関はCNCマシンを使用します 実践的な学習および研究プロジェクト.

教育におけるアプリケーション

トレーニングマシン: 学生練習用のCNC機器.

研究ツール: 大学の実験のプロトタイピング.

教育モデル: 教師とデモンストレーション.

CNCが教育において重要な理由

スキル開発: 現代の製造のために学生を準備します.

革新: 生徒は実世界のデザインを実験できるようにします.

アクセシビリティ: 手頃な価格のCNCマシンにより、学習が容易になります.

業界に関連するトレーニング: 熟練した将来の労働力を作成します.

例えば, エンジニアリングの学生はしばしば構築します ロボットプロトタイプ CNCマシンパーツの使用, 貴重な現実世界のスキルを学ぶ.

CNC加工は、教育が間のギャップを埋めるのに役立ちます 理論と実用的な応用, 次世代のイノベーターに力を与える.

宝石製造業

の ジュエリーセクター CNC加工によって変換されました, これを可能にします 複雑, 繰り返し可能, カスタマイズされたデザイン.

ジュエリーのアプリケーション

カスタムピース: 名前ペンダント, リング, ブレスレット.

複雑なデザイン: かつて手彫りだったパターン.

金型製作: 大量生産用のCNCマシン金型.

CNCがジュエリーで重要な理由

精度の詳細: 最小のパターンでさえ可能です.

カスタマイズ: CNC設計ではパーソナライズは簡単です.

効率: 生産を増やしながら人件費を削減します.

素材の柔軟性: 金で動作します, 銀, 白金, もっと.

例えば, ある ダイヤモンドリング設定 宝石を完全に所定の位置に保持する必要があります. CNC加工により、セキュリティとスタイルの両方に対する正確な許容範囲が保証されます.

CNCに感謝します, ジュエリーメーカーは組み合わせることができます 創造性と技術, 見事な生産, 規模のパーソナライズされた作品.

水処理業界

の 水処理部門 耐えることができる部品が必要です 一定の使用と水と化学物質への暴露. CNC加工により、耐久性と信頼性が保証されます.

水処理におけるアプリケーション

ポンプコンポーネント: シャフト, インペラ, およびハウジング.

バルブ部品: 流体流の制御システム.

ろ過システム: フィルター用のフレームと精度部品.

CNCが重要な理由

耐久性: 腐食性および高圧条件を処理します.

精度: 清潔で信頼できる水の流れを保証します.

効率: 治療機器の寿命を延ばします.

安全性: 汚染のリスクを減らします.

例えば, フィルターハウジング 処理された水に不純物が漏れないように、正確な仕様にCNC加工が必要です.

有効にすることによって 安全で効率的な水処理, CNCの機械加工は、公衆衛生において重要な役割を果たします.

HVAC業界

加熱, 換気, エアコン (HVAC) システムは、CNCの機械加工に依存しています 信頼性のある, 効率的, カスタマイズされた部品.

HVACのアプリケーション

ダクトワーク: CNCカットパネルとフィッティング.

ファンブレード: 効率のために精密にマシドされています.

コンプレッサーとバルブ: パフォーマンスのためのタイト耐性部品.

カスタムインストール: 大規模システム用のユニークな部品.

CNCがHVACで重要な理由

エネルギー効率: CNC加工により、最適な気流のための精密成分が保証されます.

カスタマイズ: 多くの場合、建物はカスタマイズされたHVACシステムが必要です.

耐久性: CNCマシンパーツは、継続的に使用されて長持ちします.

スケーラビリティ: 小規模および大規模な製造の両方を可能にします.

取る ファンブレード 例として. 小さな不均衡でさえエネルギーを無駄にする可能性があります. CNC加工により、ブレードは完全にバランスが取れていることが保証されます, 効率の向上と騒音の減少.

したがって, CNC加工は作成の中心です 快適, エネルギー効率の高い屋内環境.

まとめ

航空宇宙から宝石まで, CNCの機械加工は、それ自体が証明されています 現代産業のバックボーン. その配信能力 精度, 耐久性, カスタマイズ, およびスケーラビリティ セクター間で不可欠になります.

技術が進むにつれて, と 5-軸加工, オートメーション, およびAI統合, CNCマシンはより強力になります. 未来はさらに速い生産を約束します, より大きなカスタマイズ, そして、私たちがまだ想像できない方法でCNCに依存する新しい産業.

要するに, CNCの機械加工は、産業をサポートするだけではありません 世界中のイノベーションを推進しています.

よくある質問

- トップは何ですか 10 CNC加工のアプリケーション?

航空宇宙, 自動車, 医学, エレクトロニクス, 防衛, 再生可能エネルギー, 工事, ロボット工学, スポーツ用品, HVACは最も一般的なアプリケーションの1つです. - CNCで機械加工できる材料?

CNCマシンはアルミニウムを処理します, 鋼鉄, チタン, 真鍮, 銅, プラスチック, 木材, 複合材, 陶器でさえ. - 最も一般的に使用されるCNC加工とは何ですか?

最も一般的に使用されています 金属部品とプラスチック部品の精密な製造, プロトタイプから大量生産まで. - CNCの機械加工が従来の機械加工よりも優れているのはなぜですか?

CNCが提供しているからです スピード, 再現性, 精度, およびスケーラビリティ - すべてが人為的エラーを減らしながら. - CNC加工から最も利益を得る業界?

一方、ほとんどすべての業界に利益があります, 航空宇宙, 自動車, 医学, そして、電子機器はです トップセクター CNCに大きく依存しています.