真鍮 主に銅と亜鉛で構成される汎用性のある金属合金です. これらのコア要素の調整は、赤い真鍮や黄色の真鍮などのバリエーションを生成します, それぞれが異なるプロパティを備えています, 用途, そして利点. このガイドは、特定の用途に最適な金属合金を選択するのに役立つ赤い真鍮と黄色の真鍮の詳細な比較を提供します.

赤い真鍮とは何ですか. イエローブラス?

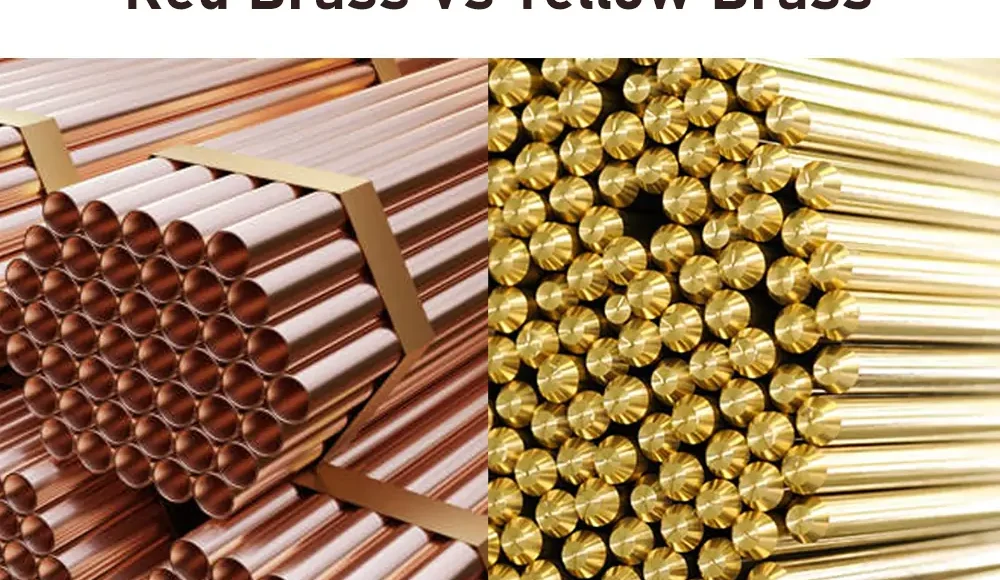

赤い真鍮と黄色の真鍮は同じ基本要素から派生していますが、銅 および亜鉛 - これらの要素の比率はそれらの特性に大きく影響します, 多様なアプリケーションに適したものにします.

赤い真鍮を理解する

赤い真鍮, 一般的にガンメタルと呼ばれます, より高い銅含有量によって区別されます (85-90%), 亜鉛によって補完されます, 錫, そして、鉛のトレース, 鉄, マンガン, そしてヒ素. この豊富な銅濃度は赤い真鍮その特徴的な赤みを帯びた色と優れた強さを貸します.

しかし, 海水との亜鉛の反応のため, 海洋環境にはそれほど適していません.

黄色の真鍮を理解する

黄色の真鍮には銅が少なくなります (60-80%) そしてより多くの亜鉛 (30-40%), 明るい, 黄金の外観. その高い亜鉛含有量は、延性の向上を提供します, 展性, および加工性, 複雑なデザインやCNC加工に最適な黄色の真鍮を作る.

化学組成: 赤い真鍮vs. イエローブラス

| 要素 | レッドブラス (%) | イエローブラス (%) |

| 銅 | 85–90 | 60–80 |

| 亜鉛 | 5–10 | 30–40 |

| 錫 | 2 分 | 1 最大 |

| 鉛 | 1 最大 | 1 最大 |

| 鉄 | 0.1 | 0.1 |

| マンガン | 0.5 | 0.5 |

| 砒素 | 0.01 最大 | 0.01 最大 |

強度の比較: 赤い真鍮vs. イエローブラス

銅含有量が多いほど、強度が高い赤の真鍮が提供されます (580 MPA引張強度) 黄色の真鍮と比較して (315 MPa). これにより、赤い真鍮は構造的および高圧アプリケーションにより適しています.

物理的および機械的特性の比較

物理的特性

| 財産 | レッドブラス | イエローブラス |

| 色 | 赤みがかった | 明るい黄色 |

| 密度 | 8.5–8.7 g/cm³ | 8.3–8.5 g/cm³ |

| 融点 | 900–940°C (1652–1724°F) | 880–920°C (1622–1690°F) |

| 電気伝導性 | 21–24 ms/m | 25–28 ms/m |

| 熱伝導率 | 118–122 w/m・k | 109–113 w/m・k |

機械的性質

| 財産 | レッドブラス | イエローブラス |

| 抗張力 | 580 MPa | 315 MPa |

| 降伏強さ | 400 MPa | 200 MPa |

| 伸長 | 30% | 40% |

| 硬度 (HB) | 80–90 | 70–80 |

| 被削性 | 素晴らしい | 素晴らしい |

コスト比較: 赤い真鍮vs. イエローブラス

赤い真鍮は銅の含有量が高いため、より高価になる傾向があります, 特に、銅価格の最近の急増を考えると. 黄色の真鍮はより経済的で広く利用可能です, 費用に敏感なプロジェクトに適しています.

