オートバイは単なる機械以上のものです。彼らはエンジニアリングのブレンドです, パフォーマンス, そして個人的な表現. すべての滑らかな乗り心地と強力な加速の背後には、正確に設計された部品のコレクションがあります, その多くはで生産されています CNC (コンピュータ数値制御) 機械加工.

CNC加工により、提供することでオートバイの製造に革命をもたらしました 比類のない精度, スピード, と柔軟性. 摩耗したコンポーネントを交換しているかどうか, パフォーマンスのアップグレード, またはカスタムスタイリングを追加します, CNCテクノロジーは、ライダーとメーカーに同様に信頼できるソリューションを提供します.

このガイドでは, 詳しく見ていきます CNC加工がオートバイの部品にとって非常に重要な理由です, この方法で一般的に作成されるコンポーネント, 使用される材料とプロセス, 仕上げオプション, そして、それがオートバイ業界にもたらす全体的な利点.

オートバイ部品のCNC加工の理由?

CNC加工は、そのためにオートバイ部品を生産するための頼りになる方法になりました 正確さ, 多用途性, およびカスタマイズの可能性. 主な理由は次のとおりです:

損傷した部品の交換

モーターサイクルは、熱への絶え間ない曝露のために高い摩耗を経験します, 振動, と摩擦. CNC加工, ピストンなどの損傷した部品, シャフト, またはホイールはそうすることができます 迅速かつ正確に複製します, ライダーが長い遅延なく道路に戻ることができるようにする. 廃止されたまたは希少な部品でさえ、適切なCADデザインで再現できます.

アップグレード & スタイリッシュな外観

ライダーはしばしば自転車に個人的なタッチを追加したい. CNC加工により カスタム設計ホイール, カバー, および装飾的な要素 パフォーマンスを向上させるだけでなく、自転車の外観を向上させる. カスタマイズのコストも近年手頃な価格になっています.

精度 & 正確さ

手動機械加工とは異なり, CNCは自動化されており、デジタルデザインを信じられないほど正確にフォローしています. これはつまり 厳しい許容範囲, 繰り返し可能な結果, 最小限の欠陥. カムシャフトやピストンなどの部品用, この精度は、エンジンのパフォーマンスに直接影響します.

クイックプロダクション

CNCマシンは継続的に実行され、最小限のダウンタイムでデザインを切り替えることができます. メーカー向け, これはつまり より速いリードタイム そして、ゼロから始めることなく設計エラーをすばやく修正する能力.

CNC加工で作られたカスタムオートバイ部品

機能的で美的には、多くのオートバイの部品は、CNCの機械加工で作られています. 以下は最も一般的な例です:

ホイール

多くの場合、オートバイのホイールはCNCにマシンされています アルミニウム合金 彼らはそうする必要があるからです 軽量でありながら強い. CNCミリングにより、作成が可能になります 複雑なスポークデザイン パフォーマンスと視覚的な魅力を組み合わせたカスタマイズされた仕上げ.

