Plastic CNC machining has become widespread across different sectors because it enables the production of high-accuracy parts with fine repeatability. Unlike other traditional means of plastic manufacture, Usinage CNC provides close tolerance and intricate geometric features that would be hard to obtain through any other method. Donc, if you produce parts for healthcare devices, aéronef, or household products, stay familiar with plastic CNC machining.

This article will examine six things you need to know about Plastic CNC Machining, including suitable material selection and finishing processes.

How Would You Define Plastic CNC Machining?

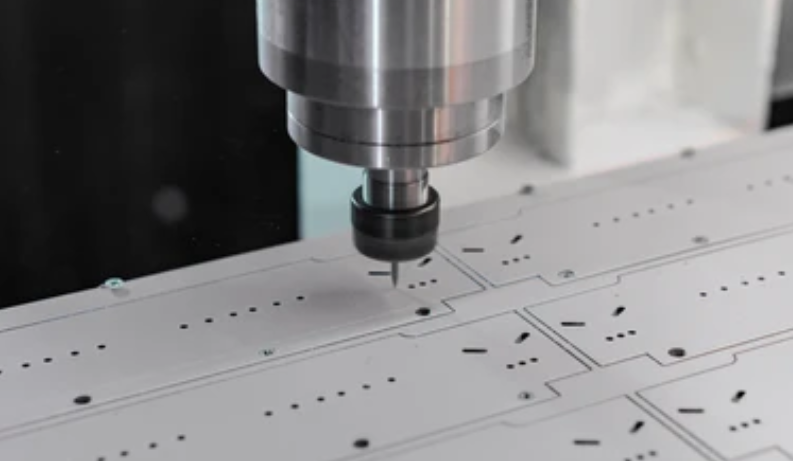

Plastic CNC machining is the process of cutting, shaping, and refining plastic materials using computer-controlled equipment. CNC (Commande numérique par ordinateur) technology allows manufacturers to produce accurate and complex plastic components based on computer-aided designs.

CNC machining is ideal for low to medium-rate production and prototypes. It is a bit cheaper than injection molding. The process has subtractive manufacturing, whereby a cutting tool grinds material from a solid plastic block to produce the final product.

Can Plastic Be CNC Machined?

Oui, plastic is CNC machinable; it is a common method used to create good-quality plastic parts. Various plastics have different machinability, c'est à dire., dureté, stabilité thermique, and structural strength.

Lower-hardness plastics are more likely to melt or deform during high-speed machining. D'autre part, engineering plastics such as PEEK and Delrin have good machinability and stability. The capability to CNC mill plastics offers several benefits, y compris;

- High accuracy and close tolerances

- No requirement for costly molds

- Customization and fast prototyping

- Smooth and clean surface finishes

Néanmoins, must machine plastics using smart tools, vitesses, and cooling methods to avoid problems like warping, fusion, or tool wear.

What Plastic can be machined?

Not all plastics are machinable on a CNC machine. The best plastics to be machined have good dimensional stability, faible dilatation thermique, et résistance à l'usure. Some of the most common plastics used for CNC machining are mentioned below:

Acétal (Delrin)

- Excellent machinability and stability

- Faible frottement, ideal for gears and bearings

- Excellent mechanical strength and durability

Polycarbonate (PC)

- Impact resistant and strong

- Transparent and hence ideal for optical components

- Resistant to heat but can be prone to stress cracking

Acrylique (PMMA)

- Sensitive and polishable

- Used in light guides, displays, and signs

- Brittle and will need to be machined carefully

Nylon

- Tough and strong

- Extensively used in mechanical components like pulleys and bushings

- Absorbs moisture, affecting dimensional stability

COUP D'OEIL (Polyether Ether Ketone)

- High-performance engineering plastic

- Heat and good chemical resistance

- Utilisé dans l'aérospatiale, médical, and automotive sectors

Complete Process of Plastics CNC Machining

CNC machining plastics apply numerous techniques to achieve the required shape, précision, et qualité de surface. These processes enable greater speed, cutting tool sharpness, and cooling. This technique also provides material integrity and dimensions.

The typical Machining Techniques are Milling, Tournant, Forage, Routing, Affûtage, and Polishing.

Fraisage

Milling with a rotating cutting tool is ideal for making intricate shapes, machines à sous, et poches. You can use sharp tools and accurate feed rates to preserve surface quality. It will prevent the surface from melting or deformation.

Tournant

It is appropriate for cylindrical parts like rods and bushings since the workpiece is turned while a fixed cutting tool forms it, rotating. Heat accumulation is an issue that can be prevented in this operation by using the right coolant to avoid too much heat.

