キャスティングダイ は、高圧下で溶融金属をカビに注入して、正確で堅牢な成分を作成する効率的な製造プロセスです。. プラスチックの射出成形に似ていますが, ダイキャスティングは、熱と機械の応力が関与しているため、はるかに複雑です. この複雑さにより、ダイはさまざまな欠陥の影響を受けやすくなります, 適切に対処されていない場合、コンポーネントの最終品質を損なう.

このガイドでは, さまざまな種類のダイカストの欠陥を徹底的に探索します, それらの原因, 実用的なソリューション, エンジニアを支援する予防のヒント, メーカー, デザイナーは一貫して高品質のダイキャストパーツを達成します.

ダイキャスティング欠陥の分類

通常、ダイカストの欠陥は2つの広いカテゴリに分類されます:

内部欠陥 (外部的には見えませんが、構造的完全性に影響します)

表面的な欠陥 (外部から表示され、表面の品質に影響を与えます)

各カテゴリを詳細に検討しましょう.

内部ダイキャスティングの欠陥

内部欠陥は、ダイキャスト部品の構造的完全性を弱め、しばしば徹底的な検査なしに気付かれずになります.

ガス気孔率

閉じ込められたガスが鋳造内に泡を形成すると、ガス気孔率の欠陥が発生します, 冷却後の丸いボイドまたは楕円形のボイドとして表示されます.

原因:

ガス溶解度の低下による冷却中の水素放出.

乱流金属流からの閉じ込められたガス.

過剰または不適切に使用されている金型放出剤から放出されるガス.

ソリューション:

保護ガス雰囲気の下で真空補助溶融または融解を利用します.

溶ける前に金属のインゴットが清潔で乾燥していることを確認してください.

キャストパラメーターを最適化します (スピード, 温度, ゲートシステム).

高品質の金型放出剤を選択し、それらを控えめに適用します.

収縮気孔率

収縮気孔率は、不均一な固化から生じます, 金属が冷却するときに体積収縮により内部ボイドまたは空洞を形成する.

原因:

不十分な冷却システムの設計.

未熟型の開口部.

注ぐ温度が過度に高い.

ソリューション:

継続的な給餌を促進する効率的なゲーティングおよびライザーシステムを設計する.

悪寒を実装します, 冷却コイル, または熱散逸を管理するリブ.

鋳造温度と凝固プロセスを最適化します.

インクルージョン

インクルージョンは、キャスティング内に閉じ込められた不純物です, 多くの場合、異物や金属汚染から, その結果、弱点が生じます.

原因:

汚染された炉料金.

金属製剤中のスラグ除去が不十分です.

過剰なグラファイトを含む不適切なカビ放出剤.

ソリューション:

高度に精製された金属電荷を使用します.

徹底的にきれいに清潔にして、定期的に死にます.

溶融金属を適切に管理および浄化します, スラグを熱心に取り外します.

グラファイトベースの金型放出剤を避けたり、厳密に制御したりします.

表面的なダイキャスティング欠陥

これらの欠陥は、鋳造コンポーネントの美学と表面の品質に影響します.

