A usinagem para os parafusos suíços é uma das técnicas de fabricação mais precisas e eficientes usadas nas indústrias modernas. Conhecido por sua capacidade de produzir pequeno, componentes complexos com extrema precisão, A usinagem para os parafusos suíços é um método preferido no aeroespacial, médico, eletrônicos, e outras indústrias de alta precisão.

Este artigo explora tudo o que você precisa saber sobre a usinagem suíça, incluindo como funciona, seus benefícios, e suas aplicações. Esteja você considerando essa tecnologia para fabricar ou apenas curiosa sobre suas vantagens, Este guia fornecerá informações detalhadas.

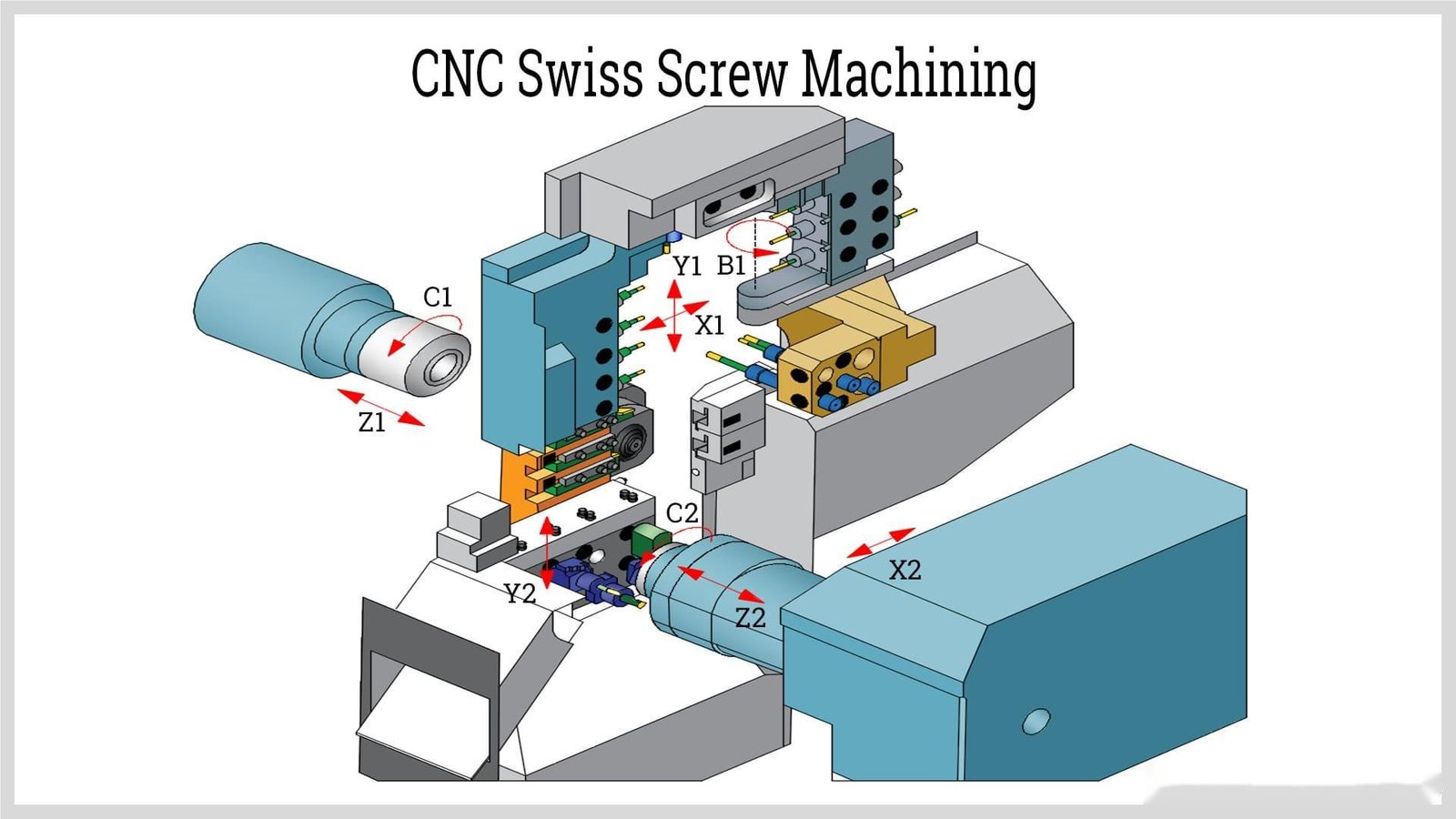

Como funciona uma máquina de parafuso suíça CNC?

