深い穴の掘削は、高度に専門化されたプロセスのように聞こえるかもしれません, and that’s because it is. Unlike standard drilling, where the hole depth is relatively shallow, deep hole drilling is designed for creating holes with a depth-to-diameter ratio of 10:1 or greater. This technique is widely used in industries where accuracy, 強さ, and reliability are critical — such as aerospace, 自動車, 油 & ガス, 医療機器でさえ.

記事上で, we’ll dive into what deep hole drilling is, なぜそれが重要なのか, the different methods used, the challenges involved, and practical solutions. 最後まで, you’ll have a complete understanding of how this process powers some of the world’s most advanced technologies.

What Is Deep Hole Drilling?

その中心に, deep hole drilling is a machining process designed to produce 正確な, 真っ直ぐ, and clean holes that are significantly deeper than they are wide.

意味: A hole is considered a “deep hole” when its depth is at least 10 times its diameter (10:1 ratio).

Origin: Historically, the process began with the manufacturing of gun barrels, which demanded long, 真っ直ぐ, and highly accurate bores. This is why gun drilling is still one of the most common techniques.

Modern Use: 今日, the same principles apply to industries like aerospace (エンジン部品), 自動車 (fuel injectors, クランクシャフト), そして油 & ガス (drilling tools and pipelines).

Deep hole drilling ensures 構造的完全性, smooth performance, and high precision where normal drilling methods fall short.

Importance of Deep Hole Drilling in Modern Industries

航空宇宙と防衛

航空宇宙分野, lightweight yet strong materials are crucial. Deep hole drilling is used to produce components like 着陸装置, hydraulic systems, and even weapon systems. Precision is non-negotiable since even minor errors can affect performance and safety.

自動車産業

Automobiles rely on deep hole drilling for components such as:

燃料インジェクター (小さい, precise holes for fuel flow)

クランクシャフト & カムシャフト (oil passageways for lubrication)

油圧シリンダー (used in steering and braking systems)

ここ, durability and accuracy directly influence engine efficiency and vehicle reliability.

油 & ガス産業

In oil exploration and drilling, tools and pipes often need long boreholes that can withstand harsh conditions. Deep hole drilling ensures 強さ, 信頼性, and resistance to wear in components like drilling heads and petroleum instruments.

Engineering & 医療用途

で hydraulic systems, 長さ, straight holes are needed for pressure control and smooth fluid flow.

で 医療機器, 手術器具など, deep hole drilling ensures components are both tiny and highly accurate for safe operations.

Key Benefits of Deep Hole Drilling

高精度 – The ability to drill straight, accurate holes over long depths.

Improved Surface Finish – Smooth walls reduce friction and wear in critical applications.

効率 & ツールライフ – Specialized drill designs and coolant delivery extend tool life and reduce costs.

多用途性 – Can handle a wide range of materials, from steels to superalloys.

