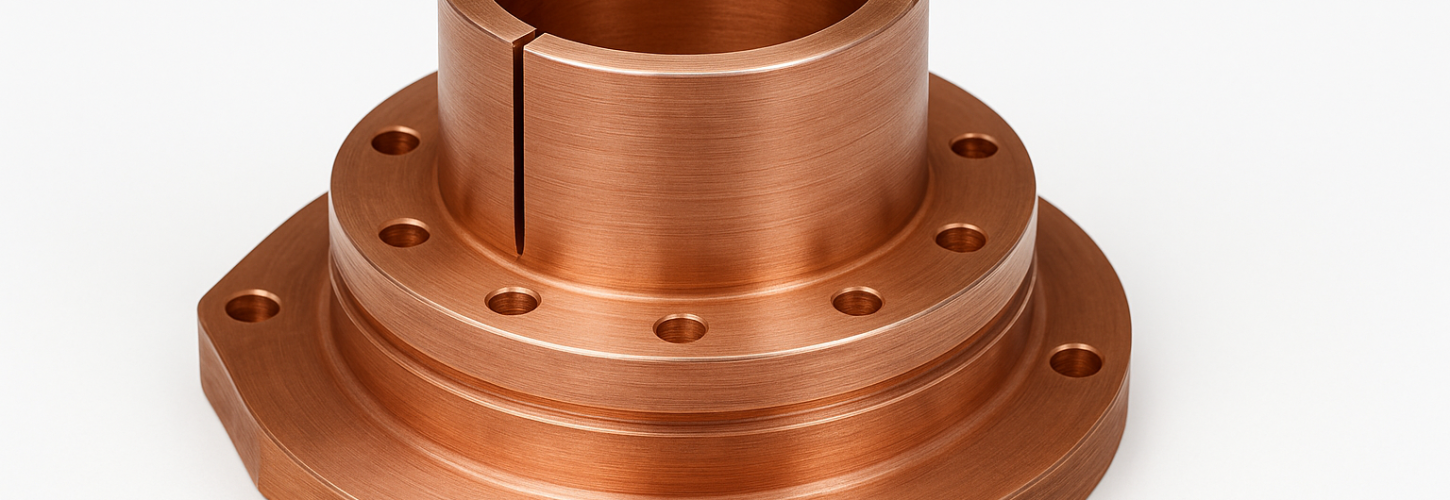

Why Copper is An Ideal Material for CNC Machining?

CNC加工 frequently utilizes 銅 due to its outstanding electrical and thermal conductivity, along with its excellent malleability and resistance to corrosion. This unique combination of properties makes copper a go-to material for a wide range of applications requiring reliable performance.

At Top Precision, we employ advanced CNC technology to produce high-accuracy copper components built to meet intricate design requirements and tight dimensional tolerances. Our experienced engineering team delivers copper parts that meet all client specifications, whether for a single prototype または 大規模な生産 runs.

今すぐお問い合わせを送信してください

Why Choose Tops Precision for Copper CNC Machining?

Commitment to Precision and Quality

Tops Precision is fully committed to producing copper components that meet the highest quality standards in every production cycle. Our clients trust us because of the following key aspects of our CNC copper machining services: With our state-of-the-art CNC equipment, we achieve dimensional accuracy up to ±0.005 mm, ensuring each component is manufactured with exceptional precision. We take full responsibility for delivering perfect fit, optimal functionality, and high performance in both custom copper prototypes and high-volume production parts.

Wide Range of Applications

Copper is widely used across industries due to its versatility. We specialize in manufacturing copper components for the electrical, 自動車, 航空宇宙, および産業部門, ensuring optimal performance under demanding operational conditions.

迅速な所要時間

We understand the urgency behind project timelines. Our integrated system of rapid prototyping and streamlined production enables us to deliver copper parts in as little as 3 日, helping clients meet tight deadlines.

Customization to Your Needs

Tops Precision offers complete customization options, from unique part geometries to special surface finishes. Our capabilities include engineering complex copper components as well as supporting full-scale production with precise dimensional control.