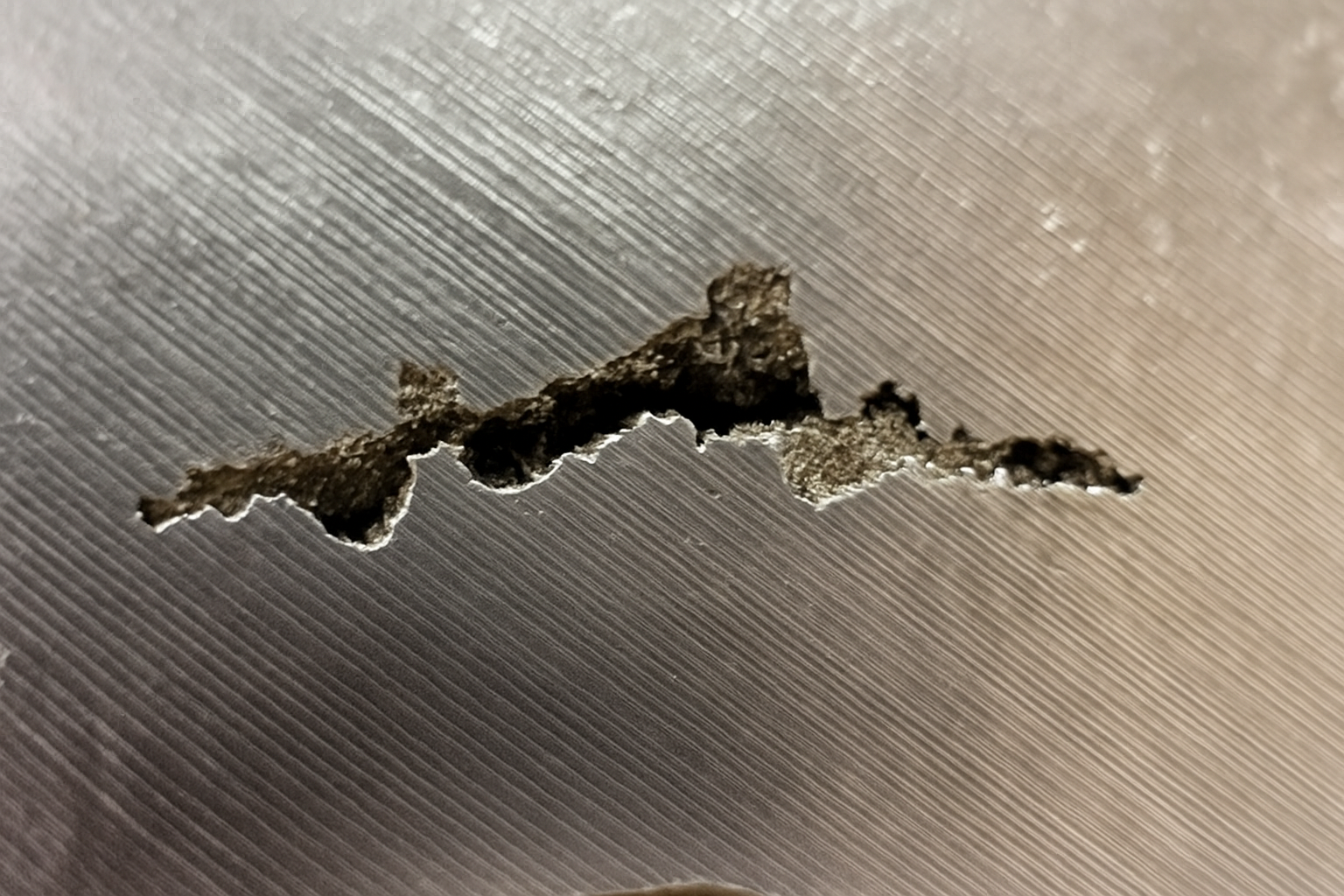

ひび割れ

亀裂は、冷却または排出中のストレスによって引き起こされる線形または不規則な破損として現れます.

原因:

不適切なコンポーネント設計からの残留応力.

誤った合金組成または金属特性.

排出力は不均一または早すぎる.

ソリューション:

意図した鋳造用に特異的に処方された合金を使用します.

バランスのとれた均一な壁の厚さのデザイン鋳物.

カビのジオメトリと排出技術を最適化して、ストレスを軽減します.

コールドシャット

コールドシャット欠陥は、溶融金属前面の不完全な融合に起因する線として表示されます.

原因:

低溶融金属温度または噴射速度が不十分.

設計が不十分なゲーティングシステム.

ソリューション:

カビと金属の温度を適切に上げます.

注入圧力を最適化します, ゲートデザイン, ランナー構成.

ネットワークの亀裂

ネットワークの亀裂は薄いことに似ています, 表面上のヘアラインパターン, 美的魅力と構造的完全性の両方を減らします.

原因:

ラフまたは不適切に処理されたダイサーフェス.

高充填温度は熱応力を生み出します.

不十分なダイキャビティ温度の均一性.

ソリューション:

定期的にダイキャビティを磨き、維持します.

制御された冷却システムを使用して、最適なカビの温度と熱バランスを維持する.