Swiss screw machines are a specialized type of CNC lathe designed to manufacture small, peças de alta precisão. Unlike conventional lathes, which hold a workpiece stationary while the cutting tools move, Swiss machines feed the material through a guide bushing, allowing for more precise and stable machining.

Here’s how the Swiss screw machining process works:

Programando o design do componente

The process begins with a CAD (Design auxiliado por computador) model of the part. The design is converted into a CNC (Controle Numérico Computadorizado) program, which dictates how the machine will cut, furar, and shape the material.

Carregando o estoque de barra

A bar feeder loads long cylindrical rods (estoque de barra) into the Swiss screw machine. This automated feeding system enables continuous production without frequent reloading, improving efficiency.

Corte e perfuração

As the bar stock moves through the guide bushing, the cutting tools operate very close to the point where the material is held, reduzindo a vibração e garantir cortes precisos. Várias ferramentas podem funcionar simultaneamente, permitindo usinagem complexa em uma única configuração.

Ejeção de peça automática

Depois que a usinagem estiver completa, A parte acabada é automaticamente separada do estoque de barra, e a próxima peça está imediatamente posicionada para usinagem. Esta transição perfeita acelera a produção, Tornando a usinagem suíça ideal para a fabricação de alto volume.

🔗 Leitura adicional: Como funciona a usinagem CNC

Materiais usados na usinagem de parafuso suíço

A usinagem da parafuso suíça é Compatível com uma grande variedade de materiais, Incluindo:

- Metais:

- Aço inoxidável (Médico, Aeroespacial)

- Alumínio (Componentes leves)

- Titânio (Peças de alta resistência)

- Latão & Cobre (Eletrônicos, Encanamento)

- Plásticos:

- OLHADINHA (Implantes médicos)

- PTFE (Teflon)

- Nylon (Automotivo & Componentes industriais)

🔗 Leitura adicional: Melhores materiais para usinagem CNC

Benefícios da usinagem para parafuso suíço

A usinagem para os parafusos suíços é uma das maneiras mais eficientes de fabricar pequenos, peças de alta precisão. Se você está no aeroespacial, médico, ou indústria eletrônica, Este método oferece várias vantagens sobre a usinagem tradicional.

Super alta precisão

Swiss screw machines are built for precision. They can cut parts with tolerances as tight as ±0.0002 inches (0.005milímetros). That means every part comes out exactly the same, which is crucial for industries like medical and aerospace, where even the smallest mistake can be costly.

Unlike conventional lathes, Swiss machines hold the workpiece close to the cutting tool, reducing vibrations and ensuring accuracy. This results in perfeito, peças repetíveis toda vez.

Produção rápida e eficiente

One of the biggest advantages of Swiss screw machining is velocidade. These machines can work non-stop for hours, churning out thousands of identical parts in a short time.

Here’s why it’s so efficient:

✅ Multiple tools can cut the material at the same time

✅ Bar feeder system keeps the machine running continuously

✅ Less operator supervision means lower labor costs

Se você precisar produção em alto volume, Swiss screw machining is the way to go.

Lida com designs complexos com facilidade

Swiss screw machining is perfect for parts with tiny holes, paredes finas, e recursos detalhados that other machines struggle to produce.

Thanks to CNC (Controle Numérico Computadorizado) programação, you can create personalizado, Designs intrincados without worrying about errors. Need a small medical implant or a delicate aerospace component? A Swiss machine can handle it.

Works with a Wide Range of Materials

Swiss machines aren’t just limited to one type of material. They work well with metais, plásticos, e mais, Incluindo:

🔹 Aço inoxidável – Great for aerospace and medical applications

🔹 Alumínio – Lightweight and corrosion-resistant

🔹 Titânio – Strong and durable for high-performance parts

🔹 Latão & Cobre – Excellent for electronics and plumbing

🔹 Plásticos (Nylon, OLHADINHA, PTFE, etc.) – Ideal for lightweight, non-metal components

No matter what material you need, a Swiss screw machine can corte, furar, and shape it with precision.

Saves Money by Reducing Waste

A usinagem da parafuso suíça é highly efficient, meaning less wasted material and lower costs. Since the machine cuts so precisely, there’s minimal scrap. Mais, Qualquer material restante pode ser frequentemente reciclado para uso futuro.

Menos desperdício = Mais economia para o seu negócio.

Consistent Quality for Every Part

Se você está produzindo milhares ou até milhões de partes, A consistência é fundamental. Máquinas suíças garantir uniformidade em todas as partes, garantindo que eles atendam exatamente as mesmas especificações todas as vezes.

Isso é especialmente importante em indústrias como médico e aeroespacial, onde as peças devem se encaixar perfeitamente para funcionar corretamente.

Great for High-Volume Production

Máquinas suíças podem produzir milhares de peças rapidamente, tornando -os perfeitos para:

✔ Produção em massa é executada

✔ Ordens de fabricação a granel

✔ Projetos industriais em larga escala

Depois que um programa é configurado, A máquina pode correr 24/7 com supervisão mínima, permitindo que as empresas produzam peças Mais rápido e mais barato.

Less Manual Labor = Lower Costs

Métodos tradicionais de usinagem requerem supervisão constante de operadores, o que aumenta os custos de mão -de -obra. Com usinagem para parafuso suíça, o processo é automatizado, reduzindo a necessidade de intervenção humana.

Menos trabalho manual significa:

✅ Custos operacionais mais baixos

✅ Fewer errors

✅ Faster turnaround times

It’s a win-win for manufacturers looking to improve efficiency and cut costs.

Smooth Surface Finishes

Swiss screw machining produces suave, clean finishes that often don’t need additional polishing or refinishing. Isso é crucial for medical and aerospace parts, where surface imperfections can affect performance.

Mais, if a specific finish is required (como anodização ou chapeamento), Swiss-machined parts are already smooth enough to make post-processing easier.

Reduced Downtime and Maintenance

Swiss machines are highly reliable and require minimal maintenance compared to traditional machining tools. Since they operate with less vibration and wear, they last longer and experience fewer breakdowns.

Isso significa:

✅ Less downtime

✅ More parts produced

✅ Lower repair costs

Para fabricantes, more uptime means more money in your pocket.

Got it! Here’s your article without bold formatting while keeping all the original content unchanged:

Types of Swiss Screw Machining

Swiss screw machining is an advanced manufacturing technique used to produce small, highly precise parts. But did you know that there are different types of Swiss screw machining? Each type is designed to handle specific tasks, materiais, and production needs.

Automatic Swiss Screw Machining

This is the traditional type of Swiss machining, where a fully automated lathe does all the work.

- Uses cams and mechanical controls

- Great for high-volume production

- Works best for simple parts with standard designs

These machines were widely used before CNC technology became popular. They are still useful today for fast, repetitive production runs with minimal setup time.

CNC Swiss Screw Machining

Este é o tipo mais avançado de usinagem suíça. Usa controle numérico de computador (CNC) Programação para automatizar todas as etapas do processo.

- Incrivelmente preciso - pode atingir tolerâncias de ± 0,0002 polegadas

- Pode lidar com geometrias complexas e pequenas, peças complexas

- Pode trabalhar com várias ferramentas ao mesmo tempo

As máquinas suíças da CNC são perfeitas para indústrias como médicos, aeroespacial, e eletrônica, Onde a precisão é tudo. Já que eles são controlados por computador, Eles podem correr 24/7 com supervisão mínima.

Usinagem de parafuso suíço

Como o nome sugere, Máquinas de espinha única usam apenas um eixo para girar a peça de trabalho.