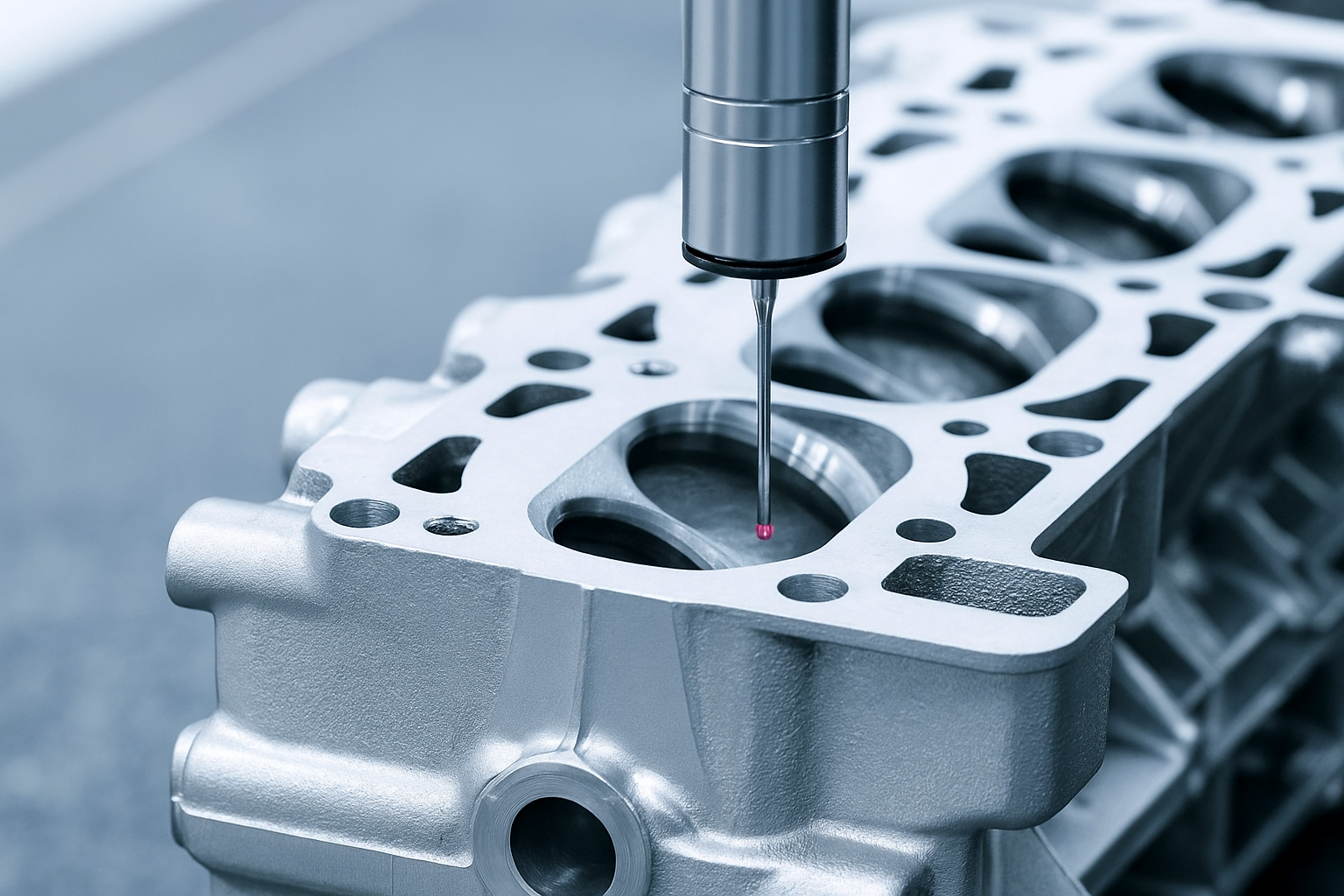

エンジンコンポーネント

すべてのオートバイの中心は、そのエンジンです, CNCの機械加工は、その建設において大きな役割を果たしています.

シリンダーヘッド: 燃料燃焼と気流を制御します; CNCは、効率的な動作のために正確な寸法を保証します.

カムシャフト: 制御バルブのタイミング; CNCターニングにより、より良い出力のために調整できる精密プロファイルが可能になります.

ピストン: 高性能ピストンは、熱とストレスに耐える必要があります. CNC加工により、耐久性とエンジンの応答を改善するカスタムデザインが可能です.

ライトとレンズ

CNC加工も使用されます ライトカバーとレンズ, 多くの場合、プラスチックやアルミニウムから作られています. これらの部品は、満たすためにカスタマイズできます 安全規制 ユニークなスタイルを追加しながら.

審美的な部分と体の部分

パフォーマンスを超えて, 多くのライダーが投資します カスタマイズされたボディカバー, シートベース, および装飾的な要素. と 5-軸CNC加工, 複雑な曲線と芸術的なデザインは簡単に生産できます.

カスタムバイク部品に使用される材料

アルミニウム - 軽量だが強い. 機械加工して磨くのは簡単です, カスタムホイールのお気に入りになります, フレーム, ハンドルバー. プラス, 簡単に錆びません.

ステンレス鋼 - その強さと光沢のある仕上げで知られています. ステンレス鋼はアルミニウムよりも重いです, しかし、それは排気システムに最適です, ファスナー, 腐食せずにストレスを処理する必要がある部分.

