CNC Machining Materials for Screws

最高の精度, we machine metals and plastics suitable for precision screws. Each material has specific properties that make it ideal for different screw types.

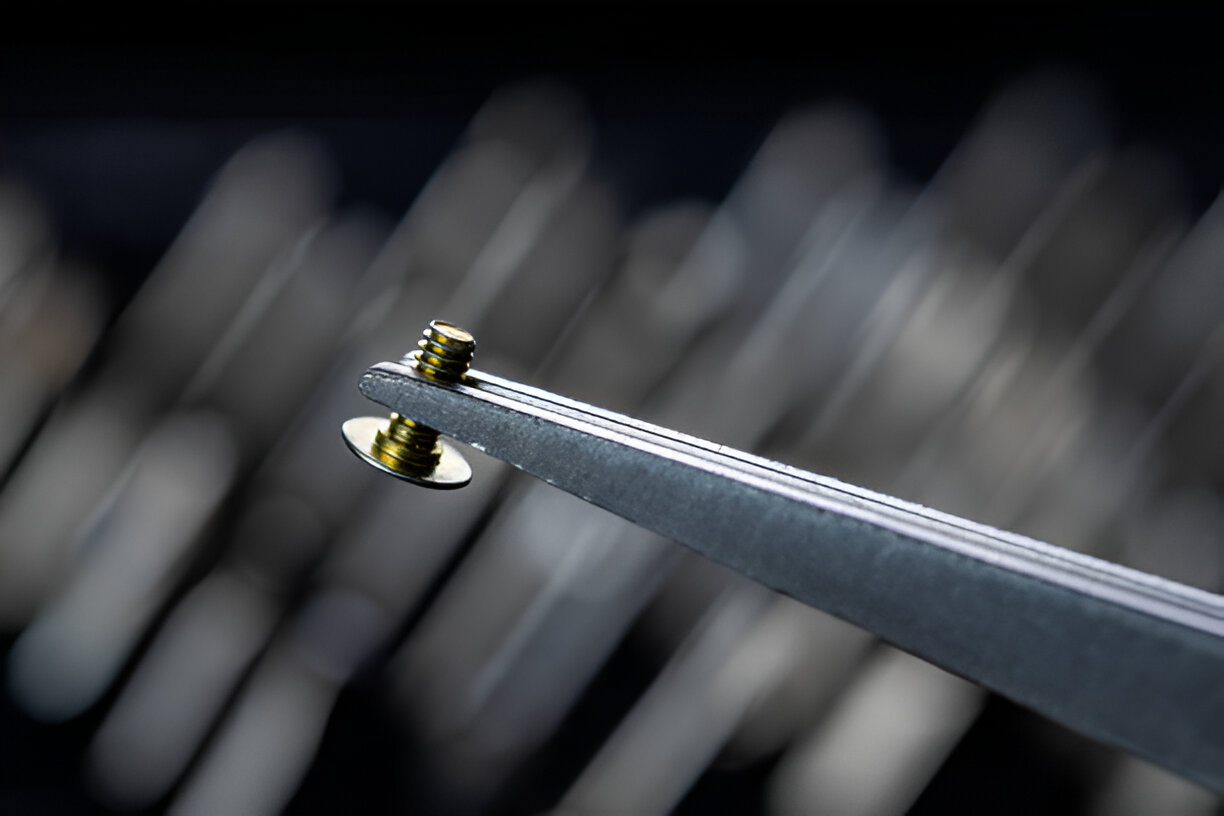

で 精度の高いトップ, we specialise in machining screw with tolerances as tight as ±0.0001インチ. Our technocrats, expert machinists, can produce miniature components with diameters down to 0.5 んん. We support medical devices, 航空宇宙コネクタ, electronics assemblies, and watch mechanisms.

Our facility uses Swiss-type CNC machines, 5-軸機, and modern CNC lathe machines to produce precise threads for scews. こちらです, we assure high precision and repeatability across small-batch or high-volume production runs.

Custom Screw Machining is a precision manufacturing process for creating screws for small and tiny items to secure a perfect fit. この過程で, ワークピースが回転します, and the movement of cutting tools is carried out simultaneously in multiple axes. This mechanism allows the machine to make miniature-sized components with extremely small tolerances and sophisticated shapes in one setup.