- Custo mais baixo em comparação com máquinas de múltiplos espacos

- Ideal para execuções de produção baixa a médica

- Funciona bem para protótipos e peças personalizadas

A usinagem suíça de espinha única é uma ótima opção para pequenas empresas ou fabricantes que precisam de precisão sem produção em massa.

Usinagem de parafuso suíço de vários fuses

Ao contrário das máquinas de espinha única, Máquinas suíças de vários espacos têm vários eixos rotativos, o que significa que eles podem trabalhar em várias partes de uma vez.

- Produção muito mais rápida do que máquinas de espinha única

- Ideal para fabricação em larga escala

- Reduz o tempo de produção e aumenta a eficiência

Máquinas de vários espacos são melhores para ordens de alto volume, onde a velocidade é uma prioridade, como em automotivo, aeroespacial, e indústrias médicas.

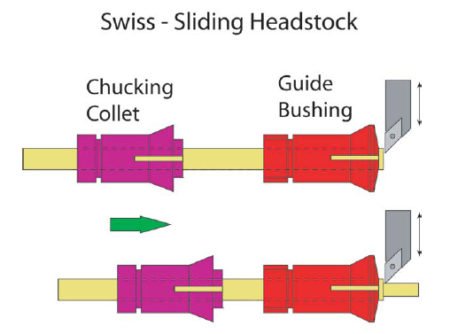

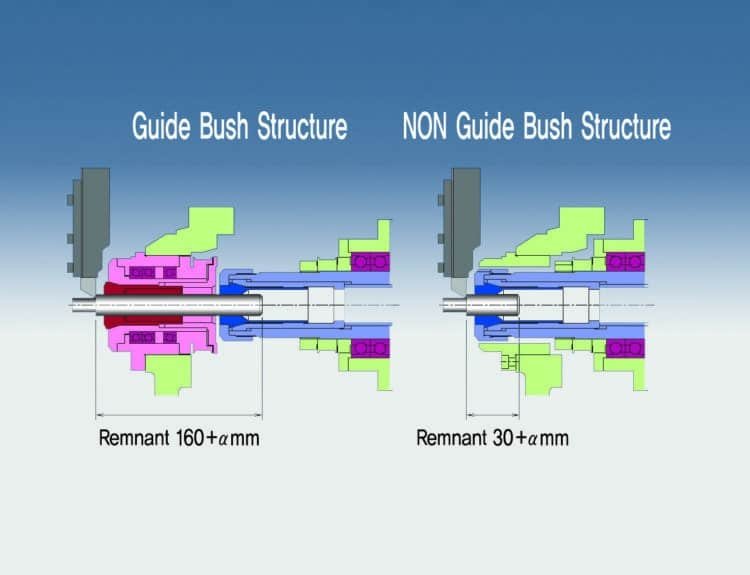

Usinagem suíça de cabeçote deslizante

Neste tipo de usinagem, O cabeçote se move para frente e para trás, guiar o material através de uma bucha guia.

- Reduz vibrações e deflexões, tornando-o ultraprecizado

- Funciona bem por muito tempo, partes finas

- Usado em indústrias médicas e aeroespaciais, onde é necessária extrema precisão

Máquinas de cabeçote deslizantes podem lidar com tolerâncias muito apertadas, tornando -os ideais para usinar pequenos, componentes delicados, como ferramentas cirúrgicas ou peças microeletrônicas.

Usinagem suíça fixa de cabeçote

Este é o oposto de deslizar a usinagem de cabeçote deslizante. Neste método, A peça de trabalho permanece fixa, e apenas as ferramentas se movem.

- Melhor para mais curto, peças mais volumosas

- Mais rígido e estável, Reduzindo o desgaste da ferramenta

- Funciona bem para aplicativos de precisão média

Se você não precisa de tolerâncias super apertadas, A usinagem fixa de cabeçote pode ser uma opção econômica, enquanto ainda oferece boa precisão.

Usinagem suíça híbrida

Máquinas suíças híbridas combinam recursos de diferentes tipos de usinagem.

