水射出成形 (WIM), also known as water-assisted injection molding (WAIM), is an advanced variation of traditional injection molding that uses pressurized water to form hollow structures inside molded parts. This process is often compared with gas-assisted injection molding, but it offers unique advantages in terms of cooling efficiency, 寸法安定性, および表面の品質. By injecting water into the molten plastic core, manufacturers can achieve lightweight yet durable products while reducing waste and cycle times. 下に, we explore the eight major benefits of water injection molding in detail.

水射出成形の主な利点

1. Hollow Structures

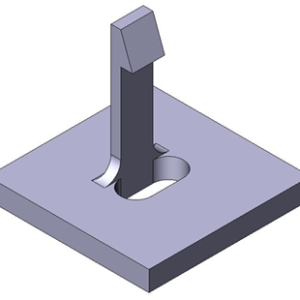

One of the biggest advantages of water injection molding is its ability to create hollow or partially hollow parts. During the process, water is injected into the molten plastic, forcing the material to flow outward toward the cavity walls while leaving a hollow channel inside.

アプリケーション: Common uses include automotive components, household handles, パイプ, ダクト, and tubular parts.

Strength-to-weight ratio: These hollow products remain structurally strong but significantly lighter than their solid counterparts.

効率: Water creates more predictable cavity filling compared to gas, reducing defective parts and minimizing scrap.

2. Shorter Cycle Times

Water has excellent thermal conductivity, making it much more effective at absorbing and dissipating heat compared to gas.

Cooling speed: Faster cooling directly shortens the cycle time, which is the most time-consuming stage in injection molding.

Higher output: Shorter cycles mean more parts can be produced per hour, which is critical for industries with high-volume demand.

Cost impact: Even a small reduction in cycle time per part adds up to substantial cost savings in large-scale production runs.

3. 均一

Consistency in wall thickness and geometry is crucial for product performance. Water injection molding enhances part uniformity in ways that gas-assisted molding cannot.

Thinner walls: WIM enables the production of thinner, evenly distributed cavity walls.

Reduced defects: With uniform filling, issues like shrinkage, 反り, and weak structural points are minimized.

Quality appearance: Improved dimensional uniformity also enhances the visual appeal of finished parts, which is essential in consumer-facing products.

4. Smoother Internal Surfaces

One common issue with gas-assisted molding is the turbulence caused by gas movement, which leaves rough internal textures, ヒケ, またはウェルドライン. Water injection molding eliminates these issues.

Smooth walls: Water creates a stable flow, resulting in flawless internal surfaces without blemishes.

Functional benefits: For hollow components like pipes, smoother surfaces improve fluid flow efficiency by reducing friction losses.

Visual quality: A polished internal finish also improves product aesthetics, making the parts more attractive for consumer applications.

5. Low Cost

Although water-assisted injection molding systems require an initial investment in specialized machines and tooling, the long-term cost benefits are significant.

Faster cycles = lower cost per part: Reduced cooling time and higher production rates lower overall costs.

Less material waste: Optimized use of resin decreases material costs per unit.

Tooling options: ある場合には, aluminum molds can replace steel molds depending on the part design, further lowering expenses.

Best fit: Particularly cost-effective for medium-to-high production runs (例えば, 20,000 units or more).

6. Material Savings

Another important benefit of water injection molding is reduced raw material consumption.

Hollow channels: By forming hollow spaces, less resin is needed to fill the part.

Thinner walls: WIM allows for thinner part designs that maintain strength without excess material use.

Environmental impact: Lower resin usage translates to less plastic waste, helping manufacturers meet sustainability goals.

Cumulative savings: Over long production runs, even small reductions in resin usage lead to significant cost savings.

7. 高次元精度

Maintaining precise dimensions during cooling is often a challenge in conventional injection molding. Water-assisted molding addresses this issue effectively.

Reduced warping and sink marks: Water cooling keeps parts from deforming as they solidify.

Tighter tolerances: Parts retain their intended shape and measurements more accurately.

Less rework: With fewer defects, post-processing and finishing steps are minimized, reducing labor and energy consumption.

Production reliability: Consistency in part dimensions is vital for assembly operations where multiple components must fit together.

8. 設計の柔軟性

WIM enables the production of parts that are difficult or impossible to achieve with standard injection molding.

複雑な形状: Intricate hollow structures, asymmetrical designs, and long flow paths can be achieved.

Advanced applications: Automotive engineers, appliance designers, and industrial manufacturers benefit from the ability to create lightweight but structurally complex components.

Thin walls and irregular sections: Engineers have more creative freedom in design, expanding product innovation possibilities.

Summary of the Benefits of Water Injection Molding

Water injection molding combines efficiency, 費用対効果, and superior product quality in a way that sets it apart from traditional and gas-assisted molding. The main advantages include:

Ability to form strong, lightweight hollow structures

Faster cycle times and higher production efficiency

Improved uniformity and dimensional accuracy

Smooth internal surfaces with fewer defects

Lower costs and material savings

Expanded design flexibility for complex geometries

While there are some limitations—such as material restrictions and the risk of mold corrosion—the benefits far outweigh the drawbacks for medium-to-high volume production. For manufacturers seeking to optimize production while improving part quality, water injection molding represents a highly valuable technology. お問い合わせ 詳細については.

よくある質問

- What is the main difference between water injection molding and gas-assisted injection molding?

The primary difference lies in the cooling and cavity formation. Water injection molding uses pressurized water to form hollow channels, which provides faster cooling and smoother internal surfaces compared to gas-assisted molding. Gas-assisted molding can sometimes leave rough textures or weld lines, while water produces cleaner and more uniform results. - What types of products are best suited for water injection molding?

Water injection molding is ideal for hollow or tubular parts such as automotive door handles, パイプ, ダクト, household appliance handles, and structural components that benefit from being lightweight yet strong. It’s especially useful when internal smoothness and dimensional accuracy are critical. - Are there material limitations in water injection molding?

はい. Not all thermoplastics are suitable for water injection molding. Materials with poor water resistance or that absorb moisture easily may not perform well. Commonly used materials include polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polyamide (PA). - What are the drawbacks of water injection molding?

The main drawbacks include limited material compatibility and the risk of mold corrosion due to water exposure. Special mold coatings or corrosion-resistant materials may be required. さらに, the process is best suited for medium to high production volumes rather than low-volume runs. - How does water injection molding help reduce manufacturing costs?

Cost reductions come from multiple factors:

Shorter cooling cycles, which increase production efficiency.

Lower material consumption, since less resin is needed for hollow parts.

Fewer defects, reducing waste and post-processing work.

ある場合には, aluminum molds can replace more expensive steel molds, further cutting costs.