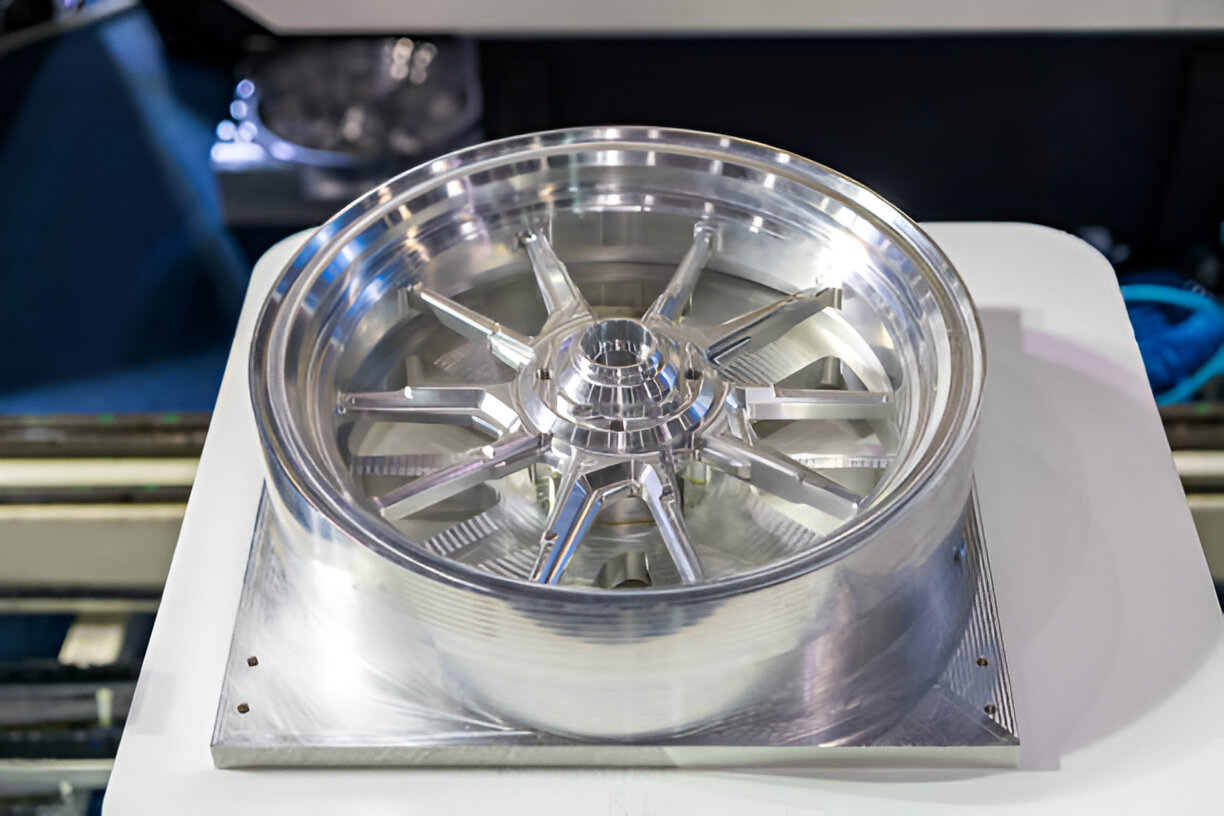

Nosso avançado 4-axis and 5-axis CNC machines can meticulously shape Invar alloys. This allows us to produce complex geometries with exceptional accuracy. We maintain tolerances as tight as five microns, even on intricate and thin-walled designs.

Every project is taken with caution. Our experts follow a step-by-step process all the way through production. Além disso, our engineering department carefully checks your CAD files so that they can be manufactured and machined in the best way possible. Where necessary, we give recommendations to optimize your design. This reduces most of the shortcomings, leads times, and facilitates seamless flow of work from start-up to finish.

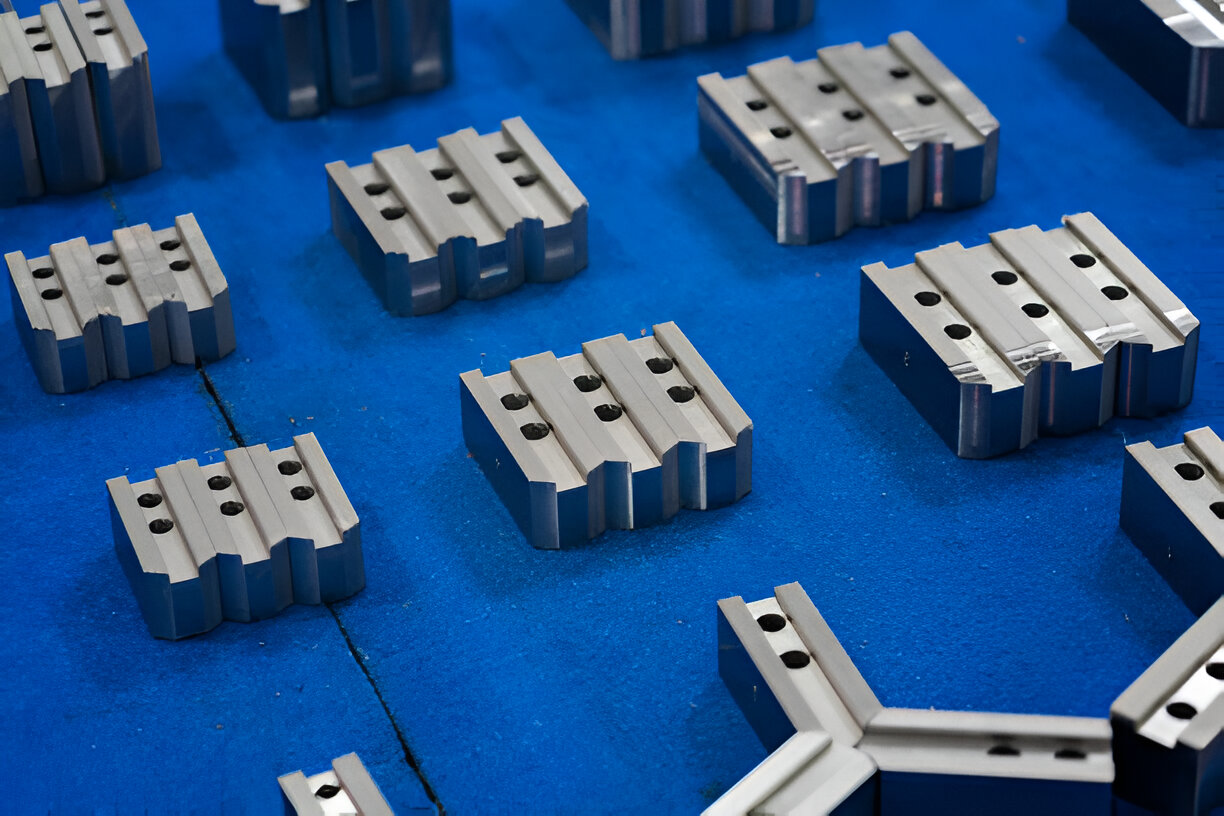

Seja um single prototype or a low production run, our process gives consistency and repeatability. Our stricter inspection procedures are conducted according to ISO quality standards. In-process and final inspections are done on all the parts. These authenticate the dimensions and the surface quality.

Our packaging methods ensure parts are protected and ready for delivery. No topo, we are committed to providing precision, confiabilidade, and exceptional service. When your application needs accuracy and thermal stability, our Invar machining capabilities deliver proven results.