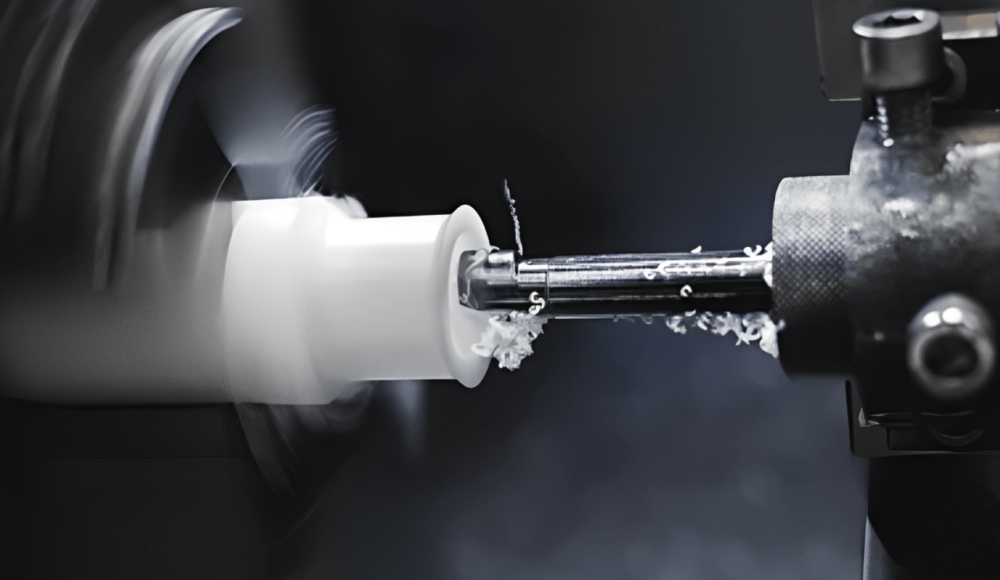

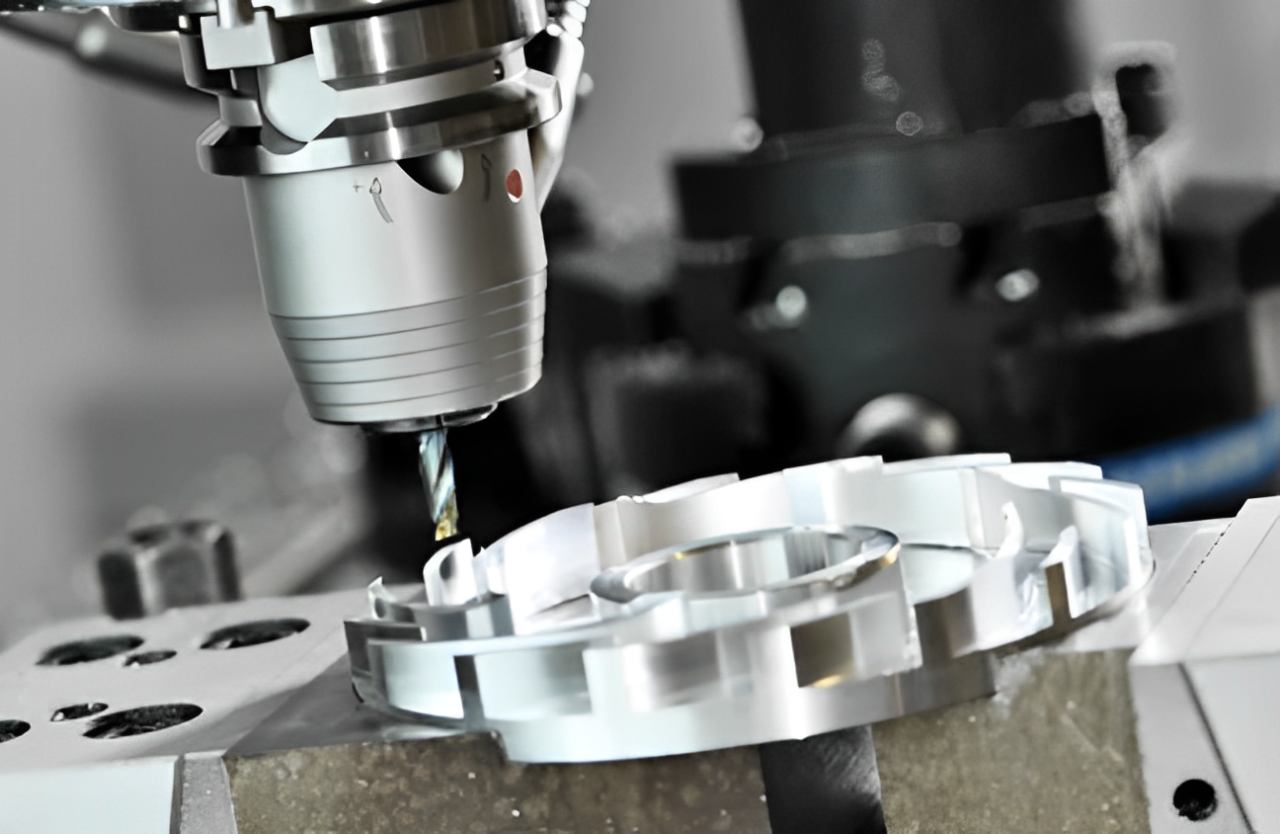

CNC加工 自動化機能で人気がある. 速度が上がるだけではありません. 高精度と正確性も促進します. このほかにも, 多くの業界の多くのアプリケーションで使用されています. それで, CNC 加工とその出力製品について話すとき. CNC 加工プロセスに使用する材料も考慮します。. 記事上で, we will explore the different materials ideal for CNC machining, the factors to consider when selecting materials, and tips for optimizing material choices for your projects.

