2色の成形とは何ですか?

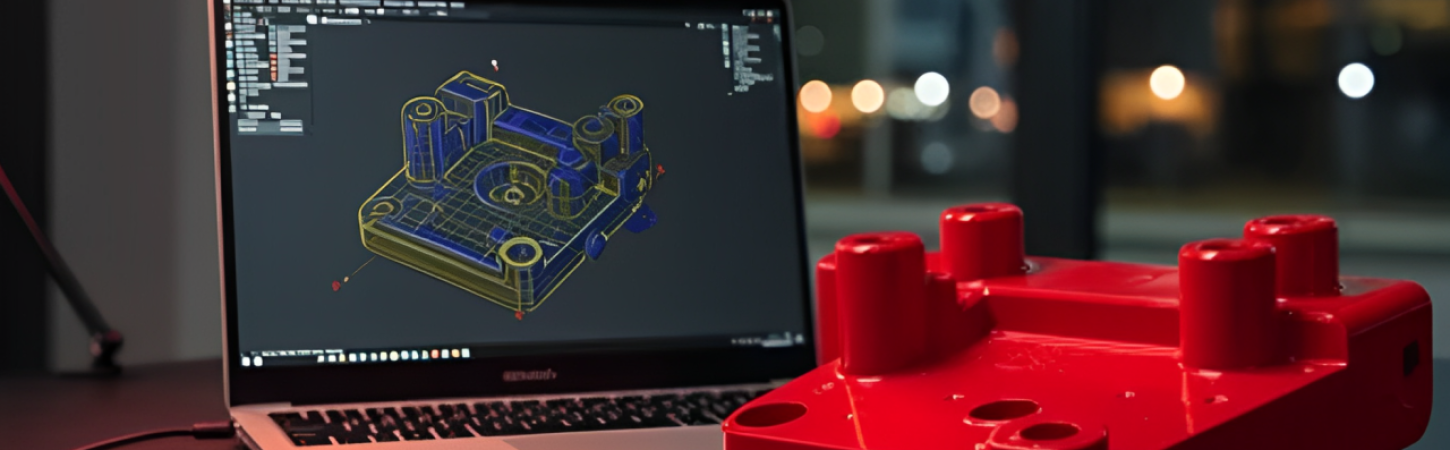

ダブルショット射出成形は、最新の製造システムを説明するために2色のモールディングという名前で戻ります. さまざまなプラスチック材料と色を1つの金型に注入することができます. 2色のモールディングは、金型製造プロセスから直接複数色またはマルチマテリアル部品を生成します. このほかにも, アセンブリステップで追加の塗装の必要性を排除します.

二重注射または2色の射出成形は、単一のコンポーネントを2つの異なるプラスチック材料または色で成形できるようにする最先端の製造方法です。. 製品の機能をもたらします, 美学, パフォーマンスとアセンブリコストの削減.

ダブルショット射出成形は、最新の製造システムを説明するために2色のモールディングという名前で戻ります. さまざまなプラスチック材料と色を1つの金型に注入することができます. 2色のモールディングは、金型製造プロセスから直接複数色またはマルチマテリアル部品を生成します. このほかにも, アセンブリステップで追加の塗装の必要性を排除します.

適切に設計された金型は、運用効率が向上し、二重色の射出成形プロセスにおける完璧な結合により精度を達成するために不可欠な立場にあります. 材料の正しい選択から欠陥のない品質生産が現れます, 最適なゲーティング, 収縮制御コア回転, 適切な冷却要素.

カビのデザインは重要です, 適切な精度と効率が重要であるためです. 主要な設計上の考慮事項には含まれます:

🔹 材料の選択 - 互換性のある融点を持つ材料を選択します.

🔹 ゲート & ランナーシステム - シームレスな結合のためにフローを最適化します.

🔹 縮小率 - さまざまな材料の収縮を説明します.

🔹 コアローテーション - 2つの材料の正確な整列を確保します.

🔹冷却システム - 冷却は、反りや欠陥を防ぐために夢を実現させます.

最初のショット: メーカーが最初のプラスチック材料注入を開始すると、金型はベース層を受け取ります.

セカンドショット: このプロセスは、最初の噴射型材料に完全に付着する2番目の材料層を生成します.

最終製品: この手法は、複数の色または材料ベースのコンポーネントを生成します, 耐久性があります, 視覚的に魅力的です, 品質基準を満たします.

