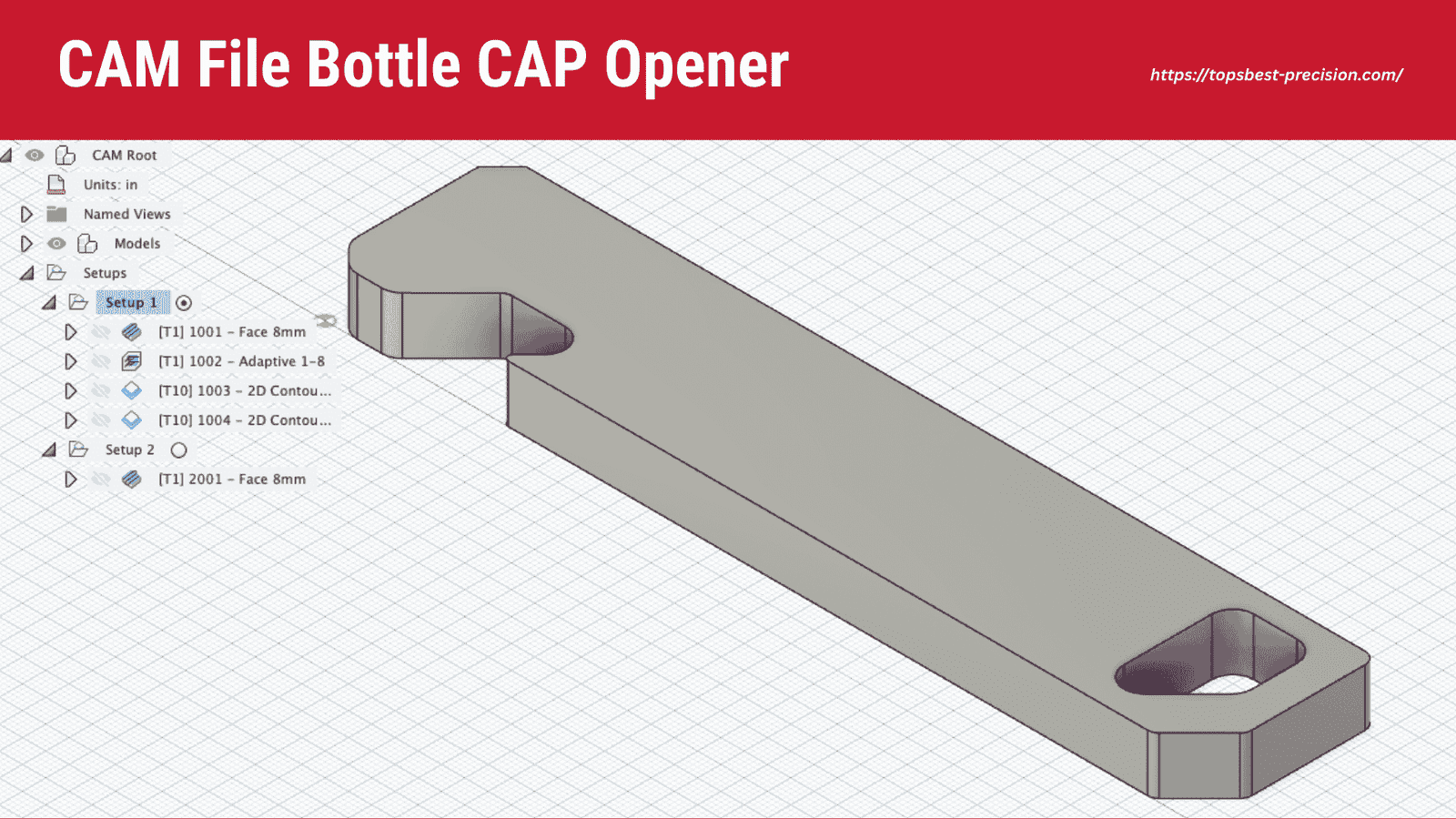

Folga inferior da cavidade

Um segundo bolso remove o produto abaixo da tampa. Isto permite a redução de peso sem fazer cortes profundos em seções de massa. A profundidade é controlada em etapas para proteger a ferramenta e o material. Para evitar trocas de ferramentas e manter o alinhamento, usamos o mesmo bit.

As taxas de alimentação são adaptadas ao tipo de madeira e à profundidade final. Isso mantém o cortador funcionando perfeitamente acima e abaixo de todos os níveis. Os caminhos de liberação estão confinados dentro do limite da tampa. Isso mantém a inserção no lugar e dá espaço suficiente para caber facilmente.

Operações de furo piloto

Fazemos furos piloto para inserir pinos e fixadores. Eles são inseridos por percursos de perfuração de profundidade e espaçamento fixos. Os furos são combinados ao configurar o modelo para evitar qualquer desvio durante o trabalho.

