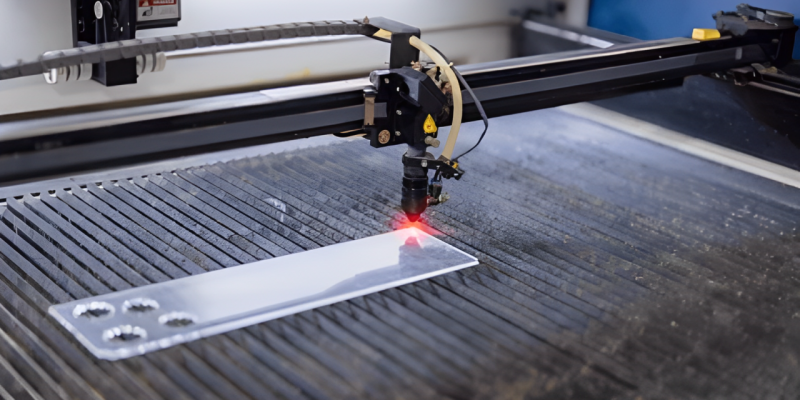

Corte a laser de fibra

O corte a laser de fibra é um processo altamente preciso destinado a cortar metal, como aço inoxidável, Aço carbono, e alumínio. A vantagem da utilização de alta energia e focalização dos feixes a laser levou à formação de obras de arte detalhadas e bordas bastante nítidas das formas projetadas. Este método é apropriado para fabricação de alta velocidade e, Assim, adequado para uso em indústrias que envolvem a fabricação de metais de alta velocidade.

Envie sua pergunta hoje