Experienced Engineers

Backed by decades of experience, our team possesses in-depth knowledge of copper’s unique machining characteristics. This expertise enables us to produce high-quality copper parts with excellent surface finishes and tight tolerances, meeting even the most detailed project specifications.

今すぐお問い合わせを送信してください

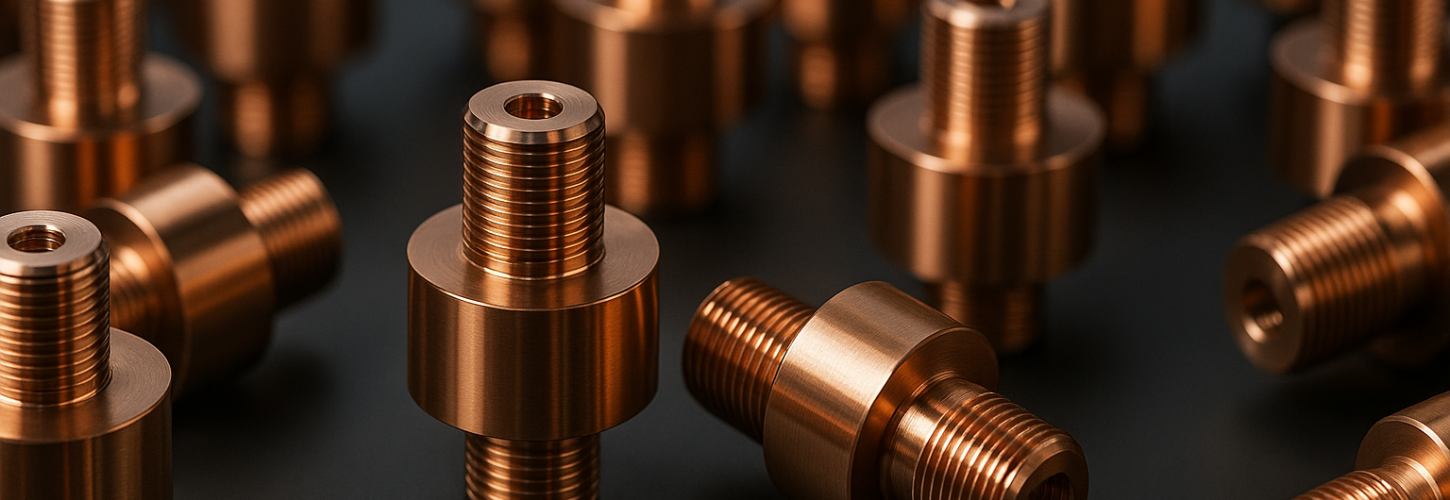

Copper CNC Machining Process

Our CNC machines are capable of producing high-quality copper components at optimal speeds. We follow a structured process to manage your project efficiently:

材料の選択

We begin by selecting the most suitable copper alloy based on your project’s requirements for conductivity, 機械的強度, 耐食性.

CAD Design and Prototyping

Our team supports you through the CAD design phase to ensure every specification is captured precisely. Design revisions can be made as needed, and once finalized, we proceed with rapid prototyping to test part functionality before committing to full-scale production.

CNC加工

We perform accurate copper machining using advanced CNC milling, 旋回, レーザー切断, and drilling equipment. These processes enable us to maintain tight tolerances and achieve exceptional precision.

表面仕上げ

Based on the application, we apply suitable surface treatments such as polishing or protective coatings to enhance both performance and visual appeal. This final step ensures superior corrosion resistance and a refined appearance for each component.

品質管理

Every part undergoes rigorous quality inspections prior to delivery. Our checks include dimensional verification, material property testing, and visual assessments to ensure compliance with all quality standards.