ドラッグとはんだ付け

ドラッグは線形表面の傷として表示されます, 一方、はんだ付けには、溶融金属がダイキャビティに過度に固執することが含まれます.

原因:

過熱溶融金属.

破損または不適切に準備されたキャビティ表面.

ドラフト角度が不十分または間違っています.

ソリューション:

ダイキャビティが十分に維持されていることを確認してください, 磨きました, 修理.

高品質の金型放出剤を適切に適用します.

摩擦を避けるために、排出方法を調整し、ゲーティングデザインを改善する.

フラッシュ

フラッシュは薄いです, 鋳造部品の端から突き出ている過剰な物質.

原因:

高い噴射速度または圧力.

汚れたまたは破損したダイアシングライン.

不十分なクランプ力.

ソリューション:

注入パラメーターと温度を最適化します.

ダイサーフェスを維持し、適切なクランプ力を確保します.

水ぶくれ

水疱は閉じ込められたガスからの表面泡のように現れ、高温下で局所的な膨張を引き起こします.

原因:

閉じ込められたエアポケットにつながる換気が悪い.

乱流充填条件.

ソリューション:

ゲーティングおよび通気システムを改善します.

速度や温度などの鋳造パラメーターを正確に制御します.

変形

変形には、不適切な取り扱いや設計上の欠陥による形状または寸法の変化が含まれます.

原因:

誤ったゲート除去慣行.

初期のカビの開口部.

貧弱な構造キャスティングデザイン.

ソリューション:

金型のオープニングタイミングとパーツ処理を最適化します.

排出中に均一な冷却とサポートを確保するために、鋳造ジオメトリを再設計する.

フローマーク

フローマークは、金属の流れ中に形成される不均一な表面パターンです, 多くの場合、美学と仕上げの品質に影響を与えます.

原因:

低ダイの温度と充填圧力.

過剰なカビ潤滑剤または放出剤.

ソリューション:

ダイ温度と噴射パラメーターを調整します.

カビのリリースエージェントの使用量を必要な量に制限します.

短い詰め物

金属が完全にダイを満たすことができないときに短い充填が発生します, 不完全な領域を離れる.

原因:

低流動性または不十分な注射圧力.

設計が不十分なゲーティングシステム.

ソリューション:

気温を上げます, 噴射速度, とプレッシャー.

ゲーティングシステムを再設計して、金属流パスを強化します.

