すべてのエンジニアリングプロジェクトで適切な材料を選択することは重要です. さまざまな材料特性の中で, 強度と重量の比率は最も重要な比率の1つです. 製品のパフォーマンスに直接影響します, 体重減少, 全体的な設計効率.

記事上で, 強度と重量の比率を説明します, それに影響する要因, さまざまな業界での実用的なアプリケーション.

強度と重量の比とは何ですか?

強度と重量の比率は、複雑な用語のように聞こえます, しかし、あなたがそれを分解すると、それは実際にはかなり簡単です.

何かがどれほど強いかということです に比べ それがどれほど重いか.

言い換えれば、あなたはポンドごとにどれくらいの強さを得ますか (またはキログラム) 体重の?

この比率は、エンジニアが重すぎることなく多くの力を処理できる材料を把握するのに役立ちます. 飛行機などの製品にとって非常に重要です, 車, ロボット, またはスポーツ用品 - あなたが物事を強くて軽いものにしたいものは何でも.

このように考えてください:

鋼片は本当に強いですが、それも本当に重いです.

プラスチック片は超軽量ですが、それほど強くありません.

特定の仕事に最適な材料は 両方 強度と低重量.

それが、強度と重量の比率が登場する場所です. それはあなたに両方の最高のミックスを与える材料をあなたに伝えます.

なぜ工学において強度と重量の比率が非常に重要なのか?

エンジニアが製品を設計するとき - それが車であるかどうか, 飛行機, 橋, または自転車でさえ - 彼らは常に強度と体重の最良のバランスを見つけようとしています.

何かが強いが重すぎる場合, 物事を遅くすることができます, 廃棄物エネルギー, または、構築と輸送にコストがかかります. 一方で, それが超軽量であるが、十分に強くない場合, それは簡単に壊れたり、安全ではない可能性があります.

そのため、強度と重量の比率が非常に重要です. エンジニアがどちらも厳しい材料を選択するのに役立ちます そして 光 - 彼らに両方の世界の最高を与えます.

これが本当に重要な理由です:

重量を節約します, エネルギーを節約します

航空宇宙や自動車などの業界で, 軽い材料は、燃料効率の向上を意味します. 軽い車や飛行機は、より少ないエネルギーを使用して移動します。これは、パフォーマンスと環境の両方に適しています.

安全を保つのに十分な強さ

体重を減らすときでさえ, 安全が最初に来ます. 強度と重量の比率が高い素材は、余分なバルクを追加せずに強くて安定している製品の構築に役立ちます.

材料のコストを節約します

より強く使用します, 軽い材料とは、頻繁に使用できることを意味します 少ない 全体的に材料 - 生産と配送のコストを削減するのに役立ちます.

より良いパフォーマンス

スポーツカーかどうか, ドローン, またはレーシングバイク - 強度を維持しながら体重を減らすことがより良い速さを与えます, コントロール, そして耐久性.

よりデザインの柔軟性

より軽い材料により、エンジニアはデザインで創造的になることができます - 小さい製品を作る, もっと早く, または品質を犠牲にすることなく、より革新的です.

何が強度と重量の比率に影響を与えるか? (素材だけではありません!)

最も軽いまたは最も強い素材を選ぶほど単純ではありません。 (または悪い) 素材の強度と重量の比率は本当にです.

ここに最大の要因がいくつかあります:

T彼は素材のタイプです

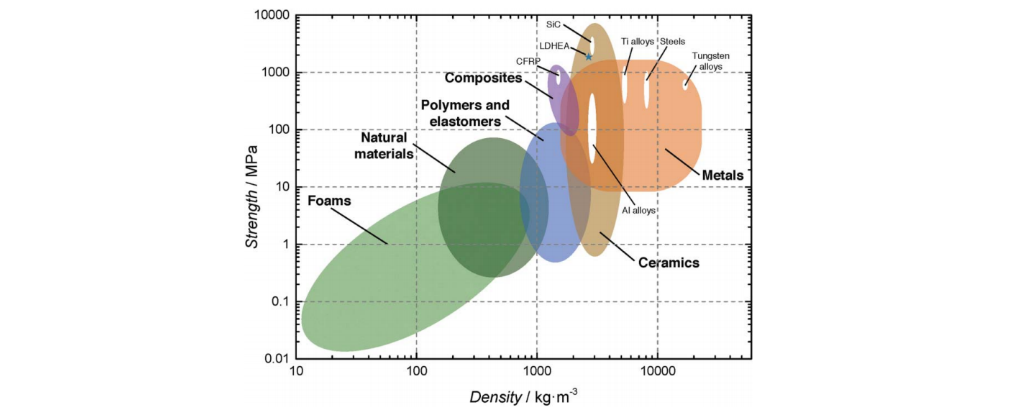

異なる材料は、自然に強度と重量の比率が異なります.

鋼のような金属, アルミニウム, またはチタンは強いです, しかし、それらはすべて異なる重みを持っています.

炭素繊維は非常に軽く、本当に強いです - それが飛行機で人気がある理由です, バイク, そしてレースカー.

