TOPS is A One-Stop Solution for Zinc Die-Casting

15+Years Experience | 0.010 milímetros Tolerance | 10 Dias | 100% Satisfaction Guaranteed |

We focus on high-precision zinc die casting service, helping our customers get the parts they need with their specific requirements and short time frames. We have state-of-the-art machinery and are staffed by qualified and trained personnel ready to meet your industry requirements worldwide.

15+Years Experience | 0.010 milímetros Tolerance | 10 Dias | 100% Satisfaction Guaranteed |

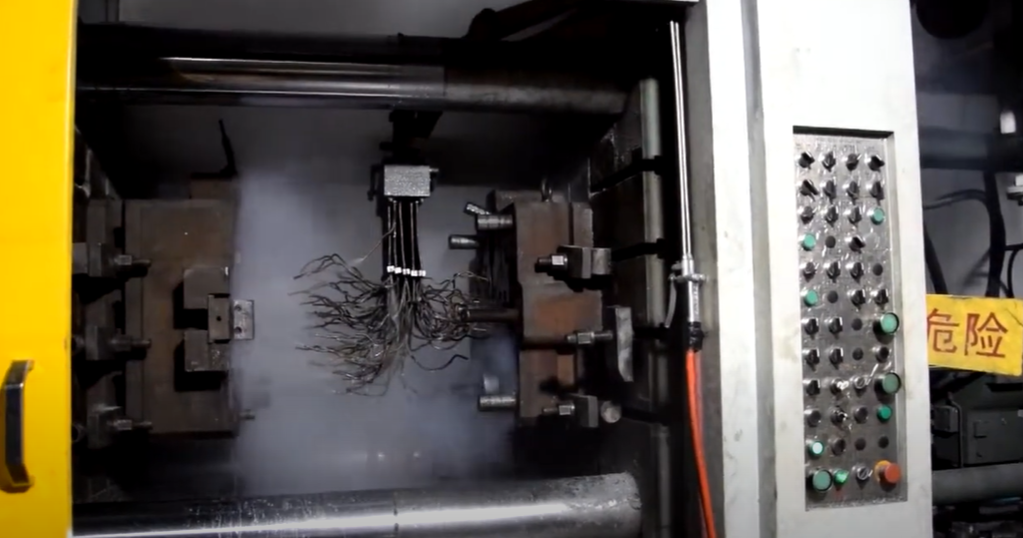

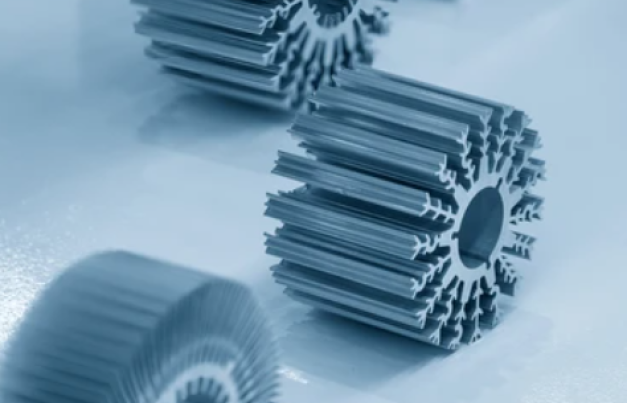

Zinc die casting is a technique of direct injection of molten zinc alloy into a die or mold to produce close tolerance fine metal parts. This manufacturing process is suitable for making sharply defined components of high strength and good surface finish. Among all the conventional die-casting materials, Zinc has been found to qualify fully for the die-casting process. It has a low melting point, high flowability, and sound mechanical properties.

Common alloys: os fardos 3, os fardos 5, and Zamak 7 Zinc die casting alloys.

Here are some of the important facts about why you must choose Zinc die-casting services from TOPS Precision:

At TOP Precision, we have a variety of zinc die-casting alloys to suit various industrial necessities. Every type of alloy has a characteristic that recommends it for use in a particular application – structural parts that require high strength, coatings that must resist corrosion, and so forth. This table also shows the prominent characteristics of widely employed zinc die-casting alloys, guaranteeing that our customers are given the best possible material for their projects.

