What Is PTFE CNC Machining?

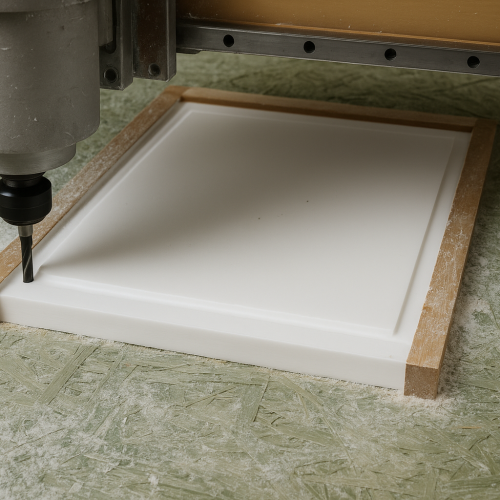

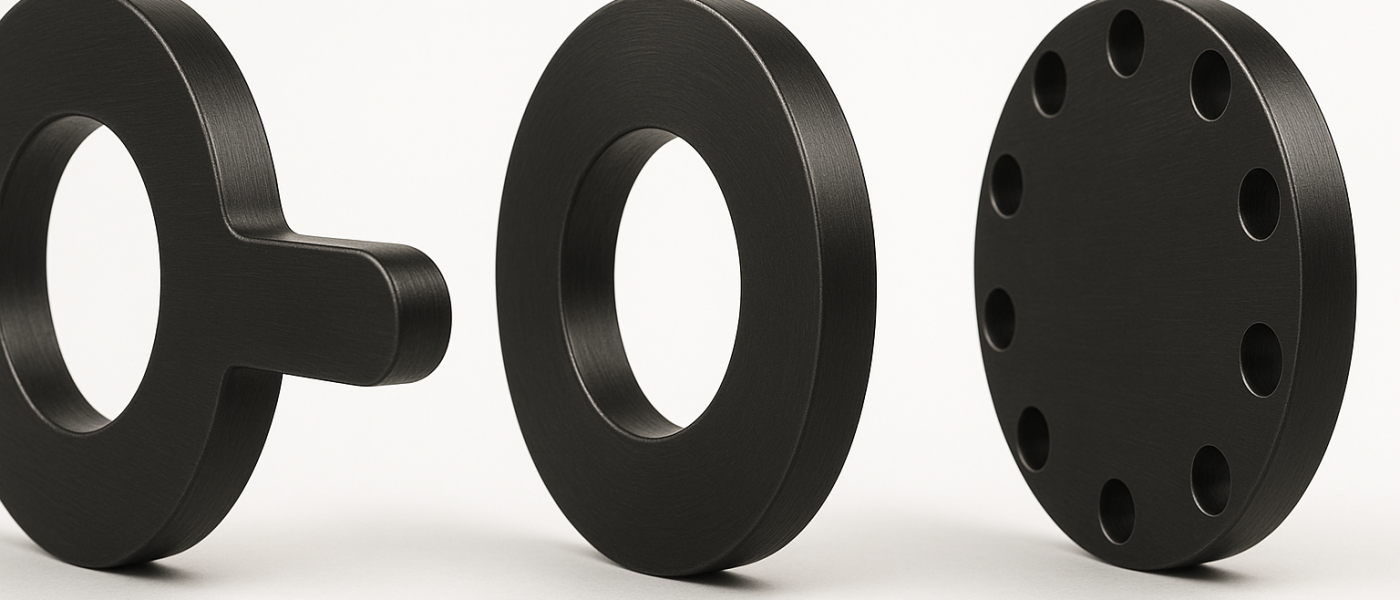

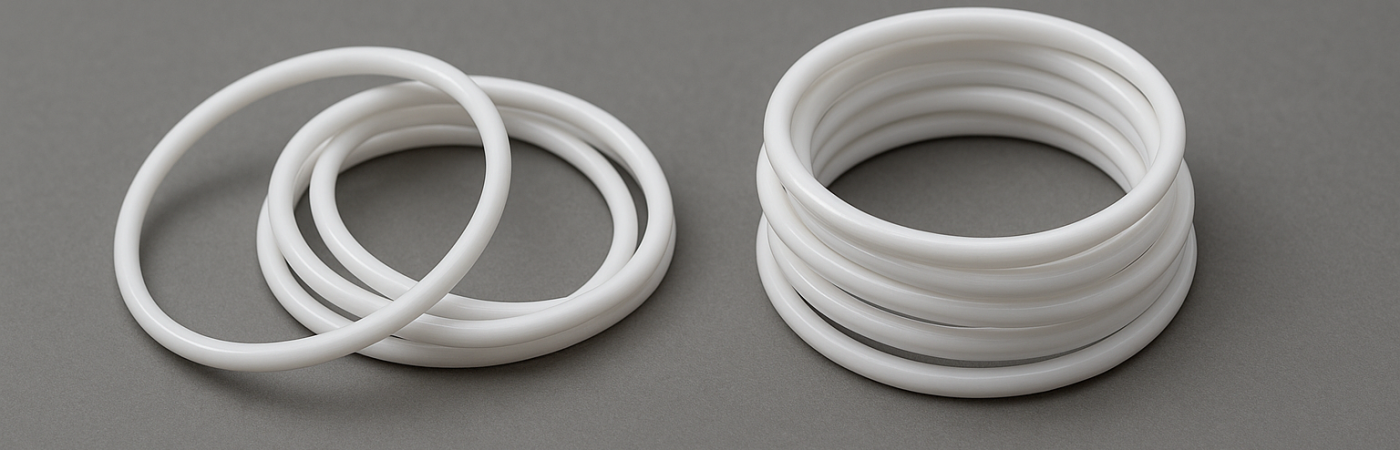

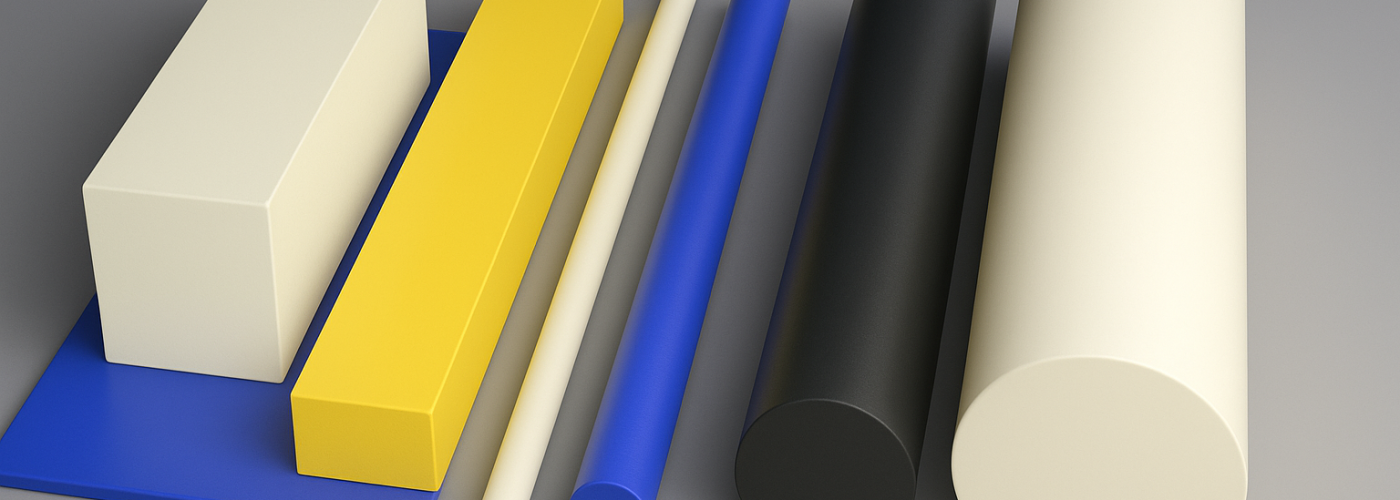

PTFE CNC machining involves shaping polytetrafluoroethylene—also known as Teflon—using computer-controlled cutting tools.

This process allows for the precise fabrication of intricate geometries. It is performed with advanced automated equipment to ensure accuracy and repeatability. La méthode maintient la résistance chimique du matériau et la stabilité thermique tout au long de l'usinage.