スクラップ価格の比較

スクラップレッドブラスの市場価値は高くなっています ($2.10 - 1ポンドあたり2.40ドル) 黄色の真鍮と比較して ($1.50 - 1ポンドあたり1.80ドル), 銅が豊富な合金の固有の価値を反映しています.

重量比較: 赤い真鍮vs. イエローブラス

密度がわずかに高い, 赤い真鍮 (8.5–8.7 g/cm³) 黄色の真鍮よりも重いです (8.3–8.5 g/cm³), 頑丈な材料を必要とする特定のアプリケーションへの適合性に影響を与える可能性があります.

耐食性

赤い真鍮, より多くの銅で, 優れた腐食抵抗を示します. このプロパティは、過酷な条件にさらされた環境に赤い真鍮を好むようにします, 黄色の真鍮は、要求の少ないシナリオの下でも合理的な腐食抵抗を提供しますが.

耐久性の比較

赤い真鍮は、特に耐久性があります, ストレスの下でその完全性を維持することができます, プレッシャー, 長期にわたる環境曝露. 黄色の真鍮, 堅牢性が低いですが, 軽量なアプリケーションでは、まだうまく保持されています.

赤い真鍮と黄色の真鍮の類似点

その違いにもかかわらず, 両方の合金は貴重な特性を共有しています:

優れた被削性

高い電気導電率および熱伝導率

変色に対する抵抗

楽器の一般的なアプリケーション, 装飾品, および電気コンポーネント

強度評価: それは強いです?

全体, 赤い真鍮は強いです, 高ストレス用途に適しています, 一方、黄色の真鍮は柔軟性と簡単な機械加工性を提供します, 詳細な作業と装飾コンポーネントに適しています.

赤い真鍮vs. イエローブラス: 比較チャート

| 財産 | レッドブラス | イエローブラス |

| 外観 | 赤みがかったゴールド | 明るい黄色 |

| 銅の含有量 (%) | 85–90% | 60–80% |

| 亜鉛含有量 (%) | 5–10% | 30–40% |

| 抗張力 | より高い (580 MPa) | 適度 (315 MPa) |

| 降伏強さ | より高い (400 MPa) | 適度 (200 MPa) |

| 硬度 | より高い (80–90 HB) | 適度 (70–80 HB) |

| 被削性 | 良い | 素晴らしい |

| 密度 | わずかに高い (8.5–8.7 g/cm³) | わずかに低い (8.3–8.5 g/cm³) |

| 融点 | より高い (900–940°C) | より低い (880–920°C) |

| 耐食性 | 素晴らしい | 良い |

| 耐久性 | 高い | 適度 |

| 料金 | より高価です (より高い銅含有量) | より手頃な価格 (低い銅含有量) |

| 代表的なアプリケーション | 頑丈な部品, 電気部品, ジュエリー, より豊かなトーンを必要とする楽器 | 装飾品, 配管, 軽量の自動車コンポーネント, 安定したトーンが必要な楽器 |

赤い真鍮vs. イエローブラス: 全体的に優れています?

赤い真鍮の利点:

より高い強度と耐久性

優れた腐食抵抗

より良い電気伝導率

黄色の真鍮の利点:

費用対効果が高い

より簡単な機密性

広く利用可能です

最適なオプションを選択することは、特定のアプリケーション要件によって異なります, 予算, および環境条件.

アプリケーション固有の比較

ジュエリー: 赤い真鍮は耐久性があり、明確な赤みがかった魅力があります, 高品質のピースに最適です; 黄色の真鍮は費用対効果が高いです, 形作りが簡単です.

楽器:

サックス: 赤い真鍮はより深いものを提供します, より豊かなトーン; 黄色の真鍮は安定した音質を提供します.

トロンボーンとトランペット: 赤い真鍮は暗くなります, より豊かな音; 黄色の真鍮は安定して生成されます, 明るい色調.

航空機コンポーネント: 赤い真鍮は、より高い強度と耐久性を提供します, 一方、黄色の真鍮の加工性は複雑に適しています, 軽量コンポーネント.

船舶用部品: 一般に、亜鉛含有量のために不適切です; 推奨される代替資料.

電気コンポーネント: より良い導電性のために、赤い真鍮が好まれます; 黄色の真鍮は実用的で手頃な価格のままです.

自動車部品: レッドブラスの筋力は構造部品に適しています; 黄色の真鍮は、装飾的または非クリティカルなコンポーネントに費用対効果が高いです.

適切なメーカーの選択

経験豊富で信頼できるメーカーを選択すると、最高品質の真鍮パーツが保証されます. KDM製造 高精度の真鍮コンポーネントの大手プロバイダーです, 産業のニーズに合わせて正確に調整された製品を確保します.

結論

赤い真鍮と黄色の真鍮の両方に、特定のニーズに合った明確な利点があります. 赤い真鍮は強さに優れています, 耐食性, そして耐久性, 手頃な価格には黄色の真鍮が好まれます, 可用性, および加工性. プロジェクトの要件を慎重に評価することは、適切な真鍮合金を選択するための鍵です.

追加のリソース