ツールスチールの機械加工とは何ですか?

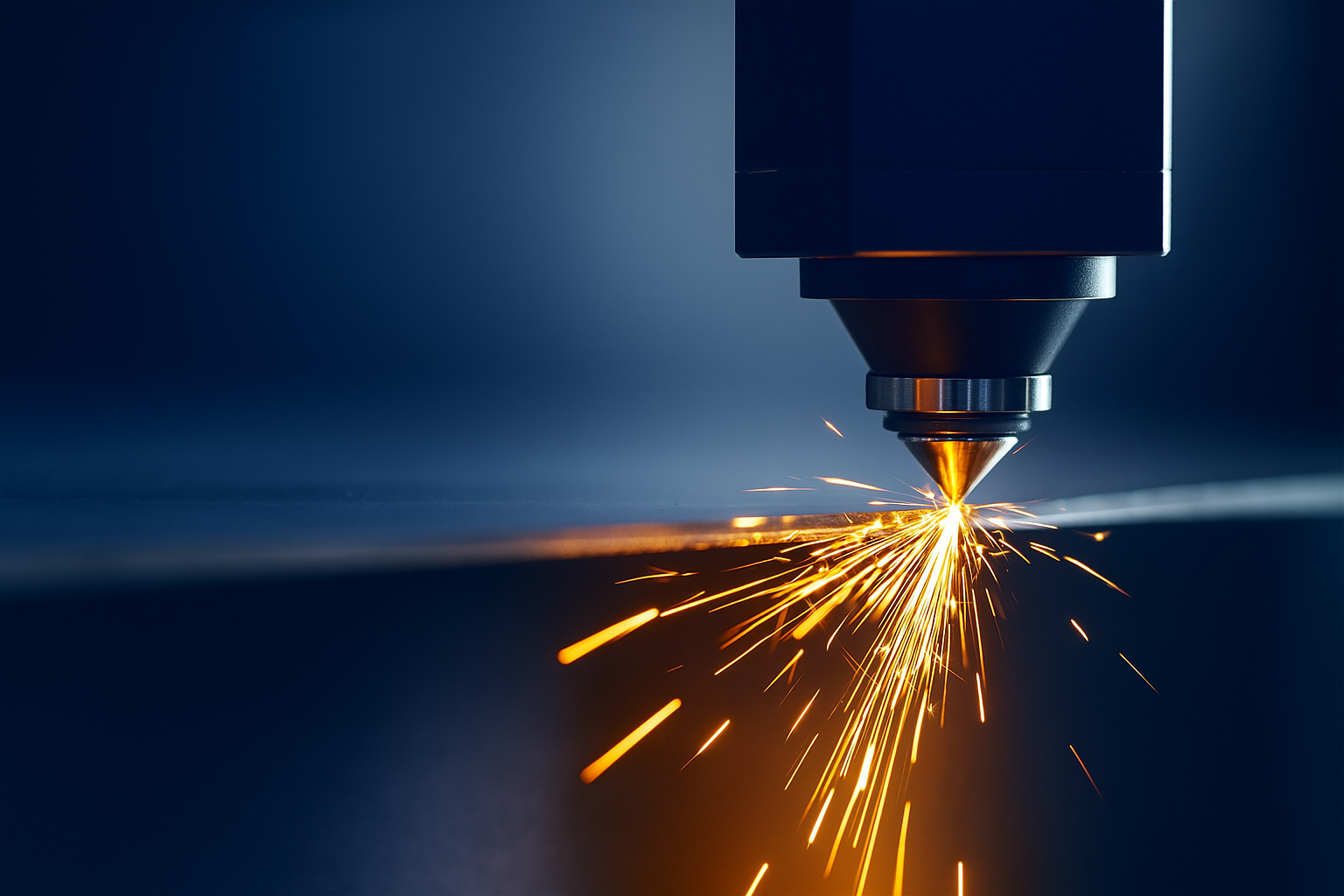

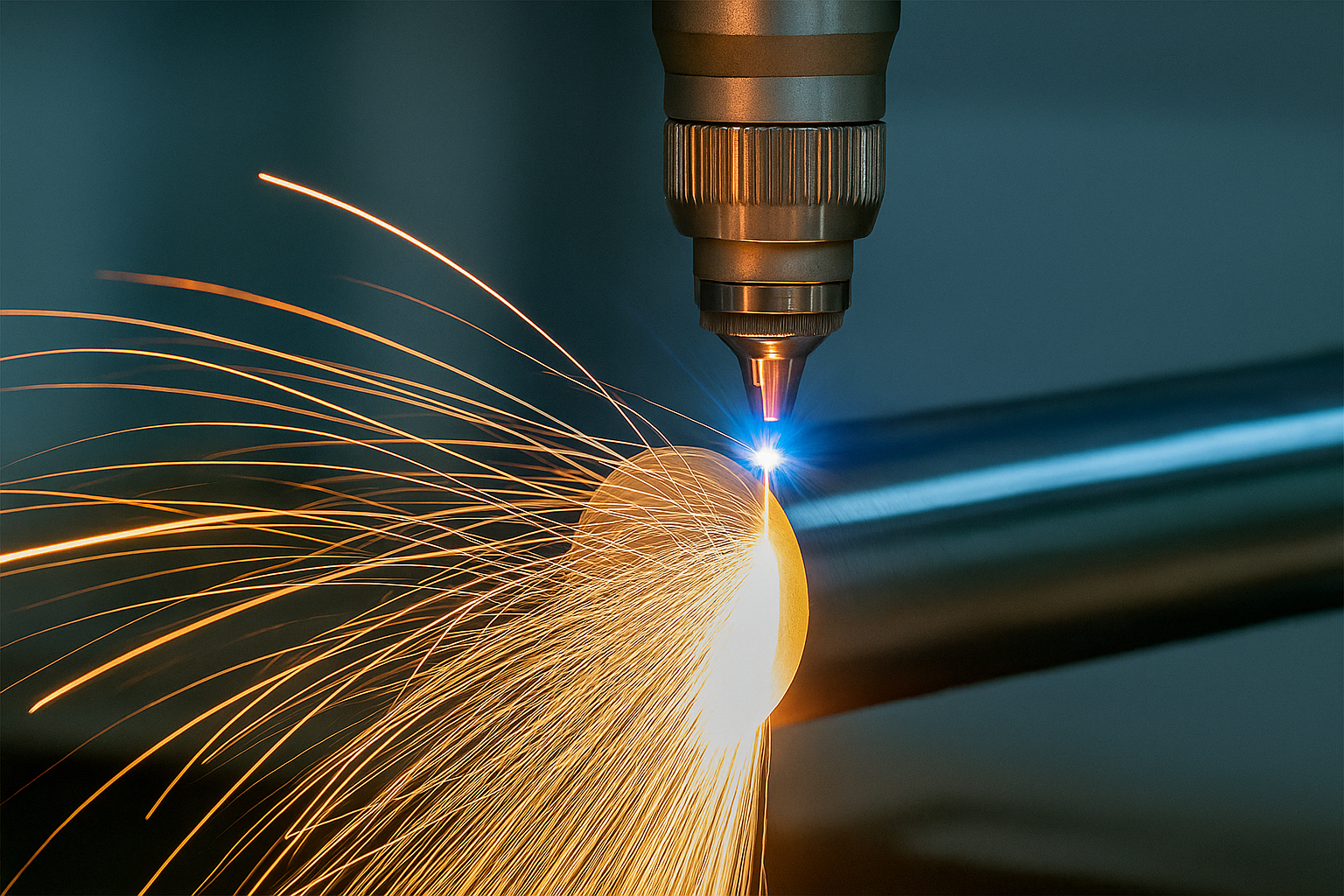

ツールスチールの機械加工にはシェーピングが含まれます, 切断, そして、便利な部品またはコンポーネントにツール鋼合金を仕上げます. CNCミリングなどの方法を使用します, 旋回, 放電加工, そして研削. 彼らの硬度, 耐久性, そして、圧力下の驚くべき強さは、それらを切断工具やさまざまな業界で最適にします.

We take care of the process from design to assembly to provide a proper manufacturing solution.

ツールスチールの機械加工にはシェーピングが含まれます, 切断, そして、便利な部品またはコンポーネントにツール鋼合金を仕上げます. CNCミリングなどの方法を使用します, 旋回, 放電加工, そして研削. 彼らの硬度, 耐久性, そして、圧力下の驚くべき強さは、それらを切断工具やさまざまな業界で最適にします.

それで, これは、ツールスチールの機械加工の段階的なプロセスです:

私たちの出発材料は、生のビレットです, ブロック, または事前に硬化したツールスチール, そして、材料証明書と硬度テストによる仕様の適合性を確認します.

CAD/CAMチームはファイルを読み取ります, アクセスが難しい領域に注目してください, 許容範囲, 備品の位置. 一度剛性のある作業, 偏向, 振動は減少します.

炭化物とPCDツーリングは、最適化されたチップ制御を介してバルク材料をカットするために適用されます, クーラントの流れと体積, 熱制御ツールパス.

最後の仕上げは最小限のステップオーバーとスピンドルrpmで行われます, そして生成します <= 16 RA表面または強化. 5-Axisライブツールセンターは、より良い表面仕上げを提供します.

ジオメトリが複雑な場合, EDMがあります (シンカー/ワイヤー) 到達するのが難しい機能に到達するため, 研削, 溶接, および第一抵抗チェック.

