Our Brass Precision Turning Services

Précision au sommet specializes in creating precision-machined brass components that excel in diverse industries by providing superior performance. Our CNC turning technology enables us to manufacture brass components with strict specifications and high surface quality, which serve the needs of the automotive, aérospatial, et les secteurs médicaux, as well as electronics applications. Our company provides exact-specification brass components accompanied by quick delivery for both prototyping needs and large production volumes.

Envoyez votre demande aujourd'hui

What Makes Our Brass Precision Turning Services Stand Out?

Tops Precision focuses on delivering high-quality precision turning services that utilize premium brass grades, which serve specific purposes. Free-cutting brass C36000 shows excellent machining properties, which enable the production of fasteners and electrical connectors on an industrial scale. The durable characteristics of C26000 cartridge brass bring excellent corrosion resistance and structural strength, thus making it preferred for plumbing fittings and electrical parts applications. C28000 Muntz metal stands out for maritime purposes because it demonstrates superior resistance to corrosion in saltwater, which qualifies it as an outstanding solution for marine hardware applications.

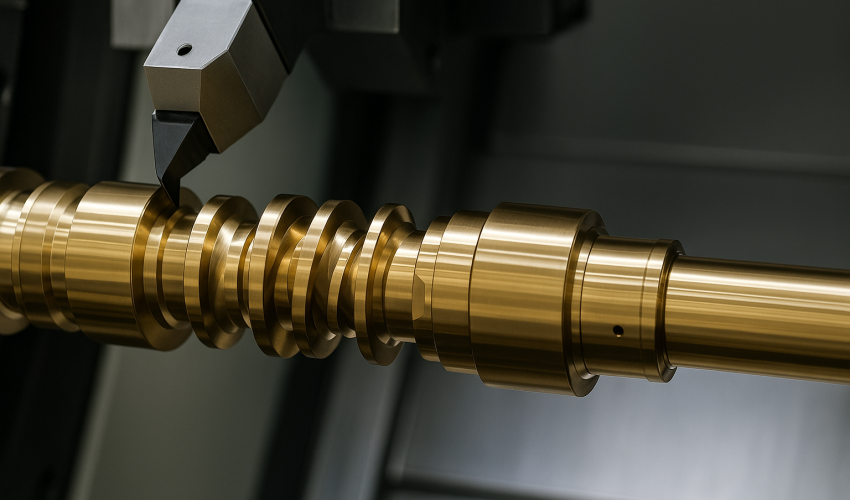

Tops Précision uses modern CNC turning centers to produce parts with an accuracy range of ±0.005mm. The exact precision level of our components enables perfect integration into end products to lower the number of mistakes. The production system from our company guarantees precise results for basic and intricate designs alike.

Tops Précision maintains its commitment to delivering products according to all established client deadlines. Our organization delivers brass parts to customers through quick production scheduling that completes orders within a 03 business period. Our efficient procedures, combined with our expert staff, enable rapid and effective control of small and large part orders that guarantee timely delivery regardless of order size

Our company takes great satisfaction from delivering quality products. The ISO-certified quality control system at our company guarantees that our manufactured components fulfill stringent performance and reliability standards found in industry. We track all manufacturing stages through complete monitoring to confirm the durability of our brass components which ensures top-quality products for your needs.

Envoyez votre demande aujourd'hui

Material Grades We Use and Their Applications

We select the best brass alloys based on the specific requirements of your project. Here are some of the most commonly used grades:

Material Grade | Propriétés | Utilisations courantes | Parties fabriquées |

C36000 (Free-Cutting Brass) | Excellente usinabilité, résistance à la corrosion, and high strength | Connecteurs électriques, attaches, et composants automobiles | |

C26000 (Cartouche Laiton) | Bonne résistance à la corrosion, excellent cold working properties | Raccords de plomberie, composants électriques, instruments de précision | |

C28000 (Muntz Métal) | Higher strength, résistant à la corrosion, ideal for marine use | Marine hardware, connecteurs électriques, et machines industrielles | |

C31000 (Brass Nickel) | High corrosion resistance, weldability, et la force | Applications marines, pièces décoratives, et électronique |  |

