Quando se trata de CNC (Controle Numérico Computadorizado) usinagem, Dois códigos importantes controlam todo o processo: Código G e Código M. While G-code tells the machine where and how to move (cutting paths, coordinates, and speeds), M-code takes care of the machine’s auxiliary functions—basically everything else that supports the machining process.

Without M-code, a CNC machine would know how to move but wouldn’t know when to start the spindle, turn on the coolant, or stop at the end of the job. Resumidamente, G-code is about movement, while M-code is about control.

Definition of M-Code

M-code stands for Miscellaneous Code or sometimes Machine Code. It is part of the CNC programming language that controls non-motion-related functions of the machine.

These codes act like switches—they turn things on e off. Por exemplo:

M03: Spindle on (sentido horário)

M05: Spindle stop

M08: Coolant on

M30: Program end and reset

Então, M-codes don’t tell the tool para onde ir but instead manage the supporting actions needed for machining to happen smoothly.

Function of M-Code

If G-code is all about telling the machine onde to move, then M-code is about telling the machine what else to do while it’s working. Think of M-codes as the “extra commands” that control the behind-the-scenes operations of a CNC machine. They don’t move the tool along a path but instead manage things like turning the spindle on or off, starting the coolant, or even stopping the program completely.

Spindle control – Commands like turning the spindle on, off, or reversing its direction. Without this, the cutting tool wouldn’t even spin.

Coolant control – Tells the machine when to start or stop spraying coolant to keep the tool and workpiece from overheating.

Mudanças de ferramenta – Switches out tools automatically so you don’t have to do it manually. This is super helpful in long or complex jobs.

Program control – Handles things like pausing the job (M00), ending the program (M30), or stopping temporarily for inspection.

Machine safety and support functions – Ensures things like clamping or chucking a part securely before machining begins.

Types of M-Code

Each type of M-code tells the CNC machine to handle a different kind of “side job” while the main cutting is happening. Let’s break them down into the most common types:

Spindle Commands

These control the cutting tool’s rotation. Por exemplo:

Turn the spindle on (sentido horário ou anti-horário).

Turn the spindle off when the cut is finished.

Without these, the tool wouldn’t spin, so no cutting could happen!

Coolant Commands

These are all about temperature control. Cutting metal generates a lot of heat, and coolant keeps the tool and workpiece from overheating. M-codes tell the machine when to start spraying coolant, stop it, ou até switch coolant modes.

Tool Change Commands

Modern CNC machines can swap tools automatically. M-codes trigger this process, making sure the right tool is loaded at the right time. Imagine running a job that needs drilling, fresagem, and tapping—without tool-change M-codes, you’d have to stop the machine and do it all by hand.

Program Control Commands

These M-codes handle the flow of the job itself. Exemplos incluem:

Pause the program (so the operator can check the part).

Stop the program completely when the job is done.

Jump to a different section of the program.

It’s like the “play,” “pause,” and “stop” buttons for CNC machining.

Machine Support Commands

These manage things that keep everything safe and stable, como:

Opening or closing a chuck.

Engaging clamps to hold the workpiece in place.

Activating accessories like chip conveyors.

Common M-Code Examples

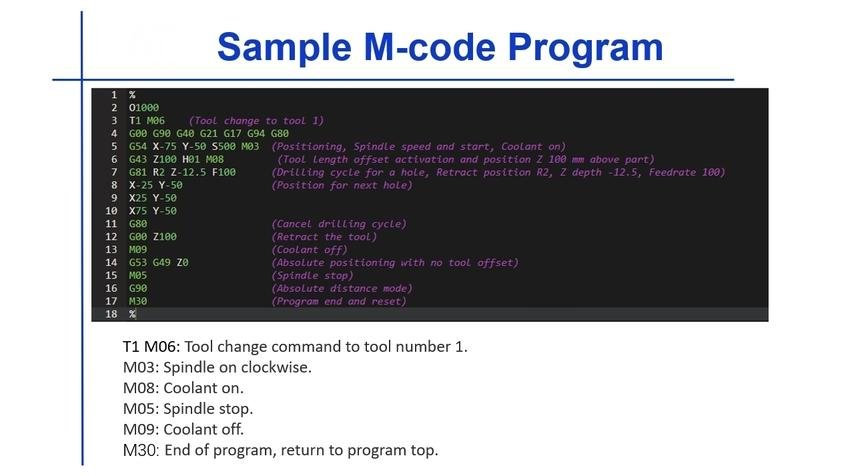

Here’s a quick table of some of the most widely used M-codes you’ll see in CNC programming:

| M-Code | Função | Categoria |

| M00 | Program stop (pause until operator restarts) | Program Control |

| M01 | Optional stop (only works if operator enables it) | Program Control |

| M02 | End of program | Program Control |

| M03 | Spindle ON (sentido horário) | Spindle Command |

| M04 | Spindle ON (counterclockwise) | Spindle Command |

| M05 | Spindle OFF | Spindle Command |

| M06 | Automatic tool change | Tool Change |

| M08 | Coolant ON | Coolant Command |

| M09 | Coolant OFF | Coolant Command |

| M10 | Chuck/fixture clamp ON | Machine Support |

| M11 | Chuck/fixture clamp OFF | Machine Support |

| M30 | End of program and reset | Program Control |

Uses of M-Code in CNC Machining

M-codes may look like just short commands, but they’re actually the ones that bring a CNC machine to life. While G-codes tell the machine onde to move, M-codes handle all the little tasks that make machining possible. Think of them as the switches and buttons that control the extra functions. Here are some of the main ways M-codes are used in CNC machining:

Starting and stopping the spindle

One of the most common jobs of M-codes is controlling the spindle. Por exemplo, you can use an M-code to make the spindle spin clockwise, counterclockwise, or stop completely. Without these commands, the cutting tool would just sit still.

Turning coolant on and off

When machining metal, things can heat up very quickly. M-codes are used to turn the coolant on or off, or even change the type of coolant flow (like mist or flood). This keeps the tool cool and prevents damage.

Mudanças de ferramenta

CNC machines often need to switch between tools for different steps of the job. M-codes can tell the machine to automatically swap out one tool for another, saving time and effort.

Program control

M-codes also help with controlling how the program runs. Por exemplo, some M-codes stop the program temporarily so the operator can check something, while others mark the end of the program completely.

Machine accessories

In more advanced CNC machines, M-codes can also control extras like turning on a chip conveyor, opening or closing machine doors, or even switching on a light. They help make the whole machining process smoother and safer.

Industrial Applications of M-Code

M-codes are used in almost every CNC-driven industry, Incluindo:

Automotive manufacturing – managing tool changes for engine and transmission parts

Aeroespacial – ensuring precision machining with coolant and spindle control

Medical device production – stopping programs for inspection and tool changes

Eletrônicos – using coolant and tool change cycles during precision machining of components

General metalworking – controlling spindles, mudanças de ferramentas, and coolant in everyday machining jobs

Advantages of M-Code

M-code plays a huge role in making CNC machining smooth and reliable. Without them, machines would be a lot harder to control. Here are some of the main advantages of using M-codes:

Easy machine control

M-codes make it super simple to control extra machine functions like spindle rotation, coolant flow, ou alterações da ferramenta. Instead of manually pressing buttons or flipping switches, the machine follows these short commands automatically.

Saves time and effort

Imagine stopping a machine every time you need to turn on coolant or change a tool—it would be slow and tiring. With M-codes, all of this happens automatically during the program, which saves both time and human effort.

Better accuracy and consistency

Since the machine is following programmed commands, you don’t have to worry about forgetting to switch something on or off. This means fewer mistakes and more consistent parts.

Improved safety

M-codes can control safety-related features, like stopping the spindle or turning off coolant when the job ends. This reduces the risk of accidents and keeps both the operator and the machine safe.

Flexibility for different jobs

Every machining job can be different, but M-codes give you flexibility. You can easily adjust things like coolant, velocidade do fuso, or tool changes within the program, without needing to reset the whole machine.

