Propriedades importantes do material FR4

FR4 é um laminado reforçado com fibra de vidro epóxi comum, particularmente notado por sua força, isolamento elétrico, e resistência ao calor. Essas especificações fundamentais o classificam como um excelente isolador elétrico, PCB, e suporte aeroespacial, entre outros componentes críticos de precisão. A seguir estão as qualidades distintivas do FR4:

1. Alta resistência dielétrica

FR4 tem isolamento elétrico muito alto, Mas geralmente é preferido em aplicações de alta tensão, com valores de força dielétrica sendo muito altos (mais do que 19.7 kv/mm). Isso é essencial nas placas de circuito impresso (PCBs), conectores, e switchgue, onde o isolamento do sinal é uma necessidade.

2. Resistência térmica

FR4 pode ser usado em 130-150 o c temperaturas contínuas de serviço com estabilidade mecânica e elétrica. Isso o qualifica para ser usado em obras de solda e lugares expostos a calor intenso. Tem uma temperatura de deflexão de baixa timcal, que permite ser usado na fabricação de equipamentos industriais e eletrônicos.

3. Estabilidade dimensional

FR4 tem um baixo coeficiente térmico de expansão (~ 14 16 ppm/c), e não está sujeito a distorção ou distorção devido a cargas mecânicas ou térmicas. Possui tolerâncias estritas, Portanto, é adequado aplicar em geometrias complexas ou na montagem de montagens de acasalamento.

4. Força mecânica

FR4 tem um módulo de alta compressão com uma resistência à flexão de mais de 480 MPa, o que o torna muito rígido e capaz de suportar cargas altas. Ele encontra sua aplicação usual em trabalhos de suporte estrutural, como suportes aeroespaciais no espaço e sistemas automotivos, bem como espaçadores e backplanes.

5. Resistência à umidade

FR4 absorve pouca quantidade de água (geralmente <0.1%) e é bastante estável em condições úmidas ou úmidas. Esta resistência à água serve para salvaguardar circuitos delicados e fornece estabilidade elétrica a longo prazo.

6. Retardância da chama

Como o nome indica, Fr (Retardador de chama) 4 tem um Ul94 V-0 Classificação inflamabilidade, o que significa que pode se auto-se auto-se auto. Esse recurso garante a segurança em locais de espaços confinados ou locais termicamente quentes, como painéis de energia e transformadores.

7. Resistência química

FR4 FR4 é resistente a ácidos, bases, e solventes, por isso é usado em aplicativos quimicamente expostos, como laboratórios, sistemas de bateria, ou unidades de controle industrial. Não diminui para uma condição facilmente quebrada, desde que seja usado.