カーボンファイバー - 超軽量でモダンな外観. 炭素繊維は、減量が重要な高性能バイクによく使用されます. ボディパネルを考えてください, フェアリング, そして時には車輪さえ.

チタン - プレミアム選択. チタンは鋼鉄のように強いですが、はるかに軽いです. ハイエンドの排気部品やパフォーマンスパーツに最適です, 通常はより高価ですが.

プラスチック および複合材料 - 腹筋やグラスファイバーなどの素材は、しばしばボディワークに使用されます, フェアリング, または、軽いのでカバーします, 成形可能, 簡単に塗装できます.

真鍮 そして 銅 (詳細については) - これらはメイン構造用ではありません, しかし、ビルダーはアクセントのためにそれらを使用するのが大好きです, 継手, またはレトロまたはビンテージの雰囲気を追加するカスタムタッチ.

オートバイ部品の機械加工プロセス

パーツジオメトリと関数に基づいて、さまざまな機械加工プロセスが選択されます:

CNC旋削加工:

カムシャフトなどの円筒形のコンポーネントに使用されます, ピストン, とシャフト. スムーズを提供します, 正確な回転対称性.

CNCフライス加工:

車輪に最適です, カスタムブラケット, および非対称部分. 3-軸と5軸フライスは、単純な形と非常に複雑な形の両方を処理できます.

研削:

シャフトに適用されます, ベアリング, 非常に滑らかな表面を必要とする他の部品. 寸法精度を向上させます.

掘削:

アセンブリで使用される穴に必要です, ファスナー, エンジン部品の冷却チャネル.

レーザー切断:

軽量カバーに使用されます, フロントガラス, 細かい細部を備えた装飾パーツ.

オートバイ部品の表面仕上げ

機械加工後, 表面仕上げにより耐久性が向上します, 耐食性, そして外観:

陽極酸化処理: ハードを作成します, 保護酸化物層, 多くの場合、美学のための色の仕上げがあります.

粉体塗装: 厚いものを提供します, チップやスクラッチに耐性のある耐久性のあるコーティング.

ビーズブラスト: 疲労強度を改善し、マットを与えます, 均一な外観.

電気めっき: 保護的で装飾的な金属層を追加します (例えば, クロム).

研磨: 光沢があります, 鏡のような表面 - 可視のオートバイ部品の人口.

CNC機械加工バイク部品の利点

高精度 - エンジンのパフォーマンスと安全性にとって重要です.

軽量でありながら強い - 燃費と取り扱いの向上.

迅速な生産 - 修理とアップグレードのダウンタイムを短縮します.

カスタマイズ可能 - ライダーは、スタイルとパフォーマンスのためにデザインをパーソナライズできます.

プロトタイピングに最適です - メーカーは大量生産の前に新しいデザインを迅速にテストできます.

CNCオートバイの部品は本当にどれくらいの費用がかかりますか?

物質的な選択

素材の種類は価格に大きな影響を与えます. 例えば, アルミニウムは通常、チタンや炭素繊維よりも安価で機械が簡単です. ステンレス鋼は真ん中のどこかにあります - それは強くて耐久性がありますが、少し難しいです (そしてコストがかかります) 機械に.

パーツの複雑さ

シンプルなブラケットまたはスペーサー? それは比較的安いでしょう. 詳細なカットを備えたカスタムエンジンカバー, 曲線, およびロゴ? 機械に時間がかかります, これは、より高いコストを意味します. デザインがより複雑です, 部品がより高価になります.

量

1つの部分を作ることは、作るよりも常に一枚あたりより高価です 50. 一括注文している場合, ユニットあたりのコストは大幅に低下します. しかし、ユニークのために, 1回限りのカスタムビルド, 保険料を支払うことを期待してください.

仕上げとエキストラ

生の部品の費用は安くなります, しかし、あなたが陽極酸化したいなら, 研磨, 粉体塗装, または彫刻, これらの仕上げの仕上げは最終請求書に追加されます. これらの詳細は、自転車を際立たせることができます, しかし、彼らは自由ではありません.

機械の時間と労働

CNCマシンは時間ごとに充電されます. あなたの部品が切るのに時間がかかります, コストが高くなります. 複雑な5軸の加工は通常、基本的な3軸作業よりも高価です.