Envoyez votre demande aujourd'hui

Case Study: Brass Precision Components for the Automotive Industry

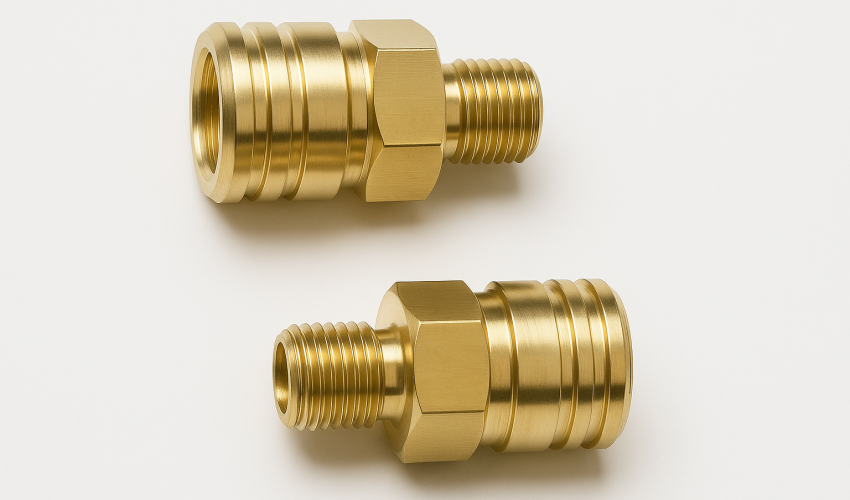

We recently manufactured precise brass fasteners for automotive purposes at an automotive company. The customer required components that had precise threading, together with precise tolerances so the parts would integrate perfectly within their engine assembly. We selected C36000 Free-Cutting Brass since it offers superior machining properties, together with exceptional strength that enabled rapid production of durable components.

Our company manufactured the fasteners using state-of-the-art CNC turning equipment that achieved tolerances within a ±0.005mm range. These components were produced within five business days, which allowed the customer to reach their production targets for delivery without quality deterioration. Our team demonstrated excellence by producing brass components with tight tolerances and functional as well as aesthetic qualities.

Envoyez votre demande aujourd'hui

Our Brass Precision Turning Capabilities

We employ advanced CNC machining to fabricate parts, whether its a prototype, or part for heavy duty use.

Tournage CNC

Tops Précision utilizes CNC turning services that deliver accurate parts with challenging designs and strict tolerance requirements to give customers dependable results. Our advanced machinery enables the production of accurate parts that achieve the most difficult design requirements. Our CNC turning services deliver first-class production quality for both complex large parts and delicate small components each time.

Enfilage & Tapotement

The threading and tapping procedures at our facility deliver precise thread features for bolts and fasteners as well as connectors to guarantee flawless assembly. Our advanced CNC turning machines produce threads which fulfill industrial requirements for both minimal applications and big-scale manufacturing. The threaded parts available at Tops Best stand as dependable and premium-quality elements that can be deployed right after purchase.

Finition de surface

Our service includes multiple surface finishing solutions that include polishing, coating and plating in order to improve component appearance while guaranteeing their durability. Our surface treatment options enable you to choose from shiny gloss or textured surface appearances which will perfectly suit your components. The components you receive from Tops Best will fulfill all your design goals while meeting their operational demands.

Custom CNC Turning

The custom CNC turning services at Tops Precision provide solution-based manufacturing for single prototype development, along with extensive production batches that meet specific customer requirements. The process requires our team to maintain extensive collaboration with you until each section achieves precise manufacturing requirements. Aux sommets Précision, they provide accurate and quick manufacturing of custom components along with large quantities of precisely identical parts.

Envoyez votre demande aujourd'hui

Industries That Rely on Our Brass Precision Components

Our brass precision turning services support various sectors:

- Automobile: Attaches, connecteurs, and engine components.

- Médical: Precision parts for diagnostic equipment and surgical instruments.

- Aérospatial: Poids léger, corrosion-resistant parts for high-performance systems.

- Électronique: Connecteurs, logements, et autres composants électriques.

- Marin: Haute résistance, corrosion-resistant parts for marine environments.

Envoyez votre demande aujourd'hui

Why Choose Tops Precision for Brass Precision Turning?

- Achieve exact tolerances with ±0.005mm précision.

- We offer a broad choice of brass alloys that includes C36000, C26000, and C28000 to suit your project specifications.

- The production process includes fast delivery because parts reach customers within a 3 à 5 business day period.

- Manufacturing takes place under ISO-certified standards to provide reliable components for every product.

- The company offers professional support from a technical team that helps customers choose materials while designing products and running production.

Envoyez votre demande aujourd'hui

Request a Quote for Your Brass Precision Turned Components

Need high-quality, custom brass components for your project? À Précision au sommet, we combine advanced technology with industry expertise to deliver precision-machined parts that meet your exact specifications. Contact us today for a free quote or to discuss your project with one of our specialists!