A usinagem do eixo do motor é um processo fundamental, porém intrincado, em engenharia de precisão. Esses eixos servem como componentes mecânicos que transmitem energia de rotação de um motor para um componente acionado. Seja usado em veículos elétricos, motores industriais, turbinas, ou equipamento médico, A geometria de um eixo de motor, material, e o acabamento da superfície influencia diretamente a eficiência e a confiabilidade do sistema. Este guia fornece uma visão geral detalhada da usinagem do eixo do motor, cobrindo tipos de eixo, processos, Técnicas de usinagem, Seleção de material, acabamento, e controle de qualidade.

O que é usinagem do eixo do motor?

A usinagem do eixo do motor é o processo de transformar o caldo de metal cru em componentes cilíndricos de precisão capazes de transmitir torque e movimento rotativo. Esses eixos são usinados a tolerâncias dimensionais apertadas e acabamentos de superfície lisa, garantir uma operação confiável sob cargas variadas, velocidades, e condições ambientais.

Usando CNC (Controle Numérico Computadorizado) máquinas, Ferramentas de corte removem o material para formar recursos importantes, como diâmetros, ombros, ranhuras, estrias, e diminuir. A precisão é fundamental - os erros na geometria do eixo podem causar vibração, vestir, ou falha em montagens críticas.

Tipos de eixos de motor

Os eixos de motor vêm em uma variedade de geometrias, cada um adaptado para aplicações mecânicas específicas:

Eixos roscados

Esses eixos têm fios externos em uma ou ambas as extremidades, ou ao longo de todo o comprimento, permitindo que eles sirvam como prendedores ou conectores em montagens. Os eixos roscados são comumente usados em atuadores elétricos, unidades lineares, e mecanismos de fixação.

Eixos estampados

Com ranhuras ou cumes longitudinais, Os eixos estampados se intertravam com componentes de acasalamento para garantir a transferência de torque sem derrapagem. Amplamente utilizado em caixas de câmbio, motores de aeronaves, e transmissão de veículos, Eles permitem o movimento axial, mantendo a sincronização de rotação.

Eixos ocos

Projetado com um furo central, Os eixos ocos reduzem o peso enquanto mantêm a resistência. A cavidade pode abrigar a fiação, canais fluidos, ou instrumentação. Comum em aeroespacial, Robótica, e sistemas de automação, Eles reduzem a inércia e melhoram a resposta.

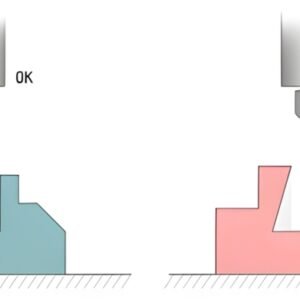

Eixos de chave

Esses eixos apresentam um corte longitudinal de teclado ao longo do diâmetro externo, Projetado para se ajustar a uma tecla correspondente e teclado no hub de acasalamento. Isso cria uma forte trava mecânica para transmissão e alinhamento de torque em bombas, motores, e polias.

Eixos cônicos

Os eixos cônicos têm diâmetros que diminuem gradualmente ao longo do comprimento, Oferecendo um ajuste auto-bloqueador com componentes de acasalamento. Comum em cubos de rodas e volantes, Eles fornecem conexões seguras sem a necessidade de fixadores adicionais.

Processos envolvidos na usinagem do eixo do motor

Cálculo de carga e torque

Antes do início da usinagem, Os engenheiros devem calcular o torque máximo esperado, axial, e cargas radiais. Esses valores influenciam o diâmetro do eixo, força do material, e concentrações de estresse, Garantir que o design atenda aos requisitos de vida e segurança de fadiga.

Design no CAD

Usando software CAD como SolidWorks ou Autodesk Inventor, Os engenheiros criam desenhos 2D detalhados e modelos 3D. O CAD Design garante que todos os requisitos de dimensional e tolerância sejam especificados e permita a otimização do projeto antes da produção.

Programação de came e usinagem CNC

O modelo CAD é importado para CAM (Fabricação auxiliada por computador) software para gerar caminhos de ferramentas e código G. Este código orienta as máquinas CNC através de movimentos precisos - virando, fresagem, perfuração, ou moagem - para criar a geometria do eixo acabado.

Acabamento superficial

Pós-formação, Os tratamentos de superfície aumentam a precisão dimensional, aparência, resistência ao desgaste, e proteção contra corrosão. Esses tratamentos variam com base em aplicação e material.

Várias técnicas de usinagem CNC na produção de eixo de motor

Torneamento CNC

A torneamento da CNC é ideal para produzir recursos concêntricos. O espaço em branco de metal é girado enquanto as ferramentas de corte estacionárias moldam o exterior. Operações comuns incluem enfrentar, OD/ID giro, grooving, rosqueamento, e giro de círio.

Fresagem CNC

A moagem usa ferramentas de corte rotativas para formar recursos não cilíndricos, como apartamentos, slots, e Keyways. A moagem CNC de vários eixos permite geometrias complexas e recortes de precisão.

Perfuração CNC

Furos de precisão para fixadores, lubrificação, ou roteamento de arame é produzido usando perfuração automatizada. Isso garante posicionamento preciso do orifício, diâmetros consistentes, e repetibilidade.

Retificação CNC

A moagem garante o acabamento da superfície final e a tolerância dimensional (geralmente dentro de ± 0,002 mm). Rodas abrasivas removem material mínimo, Ideal para alcançar alta concordância e baixa rugosidade superficial (Rá < 0.4 µm).

Usinagem por descarga elétrica (Música eletrônica)

EDM remove o material por descargas elétricas, Útil para cortar ligas endurecidas ou criar recursos internos complexos que não são viáveis com usinagem tradicional. É lento, mas altamente preciso.

Tipos de materiais usados na usinagem do eixo do motor

Alumínio

Resistente à corrosão e corrosão, alumínio (por exemplo., 6061, 7075) é ideal para aplicações de baixa carga em robótica, automação, e pequenos motores. Sua alta usinabilidade também permite a produção econômica.

Aço carbono

Notas como 1045 e 1144 são econômicos e fortes. Os eixos de aço carbono são amplamente utilizados em máquinas industriais, onde a corrosão não é uma preocupação crítica.

Aço inoxidável

Notas 304 e 316 oferecer resistência e força de corrosão superiores. Estes são frequentemente usados no processamento de alimentos, marinho, e dispositivos médicos. 316 é mais resistente à corrosão, enquanto 304 é mais econômico.

Liga de aço

Cromoly e outros aços de liga são tratáveis e extremamente difíceis. Esses materiais são escolhidos para aplicações de alto estresse, como cambotações automotivas e transmissões pesadas.

Latão

Com excelente usinabilidade e resistência à corrosão, Brass é adequado para aplicações de eixo decorativo ou de baixo atrito, como contatos elétricos ou componentes de instrumento.

Titânio

A excepcional proporção de força-peso e resistência à corrosão do Titanium o tornam adequado para eixos aeroespaciais e marinhos. Embora caro, tem um bom desempenho em ambientes extremos.

Ligas de Níquel

Ligas como o Inconel suportarem altas temperaturas, oxidação, e corrosão. Usado em turbinas a gás e motores a jato, Eles são difíceis de fazer a máquina, mas incomparáveis no desempenho.

Fatores a serem considerados durante a usinagem CNC do eixo do motor

Custos de materiais

Escolha um material que os equilíbrio custe, desempenho mecânico, e resistência à corrosão. O aço carbono é econômico, enquanto titânio e inconnel aumentam significativamente o custo da peça.

Tempo de usinagem e complexidade

Eixos com recursos complexos (estrias, Tópicos internos, furos ocos) requer ciclos de usinagem mais longos, Aumento do tempo de custo e configuração.

Custos de ferramentas

Ferramentas premium são necessárias para materiais endurecidos, como o Inconel. A vida útil da ferramenta e a frequência de reposição afeta os custos de longo prazo.

Trabalho e automação

A automação CNC reduz as necessidades de mão -de -obra, Mas a configuração e inspeção manual ainda são necessárias. Os eixos complexos podem exigir usinagem de várias setupes.

Tratamento térmico

Processos como endurecer, temering, e a nitridação melhoram a força da fadiga e a resistência ao desgaste da superfície. No entanto, Eles acrescentam custo e podem exigir usinagem adicional após o tratamento.

Garantia da Qualidade

Componentes de precisão requerem verificação dimensional, Medição da rugosidade da superfície, e teste de dureza-esses passos são essenciais, mas demorados.

Processos de acabamento de superfície em usinagem do eixo do motor

Anodização

Principalmente para alumínio, A anodização aumenta a resistência à corrosão e pode ser tingida para identificação visual. Forma uma camada de óxido durável na superfície do eixo.

Galvanoplastia

Adiciona uma fina camada de cromo, níquel, ou zinco para resistência à corrosão, desgaste de proteção, e estética.

Fosfatando

Cria uma camada de fosfato cristalino em superfícies de aço para resistir à corrosão e promover a adesão da tinta.

Passivador

Usado para eixos de aço inoxidável para remover a contaminação por ferro, Melhorando a resistência à corrosão, formando uma camada superficial passiva rica em cromo.

Nitretagem

Difunde nitrogênio em superfícies de aço de liga, produzindo um caso difícil com distorção mínima. Ideal para aplicações de alto desgaste, como eixos de acionamento.

Pulverização térmica

Um método de revestimento de alto desempenho em que os materiais fundidos são pulverizados no eixo, melhorando o desgaste, aquecer, e resistência à corrosão sem alterar as dimensões da base.

Controle de qualidade na usinagem do eixo do motor

Inspeção dimensional

As dimensões críticas são verificadas usando CMMS, micrômetros, e medidores para garantir a conformidade com as tolerâncias (normalmente ± 0,01 mm ou mais apertado).

Teste de rugosidade da superfície

Profilômetros ou testadores táteis são usados para verificar os valores de RA, especialmente para superfícies de rolamento ou interfaces de vedação.

Verificação do material

Espectrometria, Teste de dureza, e testes de tração garantem a nota e as propriedades corretas do metal base.

Documentação e rastreabilidade

Manter registros de usinagem, Certificações de materiais, e os relatórios de inspeção ajudam a rastrear a qualidade da produção e atender aos padrões regulatórios.

Inspeção visual e de defeitos

Os eixos são inspecionados quanto a arranhões, Burrs, Marcas de ferramentas, ou anormalidades da superfície que podem afetar o desempenho.

Conclusão

A usinagem do eixo do motor é uma pedra angular do projeto e produção mecânica, desempenhando um papel vital nos sistemas rotativos em quase todos os setores. Do design e seleção de material ao acabamento e controle de qualidade, Cada estágio deve ser executado com precisão e atenção aos detalhes.

No Precisão máxima, Somos especializados na produção de eixos de motor que atendem aos mais altos padrões de precisão, desempenho, e durabilidade. Entre em contato conosco hoje para obter conselhos especializados ou para solicitar uma cotação de usinagem personalizada adaptada às necessidades do seu aplicativo.

Perguntas frequentes

1. Why is concentricity the most critical geometric tolerance for motor shafts?

Concentricity is paramount because a motor shaft’s function is purely rotational, transmitting torque at high speeds. Poor concentricity means the shaft’s centerline is misaligned with its axis of rotation, leading to:

-

Severe Vibration: Causes noise and dynamic imbalance.

-

Bearing Wear: Premature failure of bearings due to uneven loading.

- Reduced Efficiency: Loss of power and heat generation.

Manufacturers often use CNC grinding as the final process to ensure concentricity and diameter tolerance are within the required micron-level specifications.

2. How do keyed shafts and splined shafts differ in torque transmission?

Both types transfer torque without slippage, but they differ in engagement and load distribution:

-

Eixos de chave: Rely on a single keyway and key to lock the hub, concentrating the load and stress at a single point, which is suitable for moderate torque applications.

-

Eixos estampados: Feature multiple longitudinal grooves (estrias), distributing the torque load evenly across a much larger surface area. This allows splined shafts to handle significantly higher torque loads and provides greater alignment precision, making them common in heavy-duty transmissions.

3. Why are hollow shafts preferred over solid shafts in high-performance applications like robotics?

Hollow shafts are preferred because they significantly reduce rotational inertia while often retaining sufficient strength. Reducing inertia allows the motor system (especially in robotics or automation) para accelerate, decelerate, and reverse direction faster and with less energy. Adicionalmente, the central bore provides a convenient channel for routing internal wiring, sensores, or fluid lines without external interference.

4. What finishing process is used to enhance the surface hardness and fatigue strength of alloy steel shafts?

Nitretagem is the key finishing process. Nitriding involves diffusing nitrogen into the surface of alloy steel at elevated temperatures. This creates a hard, resistente ao desgaste case depth without the need for quenching, thus causing minimal dimensional distortion. This makes it ideal for high-wear areas like bearing journals or gear engagement surfaces, significantly improving the shaft’s fatigue life under cyclic loading.

5. Why is Electrical Discharge Machining (Música eletrônica) sometimes used in motor shaft production despite being slow?

EDM is used exclusively when the required feature cannot be machined using conventional methods due to dureza do material ou geometry complexity. It is often used to:

-

Cut keyways or slots in already fully hardened alloy steel shafts.

- Create complex internal features or precise micro-holes without introducing mechanical stress.

EDM removes material through spark erosion, making the process slow but capable of extreme precision regardless of the material’s hardness.

6. How does the choice of stainless steel grade (304 contra. 316) impact shaft application?

-

304 Aço inoxidável: Offers good corrosion resistance, Excelente máquina, and is generally more econômico. It is suitable for general industrial, comida, and non-marine applications.

-

316 Aço inoxidável: Contém molibdênio, which provides significantly superior corrosion resistance, particularly against chlorides, água salgada, and strong acids. It is the preferred, albeit more expensive, choice for marine, pharmaceutical, and chemical processing shafts.

7. What role does Surface Roughness Testing (Valores Ra) play in motor shaft quality control?

Teste de rugosidade da superfície, usually measuring the average roughness ($Ra$), is critical because the shaft’s surface interacts directly with bearings and seals.

-

Low Ra (acabamento suave): Essential for bearing journals to minimize friction, geração de calor, and wear on the bearing.

-

Controlled Ra: Critical for superfícies de vedação (where the shaft passes through a seal) to ensure the seal maintains integrity without rapidly wearing out the lip. Roughness that is too high or too low can cause failure. Typical Ra requirements for bearing surfaces are often less than 0.4 μm.