Common Techniques in Deep Hole Drilling

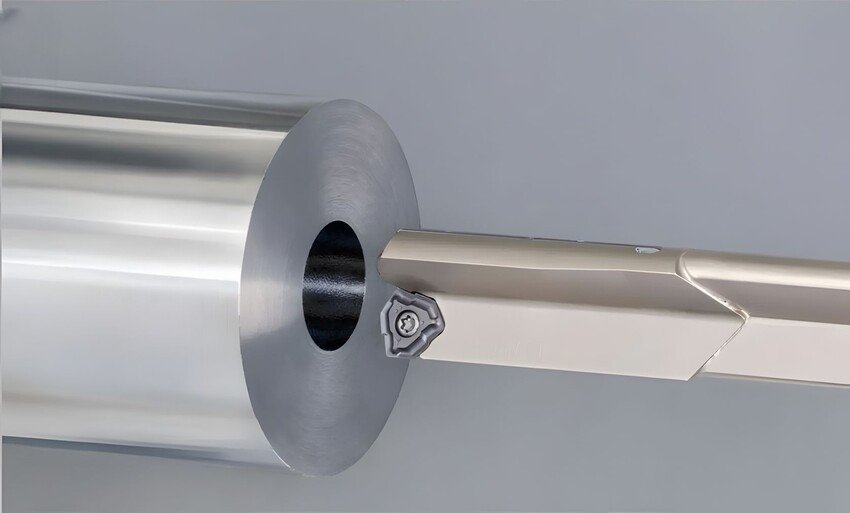

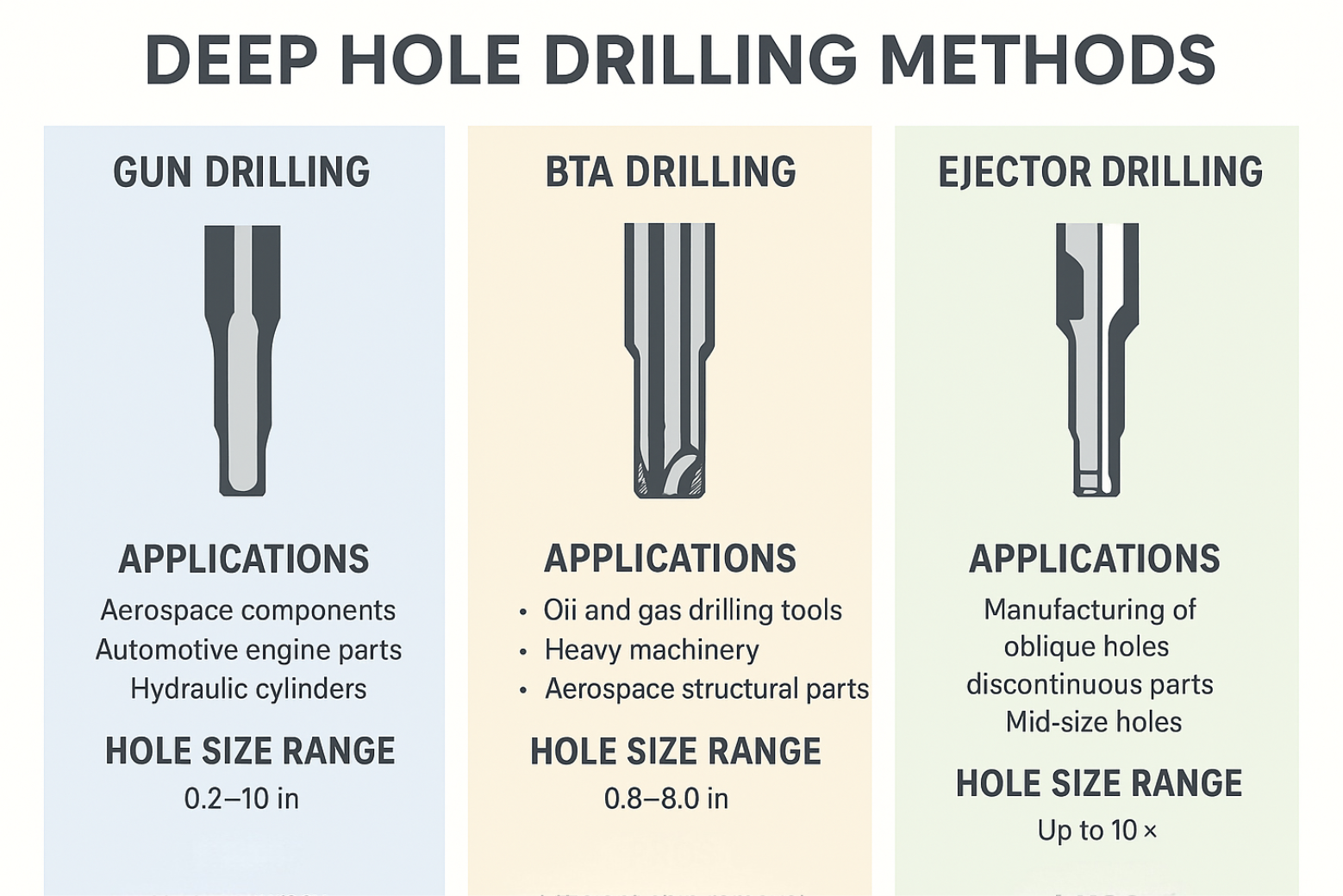

Gun Drilling

Best for small-diameter, straight holes.