Liga | Propriedades | Formulários |

os fardos 2 | Maior força, suitable for gravity casting | Replaces bushings; wear-resistant parts |

os fardos 3 | Balanced strength and castability | Standard for general-purpose die-casting |

os fardos 5 | Stronger and harder than Zamak 3 | Widely used in Europe, durable applications |

os fardos 7 | High purity, improved fluidity, and finish | Precision components, aesthetic finishes |

ZA8 | Higher aluminum, hot-chamber compatible | High-strength parts needing hot-chamber casting |

ZA12 | Hard, forte, resistente à corrosão | Automotive and heavy-duty parts |

ZA27 | High aluminum, forte, resistente ao desgaste | High-load parts like gears, automotive components |

os fardos 8 | Stability at high temp/pressure | Parts for high-temp/high-pressure environments |

ACuZinc5 | Very strong, moderate corrosion resistance | Automotive and industrial, high-load capacity |

ZL27 | Good machinability and corrosion resistance | Machined parts like gears |

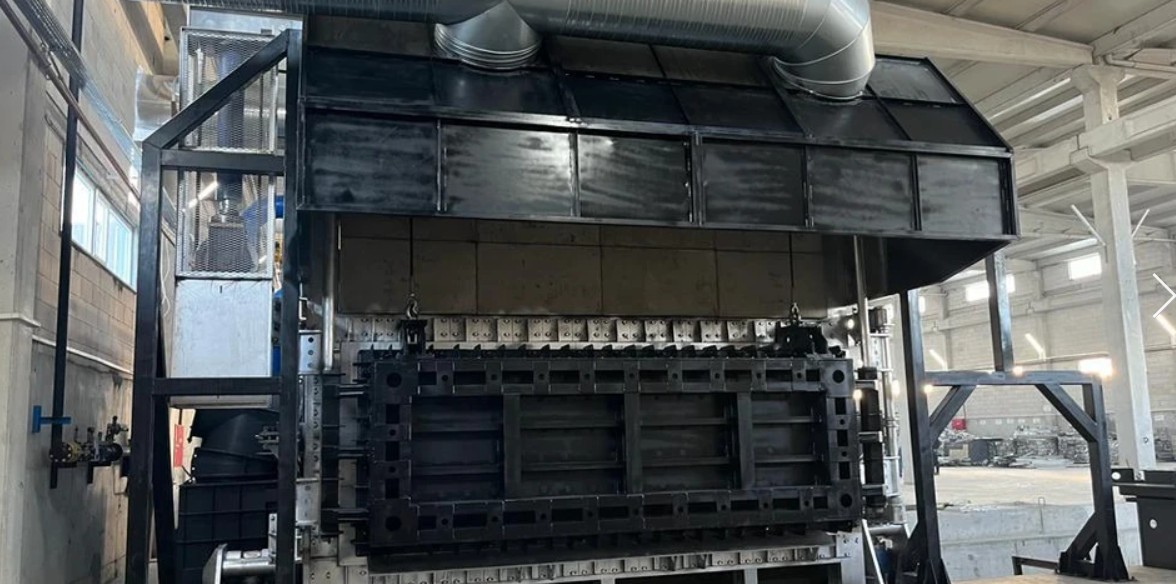

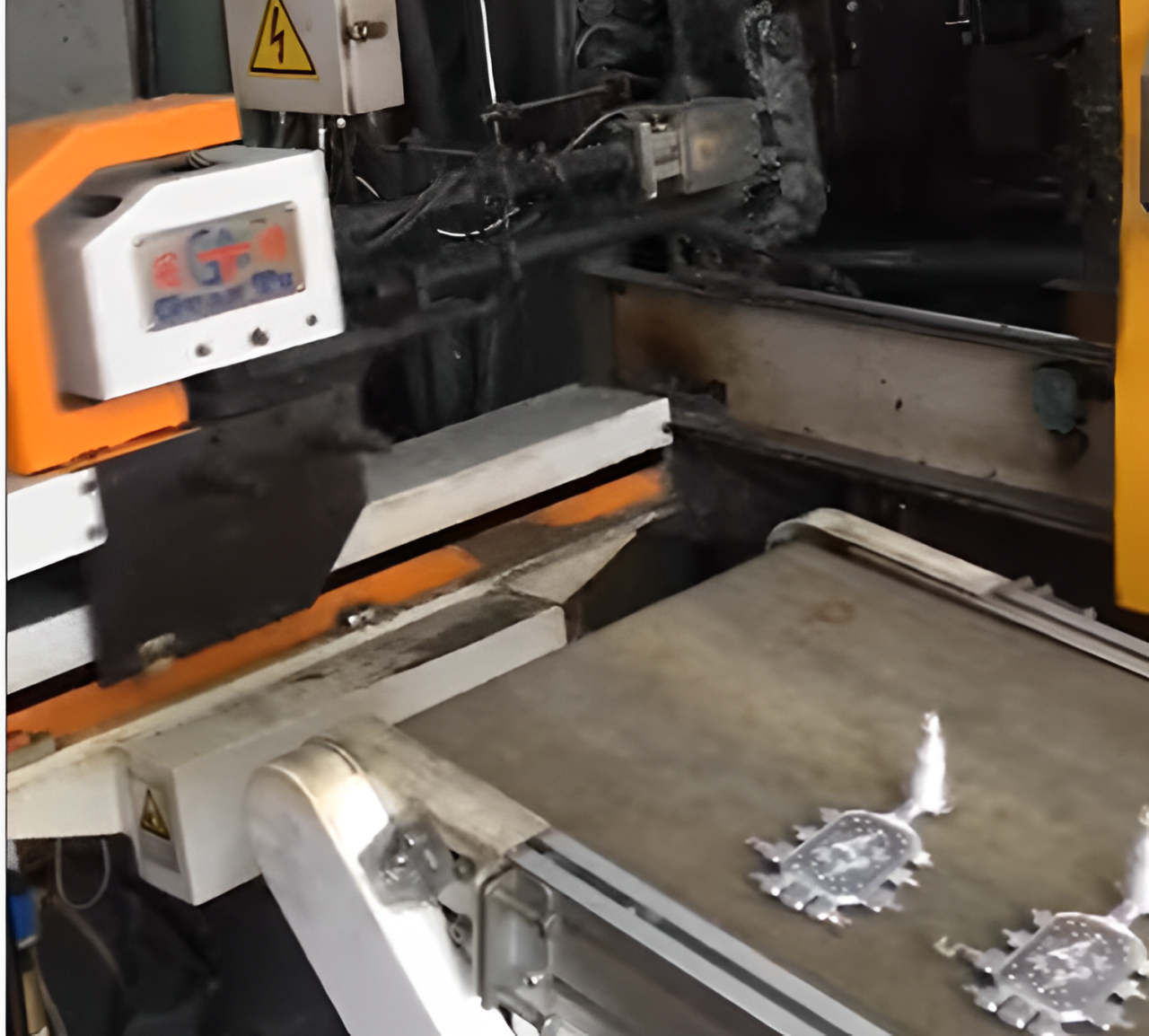

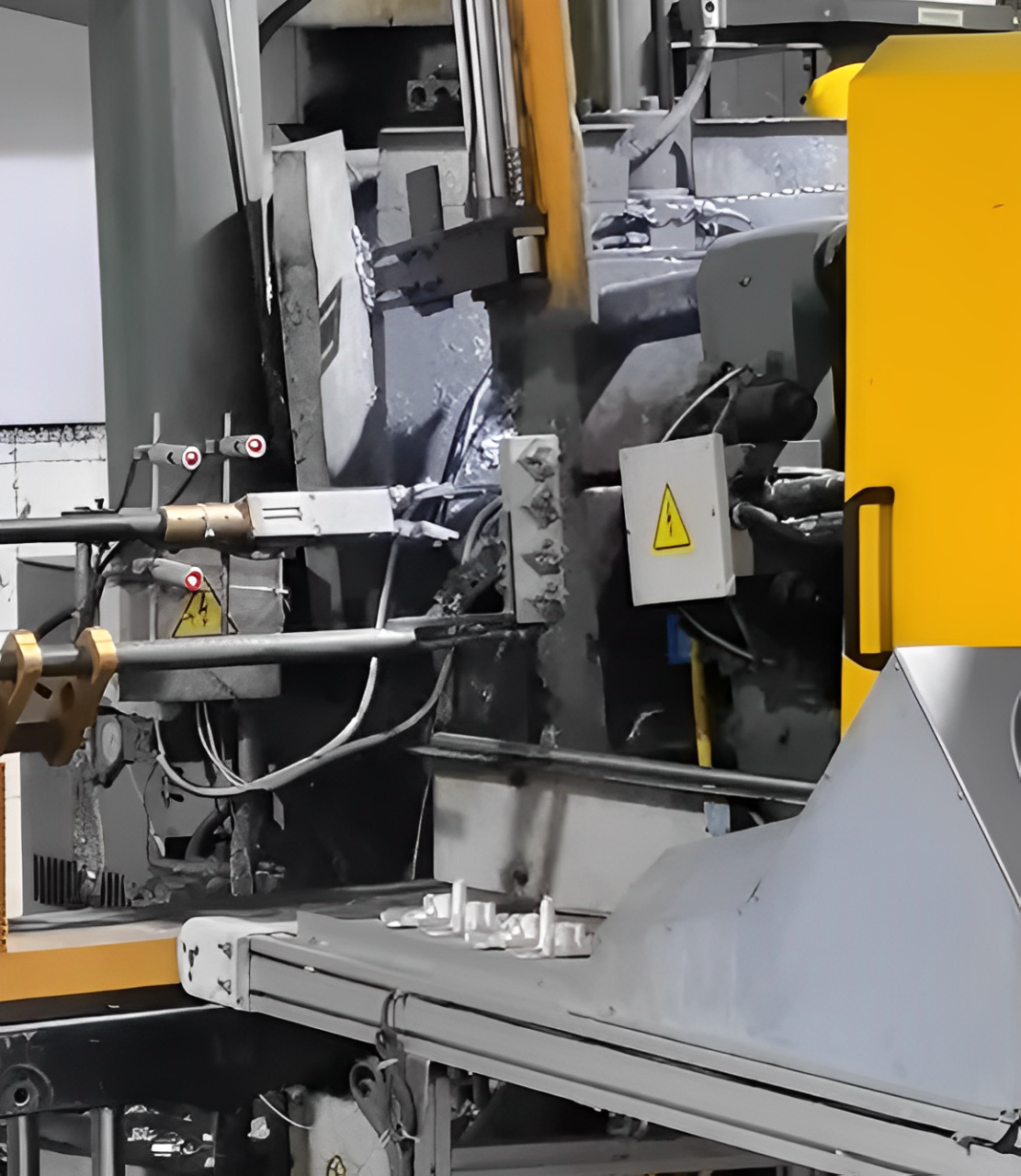

Zinc Die Casting at TOP Precision addresses your manufacturing requirement with assured precision that matches your expectations. State-of-the-art equipment is installed in our facility to guarantee clear visibility to our customers throughout the process.

