ポリテトラフルオロエチレン (PTFE), そのブランド名で最もよく知られている テフロン, 世界で最も耐薬品性と熱安定性のあるプラスチックの 1 つ. このフッ素ポリマーは、航空宇宙、製薬から食品加工、エレクトロニクスに至るまで、要求の厳しい業界全体で優れたパフォーマンスを提供します。. 機械的特性は他のエンジニアリングプラスチックに匹敵しないかもしれませんが、, テフロン加工 低摩擦を必要とするカスタムコンポーネントを製造するための実用的なソリューションです, 高耐熱性, そして不活性さ.

このガイドでは、PTFE の特性を詳しく説明します。, 機械加工の利点と課題, 適切な用途, ツーリングのヒント, および代替材料.

テフロンとは (PTFE)?

テフロンはテトラフルオロエチレンを重合して作られる合成フッ素ポリマーです。 (TFE). 最初に偶然発見されたのは、 1938 デュポン社製, 化学的には炭素原子とフッ素原子で構成されています, 有機化学において最も強力な結合の 1 つを形成する. このユニークな構造が PTFE に優れた化学的および熱的弾性を与えます。.

主要なプロパティ:

外観: 白, ワックス状固体

融点: ~327℃ (621°F)

化学式: (C₂F₄)ₙ

構造: フッ素原子に囲まれた炭素原子の直鎖

テフロンは:

疎水性: 水やほとんどの物質をはじきます

非反応性: 酸に対して非常に耐性がある, 基地, および溶媒

低摩擦: あらゆる固体の中で最も低い摩擦係数

熱的に安定: -260°C ~ 260°C で劣化することなく動作可能

テフロン加工のメリット

材料上の利点

テフロンの材料特性により、精密 CNC 加工に非常に役立ちます。:

耐薬品性: ほぼすべての工業用化学薬品に対して不活性

耐紫外線性と耐候性: 屋外暴露下でも特性を維持

耐水性: 自然な疎水性, 流体システムに最適です

電気絶縁: 広い温度範囲にわたって優れた絶縁耐力

熱安定性: 極低温および高温環境でも動作可能

低摩擦: 摺動部や回転部に最適

食品グレード: FDA準拠で滅菌が簡単

難燃性: 非常に低い可燃性

プロセスの利点

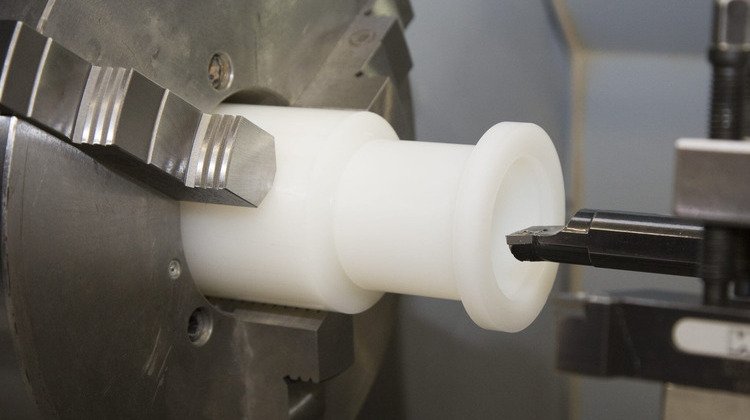

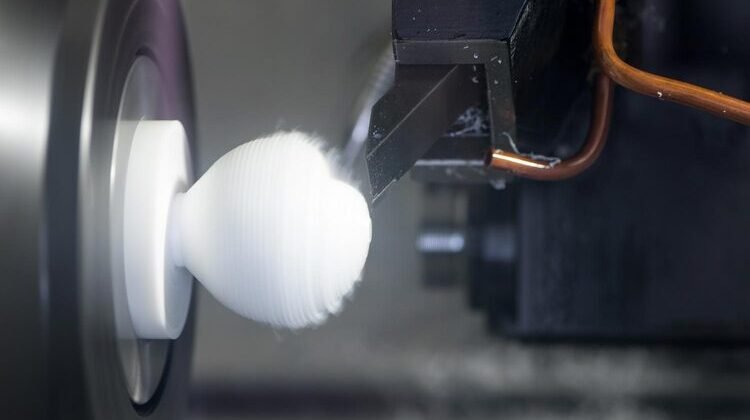

PTFE を機械加工すると、その柔らかさと機械加工性によりさらなる利点が得られます。:

容易に機械加工可能: 最小限の力で簡単にカットできます

熱変形なし: 乾式または湿式加工でも寸法安定性を維持

硬化は必要ありません: 加工後の熱処理が不要

プロトタイプに最適: 少量またはカスタムコンポーネントを迅速に生産

テフロン加工の限界

多くのメリットがあるにも関わらず、, テフロンの加工には特有の課題がいくつかあります:

高い熱膨張係数: 部品は他のプラスチックよりも膨張または収縮する可能性があります

クリープ変形: 長期にわたる機械的ストレスによりゆっくりと変形する傾向がある

許容差を維持するのが難しい: 特に薄い部分や小さな部分では

寸法安定性が悪い: 機械加工や後加工時に反りが発生する場合があります。

柔らかい素材: バリや工具跡が残る場合があります, 追加の仕上げが必要な場合

問題を最小限に抑えるには:

鋭利な工具を使用する

厳しい公差設計を避ける

効果的な冷却とバリ取り技術を採用

CNC 加工テフロン部品の一般的な用途

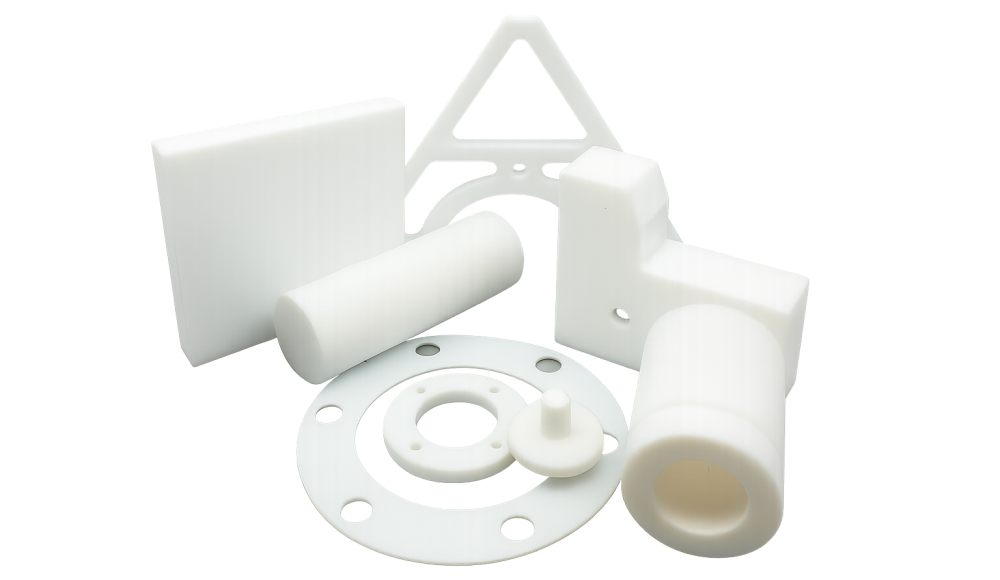

CNC加工 さまざまな産業で使用される固体 PTFE コンポーネントを製造するための好ましい方法です. 代表的な部品には次のようなものがあります。:

| 応用 | 例 |

| バルブ & 継手 | パイプシール, ワッシャー, 流量制御部品 |

| ベアリング & ブシュ | 低摩擦耐摩耗性コンポーネント |

| 絶縁 | 電気絶縁体, ケーブルスペーサー |

| 研究室のコンポーネント | 耐薬品性コネクタ, サンプルホルダー |

| 食品グレードの部品 | スクレーパーブレード, ノズル, シールプレート |

| 医療機器 | インプラント, 生体適合性チューブコネクタ |

| 航空宇宙 | 軽量ガスケットとシール |

| 半導体 | 不活性流体経路コンポーネント |

テフロン加工のヒントとベストプラクティス

PTFE を CNC 加工する際に最良の結果を得るには, 次のことを考慮してください:

ツーリング

使用 炭化物 または HSSツール 非常に鋭いエッジを持つ

シングルフルートまたは研磨フルートツールによりバリが軽減され、仕上がりが向上します

クーラントと潤滑

適用する 非芳香族, 水溶性冷却剤

スプレーミストまたは圧縮空気は、切りくずの除去と熱管理に効果的です。

速度とフィード

材料の溶解を防ぐために、適度な切削速度と高い送り速度を使用してください。

過度の工具圧力や熱の蓄積を避ける

バリ取りと仕上げ

サンディングを使用する, 極低温冷凍, または柔らかいバリを除去するための化学バリ取り

仕上げ前に部品を凍結すると、柔らかさと変形が軽減されます。

設計上の考慮事項

計画する 許容差を緩める (~±0.13mm) 部品の応力が軽減されていない限り

薄い壁や反りやすい繊細な形状は避けてください。

テフロンの代替材料

テフロンの制限が受け入れられないプロジェクトの場合, 以下の代替品は、強度または加工性が向上し、同様の利点を提供します。:

| 材料 | 主な利点 | 共通ブランド |

| PFA (ペルフルオロアルコキシ) | より良い非粘着性, より柔軟です | テフロンPFA |

| PCTFE (ポリクロロトリフルオロエチレン) | 水蒸気透過率が最も低い | ケル-F |

| エクフェ (エチレン クロロトリフルオロエチレン) | 優れた耐食性 | 出席 |

これらの材料はそれぞれ CNC 加工可能ですが、工具や取り扱いの要件が異なる場合があります。.