Produces excellent accuracy and surface finish.

Common in firearm manufacturing, 航空宇宙部品, and automotive fuel systems.

BTA (Boring and Trepanning Association) 掘削

Used for larger hole diameters.

A single-tube system removes chips efficiently through the center.

Ideal for oil & ガス, 重機, and aerospace structural parts.

Ejector Drilling

Works with a double-tube system.

Offers flexibility and can be used on standard machining centers.

Perfect for mid-size holes where production speed is important.

Considerations for Tools and Equipment

最良の結果を達成するため, several factors need attention:

Drill Bit Selection: Choosing the right bit (gun drill, BTA, or ejector) for the material and hole size.

冷却システム: High-pressure coolants are essential for removing chips and preventing tool wear.

Machine Capabilities: Specialized machines with rigid setups are often required to prevent vibration and misalignment.

What Type of Drill Bit Is Suitable for Drilling Through Metal?

When it comes to drilling into metal, not all drill bits are created equal. Using the wrong type can make the job frustrating and even damage your tools or the workpiece. That’s why picking the right drill bit is so important.

ハイス鋼 (HSS) Drill Bits

These are the most common and affordable drill bits. They work well for softer metals like aluminum, 真鍮, および軟鋼. If you just need a basic option, HSS is usually enough.

Cobalt Drill Bits

Stronger than HSS, cobalt drill bits are perfect for harder metals like stainless steel or cast iron. They can handle higher heat, which is great because drilling through tougher metals creates more friction.

Carbide Drill Bits

These are the heavy-duty champs. Carbide bits are extremely hard and can cut through really tough metals, but they’re also brittle, meaning they can snap if not used carefully. They’re often used in industrial settings where precision and durability are key.

Titanium-Coated Drill Bits

These are HSS drill bits with a titanium coating. The coating makes them last longer by reducing friction and heat. They’re a nice middle ground if you want better performance than regular HSS without paying the high cost of cobalt or carbide.

Challenges and Solutions in Deep Hole Drilling

Misalignment and Tool Breakage

Problem: Slight misalignment can cause tool deflection or breakage.

解決: Use precision fixturing, steady rests, and real-time monitoring systems.

Workpiece Stability

Problem: Long workpieces can vibrate or move during drilling.

解決: Secure clamping and vibration-dampening setups.

Material-Specific Challenges

Problem: Hard alloys or heat-resistant metals cause excessive wear.

解決: Use coated drill bits (炭化物, 錫, 等) and optimize feed/speed parameters.

選ぶ理由 精度の高いトップ for Deep Hole Drilling?

Not every machine shop is equipped for deep hole drilling. Tops Precision provides:

専門知識 – Years of experience with complex drilling projects.

高精度 – Advanced equipment and strict quality control.

コスト効率 – Competitive pricing without compromising quality.

Reliable Partnership – Commitment to delivering on time and meeting industry standards.

結論

Deep hole drilling is more than just making a hole — it’s about creating 正確な, 信頼性のある, and high-performance components that power everything from jet engines to medical tools. With the right methods, ツール, および専門知識, it opens the door to endless possibilities across industries.

If your project requires deep hole drilling services, partnering with a skilled manufacturer ensures you get the precision and performance you need.

よくある質問

Q1: What is the difference between deep hole drilling and normal drilling?

Deep hole drilling handles much higher depth-to-diameter ratios (10:1 それ以上), while standard drilling typically stays under 3:1.

第2四半期: What drill bits are best for deep holes in wood?

Specialized extra-long twist drills or gun drills designed for woodworking.

Q3: What is the standard depth-to-diameter ratio for deep hole drilling?

10:1 or greater, though in some cases, it can go well beyond 100:1 with advanced equipment.

続きを読む:

CNCフライス加工サービス (for comparison of hole-making methods)

Surface Finishing for Machined Parts

Machining Stainless Steel / Machining Titanium