プラスチックはとても軽いです, しかし、通常はそれほど強くありません (他の材料と混合しない限り).

| 材料 | 強度重量比 | 特徴 |

| チタン | 非常に高い | 軽量, 耐食性 |

| アルミニウム合金 | 高い | 軽量, 汎用性の高い強度 |

| カーボンファイバー | 非常に高い | 優れた引張強度, 低重量 |

| 鋼鉄 | 適度 | 強いが重い |

| プラスチック | 低から中程度 | 軽量, 耐久性が低い |

| 木材 | 適度 | 軽量, 湿気に敏感です |

形状またはデザイン

信じられないかもしれません, 部品や製品の形状も大きな違いを生むことができます.

中空の部分や特別なパターンのようなスマートなデザインは、何かを強くすることができることがあります それなし 重量を追加します.

例: 多くの三角形の形をした橋を考えてみてください - それは、より少ない材料を使用しながら構造を強くするので、意図的に行われます.

物質的な治療または処理

材料は、強度と重量の比率を高めるために特別な方法で扱うこともできます.

熱処理金属はそれを強くすることができます.

コーティングまたは混合材料を追加します (樹脂を含む炭素繊維のように) 多くの重量を加えることなく耐久性を向上させることができます.

環境

材料の使用方法も重要です.

一部の材料は強いですが、非常に暑くはうまくいきません, 寒い, または濡れた状態. エンジニアは考えなければなりません:

錆びますか??

凍えるような天気で割れますか?

日光はそれを弱めるでしょう?

高強度比材料の一般的な応用

強度と重量の比率の高い材料は、多くの業界で広く使用されています.

航空宇宙産業

航空機, 宇宙船, 衛星には、燃料効率と構造的完全性のために最小重量で最大の強度を提供する材料が必要です.

関連する読書: 航空宇宙CNC加工で使用されるトップ材料

自動車産業

軽量材料は車両のパフォーマンスを向上させます, 燃料効率, 安全性を損なうことなく排出規制を満たします.

市民 & 構造工学

橋, 塔, 建物は、構造質量を減らしながら荷重を処理するために強度と重量の優れた比率の材料を使用します.

スポーツ用品

カーボンファイバーとチタンは自転車で人気があります, ヘルメット, 軽量で耐久性のある特性のためのスポーツ用品.

ロボット工学 & エレクトロニクス

軽い材料は、より良い動きを可能にします, エネルギー消費の削減, ロボットとドローンのバッテリー寿命の向上.

なぜCNC加工の専門家と提携しているのか?

適切な材料を選択することは、ソリューションの一部にすぎません. 経験豊富なCNC加工メーカーと提携することで、選択された材料がプロジェクトの要件を満たしながら、費用対効果が高く、製造しやすいことを保証します.

推奨パートナー:

最高の精度, 私たちは、さまざまな業界向けのCNC加工サービスを専門としています. 当社の専門家は、プロジェクトの強度と重量の比率の要件に基づいて、最適な素材を選択するのに役立ちます.

私たちのサービスを探索してください: TOPS精度によるCNC加工サービス

結論

最新のエンジニアリングプロジェクトには、強度と重量の比率を理解することが不可欠です. 軽量の革新的なデザインを可能にします, 耐久性のある, エネルギー効率. 適切な材料と製造パートナーを選択することにより, エンジニアは、パフォーマンスの要求と予算の要件の両方を満たす製品を作成できます.

よくある質問 (よくある質問)

1. エンジニアリング材料の優れた強度と重量の比率は何ですか?

優れた強度と重量の比率は、アプリケーションに依存します. 炭素繊維のような材料, チタン, アルミニウム合金は、航空宇宙などの産業に優れた強さと重量の性能を提供します, 自動車, とスポーツ用品.

2. なぜ製品設計において強度と重量の比率が重要なのか?

エンジニアが強力で軽量の製品を作成するのに役立つため、強度と重量の比率は重要です. これにより、エネルギー効率が向上します, 安全性が向上しました, 材料コストの削減, そして、設計の柔軟性が向上します.

3. どの材料が最高の強度と重量の比率が高いか?

強度と重量の比率が最も高い材料には、炭素繊維が含まれます, チタン合金, および高度な複合材料. これらの材料は一般に航空宇宙で使用されています, 自動車レース, 高性能スポーツ用品.

4. エンジニアは製品の強度と重量の比率をどのように改善しますか?

エンジニアは、高度な材料を選択することにより、強度と重量の比率を改善できます, 製品設計の最適化 (中空の構造やサポートパターンを使用するようなものです), 熱処理や複合層の階層化などの材料処理を適用する.

5. 産業は、高強度の比率材料から最も利益を得ています?

航空宇宙などの産業, 自動車, 土木工学, ロボット工学, スポーツ用品製造は、軽量で耐久性のあるコンポーネントが必要なため、強度と重量の比率が高い材料から大きな恩恵を受けます.

SEOの推奨外部リンク (権威ある情報源)

https://www.sciencedirect.com/topics/engineering/strength-to-weight-ratio

https://www.materialstoday.com/composite-applications/features/importance-strengthed-weight-ratio/

https://www.engineering.com/story/why-strength-to-weight-ratio-is-crucial-in-modern-engineering

https://www.azom.com/article.aspx?artured = 21548 (アゾム - 材料科学)

2 』への思いエンジニアリングにおける強度と重量の比率: 意味, 要因 & アプリケーション”