場所とショップの料金

米国のCNCショップ. またはヨーロッパはおそらくアジアで複数の料金を請求するでしょう, 単に労働と頭上の違いがあるためです.

💡 クイックヒント: 予算がある場合, よりシンプルなデザインに固執します, アルミニウムを使用します, 特別な仕上げを制限します. ハイエンドの展示物を求めている場合, プレミアム素材や複雑なデザインにもっとお金を払う準備をしてください.

CNCオートバイ部品の品質管理

精度とフィット

すべての部分は、デザインを1ミリメートルのほんの一部に一致させる必要があります. カスタムブレーキレバーを注文することを想像してみてください, 右? CNC加工により、部品が非常に正確に切断されるようになります, そして品質チェックは、すべてが出荷前に完全に適合することを確認します.

材料チェック

すべての金属やプラスチックが平等に作成されるわけではありません. 機械加工する前に優れたCNCショップテスト材料が強力であることを確認する, 耐久性のある, そして仕事にぴったりです. 例えば, アルミニウム合金は硬さをチェックします, ステンレス鋼の耐食性がチェックされている間.

表面仕上げ

粗いエッジや傷は、オートバイのパートのパフォーマンスと外観の両方を台無しにする可能性があります. 品質管理には、滑らかな表面のチェックが含まれます, シャープなディテール, また、終了します (磨かれているかどうか, 陽極酸化, またはパウダーコーティング).

ストレスと耐久性のテスト

オートバイの部品は鼓動します, 振動, と重い負荷. 一部のハイエンドショップは、シミュレートされた条件下で部品をテストして、外出中に失敗しないようにします.

複数の部品の一貫性

部品のバッチを注文している場合は、たとえば, 20 フットペグ - それらはすべてまったく同じである必要があります. 品質管理は一貫性をチェックするので、不一致のピースになってしまない.

配達前の最終検査

部品が店を出る前に, 通常、検査の最終ラウンドを通過します. それには、寸法の測定が再び含まれる場合があります, 仕上げを確認します, そして、パーツが元のCADデザインと一致することを確認する.

カスタムCNCの機械加工オートバイ部品のヒント

明確なデザインから始めます

詳細を提供します, より良い. しっかりとしたCADの描画やよく考えられたスケッチでさえ、機械工があなたが必要とするものを正確に理解するのに役立ちます. 曖昧なものを残さないでください - 次元, 角度, 特別な機能は透明でなければなりません.

適切な素材を選択してください

さまざまな部品には異なる材料が必要です. 例えば, アルミニウムは軽量で、ボディワークに最適です, ステンレス鋼はより強く、ブラケットや構造部品に最適ですが. あなたが不明であればあなたの機械工と話す - 彼らは何が最適かを提案することができます.

機能について考えてください, 見た目だけではありません

驚くほどに見えますが、道路を持ちこたえない部分はそれだけの価値がありません. 常にスタイルと強さのバランスをとってください, 耐久性, そしてパフォーマンス.

トレランスを確認してください

オートバイは、多くの可動部品を備えた機械です, そして、小さな間違いは大きな問題を引き起こす可能性があります. あなたの部品が正しい許容範囲で設計されていることを確認してください (彼らがどれだけの「小刻みの部屋」を持つことができるか) したがって、それらは正しくフィットします.

経験豊富な店で働きます

すべてのCNCショップが同じではありません. 自動車またはオートバイの部品の経験があるものを探してください. 彼らはすでに一般的な問題を知っており、間違いを避けるのに役立ちます.

フィニッシュを前もって計画します

陽極酸化するような最後のタッチを忘れないでください, 研磨, またはコーティング. 生の部分は正常に動作する場合があります, しかし、適切な仕上げは、パーツの外観と寿命の両方を改善できます.

明確に通信します

プロセス全体を通して、機械工と連絡を取り合ってください. 更新を求めてください, 必要に応じて写真をリクエストしてください, そして、生産が始まる前にあなたが同じページにいることを確認してください.

テストと調整

完璧な機械加工でも, インストール中にカスタムパーツが少し調整する必要がある場合があります. 必要に応じてテストフィットし、小さな調整を行う準備をしてください.