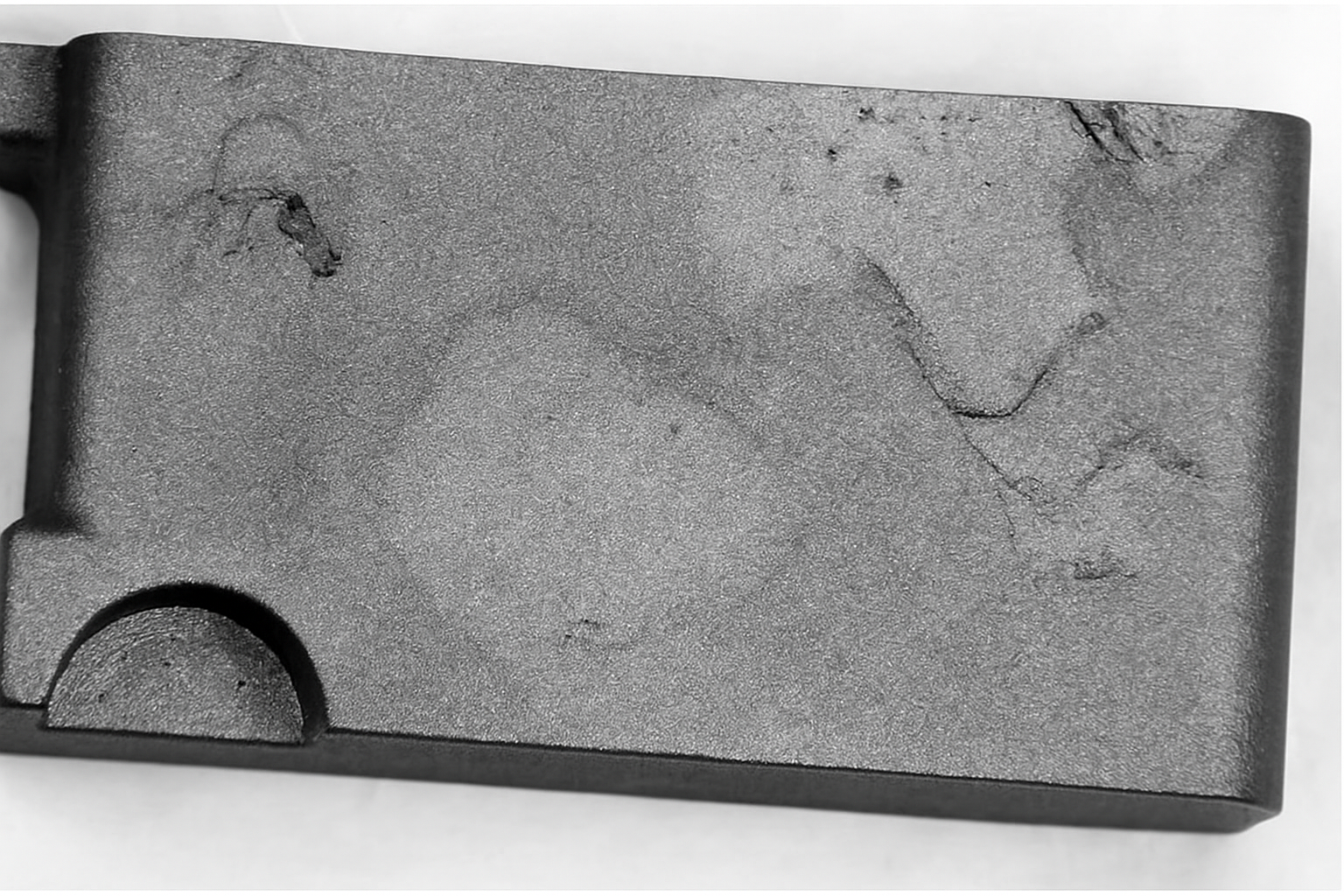

ラミネーション

積層は、金属層の分離に起因します, 通常、仕上げプロセス中に発見されます.

原因:

乱流充填条件.

誤ったゲーティングデザインにより、金属の流れが重複します.

ソリューション:

ゲートシステムを最適化して、滑らかな金属の流れを実現します.

充填条件を細かく監視および制御します.

