Industrial coatings is very important by enhancing part performance, 耐久性, 美学, 環境要因に対する抵抗. Whether you’re producing precision CNC-machined parts, 構造コンポーネント, or consumer products, selecting the right coating can dramatically affect the functionality and lifespan of your product.

この包括的なガイドで, we’ll explore what industrial coatings are, the most common types used across industries, their properties and benefits, and how to choose the ideal coating for your application.

What Are Industrial Coatings?

工業用コーティングはそうです 設計された表面処理 提供する部品またはアセンブリに適用されます 機能的または保護的な利点, 多くの場合、製造プロセスの最終ステップとして. これらのコーティングはできます:

腐食と耐摩耗性を改善します

紫外線や化学物質から保護します

機械的強度と熱安定性を高めます

視覚的な魅力を改善します (色, 光沢, テクスチャ)

導電率または断熱性を改善します

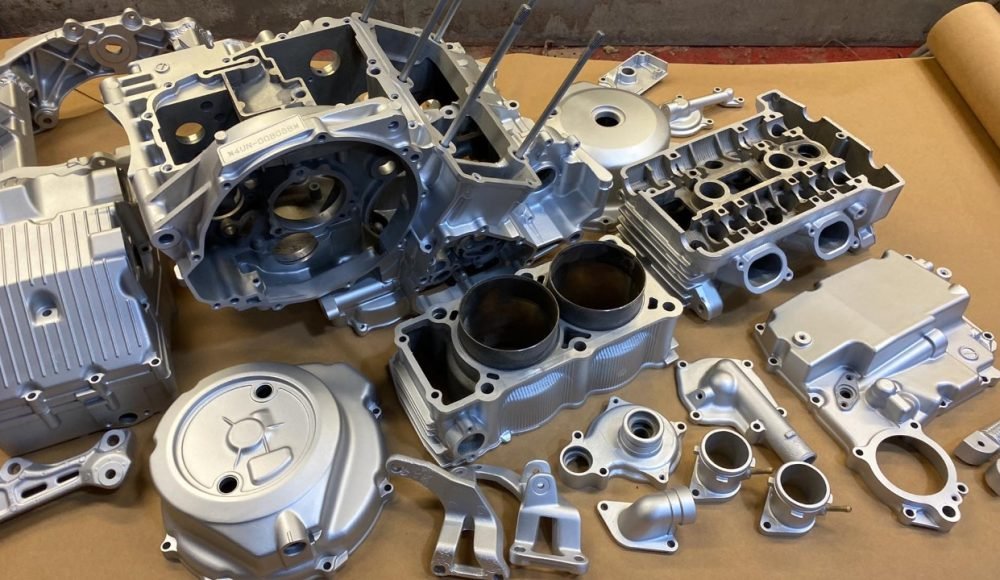