結論

CNCの機械加工により、オートバイ業界は組み合わせることで変換されました エンジニアリング精度, 創造的な自由, 効率的な生産. から 高い精度を必要とするエンジンコンポーネント に 個人的なスタイルを反映するカスタマイズされたホイールと体の部分, CNC加工は、パフォーマンスと美学の両方にソリューションを提供します.

オートバイが進化し続けるにつれて, CNCの機械加工はイノベーションの最前線にとどまります。, もっと早く, より信頼性の高いマシン.

よくある質問

1. Why is maintaining tight tolerances (精度) so critical for motorcycle engine components?

Maintaining tight tolerances (± 0.05 んん or less) is absolutely critical because engine components operate under extreme heat, high speed, and tremendous stress. Parts like ピストン, シリンダーヘッド, とカムシャフト must fit together precisely to ensure proper sealing, efficient combustion, and accurate valve timing. Any deviation can lead to excessive friction, 未熟服, power loss, and catastrophic engine failure.

2. Which materials are best for achieving a lightweight performance part versus a strong structural part?

-

For Lightweight Performance: アルミニウム合金 (のように 6061 または 7075 シリーズ) are the top choice for components like wheels, triple clamps, and non-structural covers, offering an excellent strength-to-weight ratio and good machinability. カーボンファイバー is the ultimate choice for minimal weight in fairings and body panels.

-

For Strong Structural Parts: ステンレス鋼 is preferred for brackets, ファスナー, and exhaust components where maximum strength, 剛性, and corrosion resistance are needed, despite its higher weight. チタン is the premium alternative, offering steel’s strength at half the weight.

3. What is the difference between 3-axis and 5-axis CNC machining for motorcycle parts?

-

3-軸加工: Moves the cutting tool along the X, Y, と Z 軸. It is cost-effective and suitable for flat parts, simple brackets, and basic contours (例えば, footpegs, simple covers).

-

5-軸加工: Allows the tool to also pivot on two rotational axes (A and C). This is essential for creating 複雑な, contoured surfaces like intricate wheel spokes, ergonomically curved seat bases, and complex engine cylinder heads in a single setup, improving precision and surface finish.

4. How does anodizing improve the performance and appearance of aluminum motorcycle parts?

Anodizing is an electrochemical process that creates a 難しい, 保護酸化物層 on the surface of aluminum. This layer offers three main benefits:

-

耐食性: Protects the aluminum from weathering, road salts, そして湿気.

-

耐摩耗性: Makes the surface significantly harder and more scratch-resistant.

-

美学: Allows the part to be dyed in various colors (黒, 赤, 青, 等), providing a durable, stylish finish favored by custom builders.

5. Can CNC machining be used to recreate discontinued or vintage motorcycle parts?

はい, this is one of CNC machining’s key advantages. If an original part is damaged or no longer available, a machinist can use reverse engineering テクニック (like 3D scanning or precise measurements) aを作成します CADモデル. This digital model is then used to program the CNC machine to reproduce the part with the exact original dimensions and often with superior modern materials.

6. Why is prototyping crucial before mass-producing custom motorcycle parts?

プロトタイピング (making one or a few initial parts) is essential because motorcycles are complex assemblies. A prototype allows the designer and builder to:

-

Test Fit: Ensure the part mounts correctly without interference (例えば, a brake lever clearing a throttle housing).

-

Test Function: Verify that the part performs its mechanical or aerodynamic function under real-world stress.

-

Finalize Aesthetics: Confirm the finish, 色, and design are exactly what the customer desires before committing to an expensive, large-volume production run.

7. What factors cause the biggest variation in the final cost of a CNC motorcycle part?

The largest cost drivers are:

-

材料: Using Titanium or Carbon Fiber instead of standard Aluminum.

-

Complexity/Time: Requiring high-precision 5-軸加工 for intricate shapes versus simple 3-axis cutting.

-

仕上げる: Adding premium treatments like custom 硬質陽極酸化処理 または mirror polishing rather than leaving a raw machined finish.

-

量: The cost per unit drops significantly when ordering in large batches (規模の経済).

続きを読む: