Em moldagem por injeção, cooling lines, Também conhecido como cooling channels, play a critical role in ensuring that molten plastic solidifies evenly within the mold cavity. These channels regulate the temperature of the mold, allowing the plastic to cool uniformly and preventing common defects such as marcas de pia, deformação, and internal stresses.

When molten resin is injected into a mold, it rapidly fills the cavity and conforms to its shape. Once filled, it must cool at a controlled rate to achieve the desired mechanical properties and dimensional accuracy. No entanto, if some areas of the mold cool faster than others, encolhimento irregular pode ocorrer, resultando em part deformation or poor surface finish.

Because cooling can account for up to 75% of the total injection molding cycle time, optimizing the cooling system is crucial. An effective cooling design not only reduces cycle time and energy consumption but also improves part consistency and mold longevity.

Overview of Injection Mold Cooling Systems

Overview of Injection Mold Cooling Systems

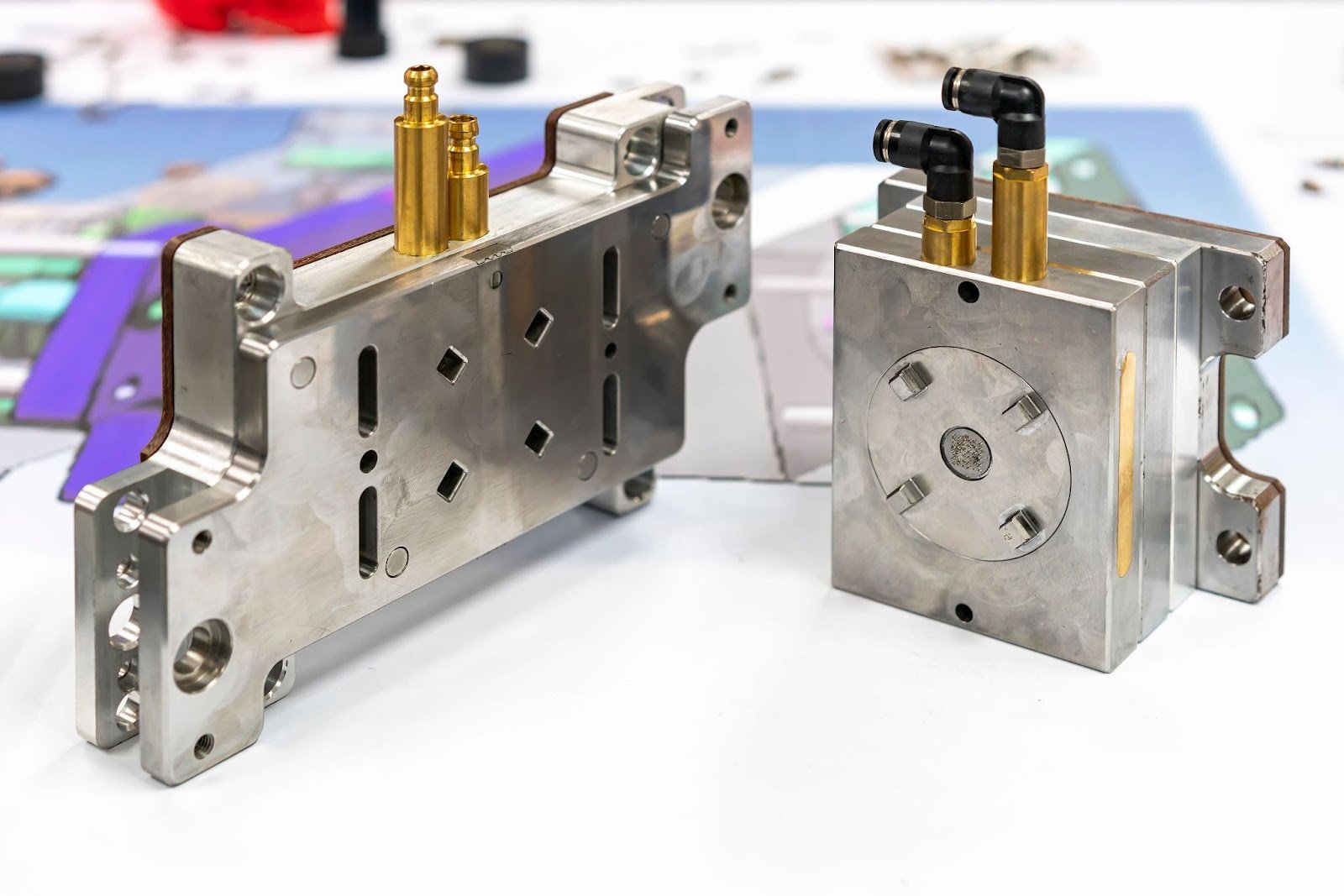

A cooling system in an injection mold consists of a network of channels that circulate coolant—usually water—throughout the mold body. As the coolant absorbs heat from the molten plastic, it carries the heat away and releases it through a cooling unit, maintaining a stable mold temperature.

The efficiency of this process depends on:

O coolant flow rate

O temperature differential between coolant and mold surface

O layout, diâmetro, e posicionamento of cooling channels

A well-designed cooling circuit ensures balanced thermal distribution, permitindo consistent part quality and shorter cycle times.

Air Cooling vs. Water Cooling

Air Cooling

Air cooling relies on fans, condensers, and evaporators to remove heat from the injection system. It’s typically used for smaller molds or where water access is limited.

Vantagens:

Simpler setup and lower maintenance cost

Suitable for molds used in dry or portable environments

Desvantagens:

Air has much lower thermal conductivity than water

Less effective at maintaining precise temperature control

Limited cooling efficiency for high-production molds

Water Cooling

Water cooling is the most common and efficient method for injection mold temperature control. In this system, refrigerante (a mixture of water and additives) circulates through channels near the mold cavity, absorbing heat and transporting it away.

Key characteristics include:

Thermolators: Devices that regulate coolant temperature and pressure.

Coolant composition:

Biocide additives to prevent bacterial growth in cooling towers

Ethylene glycol to prevent corrosion and freezing

Design goal: Keep channels as close to the cavity surface as possible without compromising mold strength.

Compared to air systems, water cooling provides mais rápido, more uniform heat transfer, improving dimensional accuracy and surface finish.

Types of Cooling Channels

Types of Cooling Channels

Straight-Line Cooling

O traditional straight-line cooling method uses drilled channels that run in direct paths through the mold base. These main channels may have intersecting side branches to increase coolant coverage and enhance heat removal.

Vantagens:

Simple to design and manufacture

Reliable for simples, symmetrical part geometries

Easy to maintain and clean

Limitações:

Inefficient for complex or curved part shapes

Hot spots can develop in areas far from the cooling lines

Conformal Cooling

Conformal cooling channels follow the exact geometry of the mold cavity, maintaining a constant distance from the part surface. This advanced approach offers superior cooling performance and is particularly effective for complexo, 3D-shaped parts.

Benefits of Conformal Cooling:

Faster heat extraction and shorter cycle time

Improved dimensional stability and part aesthetics

Reduced residual stresses and warpage

Better thermal balance throughout the mold

Tradicionalmente, manufacturing these intricate channels was expensive and time-consuming, requiring precision drilling and welding. Hoje, additive manufacturing technologies como Direct Metal Laser Sintering (DMLS) have made conformal cooling more practical and cost-effective.

Cooling Aids: Baffles, Bubblers, and Thermal Pins

Even with optimal channel design, certain mold areas—especially thick sections or deep cores—may retain excess heat. Nesses casos, cooling inserts como baffles, bubblers, and thermal pins are used to enhance thermal performance.

Baffles

Baffles are flat metal plates inserted into drilled holes that redirect coolant flow. The coolant travels up one side of the baffle and down the other, criando turbulent flow and improving heat transfer.

Some baffles feature a twisted design that induces a helical motion, ensuring more consistent temperature distribution along the mold surface.

Bubblers

Bubblers are hollow tubes that connect coolant channels. Coolant enters from the bottom, flows upward through the tube, and exits at the top, effectively “bubbling” into another channel.

This design allows coolant to reach deep or narrow areas that cannot accommodate milled channels. Bubblers are often threaded or press-fit into the mold core and are essential for localized cooling.

Thermal Pins

Thermal pins are selado, heat pipe–style inserts filled with a working fluid. As heat is absorbed, the fluid vaporizes and transfers heat to a cooler region, where it condenses back to liquid—creating a continuous heat exchange cycle.

Compared to copper rods, thermal pins offer higher thermal conductivity e faster response times, but they require precise installation to eliminate air gaps between the pin and mold surface.

Cooling Design for Different Mold Cores

Slender Cores (≤3 mm Diameter)

Conventional water channels are impractical; air cooling is preferred.

Copper or copper-beryllium inserts improve heat conduction.

Air can be directed through a central vent hole or blown over the core during mold opening.

Large Cores (≤40 mm Diameter)

Usar thermally conductive inserts combined with central coolant flow through a bore.

Several smaller channels are often better than one large one for even heat removal.

Channel diameter should remain consistent throughout the mold for stable flow.

Cylinder Cores

Typically use double-helix flow patterns—coolant flows toward the core tip in one helix and returns in the other.

This design ensures uniform cooling and minimizes temperature gradients.

Consistent temperature control in cores is essential for preventing internal stresses, marcas de pia, and uneven shrinkage.

Importance of Cooling Optimization

Cooling is not just a supporting process—it directly determines produtividade, qualidade da peça, e eficiência de custos. Optimized cooling leads to:

Reduced cycle time, improving machine utilization

Lower energy consumption and operational cost

Higher dimensional accuracy e Menos defeitos

Extended mold life due to lower thermal fatigue

Because cooling consumes the majority of the cycle time, even a 10% improvement in cooling efficiency can yield significant production savings.

Conclusão

Effective cooling system design is fundamental to successful injection molding. Quer você escolha straight-line or conformal cooling, the goal remains the same: achieve uniforme, controlado, and efficient heat transfer throughout the mold.

Integrating baffles, bubblers, and thermal pins can further enhance cooling uniformity, especially in complex or deep-cavity molds. With advanced technologies like 3D-printed conformal cooling, molders today can achieve exceptional precision and productivity.

Partnering with an experienced injection molding provider ensures that your cooling system is optimized for your specific part geometry and material, minimizing waste and maximizing efficiency.

Resumidamente, smart cooling design means faster cycles, better parts, and longer mold life—a true win for any injection molding operation.