射出成形部品の表面仕上げは単なる後付けではありません; これは、製品の美的魅力と機能的パフォーマンスの両方を決定する重要なデザイン機能です。. 適切な仕上げを選択するには、材料特性を深く理解する必要があります, ツールの制限, および部品の意図された最終使用環境. 望ましい結果を達成するには, 設計エンジニアと射出成形機の間の早期かつ継続的なコミュニケーションが最も重要です.

表面仕上げの重要な役割: 美的 vs. 関数

高光沢ポリッシュであれ深いマットな質感であれ、特定の仕上げを適用する決定は、明確に定義された目標に基づいて決定される必要があります。. 仕上げが主に視覚的な目的に役立つのか、それとも実用的な目的に役立つのかという答えが、その後のすべての成形と工具の決定に役立ちます。.

あ. 審美的な利点 (視覚的な魅力)

テクスチャ仕上げは、視覚的な向上と欠陥の軽減のための強力なツールです。:

認識される価値と深さ: Textures can give a part a sense of depth, sophistication, and a premium, finished look, subtly increasing its perceived value to the customer.

Hiding Cosmetic Imperfections: Texturing is highly effective at concealing a wide range of common flow and molding defects that would be highly visible on a polished surface, 含む:

Flow Lines & Knit Lines: Streaks or weak areas where plastic flow fronts meet.

Blush Marks: Localized discoloration or dullness.

ヒケ & Shadow Marks: Depressions caused by localized shrinkage in thick sections.

Handling and Durability: A textured finish provides a robust surface that is less prone to scratching during shipping and handling, and successfully hides fingerprint smudges and minor surface wear over the product’s lifespan.

B. 機能的な利点

Beyond appearance, surface finish provides several tangible functional advantages:

Improved Mold Release (アンダーカット): Strategically placed texture, particularly on hidden surfaces or internal features, can encourage the part to consistently pull to the desired side of the mold (typically the moving half) due to increased friction, aiding in effective mold release, especially near minor undercuts.

Enhanced Adhesion: Textured surfaces dramatically improve the bonding capabilities for secondary operations:

Paint: The micro-roughness provides a mechanical anchor, allowing paint to adhere more firmly and resist flaking.

Stickers/Labels: 同様に, textured surfaces increase the surface area and friction necessary for labels and decals to remain securely affixed.

Ergonomics and Safety (グリップ力の向上): In consumer or industrial applications where the part is handled (例えば, ツール, equipment casings), texture provides a non-slip surface, improving grip, usability, そして安全性.

Processing Aids (Gas Venting): The creation of a textured surface can increase the surface area and provide micro-channels within the cavity, allowing trapped gases to escape more quickly through the parting line, potentially reducing burn marks and short shots.

C. 決断のタイミング

Due to the cascading impact on material selection, ツーリングの複雑さ (そしてコスト), and processing parameters, the surface finish must be determined as early as possible during the 製造可能性のための設計 (DFM) stage.

2. 表面仕上げのオプションと工具の制限

The range of achievable surface finishes is inherently linked to the material used to build the mold itself.

Steel vs. アルミ金型: Steel molds offer vastly superior resilience to polishing and texturing processes. Due to its hardness, steel can be highly polished to achieve mirror-like finishes or etched with deep, complex textures (例えば, leather grains, geometric patterns). アルミニウム, being softer, is typically limited to simple finishes and cannot hold extremely high polishes or intricate textures long-term.