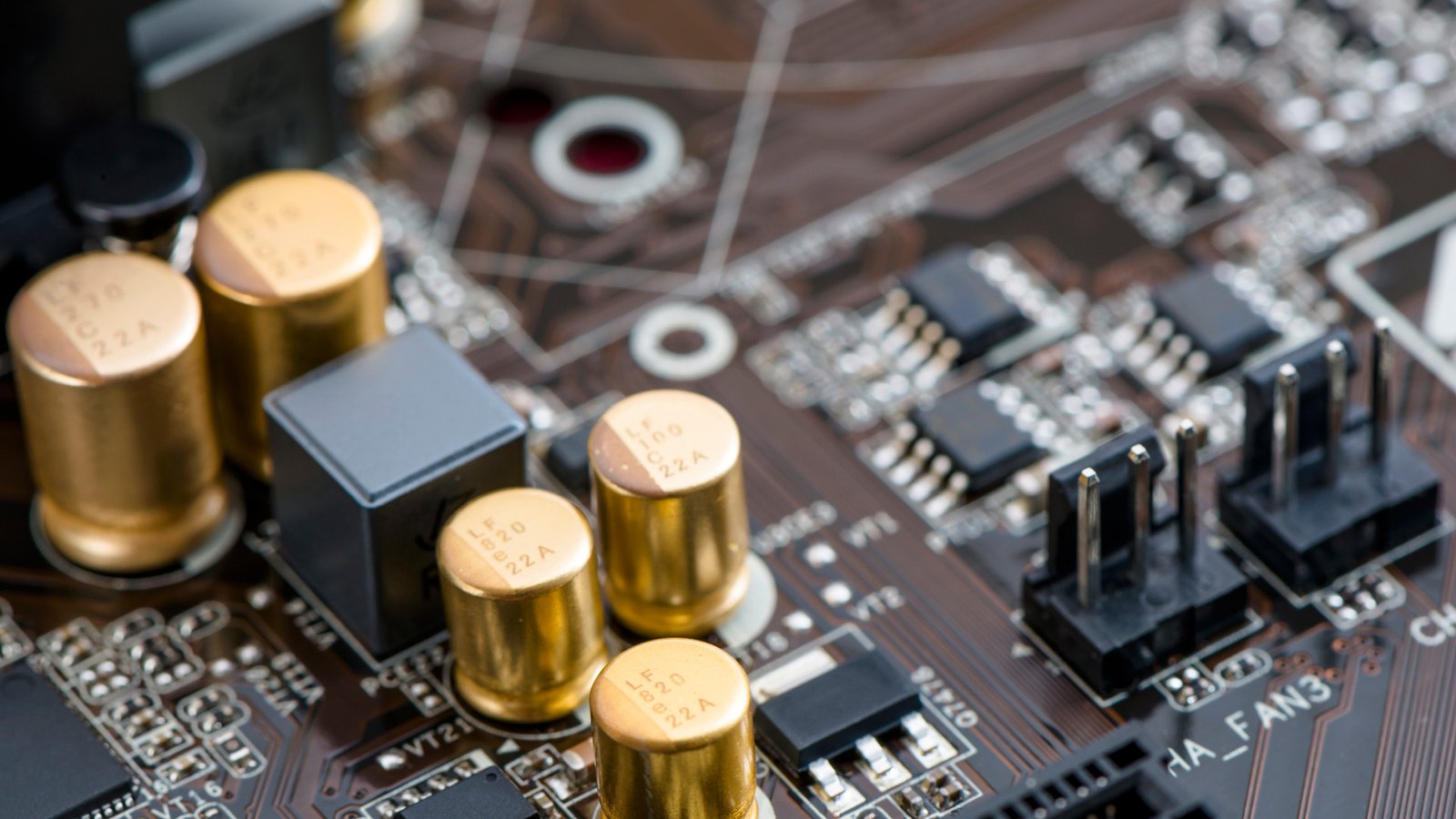

で使用されます 自動車, 航空宇宙, 海洋, エレクトロニクス, 工事, そして 産業機械, コーティングは特定のパフォーマンスを満たすのに役立ちます, 安全性, および規制要件.

Types of Industrial Coatings

Epoxy Coating – Strong and Long-Lasting

それは何ですか:

エポキシは、樹脂と硬化剤の2つの液体を混合することによって作られています. 彼らが反応すると, 彼らは厚いものを形成します, 表面にしっかりとくっつく丈夫な層.

なぜそれが素晴らしいのか:

非常に耐久性があります

水分に耐えます, 化学薬品, そして傷

多くの資料でうまく機能します

それをどこで使用するか:

パイプライン, ガレージの床, 機械部品, エレクトロニクス

適用する簡単な手順:

表面をきれいにします (オイルはありません, ほこり, または錆び)

樹脂と硬化剤を混ぜます (正確な比率に従ってください)

ブラシを使用して適用します, ローラー, またはスプレー

それを治しましょう (これには数時間かかる場合があります)

気をつけてください:

紫外線が好きではありません (黄色に変わることができます)

強い煙 - 換気の良いエリアで使用します

Polyurethane Coating – Flexible and UV-Resistant

それは何ですか:

ポリウレタンは、硬化後に柔軟なままであるコーティングです. 素材で伸びることができます, だから、それは簡単にひび割れません.

