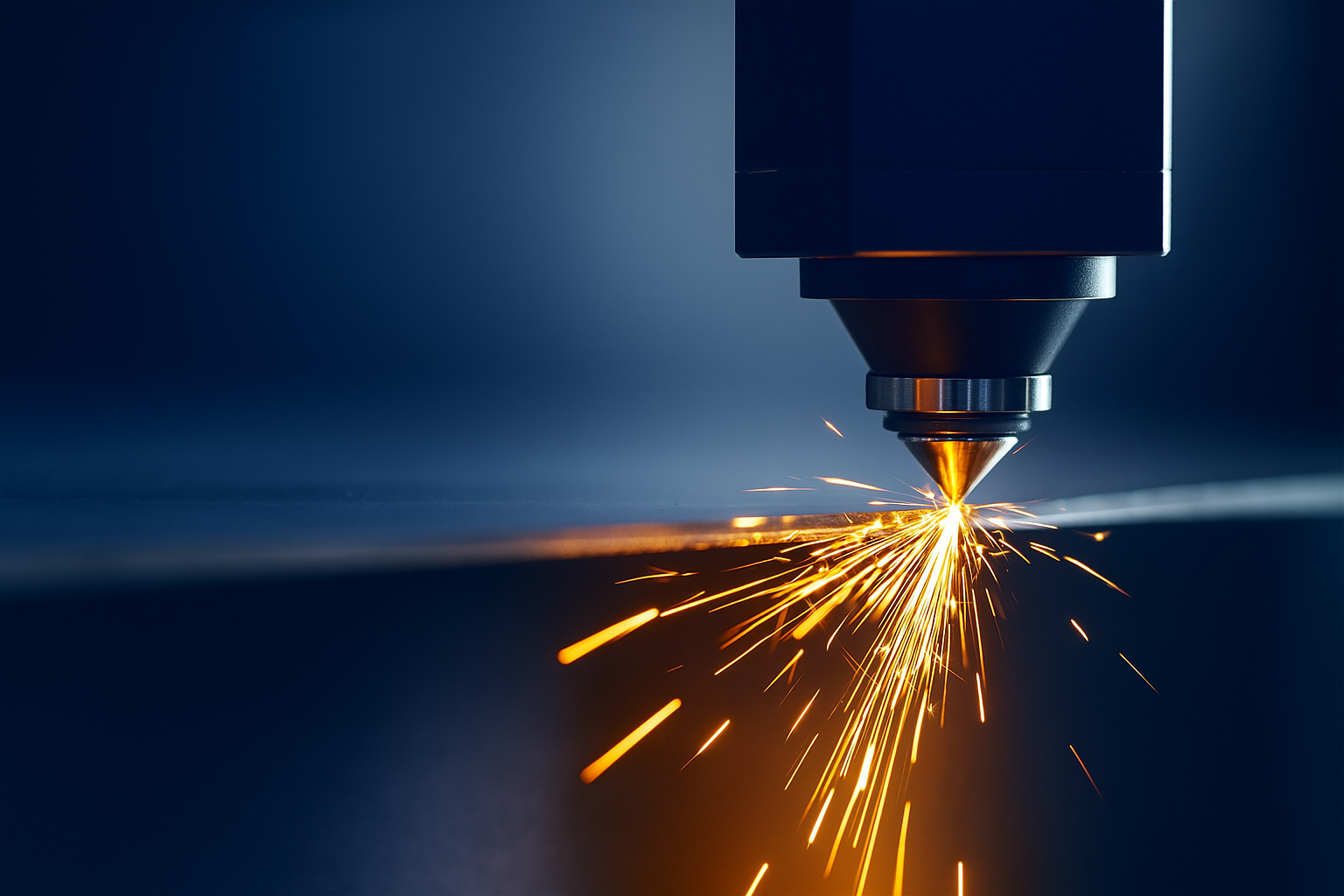

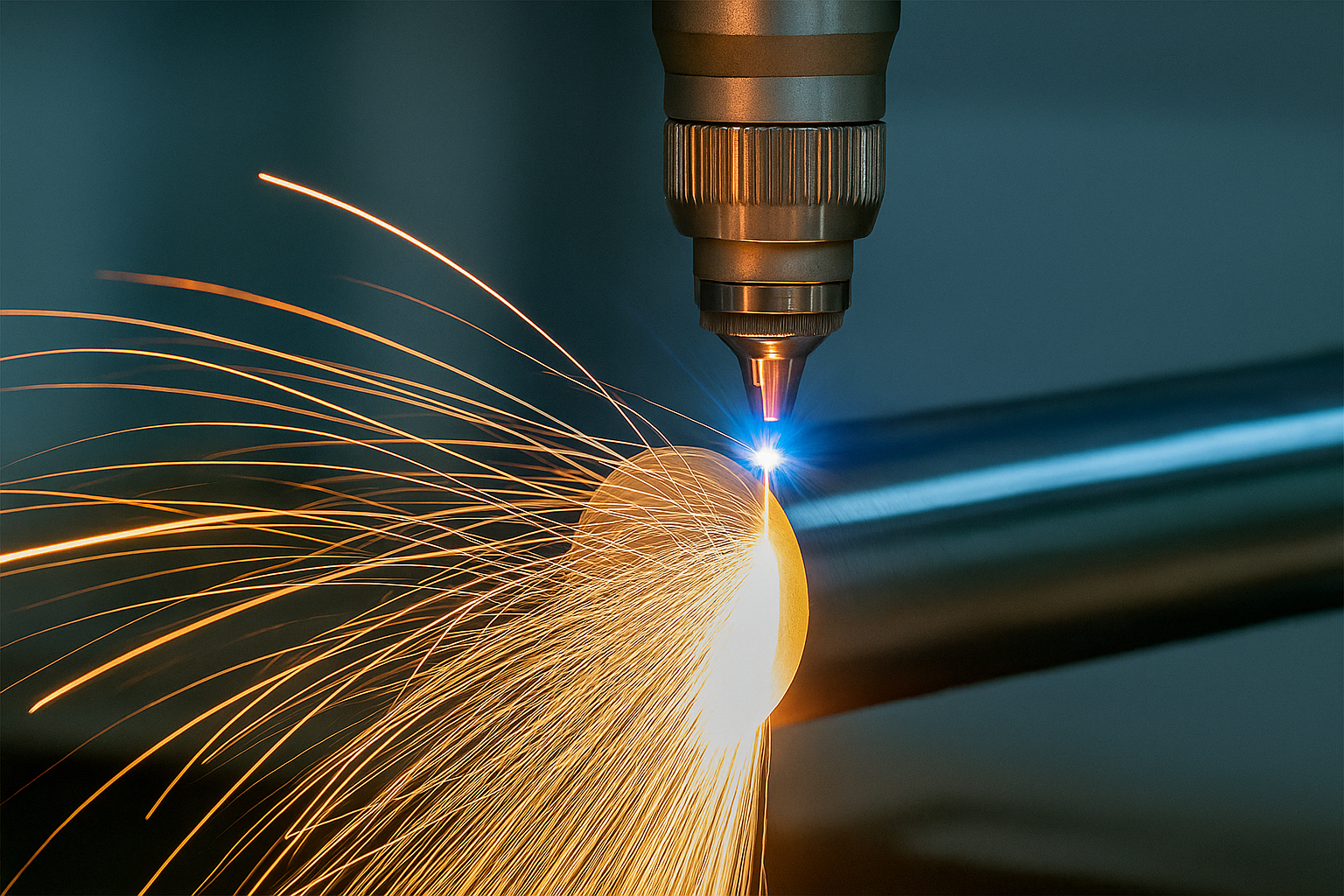

O que é usinagem de aço de ferramenta?

A usinagem do aço da ferramenta inclui a modelagem, corte, e ferramentas de acabamento ligas de aço em partes ou componentes úteis. Ele usa métodos como moagem CNC, girando, Música eletrônica, e moagem. Sua dureza, durabilidade, e força notável sob pressão os torna perfeitos para cortar ferramentas e em várias indústrias.