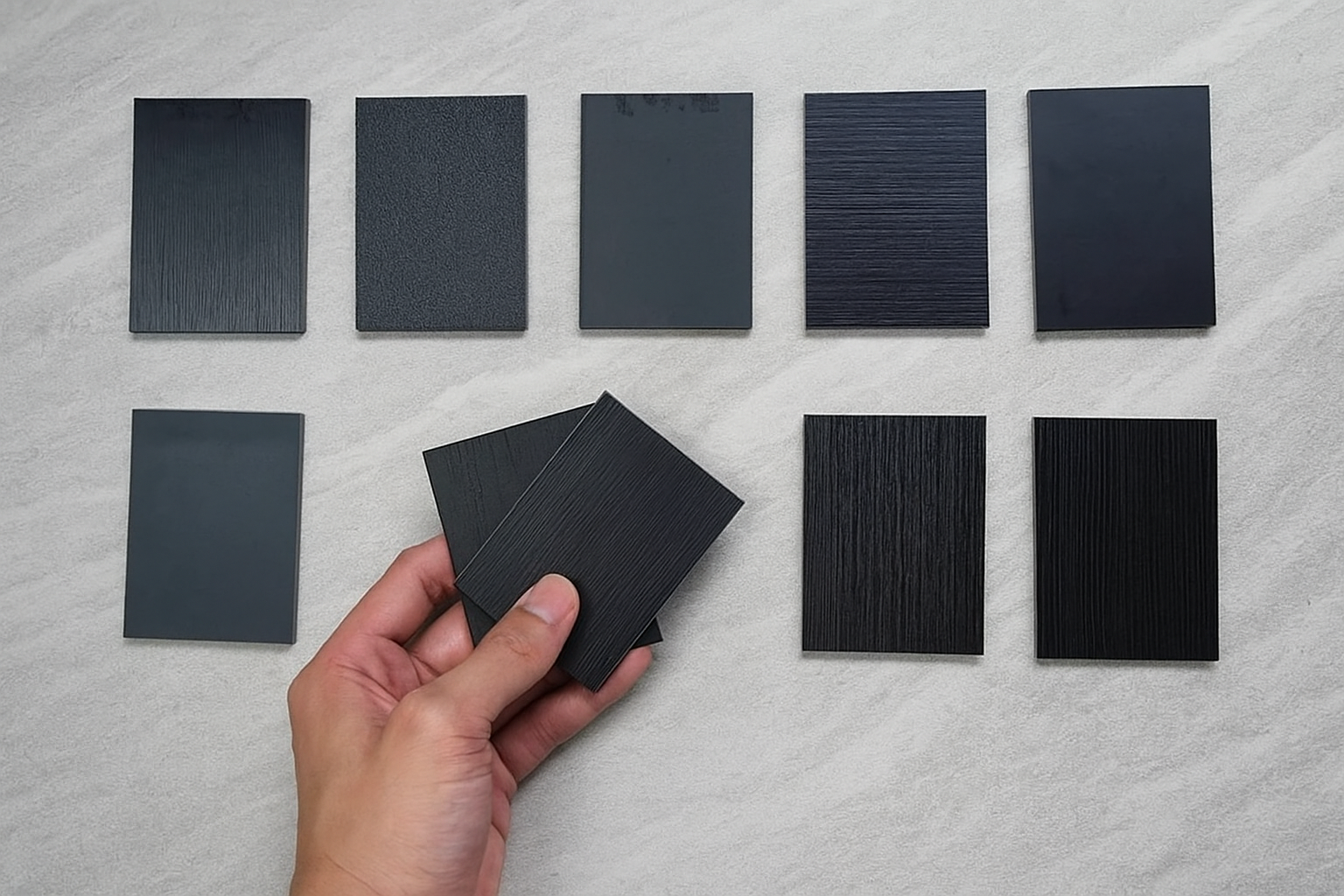

Common Finish Types: The industry often uses SPI (Society of the Plastics Industry) 基準, ranging from A-1 (mirror polish, highest gloss) down to D-3 (dull sandblast, highest roughness). Beyond SPI, custom finishes include:

ビーズブラスト (Matte Finish)

Chemical or Laser Etching

Leather Grains and Wood Textures

Geometric and Graphics Patterns

3. 材料選択の影響

The chosen resin interacts physically with the mold surface, meaning the material type has a significant and non-negotiable impact on the final surface quality, particularly gloss and roughness.

Crystalline Resins (例えば, ナイロン, PE, PP): These resins tend to contract more upon cooling and have a structured, ordered internal geometry. To achieve a smoother, high-gloss finish, they often require higher melt temperatures そして higher mold temperatures. This ensures the plastic remains fluid against the mold wall long enough to replicate the polished surface before solidification, increasing gloss and reducing surface roughness.

Amorphous Resins (例えば, パソコン, ABS, PS): These resins are generally easier to get a high gloss on because their contraction is less significant and more uniform, and they tend to replicate the mold surface more faithfully, even at slightly lower temperatures.

Additive Compounds: The inclusion of fillers must be carefully managed. Adding certain particulate fillers (例えば, glass fibers, mineral fillers) will invariably increase the final part’s surface roughness, often making a mirror finish impossible. Design engineers must utilize their knowledge of material science to select compatible additive packages that maintain or enhance the desired surface quality (例えば, using specialized flow promoters to offset roughness caused by fibers).