なぜそれが素晴らしいのか:

太陽と屋外の天気を処理します

壊れずに伸びます

化学的および耐摩耗性

それをどこで使用するか:

自動車部品, 飛行機インテリア, コンクリートの床, 海洋部品

適用する簡単な手順:

部品をきれいにして乾燥させます

必要に応じてプライマーを適用します

ポリウレタン成分を混ぜます

ブラシ, ロール, またはスプレーします

適切に治療してください

気をつけてください:

時間の経過とともに黄色にできます

大きな影響を与える部品には理想的ではありません

Polysiloxane Coating – Tough for the Outdoors

それは何ですか:

ポリシロキサンは、困難な屋外環境でうまく機能する高性能コーティングです. 熱を処理します, 紫外線, ほとんどの化学物質.

なぜそれが素晴らしいのか:

日光と雨に耐性があります

フェージングせずに長く続きます

化学物質と熱に立ち向かいます

それをどこで使用するか:

橋, 風力タービン, 化学タンク, オフショア機器

適用する簡単な手順:

表面を徹底的にきれいにします

ベースと硬化剤を混ぜます

スプレーまたはブラシをかけます

それを治しましょう (いくつかのタイプは速く乾燥しています, 他の人はもっと時間がかかります)

気をつけてください:

より高価です

過度に露出していると脆くなる可能性があります

Zinc-Rich Coating – Rust Blocker

それは何ですか:

亜鉛が豊富なコーティングは鎧のように機能します. 亜鉛が最初に腐食します, 下の金属を保護する - これは「犠牲保護」と呼ばれます。

なぜそれが素晴らしいのか:

優れた錆の保護

費用対効果が高い

適用しやすい

それをどこで使用するか:

スチールビーム, パイプライン, 塔, 車のフレーム

適用する簡単な手順:

金属をきれいにします (サンドブラストが最適です)

スプレーまたはディップ方法を使用して亜鉛コーティングを塗布します

完全に乾燥させます

必要に応じてトップコートを追加します

気をつけてください:

高熱エリアには適していません

時間の経過とともに鈍く見えることがあります

Ceramic Coating – Heat and Scratch Proof

それは何ですか:

セラミックコーティングは、熱に抵抗する超頻繁な層です, 着る, 化学物質と. 部品が極端な状態に耐える必要がある場合に使用されます.

なぜそれが素晴らしいのか:

非常に高い温度に耐えます

傷や錆に抵抗します

化学耐性

それをどこで使用するか:

エンジン部品, タービン, エレクトロニクス, 医療ツール

適用する簡単な手順:

部品を注意深く掃除します

サーマルスプレーを使用します, 浸漬, またはブラシメソッド

コーティングを冷やしたり治療したりします (プロセスに応じて)

気をつけてください:

脆くなる可能性があります

適用するには、特別なツールが必要です

他の人よりも高価です

Metallic Coating – Strong and Shiny

それは何ですか:

このコーティングは、ニッケルのような金属を使用します, クロム, または、光沢を加えるアルミニウム, 保護面. それはあなたの部品をより丈夫で魅力的にすることができます.

なぜそれが素晴らしいのか:

耐食性

よさそうだ (装飾仕上げ)

電子機器の導電率を向上させます

それをどこで使用するか:

電子部品, 医療用インプラント, 装飾ハードウェア

適用する簡単な手順:

表面をきれいにします

メソッドを選択します (電気スプレーまたは熱スプレー)

金属層を適用します

必要に応じてバフまたはポリッシュ

気をつけてください:

頻繁に維持する必要があります

すべての材料に固執しません

コーティングを選択する際に何を考慮するか?

どんな素材をコーティングしていますか?

コーティングは特定の材料により適しています.

エポキシ 金属でうまく機能します, プラスチック, とコンクリート.

亜鉛 主に鋼と鉄用です.

一部のコーティングはゴムやシリコンでうまく機能しません.

✅ヒント: あなたの部品の素材がコーティングに適しているかどうか常に確認してください.