- Pode alternar entre cabeças deslizantes e cabeçote fixo

- Oferece versatilidade - pode lidar com peças longas e curtas

- Melhor para empresas que fabricam uma grande variedade de peças

Máquinas híbridas reduzem a necessidade de várias configurações, making them a great all-in-one solution for manufacturers that need flexibility.

Which Type of Swiss Screw Machining is Best for You?

The right type of Swiss screw machining depends on your project needs. Here’s a quick guide to help you choose:

| Tipo de usinagem | Melhor para | Benefício principal |

| Automatic Swiss | Simples, peças de alto volume | Fast production with lower costs |

| CNC Swiss | Complexo, peças de alta precisão | Extreme accuracy and automation |

| Single-Spindle | Protótipos, pequenos lotes | Menor custo, good for custom parts |

| Multi-Spindle | Produção em massa, Fabricação em larga escala | Higher speed and efficiency |

| Sliding Headstock | Longo, afinar, peças delicadas | Ultra-precise with minimal vibration |

| Fixed Headstock | Curto, peças mais volumosas | More stable and cost-effective |

| Hybrid Swiss | Various part sizes and complexities | Versatile and reduces setup time |

If you’re making high-precision medical implants, CNC Swiss machining or sliding headstock machining is your best bet. If you need high-volume, peças simples, go with multi-spindle or automatic Swiss machining.

Comparação: Swiss Screw Machining vs. Conventional CNC Machining

| Recurso | Usinagem da parafuso suíça | Conventional CNC Machining |

| Holding de peça de trabalho | A bucha guia fornece estabilidade | Peça de trabalho realizada em uma extremidade |

| Tolerâncias | ±0.0002 inches (0.005milímetros) | ± 0,001 polegadas (0.025milímetros) |

| Eficiência | Usinagem contínua com alimentadores de bares | Carregamento/descarregamento manual |

| Melhor para | Pequeno, peças complexas (por exemplo., implantes médicos) | Maior, peças menos complexas |

💡 Takeaway -chave: A usinagem suíça é ideal para alta precisão, peças de pequeno diâmetro que exigem tolerâncias apertadas e produção em massa.

Applications of Swiss Screw Machined Parts

A usinagem para os parafusos suíços é amplamente utilizada em vários setores, onde precisão e eficiência são críticas. Aqui estão algumas aplicações comuns:

Indústria aeroespacial

Os componentes de aeronaves e espaçonaves devem atender a tolerâncias estritas para garantir a segurança e a confiabilidade. A usinagem para os parafusos suíços é usada para produzir:

- Parafusos e prendedores

- Eixos e acopladores

- Conectores e anéis de retentor

- Suportes estruturais

Medical and Dental Industry

A usinagem suíça é crucial na fabricação de equipamentos médicos e odontológicos, Como essas ferramentas requerem precisão extrema. Peças médicas comuns usinadas na suíça incluem:

- Instrumentos cirúrgicos

- Cateteres e stents

- Implantes e aparelhos dentários

- Componentes do scanner de ressonância magnética

Indústria automobilística

Veículos de alto desempenho requerem peças usadas por precisão para obter eficiência e durabilidade ideais. A usinagem da parafuso suíça é usada para fabricar:

- Injetores de combustível

- Componentes da válvula

- Peças do sistema de freio

- Altas do sensor

Electronics and Telecommunications

À medida que a tecnologia continua a avançar, a demanda por miniatura, Componentes eletrônicos de alta precisão cresceram. A usinagem da parafuso suíça é usada para criar:

- Componentes da placa de circuito

- Conectores de rádio e antena

- Parafusos em miniatura e prendedores

- Pinos de precisão para contatos elétricos

Military and Defense Industry

O setor militar requer durável, Componentes de alto desempenho que podem suportar condições extremas. A usinagem da parafuso suíça é usada para:

- Componentes de arma de fogo

- Peças de veículos militares

- Componentes do sistema de defesa aeroespacial

Food Processing Equipment

Máquinas de qualidade alimentar devem ser duráveis, resistente à corrosão, e fácil de limpar. Os componentes usinados suíços na indústria de alimentos incluem:

- Misturadores de aço inoxidável

- Componentes da correia transportadora

- Peças da máquina OEM

Machine Tools Used for Swiss Screw Machining

Swiss screw machining is all about precision, and to achieve that, you need the right tools. These machines are designed to create tiny, highly detailed parts with extreme accuracy. But what are the key tools that make Swiss screw machining so effective? Vamos quebrá -los.