Processus d'usinage PTFE CNC

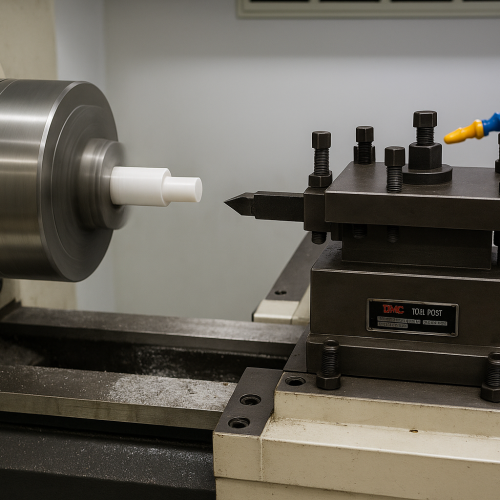

Nous utilisons des techniques telles que le logiciel CAD / CAM et l'équipement CNC pour guider les outils de coupe pour le fraisage, tournant, ou percer ptfe sous des formes précises.

Outillage spécialisé, taux d'avance, et la fixation est appliquée pour obtenir des résultats optimaux sans provoquer de distorsion.

Ces ajustements sont essentiels pour s'adapter aux propriétés uniques de PTFE.

Sa surface douce et lisse nécessite une manipulation minutieuse pendant l'usinage.

Envoyez votre demande aujourd'hui