今日の動きの速い製造業界で, 過剰な重量を発生させずに強度を実現する材料への需要がこれまで以上に高まっています. 軽量金属はこのトレンドの最前線にあります, より燃料効率の高い製品の設計が可能になります, エネルギーを意識した, そして製造が容易になる. 航空宇宙部品から家庭用電化製品まで, これらの素材は、エンジニアやメーカーが製品設計について考える方法を形作っています。.

このガイドでは、軽量金属とは何かについて説明します。, 彼らのさまざまなタイプ, 主な利点, 課題, および産業用途.

軽量金属の種類とは何ですか?

軽量金属は一般に、次のような金属として定義されます。 低密度 でも十分 強さ, 耐久性, そして抵抗 要求の厳しい環境で役立つために. 以下は最も広く使用されているオプションです.

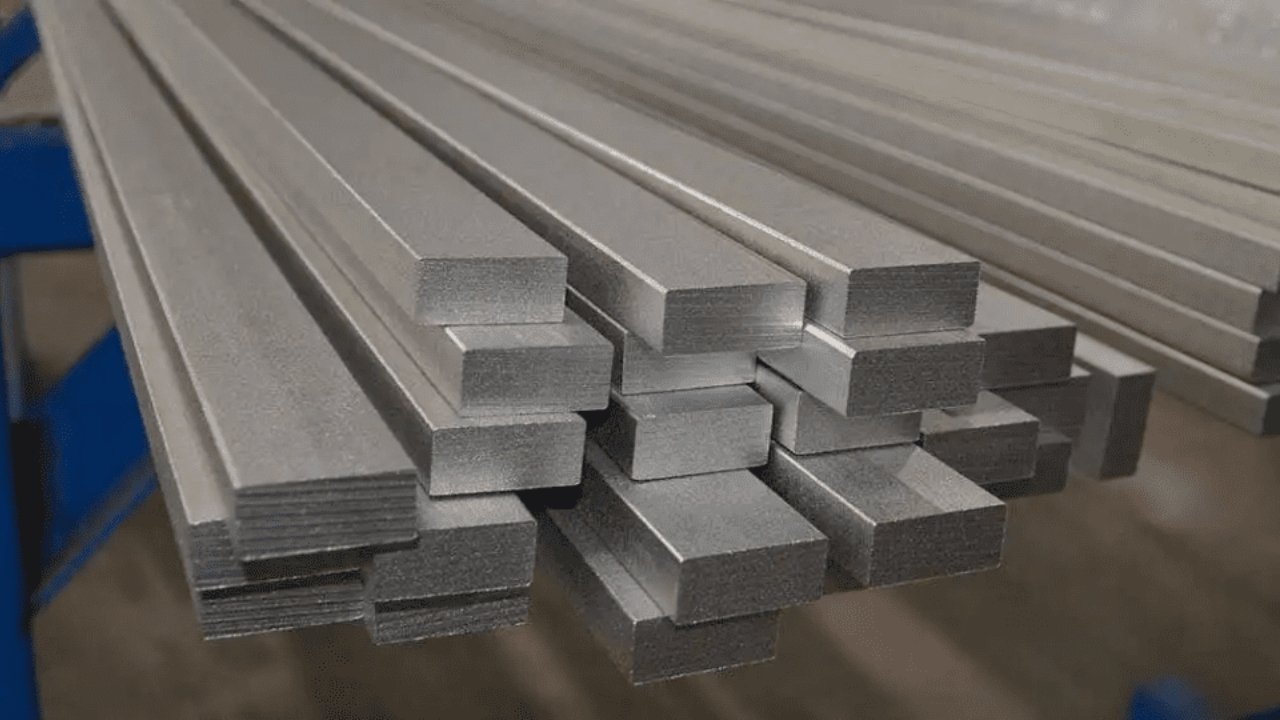

1. アルミニウムおよびその合金

密度: ~2.7 g/cm3 (鉄の約3分の1).

主要なプロパティ: 高い腐食抵抗, 優れた加工性, 熱伝導率と電気伝導率.

合金:

6061 アルミニウム (マグネシウム + シリコン) →強い, 延性のある, 耐食性.

7075 アルミニウム (亜鉛系) →とても強い, 航空宇宙や防衛でよく使用されます.

製造方法: 鋳造, 押し出し, ローリング, そして機械加工.

アプリケーション: 航空機の胴体, 自動車部品, 熱交換器, 飲料缶, そして建築資材.

なぜアルミニウムなのか?

コストとのバランスが優れています, 体重減少, および汎用性. リサイクル性も高い, 経済的かつ持続可能なものにする.