Supports automation

Modern CNC machines are all about automation, and M-codes are key to that. They allow the machine to handle tasks on its own—from starting and stopping to switching tools—so operators can focus on monitoring instead of constant manual control.

What is the Structure of an M-Code?

Starts with the letter “M”

Every M-code begins with the letter M, which simply tells the CNC machine, “Hey, this is a machine command.”

Followed by numbers

After the “M,” you’ll usually see two or three numbers. These numbers are what tell the machine exatamente what action to perform.

Por exemplo:

M03 = Start the spindle clockwise

M05 = Stop the spindle

M08 = Turn on coolant

M30 = End the program

Sometimes paired with other codes

M-codes don’t usually work alone—they’re often written together with G-codes (which control movement). The G-code decides where the tool goes, while the M-code handles what the machine faz during that movement.

Simple and direct

One of the best things about M-codes is how straightforward they are. You don’t need long instructions—just a short command like M03 or M08, and the machine knows exactly what to do.

How to Read M-Code Commands?

Reading M-codes is easier than G-codes because they are mostly switch-like commands.

Look for the letter M – it signals a machine operation.

Check the number after it – this tells you what action is being performed.

Read the machine’s manual – since some M-codes are machine-specific.

For beginners, a simple M-code chart is the best way to get familiar with common commands.

Safety Considerations When Using M-Code

Even though M-codes seem simple, they can control powerful machine functions. Here are some safety tips:

Sempre double-check tool change commands (M06) to avoid crashes.

Be careful with coolant commands to prevent spills and slipping hazards.

Usar program stop commands (M00, M01) responsibly so operators can safely inspect parts.

Remember that some M-codes are machine-specific—using the wrong one could damage equipment.

Difference Between G-Code and M-Code

Many people confuse G-code and M-code, but they are different:

Código G controles motion → tells the tool how to move.

Código M controles machine functions → tells the machine what to turn on or off.

Por exemplo:

G01 X50 Y50 (move the tool in a straight line)

M03 (turn the spindle on)

They work together like a team—without G-codes, there’s no cutting path; without M-codes, the machine can’t support the process.

M-Codes vs. Usinagem Manual

Before CNC machines and M-codes, everything was done the old-fashioned way—usinagem manual. That meant the machinist had to physically flip switches, turn dials, and push buttons to control things like spindle rotation, coolant flow, ou alterações da ferramenta. It was all hands-on and required constant attention.

Agora, com M-codes, the process is much smoother and more automated. Instead of stopping the machine to press a button, you just write a short command in the CNC program, and the machine does the job for you—no extra effort needed.

Here’s how the two compare:

Spindle Control

Manual: The machinist would walk over and flip a switch to start or stop the spindle.

With M-code: You just type M03 to start it and M05 to stop it. Done automatically.

Coolant Flow

Manual: You’d turn a valve or press a button to get coolant flowing.

With M-code: A simple M08 turns it on, e M09 shuts it off—right when the program needs it.

Tool Changes

Manual: The machinist had to stop the machine, loosen the chuck, swap tools, and restart everything.

With M-code: Just add M06 in the program, and the CNC machine switches tools by itself.

Program End

Manual: The machinist would need to stop the machine after the last cut.

With M-code: M30 ends the program and resets everything automatically.

👉 The big difference?

Manual machining = more physical work, more chance of mistakes, slower cycle times.

M-codes = less manual effort, more precision, mais rápido, and way more consistent results.

Conclusão

M-code may not look as “fancy” as G-code, but it’s just as important. It manages all the behind-the-scenes functions that keep a CNC machine running properly—like controlling the spindle, refrigerante, and tool changes.

Whether you’re machining car parts, componentes aeroespaciais, or medical devices, M-codes are the key to making CNC machining safe, eficiente, and automated. By learning both G-codes and M-codes, machinists and programmers can unlock the full potential of CNC technology.

Leia mais:

12 Tipos de máquinas CNC e suas aplicações na fabricação moderna

Compreendendo as linguagens de programação CNC usando códigos G e M

1 pensei em “O que é M-Code: Definição, Função, Tipos & Usos”