🔹コンシューマーエレクトロニクス (ボタン, ケーシング, キーパッド)

🔹自動車部品 (ダッシュボードコントロール, ノブ, トリム)

🔹世帯 (歯ブラシハンドル, キッチンツール)

🔹医療機器 (人間工学に基づいたグリップ, シリンジプランジャー)

2色の成形 (ダブルショット射出成形) 材料の組み合わせを使用しているが、それは製造方法では異なる動作をしています. これにより、生産者はシーケンシャルマテリアルデリバリーを1つの金型に使用して、キーパッドアプリケーションでうまく機能する強力な結合マルチカラーまたは複数の材料部品を形成することができます, 自動車部品, および消費者電子デバイス.

オーバーモールディングは、事前に形成されたコンポーネントの周りに二次材料層をラップして、保護外層を作成します, 絶縁表面, または医療機器の電動工具に見られる強化グリップ, およびツールハンドル. 継続的な成形プロセスは、ボリューム製造のための高精度ソリューションとして位置付けられ、オーバーモールディングは人間工学を最適化し、その階層化技術を通じてオブジェクトを保護します.

2色の型の違いを要約しましょう & 次の表にオーバーモールドします:

特徴 | 2色の成形 | オーバーモールディング |

プロセス | 1つの型に2つの材料を同時に注入します | 既存の部分における二次成形 |

材料結合 | 2つの材料間の強力な化学結合 | 物理的な接着 (プライマーが必要な場合があります) |

精度 | 高精度と詳細 | レイヤーを追加するのに適していますが、2色の成形よりも複雑ではありません |

に最適です | 複雑なマルチカラー部品 | ソフトグリップハンドル, 保護層 |

料金 | 初期カビのコストが高くなりますが、大量生産には効率的です | 金型コストは低いですが、追加の処理が必要になる場合があります |

製品に複数の色の美学が必要な場合, 複数の機能, または1つのステップでの強力な材料結合, ここでは、2色の成形が最善の方法です. 2つのカラーモールディングを選択するとき, 一緒に行くべきです:

bultialマルチカラーでシームレスなデザインが必要です - 牽引色のモールディングを選択してください. ロゴに最適です, アイコン, または視覚的に異なるコンポーネント.

cこの製品にはさまざまなプロパティが必要です - ここでは、より良いグリップのためのハードソフトな組み合わせ, 柔軟性, または永続的な耐久性.

hobor労働を減らします, 費用, および生産時間 統合して 2 または1つのステップでより多くの材料.

✔高精度と複雑なデザイン - 複雑なコンポーネントに最適です, つまり. 自動車ダッシュボード, キーパッド, ボタン, 等.

host強力で耐久性のある化学的結合が必要です - 家電の寿命, 医療機器, および自動車部品.

2色の成形で適切な色を選択することは、必要な視覚的影響と機能を達成するために重要です. 次の要因を考慮してください:

2色の射出成形により、視覚的に魅力的な生産を可能にし、機能的に質の高い製品を改善できます. 二次アセンブリステップが削除されるため、生産費は減少します。. 2色の射出成形のプロセスは、魅力的な高品質製品を生成します.

正しい材料結合正確な温度制御と正確な噴射シーケンス方法でカビの設計が最大化されると、結果は最適です。. 高度な2ショットマシンテクノロジーは、高品質のコンポーネントの欠陥を排除する制御された冷却システムとともに、正確な動作を提供します.

Tops Precisionの使命は、仕様に合わせたカスタマイズされた高品質の2色の成形製品を生産することです. デザインファイルを当社に送信すると、パーソナライズされた見積もりを生成し、相談サービスを提供します.

2色の射出成形は、1つのマシンから動作し、継続的な製品を構築するための単一のユニットとして金型ですが、モールドを超えて異なる材料で個別の成形操作を実行する必要があります.

さまざまな2色の成形アプリケーションがABSを使用しています, パソコン, PMMA, TPE, TPU, 物質的な選択としてのPP.

あ: はい! 2色の射出成形は、硬質プラスチック製品に人間に優しいグリップを設置する必要があるときに最適に機能します.

このプロセスにはセットアップ段階が含まれていますが、組み立て操作が不要になったため、生産のタイムラインが短くなります。.

2色の射出成形により、自動車セクターの家電医療分野と産業ドメインに機能性と審美的な利点が向上します.