Simulation Software: Mold flow simulation is crucial here, as it allows designers to explore how different resin choices (and their associated shrinkage rates) will affect the surface finish and potential for defects like warp or sink marks, 前に committing to tooling.

4. 射出速度と温度の影響

The processing parameters—specifically how fast and how hot the plastic is injected—are the final tools used to fine-tune the surface finish.

Enhancing Gloss and Smoothness: A combination of fast injection speeds そして higher melt or mold temperatures typically enhances gloss and smoothness.

Increased Speed: A fast injection speed improves the gloss because the molten plastic fills the cavity quickly, generating heat through shear action which keeps the surface layer molten longer. This allows the material to conform perfectly to the mold surface before freezing.

Increased Temperature: A higher melt or mold temperature ensures the polymer’s outer layer remains above its glass transition or crystallization temperature longer, allowing for better surface replication.

Reducing Weld Lines: Quick and robust cavity filling, achieved through optimized speed, also minimizes the visibility of weld lines. By filling the mold cavity quickly, the two converging flow fronts meet while they are still hot and highly fluid, facilitating better molecular entanglement and diffusion, leading to a stronger and aesthetically superior weld.

結論

The surface finish is an integral consideration in the overall product development lifecycle. It is not just about choosing a texture from a sample book, but a strategic decision that impacts tooling cost, 材料の互換性, and overall product performance. By determining the surface finish early in the design phase and considering the end-use requirements—whether that is maximizing grip, hiding manufacturing flaws, or achieving a high-end aesthetic—manufacturers can achieve predictable, high-quality results from their injection molding process.

よくある質問

Q1: SPI表面仕上げ規格とは何ですか, そしてなぜそれが使われるのか?

あ: The SPI (Society of the Plastics Industry) surface finish standard is a set of defined benchmarks for mold cavity finishes, ranging from high-gloss polished surfaces (A-1, A-2, A-3) to various grades of matte, sandblasted, or stoned finishes (B, C, D grades). This standard is used to create a universal language between designers, mold makers, and molders, ensuring that everyone is referencing the same precise level of surface quality without ambiguity.

第2四半期: テクスチャ仕上げは「離型」または「アンダーカット」にどのように役立ちますか?

あ: Strategically placed texture, often on the non-critical or hidden surfaces of the part, increases the localized coefficient of friction. This increased friction encourages the part to pull toward the textured side of the mold (typically the side with the ejector pins or the moving half). For parts with minor undercuts, this controlled friction can ensure the part consistently stays on the moving half for proper ejection, preventing sticking or damage to the part or mold.

Q3: 結晶性樹脂で高光沢仕上げを実現するのが難しいのはなぜですか (ナイロンのような) アモルファス樹脂よりも (腹筋のように)?

あ: Crystalline resins are harder to gloss because they undergo a higher and less uniform volume change (収縮) during cooling compared to amorphous resins. As they cool, the polymer chains pack tightly into an organized crystalline structure, pulling away from the mold wall and reducing the fidelity of the surface replication. Achieving high gloss requires higher mold temperatures to slow down the cooling and allow the molten plastic to replicate the mold surface more fully before crystallization occurs.

Q4: デザインにテクスチャが必要な場合, それは必要な「抜き勾配角度」にどのように影響しますか?

あ: A textured finish always requires a greater draft angle than a smooth or polished finish. The depth of the texture acts as an undercut resistance during ejection. The rougher and deeper the texture (例えば, a heavy leather grain), the more angle is needed (頻繁 3 に 5 degrees or more per 0.001 inch of texture depth) to ensure the textured peaks and valleys clear the mold wall without dragging, scuffing, or damaging the part surface during release.

Q5: 表面の光沢を向上させるために非常に速い射出速度を使用することの主な欠点は何ですか?

あ: While increasing injection speed often improves gloss and reduces weld line visibility, the main downside is the risk of shear heating and resulting material degradation or burning. Excessively fast injection generates significant heat due to friction (shear) as the plastic rubs against the mold walls. If venting is poor, this heat can scorch the material, につながる Burn Marks (black streaks) or cause the polymer to degrade, which compromises the part’s mechanical strength.