Forage

Special drill bits are used to make holes in plastic parts. The method has the benefits of slow speed and sharp tools to avoid cracking or damage and is, donc, highly appropriate for making enclosures, trous de fixation, et accessoires.

Routing

High-speed routers route through complex designs and contours into plastic sheets or blocks by routing. Uses such as signage, acrylic displays, and decorative pieces utilize this method because of the demand for fine detailing.

Affûtage & Polissage

Finition: the grinding and polishing of plastic parts, eliminating machining marks, and enhancing the surface appearance. Cependant, these operations are essential in smooth surface finishes due to more precise applications (par exemple., Optical or decorative parts),

Why is CNC Plastic Machining More Popular Than Other Techniques?

CNC machining is the most prevalent method used for plastic manufacturing due to its many advantages:

- High Precision and Replicability: CNC machining is more precise and appropriate for complex parts with tight tolerances.

- No Need for Expensive Molds: CNC machining does not require expensive tooling such as injection molding. Ainsi, it is cost-effective for low-production runs and prototypes.

- Large compatibilité matérielle: CNC machining supports a variety of plastic materials, each having certain characteristics for different industries.

- Délais d'exécution rapides: Prototyping and low-volume production are much faster than traditional molding operations.

- Personnalisation & Flexibilité de conception: CNC machining allows for intricate and highly customized designs without the limitations of molds.

Method to Get an Ideal Finish on Plastic Components

Proper tools, machining parameters, cooling methods, and post-machining operations are needed for the superior finish of plastic CNC components. Let us see how we can get an ideal finish on CNC plastic components.

- Select Suitable Cutting Tools: Sharp tips of carbide or diamond-coated cutters and single-fluted end mills prevent heat generation.

- Modify Cutting Speeds and Feeds: Lower cutting speeds to avoid melting the workpiece and suppress tool chatter.

- Implement Proper Cooling Methods: Air blowers and mist coolers aid in heat dissipation from the plastic surface without harming the plastic surface.

- Implement Post-Machining Operations: Smooth surfaces and transparency, such as vapor polishing, flame polishing, ponçage, and buffing.

Various Uses of CNC Plastic Parts

CNC plastic machining is utilized widely in numerous industries because it saves cost, is versatile and precise. CNC plastic parts machined by CNC are manufactured in dimensions ranging from the smallest micro to the largest. They are applied to medical devices, aerospace components because they are strong, lumière, and possess high-performing characteristics.

The following are five common applications:

- Landfill and solid disposal: PEEK and PTFE are biocompatible polymers. They have various applications in surgical devices, implants, and diagnostic devices in the Medical & Healthcare sector.

- Aérospatial & Défense: Polymers such as Ultem and PEEK can be lightweight yet high-strength materials. They have applications in varying ranges in aircraft and defense component manufacturing.

- Automobile & Transport: Heat plastic parts may be Delrin or Nylon. It is a heat-resistant pinch in dash components, composants du moteur, or prototypes.

- Wear Against Abrasion: Polycarbonate and ABS offer abrasion resistance in rims, control panels, couvertures, guards, balustrades, and other components with moderate loading.

- Hard-wearing materials: Delrin and UHMW-PE materials find applications in gears, machines, and abrasion-resistant components.

Conclusion

En conclusion, six things you need to know about Plastic CNC Machining. Plastic CNC machining is a precise and adaptable production process that provides precision, adaptability, et l'abordabilité. The correct knowledge of material choice and finishing processes supports guaranteeing quality plastic parts for numerous applications.

CNC plastic machining is the first choice of industries due to the ability to manufacture intricate, hardened, and high-performance parts. Donc, CNC machining guarantees quality products with the least wastage and optimal efficiency for prototypes.

FAQs – Things you need to know about Plastic CNC Machining

- Is CNC machining superior to 3D printing for plastic components?

It depends. CNC machining is more precise, has improved surface finishes, and creates stronger components. It has wide examples in functional parts and precision applications. 3D printing is best for rapid prototyping and complex shapes. It can be less robust and poorer in surface finish, cependant.

- What is the normal tolerance of CNC-machined plastic components?

The tolerance is ±0.005 inches (±0,127 mm). It is ±0.001 inches (±0,025 mm) for special equipment applications. Tolerance is variable according to the nature of plastic and machine operation.

- Is plastic CNC machining expensive?

The price changes with factors, c'est à dire., type de matériau, complexité, et volume de production. Low-complexity plastic parts can cost just a few dollars per unit, whereas precision or custom-designed ones will be costly. CNC machining is affordable for low and medium-volume production compared to injection molding.

- How is the production of CNC plastic parts done?

Lead times differ based on part complexity and order quantity. We can manufacture simple parts in hours, whereas complex parts or big orders take weeks.