Empregamos a mesma fresa usada para perfurar esses pontos. Elimina a necessidade de uma segunda ferramenta e simplifica o processo. A posição e a profundidade são monitoradas durante a simulação para evitar corte excessivo.

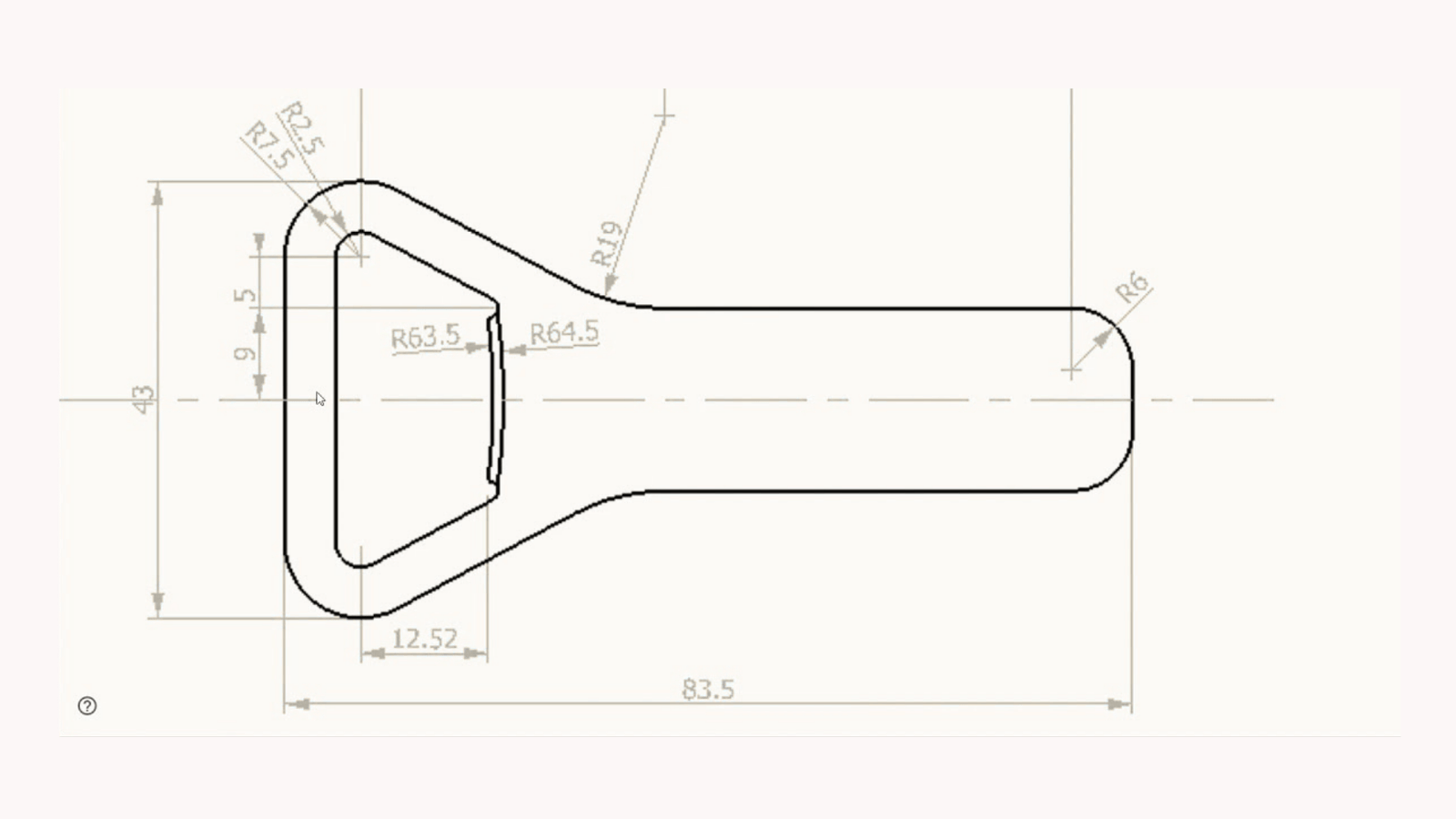

Contorno de perfil externo

A forma final é cortada por um caminho de contorno. Este percurso segue toda a aresta externa e corta o manipulador para fora do bloco. Um deslocamento de profundidade foi aplicado para fornecer separação total da base.

Usamos guias de retenção ao redor do contorno da forma. Essas abas evitam o movimento durante o corte e estabilizam a peça. Cada um é adicionado de acordo com o tamanho do modelo e comportamento do material. As guias são perfuradas, e a borda está completa. O corte de contorno proporciona um perímetro limpo que já segue o formato original do modelo.