部品はどこで使用されますか?

環境について考えてください:

太陽や雨の中で外にあるでしょうか?

海水または化学物質の近く?

極端な暑さや寒さに直面しています?

whired屋外に行く場合, ポリシロキサン または ポリウレタン より良いピックです エポキシ.

コーティングをどのように適用しますか?

一部のコーティングは、ブラシまたはローラーで簡単に塗ることができます, その他は、派手なスプレーツールや特別なギアが必要です.

自分自身に問いかけてください:

素早くシンプルなものが必要ですか??

ツールがありますか、それともプロが必要ですか?

time時間またはツールが制限されている場合, 行ってください 亜鉛 または ポリウレタン.

部分は何を処理する必要がありますか?

さび? 行ってください 亜鉛 または エポキシ

熱? 試す セラミック

柔軟性? ポリウレタン

UV抵抗? ポリシロキサン

cortあなたの部分に対処する必要があるものを簡単にチェックリストします - それをコーティングタイプに一致させます.

あなたの予算は何ですか?

一部のコーティングは他のコーティングよりも高くなります, 適用に時間がかかる人もいます.

💰 亜鉛 予算に優しいです. セラミック そして ポリシロキサン より高価ですが、長持ちします.

従うべき業界のルール?

飛行機用の部品を作っていますか, 医療ツール, または食品機器? はいの場合, 特定の安全または品質のルールに従うコーティングが必要です.

cortiveのような認定付きのコーティングを探します Rohs, SGS, または FDA 承認された.

クイック比較テーブル - どのコーティングを選択する必要がありますか?

| コーティングの種類 | に最適です | 主な利点 | 欠点 | 理想的な… |

| エポキシ | 屋内使用, 化学保護 | 強い, 厳しい, 耐薬品性 | UV感受性, 準備が必要です | 床, タンク, エレクトロニクス, パイプライン |

| ポリウレタン | 屋外使用, 柔軟性 | UV耐性, フレキシブル, 耐衝撃性 | 5月黄色, エポキシよりも難しい | 自動車部品, 船デッキ, インテリア, 床コーティング |

| ポリシロキサン | 厳しい屋外の状態 | 紫外線, 長く続きます, 化学的および耐熱性 | 高い, 脆くなる可能性があります | 橋, タービン, オフショア構造 |

| 亜鉛が豊富 | 腐食保護 | 防錆, 低コスト, 適用しやすい | 高熱用ではありません, フェードできます | スチールビーム, 塔, 構造部品 |

| セラミック | 高熱 & 摩耗 | 熱防止, スクラッチ耐性, 化学保護 | 費用がかかります, 脆い, 厚い層 | エンジン, 排気, 医療ツール, タービン |

| メタリック | ルックス + パフォーマンス | 光沢, 導電性, 耐食性を改善します | 維持が必要です, すべての表面用ではありません | インプラント, エレクトロニクス, 装飾部品 |

結論

適切な産業コーティングを選択することは、表面の外観だけではありません。 信頼性, 安全性, そして長寿 あなたの製品の. オフショアパイプラインを保護することから、CNCマシンパーツの強化, コーティングは、美的機能と重要な機能の両方の役割を果たします.

材料の互換性を理解することにより, 環境, 申請プロセス, および規制基準, 製造業者は、パフォーマンスを後押しし、長期コストを節約する情報に基づいた決定を下すことができます.

よくある質問

Q1: 工業部品にはコーティングが必要です?

はい, コーティングは部品の寿命を高めます, 摩耗を減らします, 耐食性を改善します, 価値を追加します.

第2四半期: 塗装とコーティングの違いは何ですか?

絵画は、美学のためのコーティングの一種です. 産業用コーティングは、保護と性能のために策定されています.

Q3: どのコーティングが亜鉛メッキ鋼に最適です?

亜鉛めっきによる亜鉛コーティングは、腐食保護のために亜鉛メッキ鋼の標準です.

1 「」について考えました産業用コーティングタイプ: プロパティ, プロセス, および実際のアプリケーション”