Swiss-Type CNC Lathe

The heart of the Swiss screw machining process is the Swiss-type CNC lathe. Unlike traditional lathes, Swiss lathes hold the workpiece with a collet and guide it through a bushing, reducing vibration and increasing precision.

Por que é importante:

- Allows for tight tolerances (as precise as ±0.0002 inches)

- Reduces deflection in long, partes finas

- Can perform multiple operations in one setup

Swiss-type CNC lathes come in single-spindle e multi-spindle versions. If you need high-volume production, multi-spindle machines can produce multiple parts at once, tornando o processo muito mais rápido.

Guide Bushing

A guia bucha é um componente pequeno, mas crítico, que ajuda a estabilizar o material à medida que é usinado. Ele mantém o estoque de barra próximo à ferramenta de corte, que minimiza a flexão e a deflexão.

Por que é importante:

- Melhora a precisão mantendo a peça de trabalho estável

- Reduz a vibração, levando a acabamentos mais suaves

- Essencial para usinagem longa, partes finas

Sem uma bucha guia, Peças pequenas podem dobrar ou quebrar, tornando impossível alcançar resultados precisos.

Rotary Tools (Fresagem & Drilling Attachments)

Máquinas parafusadas suíças não apenas giram peças - elas também moinho e broca. Ferramentas rotativas Ajude a adicionar recursos como orifícios, slots, e threads para a peça de trabalho.

Por que é importante:

- Permite formas e recursos complexos

- Reduz a necessidade de operações secundárias

- Aumenta a eficiência executando várias tarefas em um ciclo

Esses anexos tornam as máquinas suíças altamente versáteis, permitindo que eles criem tudo, desde implantes médicos para conectores aeroespaciais.

Live Tooling

Ao contrário dos tornos regulares, Máquinas parafusos suíços podem ter ferramentas ao vivo, o que significa que algumas ferramentas podem girar enquanto corta. Isso é especialmente útil para o arremesso cruzado, tocando, e outras operações de usinagem secundária.

Por que é importante:

- Aumenta as capacidades de usinagem

- Reduz o tempo de configuração

- Elimina a necessidade de máquinas adicionais

Tooling ao vivo permite que os fabricantes completem peças um vai, em vez de movê -los para outra máquina para operações secundárias.

Fusos de alta velocidade

O fuso é o que mantém e gira a peça. Na usinagem suíça, Fusos de alta velocidade são essenciais porque eles permitem um corte ultra-rápido, mantendo a precisão.

Por que é importante:

- Pode atingir velocidades de até 10,000 RPM

- Ativa o corte suave para peças pequenas e delicadas

- Ajuda a alcançar tolerâncias rígidas

Os fusos de alta velocidade são especialmente úteis ao usinar aço inoxidável, titânio, e outros materiais difíceis.

Bar Feeder

As máquinas de parafusos suíças são projetadas para produção contínua, é por isso que eles usam um alimentador de barra Para carregar automaticamente o material na máquina.

Por que é importante:

- Mantém a produção funcionando sem intervenção manual

- Reduz o tempo de inatividade e aumenta a eficiência

- Ideal para produção de alto volume

A bom alimentador de barra pode segurar várias barras de material, Significando que a máquina pode ser executada por horas ou até dias sem precisar ser reabastecido.

Sistema de refrigeração

Com usinagem suíça de parafuso corte de alta velocidade, um sistema de líquido de arrefecimento é necessário para evitar superaquecimento e estender a vida útil da ferramenta.

Por que é importante:

- Mantém as ferramentas de corte e a peça de trabalho frias

- Evita o desgaste da ferramenta e os danos materiais

- Garante suavidade, acabamentos livres de rebarbas

Usar o líquido de arrefecimento certo também ajuda a reduzir o atrito, melhorando a eficiência geral do processo de usinagem.