結論: 専門家による精密 PTFE 加工サービス

テフロン (PTFE) 耐薬品性が必要な厳しい環境に最適な材料です, 熱安定性, そして低摩擦. しかし, その柔らかさと寸法の不安定さは、 PTFE精密加工 慎重なアプローチと経験豊富なオペレーターが必要です.

カスタム テフロン コンポーネントのプロトタイプまたは量産を検討している場合, エンジニアリングプラスチックに精通したメーカーと提携. で 精度の高いトップ, 当社は、設計支援から最終品質検査まで、専門家のサポートを受けながら高度な PTFE CNC 加工を提供します。.

今すぐ私たちのチームにご連絡ください 無料の見積もりを入手したり、次のプロジェクトをどのように支援できるかを知るには.

よくある質問

1. テフロンを作るもの (PTFE) 低摩擦用途に適した材料?

テフロン (PTFE) のいずれかを持っています 最低の摩擦係数 あらゆる固体材料の, 濡れた氷の上を滑るのに匹敵する. このユニークな特性は、炭素主鎖を取り囲むフッ素原子の均一なブランケットに由来します。. この構造により、他の分子が PTFE 表面と強い結合を形成するのを防ぎます。, 非常に「滑りやすい」ので、 ベアリング, ブッシング, アザラシ, および滑り面 耐摩耗性と最小限のエネルギー損失が重要な場合.

2. PTFE は調理器具に見られる焦げ付き防止コーティングと同じですか?

はい, 化学的に, それは同じ素材です. PTFE は、ほとんどの高品質の焦げ付き防止調理器具コーティングの主成分です。. しかし, 調理器具の中, PTFE は 薄い, 高温硬化コーティング. で CNC加工, PTFEは固体ブロックとして加工されます (ビレットまたはロッドと呼ばれることが多い) 厚いものを作る, 構造的な, ガスケットなどのカスタムパーツ, 絶縁体, またはポンプコンポーネント.

3. 「クリープ変形」とは,」そしてそれが機械加工された PTFE 部品にとって重大な制限である理由?

クリープ 降伏強度を下回る機械的応力下で固体材料がゆっくりと永久に変形または流動する傾向. PTFEはガラス転移温度が低い比較的柔らかい材料であるため、, クリープが発生しやすい, 特に継続的な負荷またはわずかに高い温度下で. これは、一定の圧縮下にある PTFE ガスケットやシールは、時間の経過とともに最終的に厚さが失われ、適切にシールできなくなる可能性があることを意味します。.

4. 機械加工された PTFE 部品の仕上げに極低温バリ取りがよく使用されるのはなぜですか?

PTFEはとても柔らかいので, 従来の機械式バリ取り (スクレーピングまたはサンディング) 素材を簡単に汚すことができます, 表面仕上げを傷める, またはわずかな寸法変化を引き起こす. 極低温バリ取り 液体窒素または二酸化炭素を使用して PTFE 部品を一時的に硬くなり脆くなるまで凍結する. 柔らかいバリは脆くなり、タンブリングや軽いブラストで下地を損傷することなく簡単に除去できます。, より丈夫な素材.

5. PTFE で厳しい公差を維持する場合の加工における最大の課題は何ですか?

最大の課題は PTFE です 高い熱膨張係数 (CTE). わずかな温度変化 (周囲の熱や機械の摩擦によっても) 部品が他のプラスチックや金属よりも大幅に膨張または収縮する原因となります。. さらに, 素材本来の 寸法安定性が悪い そしてその傾向 ストレス解消とワープ 材料除去後は、公差の達成と保持を従来よりも厳しくする $\午後 0.13 \文章{ んん}$ 特別なストレス軽減手順がなければ難しい.

6. 標準 PTFE の代わりに PFA または PCTFE を代替品として使用すべき場合?

PTFE 特有の制限を克服するために代替手段が選択されます:

-

PFA (ペルフルオロアルコキシ): ときに使用されます 溶融加工性 必要です (複雑な成形用) PTFE の低摩擦性と耐薬品性を維持しながら.

-

PCTFE (ポリクロロトリフルオロエチレン): 重要な要件が以下の場合に使用されます。 可能な限り低い水蒸気透過率 (不浸透性) より高い機械的強度を実現, 湿気を完全に排除する必要がある医薬品の包装や極低温シールに最適です。.

7. PTFE は柔らかいにもかかわらず、高送り速度が有利な場合があるのはなぜですか?

高い送り速度を使用する (工具が材料に進入する速度) ツールでより厚いものを作成できるため、有益である可能性があります, クリーナー チップ. このアクションにより、材料が迅速に除去され、工具の破損を防ぐことができます。 こすったり、汚れたりする 柔らかいプラスチック. 厚いチップは熱をより効率的に逃がし、軟化物の形成を減らすのにも役立ちます。, 除去しにくいバリ.