今すぐお問い合わせを送信してください

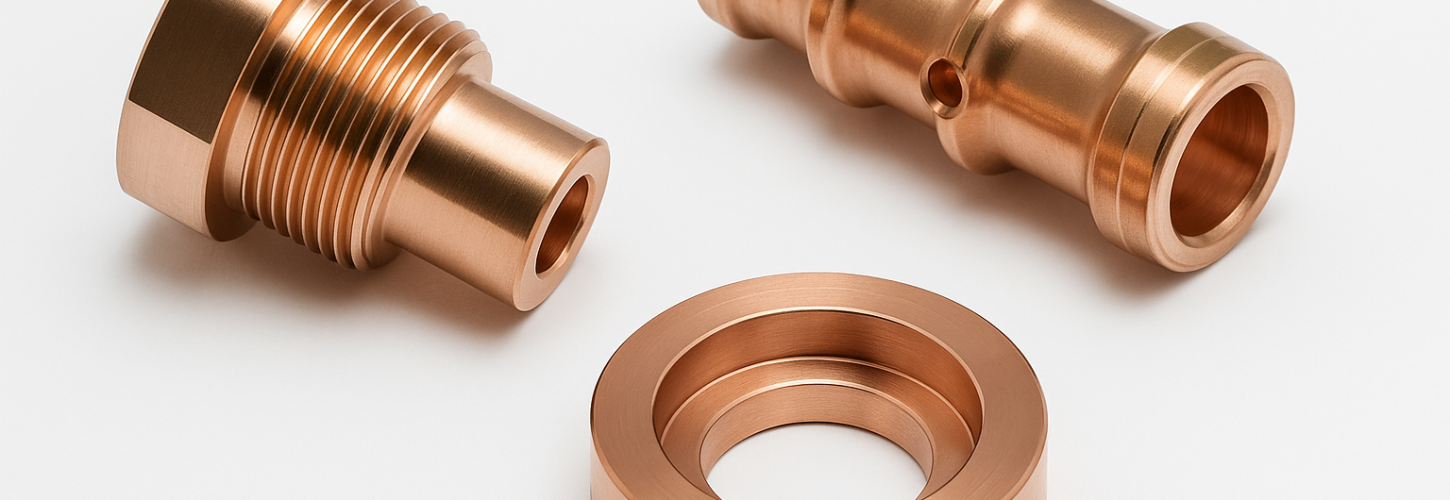

Copper Materials Offered for CNC Machining

We provide a wide selection of copper alloys to match the exact requirements of your project. Each type offers distinct characteristics that make it ideal for various applications. The table below outlines some of the most commonly used copper materials in our machining operations:

材料 | 主な特長 | に最適です | 作られた部品 |

銅 (C11000) | 優れた導電性, highly malleable, 耐食性 | 電気コネクタ, 熱交換器, wiring. | |

真鍮 (C36000) | 強い, 機械加工が簡単, 耐食性 | 配管継手, 電気コネクタ, 歯車. | |

ベリリウム銅 (C17200) | 高強度, non-sparking, excellent electrical conductivity | 航空宇宙部品, 電気接点, military parts. | |

リン青銅 (C51000) | 優れた耐摩耗性, fatigue resistant, 耐食性 | ベアリング, ブッシング, and marine applications. | |

ブロンズ (C90700) | 耐食性, 強い, 耐摩耗性 | Marine hardware, ブッシング, ギア部品. | |

Copper-Nickel (C70600) | Excellent resistance to seawater corrosion, 強い | Marine piping, 熱交換器, and desalination systems. |  |

今すぐお問い合わせを送信してください

Industries That Use Copper CNC Machining

Copper parts play a critical role in many industries due to their conductivity, 強さ, 耐食性. Here are some of the industries that rely on Tops Precision for copper CNC machining:

エレクトロニクス:For copper PCBs, コネクタ, and heat sinks used in consumer electronics and industrial applications.

航空宇宙:High-performance copper parts used in aircraft systems, エンジン部品, および電気コネクタ.

マリン: Corrosion-resistant copper parts for marine engines, 継手, and ship hardware.

自動車: Copper heat exchangers, electrical terminals, and brake components in electric vehicles and traditional cars.

HVAC: Copper tubes, パイプ, and fittings used in cooling systems and air conditioning units.

Get Your Custom Copper Parts Today

最高の精度, we’re ready to help you with all your copper CNC machining needs. Whether you need precision-engineered components or high-volume production runs, we have the technology, 経験, and expertise to meet your requirements.

Contact us today to get a free quote, discuss your project with an expert, or request a rapid prototype. Let us help you bring your copper parts to life!