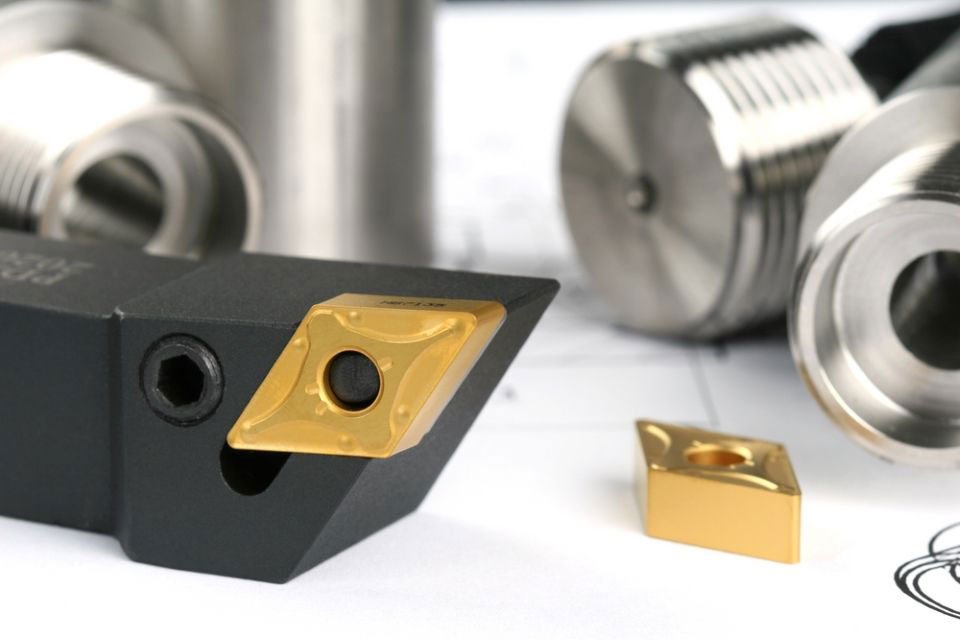

Tool Holders & Cutting Inserts

Máquinas parafusos suíças usam titulares de ferramentas especializados e inserções that allow for extreme precision and long tool life. These cutting tools can be changed out quickly, reducing downtime.

Por que é importante:

- Helps maintain consistent cutting quality

- Allows for quick tool changes to keep production moving

- Reduces waste and improves efficiency

Por exemplo, carbide inserts are commonly used because they stay sharp longer, especially when cutting tough materials like titanium and stainless steel.

Why Choose CNC Swiss Screw Machining?

Swiss screw machining stands out for its:

✔ Unmatched precision – Capable of producing intricate parts with tight tolerances

✔ Escalabilidade – Suitable for both small prototype runs and mass production

✔ Automação – Runs for long hours with minimal human intervention

✔ High material efficiency – Less waste, more sustainability

✔ Versatile material compatibility – Works with metals and plastics

A usinagem para os parafusos suíços é ideal para os fabricantes que precisam alta precisão, alto volume, e econômico componentes.

Cost Breakdown of Swiss Screw Machining

| Fator | Impacto no custo |

| Material | Custos de titânio mais do que alumínio |

| Complexidade | Designs mais complexos aumentar o custo |

| Volume do pedido | Lotes maiores reduzir o custo por parte |

💡 Faixa de custo típica:

- Peças simples:$1 – $5 por unidade

- Complexidade média:$5 – $15 por unidade

- Peças de alta precisão:$20 – $100 por unidade

🔗 Leitura adicional: Repartição de custos de usinagem CNC

Conclusão

A usinagem para os parafusos suíços é um processo revolucionário que transformou as indústrias que exigem componentes de alta precisão. Isso é eficiência, precisão, e capacidade de lidar com designs complexos Faça uma ferramenta essencial na fabricação moderna.

Se você está procurando Peças personalizadas da forma suíça, Tops Precisão Oferece serviços de alto nível com materiais de alta qualidade e artesanato de precisão. Entre em contato conosco hoje para saber como podemos dar vida aos seus designs!