Unlike conventional machining, which might need several setups for completion, the Swiss screw machining can finish the part in one go. 長さ, 薄い, or small-diameter parts can cause issues for conventional lathes and mills. It often results in compromised accuracy, increased material waste, and production downtime. But Swiss screw machining is an efficient way to overcome these obstacles. It is a suitable method for manufacturing miniature screws, ピン, シャフト, and other cylindrical parts with diameters that are frequently less than 2 んん.

With custom Swiss screw machining, engineers can create intricate features that aren't possible with traditional machining. Each element can be specified to precise requirements. On top of benefits, it eliminates errors, conserves material, and permits more rapid production.

最高の精度, we take every project with care, whether you need single prototype parts or bulk products. Our team always ensures you get accurate parts with exact measurements and on time. Here are our capabilities that set us apart from other companies.

最高の精度, we machine metals and plastics suitable for precision screws. Each material has specific properties that make it ideal for different screw types.

We manufacture a wide range of precision screws in-house. Each screw type is produced with tight tolerances and exact size ranges. Our customers benefit from high-quality screws suitable for electronics, 医療機器, 機械, and other technical applications.

We machine screws with smooth threads with an accurate diameter for metal fasteners. They are used for electronic, ロボット工学, and medical device applications. Each screw has a standardized thread pitch and straightness, for smooth assembly of machinery and for accurate alignment with tiny parts.

We manufacture self-tapping screws that cut threads directly into soft metals and engineering plastics. These screws are suitable for automotive parts, 家電, and appliance assembly. They save the need for pre-drilled holes and offer strong and vibration-resistant connections.

Wood Screws from our facility are provided with coarse threads and tapered points for the best holding in wood components. They are used in furniture, cupboards, and wooden fittings. The unique thread shape eliminates splitting, assures good tightness, and lasts longer.

Our set screws are headless and designed to lock rotating or sliding parts like shafts or collars. We machine these screws for robotics and automation equipment. Accurate holding force without protrusions: each screw allows compact assembly without sacrificing performance.

We also manufacture socket head cap screws (cylindrical head, hexagonal drive). They are used in aerospace, 機械, and automotive applications where high torque is needed. The screws are manufactured to sustain high loads with dimensional integrity in tight areas.

Thread-forming screws displace material instead of cutting, creating precise threads in plastics or soft metals. They are used in electronics, 自動車部品, and home appliances. This method avoids material stress and provides vibration-resistant fixing of even sensitive assemblies.

Our tapping screws are suitable for metals and rigid plastics and create threads without nuts. These are mostly used in industrial equipment, エレクトロニクス, および機械アセンブリ. Each screw is designed to hold a tight fit and high engagement, even in thin material.

Precision microscrews are tiny and designed for small assemblies. They serve best in medical devices, watches, and small electronics. Each screw is produced with precision thread geometry and length control to offer precise assembly.

Our company provides screws and components that fit accurately every time. This reduces your assembly problems and ensures your products work reliably and perform longer. Our Customers get parts according to their strict tolerances and exact design specifications.

We can work with metals and plastics to provide solutions for industries like electronics, 医療機器, 自動車, および産業用具. Once we receive your design, our engineers evaluate it thoroughly and suggest changes and feedback. こちらです, you can refine your design and make efficient parts. また, you can ask us for a free DFM analysis.

Working with us guarantees you will always get consistent quality, reliable performance, and parts ready for actual use. We solve your machining challenges and support your project goals from the basic level to the end.

We can produce screws from 0.5 mm up to 32 直径のmm.

We machine screws from stainless steel, 真鍮, アルミニウム, チタン, and engineering plastics. Each material is selected based on your design and its intended use case.

はい, our CNC Swiss machines can create off-center holes, スロット, and multiple thread forms on a single screw. It allows us to meet custom design requirements.

We achieve tolerances as tight as ±0.0001 inches. This ensures your screws fit precisely in assemblies and perform reliably under high mechanical stress situations.

Our team closely inspects every stage of production. Every screw is checked with vernier calipers, thread gauges, and parts through the CMM machine. Critical dimensions, thread pitch, and surface finish are verified before delivery settlements.