Em Usinagem CNC, cutting tool selection has a direct impact on productivity, qualidade da superfície, tooling costs, and machine uptime. Among advanced cutting tools, PCD inserts have become a preferred solution for manufacturers machining non-ferrous and abrasive materials at scale.

But what exactly is a PCD insert, and why is it often chosen over carbide, CBN, or ceramic tools?

Este guia fornece um complete, practical explanation of PCD inserts, including how they work, where they perform best, their advantages and limitations, and how to select the right PCD insert for your machining application.

O que é uma inserção de PCD?

A PCD insert, short for Polycrystalline Diamond insert, is a high-performance CNC cutting tool made from synthetic diamond particles that are sintered together under extreme temperature and pressure. During this sintering process, microscopic diamond crystals bond into a dense, ultra-hard cutting layer.

In most designs, the PCD cutting layer is permanently bonded to a tungsten carbide substrate. This structure combines:

O extreme hardness and wear resistance of diamond

O toughness and shock resistance of carbide

This hybrid structure allows PCD inserts to deliver exceptional cutting performance while remaining mechanically stable during high-speed machining.

Key Characteristics of PCD Inserts

Extremely high hardness (far exceeding carbide)

Outstanding resistance to abrasive wear

Excellent edge sharpness and edge retention

Very low friction during cutting

Longo, predictable tool life

Typical Machining Operations

PCD inserts are widely used in:

Tedioso

Perfuração

Alargamento

They are especially effective when machining non-ferrous metals and abrasive materials, where conventional tools wear rapidly.

Common Application Industries

PCD inserts are widely adopted in:

Automotive manufacturing

Componentes aeroespaciais

Electronics and semiconductor parts

Dispositivos médicos

Precision aluminum machining

Composite and plastic machining

Benefits of Using PCD Inserts

Longer Tool Life

One of the most significant advantages of PCD inserts is their exceptionally long tool life. Compared to carbide tools, PCD inserts can last 10 para 90 vezes mais, depending on the material and cutting conditions.

This makes them ideal for:

Produção em alto volume

Automated machining lines

Lights-out manufacturing

Longer tool life also means Menos mudanças de ferramentas, which directly reduces production interruptions.

High-Speed Machining Capability

PCD inserts can operate at much higher cutting speeds than conventional carbide tools. Their low friction and high thermal stability allow them to maintain cutting integrity even under aggressive machining conditions.

Os benefícios incluem:

Shorter cycle times

Higher machine throughput

Increased production capacity without adding machines

Excellent Accuracy and Surface Finish

PCD inserts maintain a sharp cutting edge for extended periods, which allows manufacturers to achieve:

Tight dimensional tolerances

Minimal burr formation

Smooth surface finishes

Consistent part quality across long production runs

This is particularly important for:

Precision mating parts

Sealing surfaces

Decorative or visible components

High Durability and Process Stability

Because PCD inserts resist abrasive wear so effectively, they provide estável, predictable machining performance. This stability reduces:

Tool chipping

Edge breakdown

Vibration-related defects

Como resultado, CNC machines can run more consistently with fewer unplanned stoppages.

Lower Total Cost of Ownership

While PCD inserts have a higher initial purchase cost, they typically reduce total machining costs over time. Cost savings come from:

Fewer tool replacements

Lower inventory requirements

Reduced machine downtime

Less scrap caused by worn tools

For high-volume or abrasive-material applications, PCD inserts often deliver the lowest cost per part.

Reduced CNC Machine Downtime

Frequent tool changes interrupt production and reduce machine utilization. PCD inserts minimize these interruptions, allowing:

Longer unattended machining runs

Improved OEE (Overall Equipment Effectiveness)

Better use of skilled labor

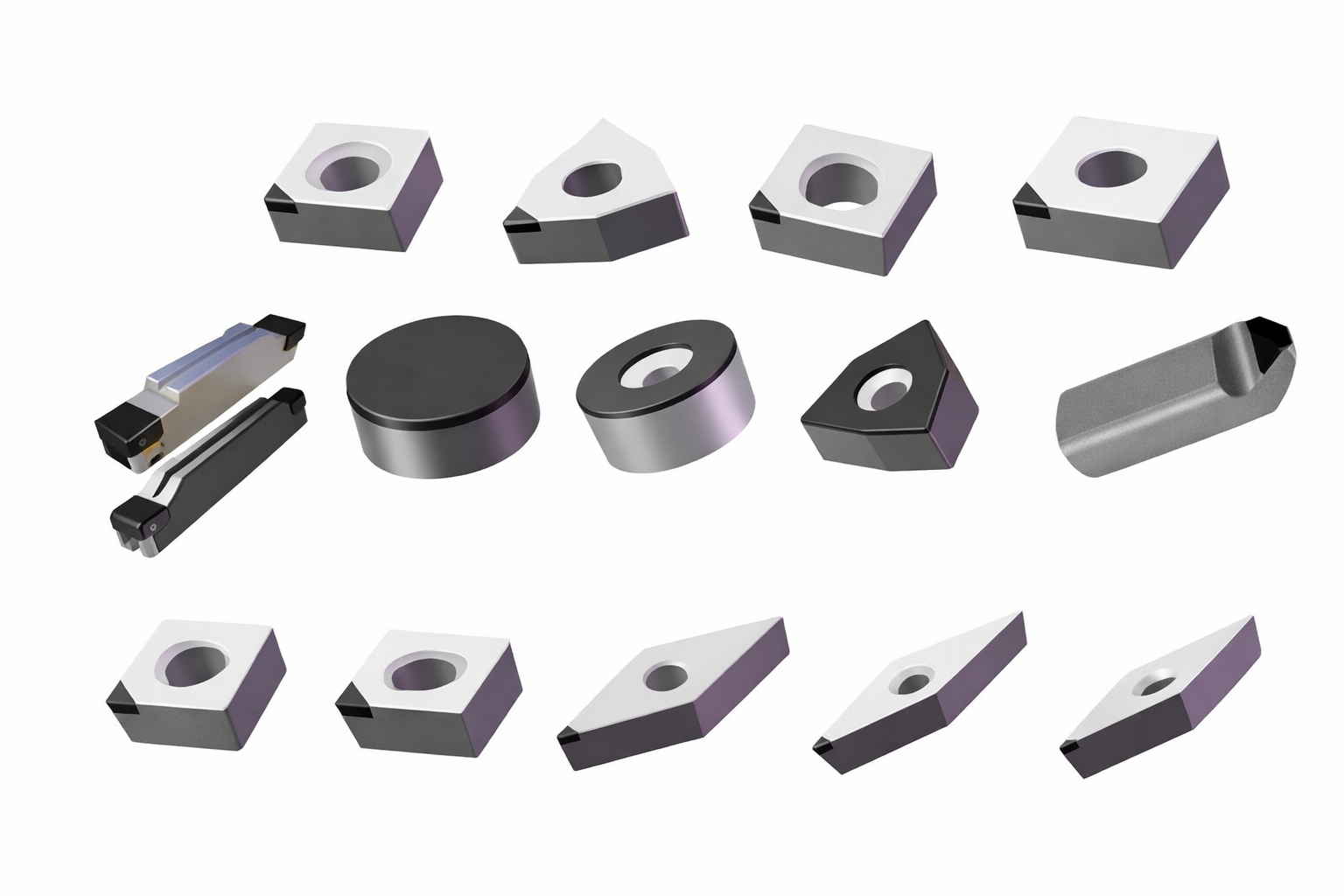

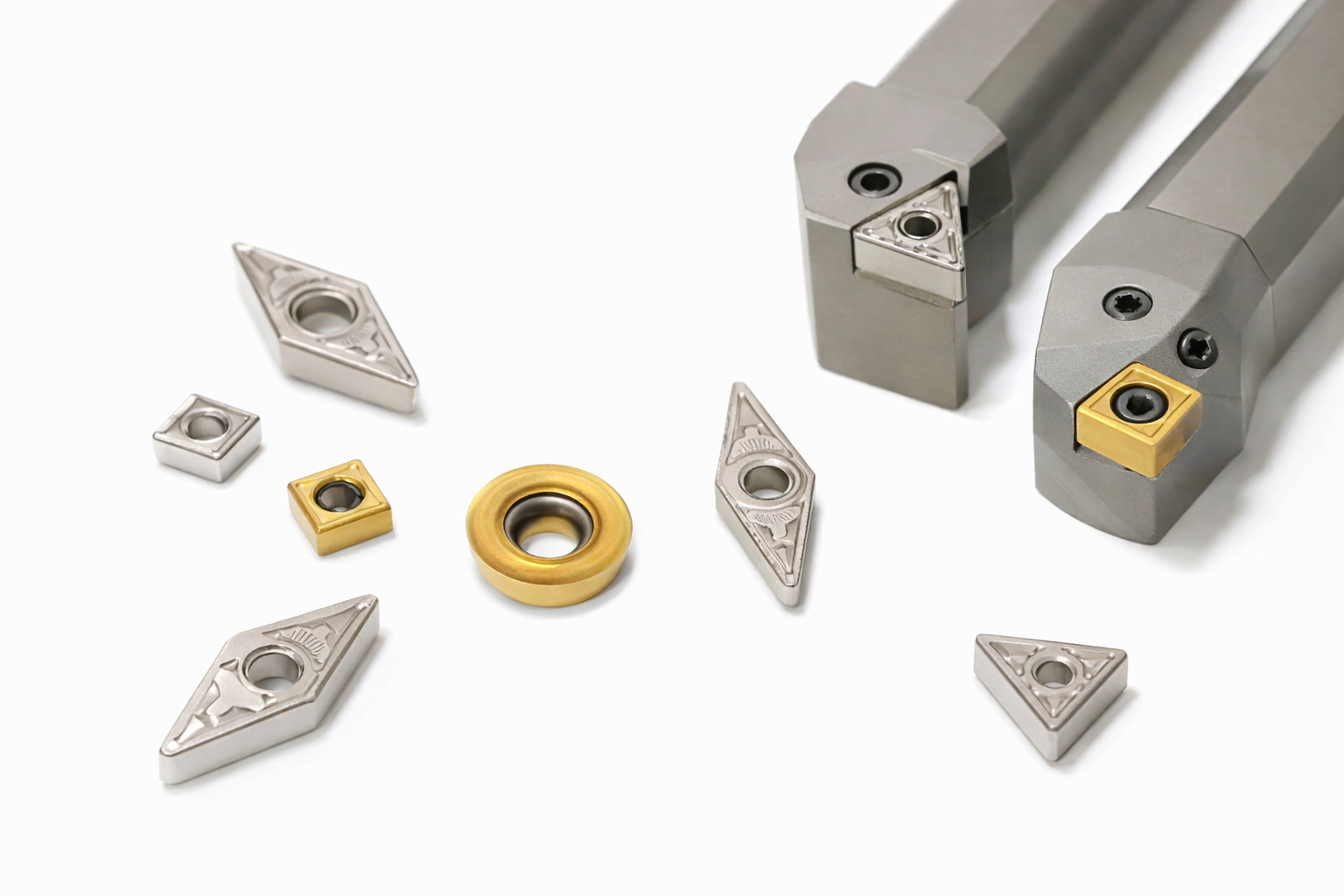

Common PCD Tools Used in Machining

PCD technology is available in multiple tool formats to support different machining tasks:

PCD Turning Inserts

Ideal for finishing and semi-finishing operations on aluminum and non-ferrous metals.

PCD Milling Cutters

Used for high-speed milling of aluminum alloys, compósitos, e plásticos.

PCD Boring Tools

Designed for precision internal machining where tight tolerances are critical.

PCD Drills and Reamers

Used for ultra-precise hole making with excellent surface finish.

PCD End Mills

Commonly applied in composite machining, graphite cutting, and plastic processing.

Each tool type can be customized based on geometry, edge preparation, e condições de corte.

Comparing PCD Inserts with Other Cutting Tools

PCD vs. Carbide Inserts

Carbide inserts are manufactured from tungsten carbide particles bonded with cobalt. They are versatile and cost-effective but wear relatively quickly when machining abrasive materials.

PCD vs. Carbide Summary:

PCD offers significantly longer tool life

PCD produces better surface finish

Carbide has lower initial cost

PCD has lower long-term cost in high-volume applications

PCD vs. CBN (Nitreto Cúbico de Boro)

CBN is the second-hardest cutting material after diamond. It excels in machining ferrous and hardened materials.

Key differences:

PCD is best for non-ferrous and abrasive materials

CBN is better for hardened steel and cast iron

Both offer excellent wear resistance, but for different materials

PCD vs. Ceramic Cutting Tools

Ceramic tools perform well in high-temperature, dry cutting applications, especially on hard metals.

Comparison highlights:

PCD is much harder and more wear-resistant than ceramics

Ceramics are better for ferrous materials and dry cutting

PCD is superior for aluminum, compósitos, e plásticos

How to Choose the Right PCD Insert

Selecting the right PCD insert requires evaluating several technical factors.

Material da peça

PCD inserts perform best on:

Aluminum and aluminum alloys

Copper and brass

Magnesium alloys

Plastics and polymers

Grafite

Composite materials (PRFC, PRFV)

They are not recommended for ferrous metals, as iron causes rapid chemical wear.

End-Product Application

Consider whether your application requires:

Rough machining

Semi-finishing

High-precision finishing

PCD inserts are particularly valuable where surface finish, precisão, and consistency are critical.

Workpiece Shape and Geometry

Insert geometry must match part design. Common PCD insert shapes include:

CCMT

DCGT

CCGT

Sharp-edged PCD inserts are preferred for finishing, while chamfered edges provide better durability for variable cutting conditions.

Cutting Parameters and Machine Stability

PCD tools require:

Stable CNC machines

Proper fixturing

Optimized speeds and feeds

Machine rigidity is essential to avoid vibration, which can damage even super-hard cutting edges.

When to Use a PCD Insert

PCD inserts are the best choice when:

Producing high volumes of non-ferrous parts

Machining abrasive materials

Surface finish quality is critical

Tool life and process stability outweigh initial tool cost

Reducing downtime is a priority

Considerações Finais

For CNC shops and manufacturers machining aluminum, compósitos, or other abrasive materials, PCD inserts are often the most economical and reliable solution over time.

If you are evaluating PCD inserts for your production line, working with an experienced tooling or machining partner can help ensure the right geometry, parâmetros de corte, and cost-performance balance for your application.

Perguntas frequentes

1. Why do my carbide tools wear out so quickly when machining aluminum or composites?

Carbide tools wear rapidly on aluminum alloys and composite materials due to abrasive particles, built-up edge, and friction-related heat. PCD inserts are specifically designed to resist abrasive wear and reduce material adhesion, which dramatically extends tool life in these applications.

2. Are PCD inserts worth the higher upfront cost?

Sim, in most high-volume or abrasive-material applications. Although PCD inserts cost more initially, they significantly reduce tool change frequency, machine downtime, scrap rates, and labor intervention, resulting in a much lower cost per part ao longo do tempo.

3. Can PCD inserts be used on steel or stainless steel?

Não. PCD inserts are not recommended for ferrous materials such as carbon steel or stainless steel. Iron reacts chemically with diamond at high temperatures, causing rapid tool wear. For ferrous materials, CBN or ceramic tools are more suitable.

4. Do PCD inserts require special CNC machines or setups?

PCD inserts do not require special machines, but they do perform best on rígido, well-maintained CNC equipment with stable fixturing. Proper speeds, Feeds, and vibration control are essential to fully realize their performance and tool life advantages.

5. How do PCD inserts improve surface finish and part consistency?

PCD inserts maintain a sharp cutting edge for a long time, which minimizes burrs, conversa, and edge breakdown. Isso leva a consistent surface finishes, tolerâncias mais rígidas, and uniform quality across long production runs—especially important for precision or cosmetic parts.

6. What industries benefit the most from using PCD inserts?

Industries that frequently machine non-ferrous or abrasive materials beneficiar mais, incluindo automotivo, aeroespacial, eletrônicos, dispositivos médicos, and composite manufacturing. Any operation prioritizing high output, precisão, and low downtime can gain value from PCD tooling.

7. How do I choose the correct PCD insert geometry for my application?

The correct geometry depends on tipo de material, cutting conditions, and part design. Sharp-edge geometries are best for finishing, while chamfered or reinforced edges provide better durability for variable or interrupted cuts. Consulting with tooling or machining experts can help optimize insert selection.