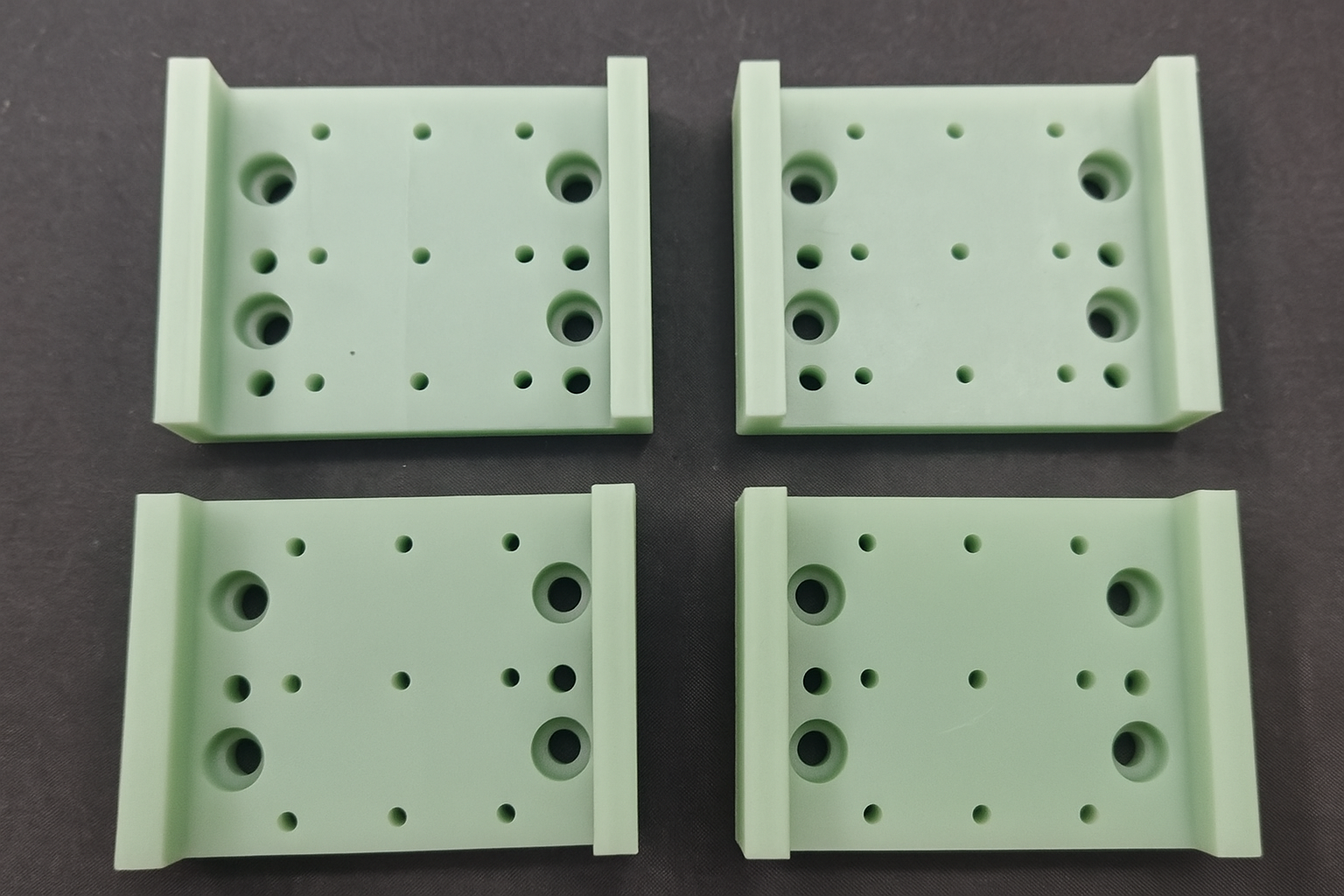

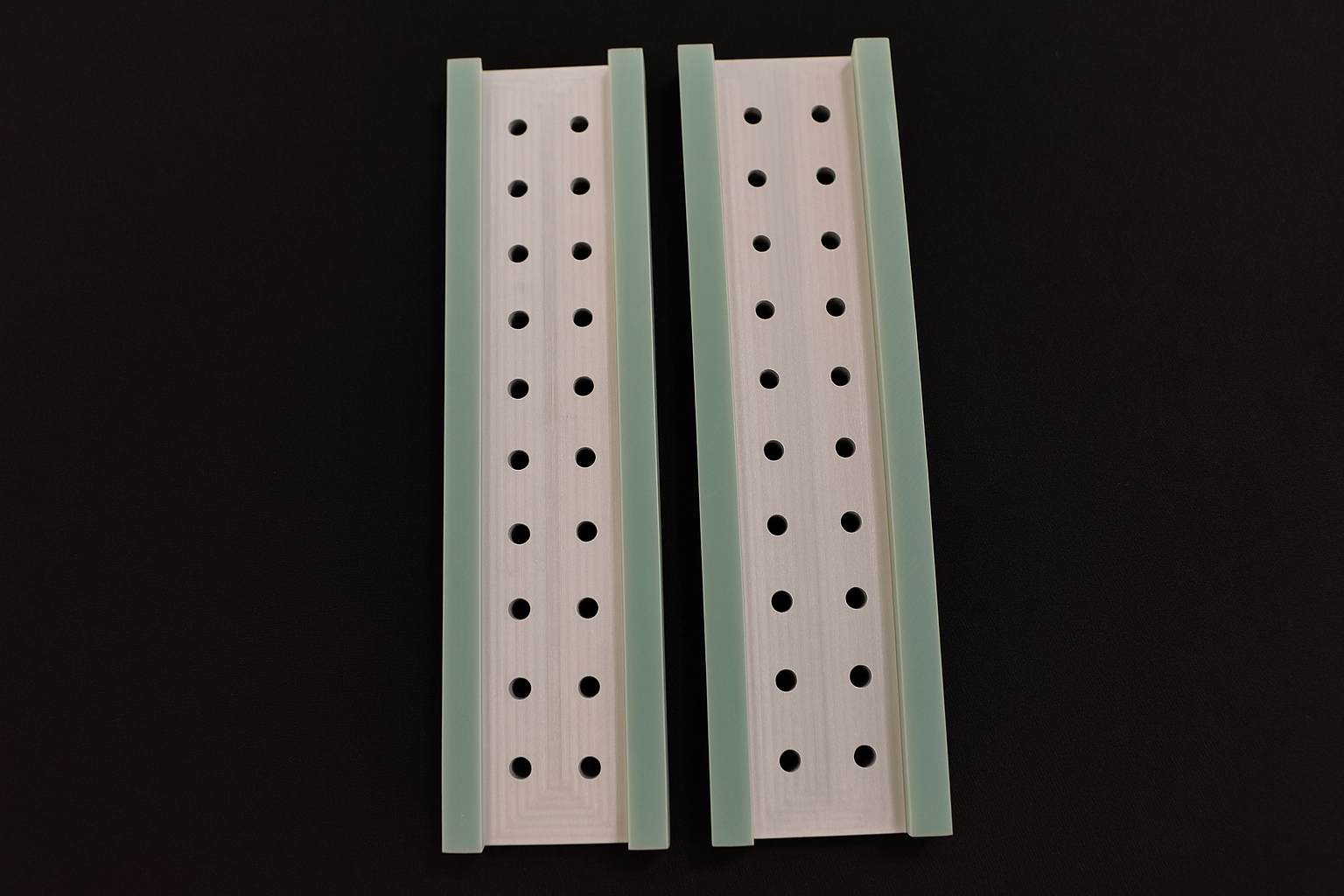

8. Maquinabilidade

Máquinas FR4 bem com ferramentas adequadas, Embora seja abrasivo por causa das fibras de vidro. Serve uma ampla gama de acabamentos de pós-processamento, tolerâncias apertadas, e formas complexas, o que torna útil na fabricação de peças personalizadas em vários setores.

Podemos resumir essas propriedades na tabela a seguir:

Propriedade | Valor típico / Descrição | Beneficiar |

Força dielétrica | > 19.7 kv/mm | Ideal para isolamento de alta tensão |

Resistência térmica | Até 130-150 ° C contínuo | Estável em ambientes de alta temperatura |

Estabilidade dimensional | Cte ≈ 14-16 ppm/° C | Mantém precisão sob estresse térmico/mecânico |

Força de flexão | > 480 MPA | Fornece excelente rigidez e integridade estrutural |

Absorção de água | < 0.1% | Tem um bom desempenho em ambientes úmidos ou úmidos |

Retardância da chama | Ul94 v-0 Avaliado | Seguro para sistemas elétricos e fechados |

Resistência química | Resiste a ácidos, bases, e solventes | Adequado para ambientes quimicamente severos |

Maquinabilidade | Abrasivo, mas compatível com CNC | Permite fabricação precisa de peças complexas |