Diverse Offerings Também, we use a large range of Zinc Alloys and provide excellent surface finishes, close dimensions, and value-added production. Because our equipment and the people we hire possess the necessary skills and experience, we are in a position to undertake simple and complex projects without developing a hitch. | Modern and Strong Facility With the expert knowledge of our staff and the amenities provided by our plant, we are able to work on any production big or small. Whether producing in small batches or for large orders, we achieve the former while keeping the latter close at hand. De fato, intricate zinc die castings are catered for in their entirety. |

Adherence to Quality Standards TOP Precision is an ISO 9001 e ISO 13485 Empresa, por isso, we give a high priority to quality and accuracy. All the stages of production are critically examined by our staff to ensure optimum performance. | Quick quoting & order tracking Our online quote system includes all modern technologies to provide you with fast and troubleless quotes. You are able to monitor the location of your orders and the manufacturing process, which is fully open at any stage. |

TOPS Precision offers zinc die-casting services to manufacture precise parts and components for the automotive, eletrônicos, aeroespacial, e indústrias médicas. Die casting and machining do not only involve technological advancement but also integrate high precision to offer quality and durability of all parts. This type of construction delivers dependable solutions that are adapted to the exact requirements of every industry because our design and engineering are done in-house. Please do not hesitate to drop us a call for more details on the zinc die casting, you have in mind, or you could call us to enable TOPS. Então, we can sum up the uses in the following way:

Contact us today for more information on our precision zinc die-casting services, or call us and let TOPS Precision be your trusted partner for zinc die-casting solutions.

Finalmente, zinc die casting is the process of using casting dies to inject molten zinc to produce strong, accurate parts, suitable for complicated profiles.

They include Zamak (3, 5, 7) and ZA (8, 12, 27) alloys which were selected with regards to strength, resistência à corrosão, and the quality of nickel finish.

Durability and precision make automotive, eletrônicos, médico, industrial parts, and consumer products favorable for zinc die casting.

Our company boasts of accuracy, where we maintain tolerances of ± 0.004 polegadas, qual é 0.1 millimeters for these specialized fixtures.

We specialize in hot chamber, cold chamber gravity die casting, and centrifugal die casting.

Of course, we provide OEM/ODM services according to your requirements.