2. マグネシウム合金

密度: ~1.7 ~ 1.8 g/cm3 (最軽量の構造用金属).

主要なプロパティ: 非常に低い密度, 適度な強さ, 優れた振動減衰, 高い加工性.

制限事項:

保護されていない場合は腐食する可能性があります.

加工中に可燃性の切粉や粉塵が発生する, 慎重な安全管理が必要.

アプリケーション:

自動車→エンジンブロック, トランスミッションハウジング, 車輪.

消費財 → ノートパソコン, カメラ, 自転車フレーム, スポーツ用品.

なぜマグネシウムなのか?

構造用金属の中で最も軽いものです, 極端な軽量化が必要な場合に最適です. しかし, 耐食性と耐久性を向上させるために、追加のコーティングや合金化が必要になることがよくあります。.

3. チタンとその合金

密度: ~4.5 g/cm3 (アルミニウムより重い, しかし、はるかに強い).

主要なプロパティ:

優れた耐食性 (特に海洋環境や化学環境では).

高い強度重量比.

高温下でも優れた性能を発揮 (~550℃まで強度を維持).

課題:

硬くて熱伝導率が低いため、機械加工が難しく高価です.

原材料費が高い.

アプリケーション:

航空宇宙 → ジェットエンジン, 着陸装置, 機体.

医療→インプラント, 手術器具.

海洋→海洋構造物, 船舶のコンポーネント.

なぜチタンなのか?

アルミより重いですが, チタンは優れた強度と耐食性を備えているため、重要な用途に最適です。, 安全性と耐久性が不可欠な高性能アプリケーション.

軽量金属の比較

| 財産 / 特徴 | アルミニウム | マグネシウム | チタン |

| 密度 (g/cm3) | ~2.7 | ~1.7~1.8 | ~4.5 |

| 相対的な重み | 中くらい (鋼鉄より軽い) | 最軽量の構造用金属 | アルミより重い, 鋼鉄より軽い |

| 強度重量比 | 良い | 適度 | 素晴らしい |

| 耐食性 | 高い (特にコーティングの場合) | 低から中程度 (保護が必要です) | 非常に高い (特に海洋環境や化学環境では) |

| 被削性 | 良い, ただし熱伝導率を高めるために冷却が必要 | 機械加工が容易, でも粉塵は燃えやすい | 難しい, 特別な工具と冷却が必要です |

| 熱伝導率 | 高い | 適度 | 低い |

| リサイクル性 | 素晴らしい | 良い | 限定 (リサイクルするにはエネルギーを大量に消費する) |

| 料金 (相対的) | 低い (予算に優しい) | 中程度から高程度 | 高い (最も高価な) |

| 一般的なアプリケーション | 自動車, 航空宇宙, 工事, エレクトロニクス | 自動車部品, スポーツ用品, 電子機器の筐体 | 航空宇宙, 医療用インプラント, 海洋, 防衛 |

| 主な利点 | コスト効率が高く多用途 | 最軽量 | 最も強くて耐久性のある軽量金属 |

プロジェクトに軽量金属を選択する理由?

軽量金属は単に重量を減らすだけではありません; 幅広い機能上の利点を提供します.

耐食性

例: チタンは海水腐食に強い, 海洋工学に欠かせないものとなっています.

耐久性と頑丈さ

体重が軽いにもかかわらず, マグネシウムやチタンなどの金属は、重荷重や過酷な使用条件に耐えることができます。.

高い強度重量比

この特性により、設計者は強度を維持または向上させながら質量を減らすことができます。.

自動車設計で, より軽い金属は燃料消費量と排出ガスを削減します.

リサイクル性

アルミニウムとマグネシウムは、特性の損失を最小限に抑えてリサイクルできます。, 循環型製造をサポートし、環境フットプリントを削減する.

熱特性

アルミニウムは熱伝導性に優れている → 熱交換器や電子機器の冷却に有用.

低い熱膨張により、高温用途での寸法安定性の維持に役立ちます.

軽量金属を選択する際の重要な考慮事項

適切な軽量金属の選択は複数の要因に依存します:

機械的および熱的特性

アルミニウム → 加工性良好, 高い導電性.

マグネシウム→非常に軽い, ただし保護コーティングが必要.

チタン→最強で耐久性抜群, 高ストレスおよび高温環境に最適.

持続可能性と環境への影響

リサイクル可能性と二酸化炭素排出量を考慮する.

マグネシウムとアルミニウムはリサイクル性が高い; チタンは製造にエネルギーを大量に消費します.

予算の制約

アルミニウム 一般的には最もコスト効率の高い選択です.

マグネシウム 軽量ですが、安全に処理するにはコストがかかります.