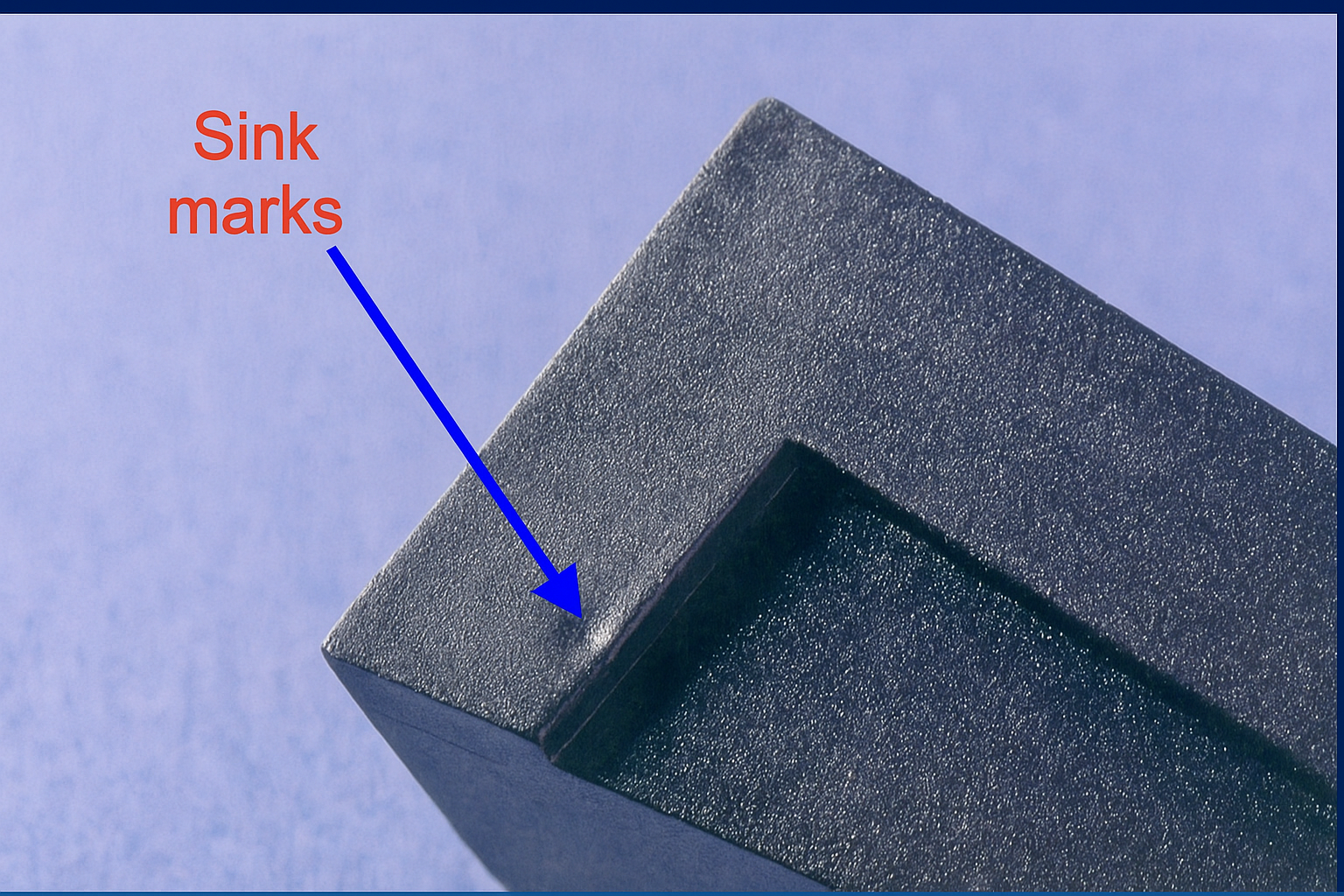

シンク

シンクマークは、不適切な凝固と冷却のために厚いセクションに現れるdect的です.

原因:

低噴射圧または短い圧力保持時間.

不均一な壁の厚さ.

ソリューション:

デザインで均一な壁の厚さを使用します.

保持圧力と固化時間を増やします.

ダイキャストの欠陥を避けるためのヒント

欠陥を包括的に減らす, これらの重要なベストプラクティスに従ってください:

効果的な欠陥評価システム: 欠陥を継続的に定量化および監視して、問題領域を早期に特定する.

正しい壁の厚さ: 厚さのガイドラインに従ってください (例えば, 1.5–2.5 mmアルミニウム, 1.0 mm亜鉛).

予測可能な充填時間: PQ²計算を使用して、充填時間と噴射パラメーターを最適化します.

最適な金属フローパターン: 滑らかなゲーティングシステムを設計します, 制御された金属フロー.

正しいダイ温度制御: 理想的な金属の流れと冷却のために、ダイ温度を維持します.

結論

ダイカストの欠陥を効果的に管理することは、高品質のコンポーネントを達成するために不可欠です. 綿密な計画を採用します, 適切な設計原則, 厳密な品質管理, そして、定期的なプロセスの改善により、欠陥が大幅に減少し、製品の信頼性が向上します. RapidDirectのような経験豊富なメーカーと提携することで、優れた結果と信頼できるコンポーネントが確保されます.

よくある質問:

- キャストの欠陥を減らすにはどうすればよいですか?

効果的な欠陥監視システムを使用します, 適切な鋳造温度を維持します, 金型設計を最適化します. - ダイのキャスティングは何ですか?

自動車部品に最適です, 電子ハウジング, 装飾的な備品, 高精度と強度を必要とするコンポーネント. - 鋳物の気孔をどのように除去しますか?

金型のデザインを強化します, 通気口を最適化します, 真空鋳造技術を使用します, 溶融アルミニウムに窒素を加えます.