Laiton est un alliage de zinc et de cuivre et est considéré comme un alliage métallique populaire pour les applications esthétiques. A ses admirateurs, beaucoup se demandent Le laiton est-il magnétique? Le laiton n'a pas de propriétés magnétiques. Cependant, ses propriétés magnétiques dépendent du contenu matériel fabriqué.

Il convient de mentionner que, le cuivre et le zinc sous leur forme pure ne sont pas des matériaux magnétiques. La plupart des alliages de laiton peuvent peu réagir au magnétisme. Explorons magnétisme du laiton en comprenant ses propriétés, et applications pratiques.

Le laiton est-il un matériau ferromagnétique?

Magnétisme du laiton

Laiton n'est pas considéré comme un matériau ferromagnétique. Le 5ème groupe de métaux appartient aux matériaux ferromagnétiques. Ces matériaux sont généralement attirés par les aimants par une force externe. Par exemple, fer. Mais le cuivre, un élément qui compose le laiton, n'a pas une telle propriété, et le zinc non plus.

Le laiton est non ferromagnétique, cependant, ses propriétés magnétiques peuvent varier selon le type. En outre, il est relativement beaucoup plus faible pour les métaux ferromagnétiques en termes de performances dans les champs magnétiques.

Propriétés paramagnétiques et diamagnétiques du laiton

Le laiton n’est ni une substance hautement paramagnétique ni hautement diamagnétique. Les matériaux paramagnétiques sont faiblement attirés par les champs magnétiques. inversement, les matériaux diamagnétiques sont repoussés par les champs magnétiques.

Le laiton présente de faibles propriétés diamagnétiques. Il repousse donc faiblement le champ magnétique. Cependant, cet effet est trop faible pour être observé dans des situations réelles. La composition du laiton joue un rôle majeur dans le comportement magnétique.

Facteurs clés influençant le magnétisme du laiton

Les facteurs les plus courants comprennent:

Composition de l'alliage

Le type de laiton détermine ses propriétés magnétiques. La composition principale du laiton est le cuivre et le zinc. En général, le cuivre et le zinc ne sont pas magnétiques. Le fer ou le nickel augmentent les propriétés magnétiques du laiton. En outre, plus le zinc est élevé, plus ça devient magnétique.

Température

La chaleur/thermique affecte négativement la réponse magnétique du laiton. Chauffer le laiton peut diminuer ses propriétés magnétiques: Le refroidissement du laiton pourrait peut-être supprimer certains de ces effets magnétiques.. En termes simples, des températures basses ou élevées peuvent altérer la structure du laiton. Cependant, à température ambiante, le comportement du laiton devient stable.

Impuretés

Le magnétisme du laiton dépend de la présence d'impuretés. La présence de petites quantités de métaux ferromagnétiques dans le laiton le rend magnétique. L’existence d’un individu ou la présence de fer ou de nickel peuvent affecter son attrait.. Le laiton avec une moindre teneur en impuretés a moins de propriétés magnétiques.

Intensité du champ magnétique

Des champs magnétiques plus puissants peuvent altérer le laiton. Un aimant puissant peut induire un faible magnétisme. Les laitons ne sont peut-être pas fortement attirés mais peuvent réagir. L'impact est masqué et à peine visible. L'expérience sur l'intensité du champ montre des caractéristiques magnétiques du laiton légèrement différentes de celles des deux expériences précédentes..

Méthodes de traitement

Le traitement du laiton peut modifier ses propriétés après un écrouissage ou un durcissement.. La manipulation de la structure en laiton modifie ses propriétés concernant sa réponse aux aimants. Le laiton laminé ou martelé peut également avoir un comportement différent. Donc, le traitement de fabrication joue un rôle important dans la détermination des caractéristiques magnétiques de fabrication du laiton.

Structure cristalline interne

Magnétisme de contrainte de structure cristalline en laiton. Puisqu'il a un cube compact (PCC) structure cristalline connue sous le nom de cube à faces centrées (FCC) structure, la structure prévue ne doit pas être facilement alignée magnétiquement. Le positionnement des atomes est limité par les caractéristiques magnétiques. La structure cristalline peut être modifiée, ce qui modifie le magnétisme.

Tester le magnétisme du laiton

Les méthodes typiques de test de magnétisme pour le laiton comprennent:

Test de susceptibilité magnétique

La susceptibilité magnétique décrit la nature du matériau en réponse à un champ magnétique. Il est conseillé d'utiliser un instrument nano-sensible (un magnétomètre à échantillon vibrant (VSM)). Le VSM détermine la réponse du laiton dans un domaine appliqué. Donc, donne un résultat soit nul, soit une valeur faible pour la magnétisation, confirmant ainsi la caractéristique non magnétique du métal.

Mesure du Gaussmètre

Un gaussmètre mesure l'intensité du champ magnétique dans une zone. Dans le processus, Tenez le Gaussmètre à côté de l'échantillon de laiton.. Il ne produit normalement aucune lecture ou une lecture proche de zéro.. Cela signifie qu'aucun champ magnétique n'est présent.

Analyse de la courbe de magnétisation

Une courbe de magnétisation(boucle d'hystérésis) permet de déterminer le degré d'aimantation du laiton. Placer le laiton à travers un champ magnétique externe. Déterminez ensuite sa magnétisation. L'échantillon de laiton montrera peu ou pas de réaction aux aimants, démontrant des propriétés ferromagnétiques minimales.

Calcul de la température de Curie

La température de Curie définit le matériau ferromagnétique qui n'obtient plus ses propriétés magnétiques. Prends le laiton et chauffe-le. Alors, mesurer précisément l'évolution de son aimantation. Aucun des trois éléments n'a de point de Curie car ils ne sont pas ferromagnétiques.

Analyse DRX(Analyse par diffraction des rayons X)

La diffraction des rayons X renseigne sur la disposition interne du laiton. La structure cristallographique du laiton est le plus souvent cubique à faces centrées. (FCC). Cela ne lui permet pas de posséder des caractéristiques magnétiques. XRD prend également en charge l'absence de domaines magnétiquement actifs dans le matériau d'un point de vue structurel..

Magnétisation en fonction de la température (M-T) Test

Les tests M-T peuvent être effectués à l'aide d'un magnétomètre. Cela devrait être fait à différentes températures. Cependant, le laiton ne subit généralement pas de changement important de magnétisation à un grand intervalle de température.

Le laiton peut-il être magnétisé?

En fait, le laiton n'est pas magnétique bien qu'il puisse être légèrement attiré par un aimant à cause du cuivre et du zinc. Ces constituants ne permettent pas le développement de caractéristiques magnétiques. Une autre caractéristique qui distingue le matériau ferromagnétique du laiton est qu'il ne peut pas supporter l'alignement permanent des molécules en présence d'un champ magnétique..

Dans certains cas, le laiton peut présenter une petite propriété magnétique. Cependant, il ne peut pas être rendu magnétique de façon permanente car il ne possède pas le comportement des métaux ferromagnétiques comme le fer. C’est pourquoi le processus de magnétisation du laiton diffère de celui de l’acier ou du fer..

Applications du laiton non magnétique

Le laiton est largement utilisé dans les environnements de fabrication. Les applications courantes incluent:

Connecteurs électriques

Le laiton est le matériau le plus fréquemment utilisé dans les connecteurs électriques. Cela n'interfère pas avec les signaux, ce qui le rend idéal pour l'application car il est non magnétique. Le laiton a une conductivité électrique élevée et résiste à la corrosion. Ces qualités sont optimales pour les applications électriques à courant élevé. Le laiton non magnétique contribue à améliorer la stabilité des équipements électriques.

Instruments de musique

De nombreux instruments de musique sont fabriqués en laiton. Les trompettes et les saxophones ne peuvent pas être fabriqués à partir de matériaux magnétiques. Pour la production sonore, les caractéristiques de réflectivité acoustique de l’alliage sont parfaites. Le laiton non magnétique contribue à donner la solidité et la résistance nécessaires à la corrosion. En outre, la qualité tonale du son se maintient dans le temps.

Matériel marin

Le laiton est souvent utilisé dans les applications marines. Il convient à une utilisation en eau de mer. Raccords de pompe, vannes, et les hélices sont en laiton. Parce qu'il protège la surface externe de l'appareil de l'influence magnétique des appareils de navigation et garantit la longévité du matériau..

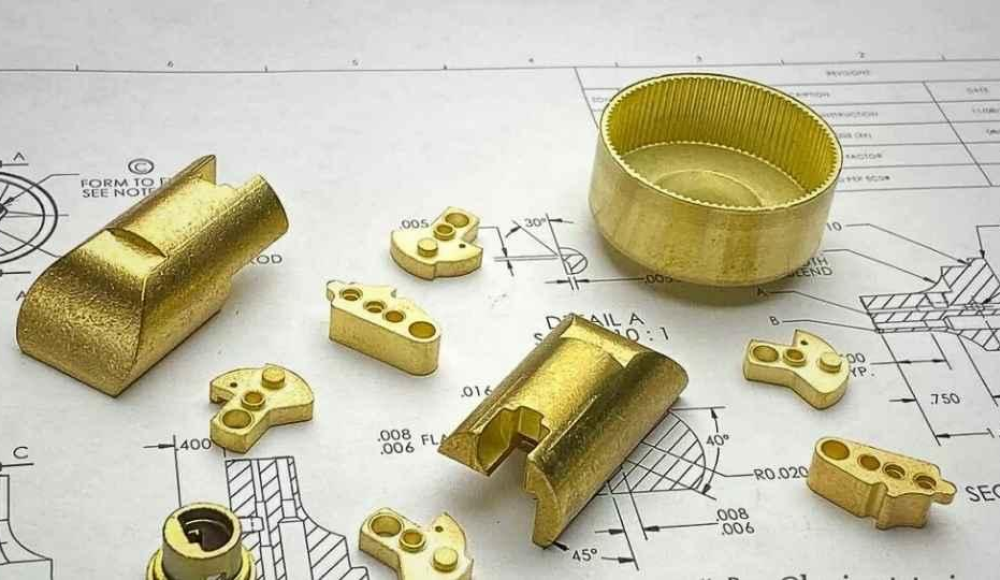

Pièces d'usinage de précision

Le laiton non magnétique est facile à usiner. Donc, il peut être transformé en formes complexes. Il est sans retrait et non corrosif. Donc, il n'interfère pas avec les outils magnétiques. Les machines de haute précision nécessitent des pièces en laiton.

Comment le magnétisme du laiton affecte son usinage?

Généralement, Le laiton ne pose pas beaucoup de problèmes en terme d'usinage du fait de son magnétisme modéré. Cependant, les propriétés non magnétiques peuvent toujours avoir un impact. Vous trouverez ci-dessous cinq techniques d'usinage et leur interaction avec les propriétés magnétiques du laiton.:

Fraisage CNC en laiton

Fraisage CNC en laiton

Dans Fraisage CNC, le laiton est découpé dans la forme requise avec des spécifications précises en utilisant des instructions assistées par ordinateur. Comme le laiton est moins affecté par le magnétisme,, il est plus facile à manipuler pendant les opérations. En outre, puisque le matériau ne colle pas aux aimants, il n'y a aucune exigence concernant les pinces ou les fixations magnétiques.

Tournage CNC en laiton

Pièces tournées CNC en laiton

Le tournage CNC du laiton est un moyen d'usinage conventionnel. Le laiton est ferromagnétique, il n'y a donc aucune possibilité qu'un outil magnétique affecte le matériau. De plus, le laiton non magnétique réduit également les problèmes de fixation de la pièce, réduisant ainsi le temps et le coût de configuration de la machine.

Meulage CNC en laiton

Le meulage du laiton est un processus délicat. Mais la propriété non magnétique est pratique. Le laiton ne tirera pas ou n’endommagera pas les outils de meulage par magnétisme, donc ça donne une mouture vraie et précise. Cette propriété permet d'obtenir des finitions de surface uniformes pour le bâtiment.

Forage CNC en laiton

Forage CNC en laiton

Le laiton est généralement facile à percer en raison de ses caractéristiques non magnétiques. Il n'adhère pas magnétiquement aux forets et élimine ainsi l'usure rapide des forets.. Cela conduit à une création de trou plus rapide et à une traînée réduite entre le foret et la formation en plus d'un fonctionnement fluide de l'outil.. Le laiton non magnétique ne permet pas le grippage ou le blocage du foret.

Usinage électrochimique du laiton

La technique ECM est optimale pour les travaux complexes et à tolérance serrée. Les propriétés non magnétiques du laiton sont souhaitables pour le processus ECM. Comme les forces magnétiques ne sont pas impliquées dans le fonctionnement. Les courants électriques utilisés dans l'ECM, et le laiton amagnétique garantissent un taux d'enlèvement de matière contrôlable. Les caractéristiques du matériau incluent la capacité à enlever de la matière de manière contrôlée sans consommation excessive d'outils..

Résumé

Laiton a de nombreuses utilisations dans les applications d'usinage en raison de son non-magnétisme. L'aspect a fait des processus tels que Commande numérique par ordinateur (CNC) fraisage, tournant, et forage être rendu plus facile car il a une résistance inhérente aux interférences magnétiques. En outre, cela ne pose aucun problème lié au magnétisme, mais l'utilisation des méthodes d'usinage appropriées garantit des résultats de haute qualité. La connaissance des propriétés du laiton permet d'obtenir des performances maximales dans des conditions industrielles.

Pour obtenir un usinage du laiton de haute précision et des solutions personnalisées, Précision au sommet est le meilleur endroit où aller. Appelez-nous aujourd'hui pour en savoir plus sur la façon dont nous pouvons répondre précisément à vos besoins.