チタン 最も高価ですが、特殊なアプリケーションでは比類のないパフォーマンスを提供します.

申請要件

航空宇宙 → 強度と耐疲労性を優先 (チタン, 高強度アルミニウム).

自動車 → コストと軽量化のバランス (アルミニウム, マグネシウム).

エレクトロニクス → 軽量かつ導電性 (アルミニウム, マグネシウム合金).

軽量金属の使用における課題

軽量金属には明らかな利点がありますが、, メーカーはいくつかの課題に対処する必要がある:

材料廃棄物: 精密加工なし, 過剰なスクラップはコストを押し上げる可能性があります.

加工難易度:

チタンには特別な工具と冷却システムが必要です.

マグネシウムの加工では火災の危険性を考慮する必要がある.

アルミニウムは伝導率が高いため、熱管理が必要です.

原材料費が高い: チタンとマグネシウムの合金はプロジェクト全体の予算を大幅に増加させる可能性があります.

特別な処理が必要な場合: コーティング, 熱処理, 保護層は複雑さとコストを追加します.

軽量金属の応用

軽量金属はあらゆる業界で不可欠です:

航空宇宙: 航空機の胴体, 着陸装置, ジェットエンジン部品.

自動車: ボディパネル, 車輪, 燃費を向上させるエンジン部品.

医学: 外科用インプラント, 補綴物, および医療機器.

スポーツ用品: ラケット, 自転車, ヘルメット, パフォーマンスギア.

家電 & 3C製品: ラップトップ, スマートフォン, カメラ, そして三脚.

工事: ウィンドウフレーム, カーテンウォール, 屋根材.

電気 & エネルギー: 伝送線路 (アルミニウム), バッテリーハウジング, ソーラーフレーム.

マリン: 海洋石油プラットフォーム, 船の部品, 耐食性コンポーネント.

軽量素材の未来

軽量金属と材料の未来は非常に明るい. 航空宇宙のような産業として, 自動車, そしてエレクトロニクスは成長し続けます, 軽量化への要求, より強い, そして環境に優しい材料はさらに強くなるばかりです.

すでに大きな変化が起きています:

電気自動車 1回の充電でより遠くまで移動するには、軽量のフレームとバッテリーハウジングが必要です.

飛行機 より高度なアルミニウムを使用しています, マグネシウム, 燃料を節約し、排出ガスを削減するチタン合金.

家電 スマートフォンやノートパソコンが強度を損なうことなく薄く、軽くなっているように, 新しい材料設計のおかげで.

もう 1 つのエキサイティングなトレンドは、 複合材料 (金属とカーボンファイバーの混合物, セラミックス, またはポリマー). これらは多くの場合、金属単独よりも優れたパフォーマンスを実現します。.

その上, リサイクル技術は向上しています. 将来, アルミニウムを再利用するのが簡単で安価になります, マグネシウム, そしてチタンさえも. つまり無駄が減ります, 低コスト, より環境に優しい生産.

簡単に言うと, 軽量素材の未来がすべてです:

軽量化 (効率の向上のために).

強くなる (厳しい状況に対処するために).

より環境に優しいものになる (リサイクルと持続可能な生産を通じて).

それで, 車をデザインしているかどうか, 飛行機, あるいは医療機器さえも, 軽量の金属と材料は、製品をよりスマートにする上で大きな役割を果たすことになる, もっと早く, そして地球にとってもより良い.

結論

軽量金属は現代工学の中心です, 低密度の組み合わせを提供, 強さ, 耐久性により、あらゆる業界で非常に価値のあるものになります. 輸送における燃料消費量の削減が目標かどうか, 過酷な環境での耐久性を向上, または消費者向け製品のパフォーマンスを向上させる, 軽量金属は競争力をもたらします.

アルミニウムの選択, マグネシウム, チタンは依存します 予算, パフォーマンス要件, と持続可能性の目標. 加工の難しさやコストの高さなどの課題はあるものの、, 軽量金属の利点はその限界をはるかに上回ります.

よくある質問

- 軽量金属は部品設計にどのような影響を与える可能性がありますか?

材料の使用量を削減できます, より複雑な形状, 設計の柔軟性が向上しました, 構造上の完全性を維持しながら. - どちらが軽いですか: アルミニウムまたはチタン?

アルミの方が軽い. チタンは密度がほぼ 2 倍ですが、優れた強度を備えています. - 製造に最も安くて軽い軽量金属はどれですか?

アルミニウムは最も手頃な価格の軽量金属です, マグネシウムは構造用金属の中で最も軽いですが、.

続きを読む:

私たちのへのリンク CNC加工サービス

フォームフリーミングエッセンシャルユーザープラクティスガイド