各部品はCMMを使用して検査され、最初の記事レポートが提供されます (遠い) または必要に応じてAS9102フォーム.

コンポーネントは洗浄されます, メッキ, 熱処理 (まだそうではありません), 準備ができています (服を着た) 組み立てまたは派遣されます.

次の高品質のツールスチールに機械加工サービスを提供しています, それぞれが特定のパフォーマンス特性に選択されます:

ツールスチールグレード | 主要なプロパティ | 一般的なアプリケーション | 硬度 (HRC) |

D2 | 高硬度, 優れた耐摩耗性, 空気硬化 | 死ぬ, ブランキングツール, ツールの形成 | 58–62 |

A2 | バランスの取れた靭性と耐摩耗性, 良好な寸法安定性, 空気硬化 | パンチ, せん断刃, 射出成形金型 | 57–62 |

O1 | 機械加工が容易, 良いエッジ保持, オイル硬化 | ナイフ, 切削工具, 精密ゲージ | 57–63 |

A3 | 汎用ツールスチール, 中程度のタフネス, そして着用 | 金型, ジグ, 備品 | 50–58 (約) |

S7 | 高い耐衝撃性, 衝撃負荷の耐久性, 中程度の耐摩耗性 | ハンマー, ノミ, インパクトダイ | 54–58 (硬化後) |

H13 | 優れた熱疲労抵抗, 高温で硬度を維持します | ダイキャスティング型, 押出ダイス, 鍛造ツール | 48–53 (ホットワーキング) |

ツールスチールの機械加工には、高硬度合金を正確に形作るための高度な技術が含まれます, 耐久性のあるコンポーネント. TOPSプレシジョンでは, 業界をリードするテクノロジーと方法を利用して、信頼できる一貫した結果を提供します.

多軸CNCミリング - 高速, 複数の軸にわたる精密機械加工, 複雑な幾何学と厳しい許容範囲に最適です.

5軸の機械加工 - 単一のセットアップで複雑な輪郭とアンダーカットを有効にします, 精度の向上とサイクル時間の短縮.

CNCターニングと旋盤 - 円筒形のコンポーネントに最適です, スレッド, 再現性の高い緊密な同心性.

EDMの機械加工 - 電気放電を使用して、材料を正確に除去します, ハードツールの鋼や狭いコーナーに最適です.

EDM配線 - 硬化鋼で複雑な形状と鋭い内部角を生成するためのワイヤーカットEDM.

研削 - 優れた表面仕上げと正確な寸法を達成します, 硬化後の精度に不可欠です.

溶接と製造 - 強度と完全性のためにTIG/MIG溶接を使用した機械加工コンポーネントの構造結合とアセンブリ.

CMM検査 - Coordinate Measuring Machine used for precise dimensional verification of machined parts.

Injection Mold Building – Fabrication of mold bases and cores using tool steel for plastic and die casting applications.

Custom Part Manufacturing –Tailor-made machining based on specific customer drawings, 公差, and material requirements.

Precision Tooling –Manufacture of punches, 死ぬ, and cutting tools with sharp tolerances and long service life.

プロトタイピング - Rapid production of tool steel prototypes for design validation and functional testing.

Build to Print –Production of parts exactly as per customer-supplied engineering drawings, ensuring design fidelity and compliance.

Try to follow these tips to cut the cost of tool steel machining.

ツールを変更します’ 処理中にオプションを使用した外観と品質.

産業や企業は多くの場所でツールスチール部品に依存しています. これらには以下が含まれる場合があります:

TOLスチールの機械加工の利点は次のとおりです:

ツールスチールで機械加工を実行しながら、次の課題があります:

ツールスチールの機械加工方法と一緒に, Topsの私たちの精度は、あなたのデザインを生産用に準備する準備ができています. 高品質のアイテムを提供します, 正確な結果, 生産のあらゆる段階での効率, プロトタイプから始めます. デザインを送信できます, 仕様, またはプロトタイプ, ツールスチールパーツを構築します.

私たちが提供するすべてのサービスは品質がチェックされ、ISOに従って検査されます 9001:2015 基準. 機械加工プロセスはすべて、追跡可能な材料によってサポートされています, 適切な研究, プロジェクト全体の継続的な支援.

H13 Tool Steelは熱疲労からの並外れた保護を提供し、非常に困難であるため、人気があります.

はい, 私たちは、どの材料が使用されているか、どこでアイテムを使用するかに基づいて、パートナーの熱処理を実行または依存しています.

あ: 絶対に. フォームを確認するために必要なすべてのプロトタイピングサービスを提供します, フィット, 機能は正しいです.

私たちは小さな作品と大規模なプロダクションの両方を1か所で扱うことができます.

あ: はい. 私たちは、プリントからプリントの製造サービスを提供し、すべての顧客の要件を維持します.