Different Categories of Material in CNC Machining

CNC machining is a versatile process capable of working with a wide array of materials. While metal and plastic are the most commonly used materials, CNC machining can also accommodate materials such as ceramics, 木材, および複合材料. Each material category has distinct advantages and challenges, which make it important to choose the right one depending on the application.

Categories of CNC加工材料:

- 金属– Commonly used in industries like aerospace, 自動車, and medical devices due to their durability and strength.

- プラスチック– Popular in the consumer goods and medical industries, where lightweight, corrosion-resistant parts are needed.

- 複合材料– Used in specialized industries such as aerospace and sports equipment manufacturing, offering high strength-to-weight ratios.

- Wood and Ceramics– Used for specialized and low-volume production, typically for artistic or unique products.

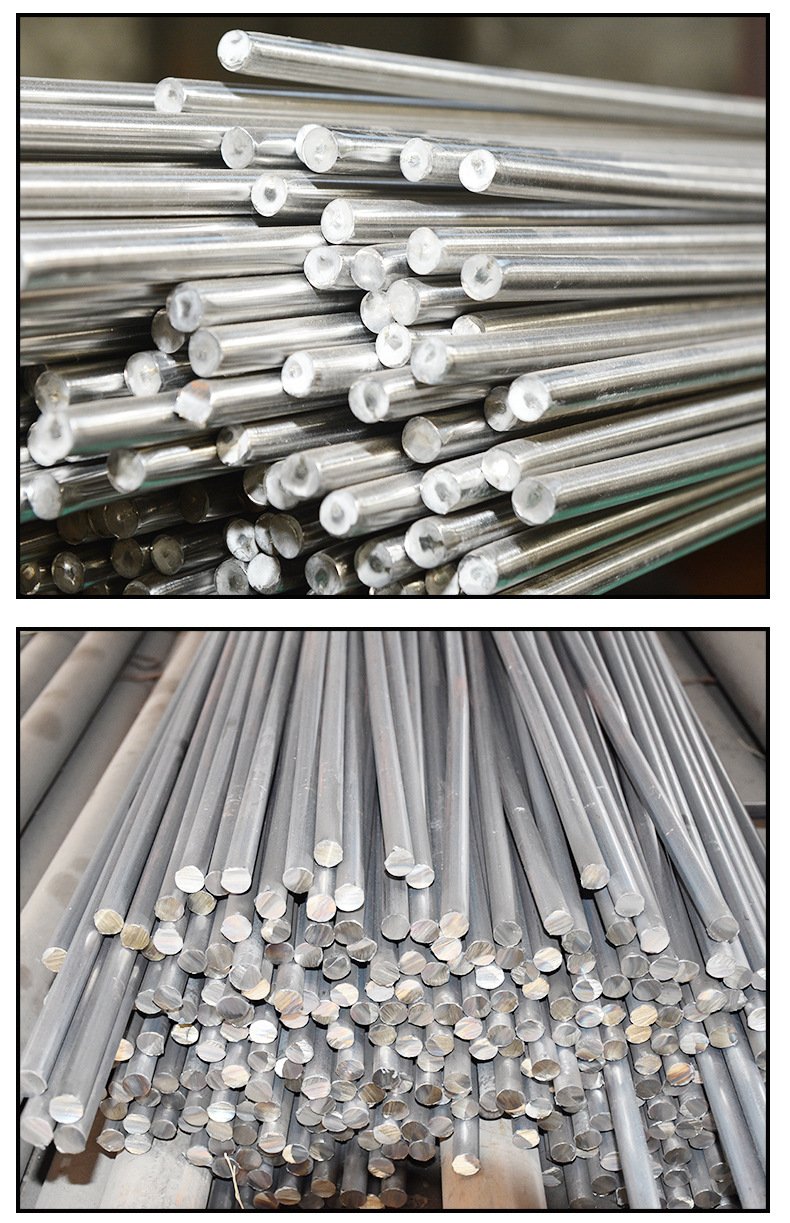

Types of Metal Materials for CNC Machining and Examples

Metals are the go-to material for most CNC machining operations due to their strength, 耐熱性, and ability to endure heavy loads. 下に, we explore the most commonly used metals in CNC machining.

アルミニウム

Aluminum is one of the most commonly used metals in CNC machining. Its advantages include a low density, 高い強度重量比, and excellent machinability. アルミニウム合金, のような 6061 そして 7075, are widely used in industries requiring lightweight but strong materials, 航空宇宙など, 自動車, および家庭用電化製品. It’s corrosion-resistant and offers excellent surface finishes, making it suitable for both functional and aesthetic parts.

ステンレス鋼

Stainless steel is known for its corrosion resistance, 靭性, and high strength. It’s often used in medical devices, 航空宇宙, and marine applications. While stainless steel has superior resistance to corrosion, its hardness can make it challenging to machine. Common grades of stainless steel used in CNC machining include 303, 304, そして 316.

Carbon Steel and its Alloys

Carbon steel is widely used due to its excellent machinability, 強さ, 手頃な価格. It is especially favored for applications requiring robust mechanical properties like structural components, 歯車, とファスナー. しかし, carbon steel’s lack of corrosion resistance limits its applications in harsh environments unless coated.

Copper and its Alloys

Copper is chosen for its high thermal and electrical conductivity. It’s often used in electrical components like wiring and connectors, as well as in cooling systems. 真鍮 そして ブロンズ, alloys of 銅, offer improved machinability and corrosion resistance, making them ideal for manufacturing precision components like gears, ベアリング, およびコネクタ.

チタン

Titanium offers an exceptional combination of strength and lightweight properties. It’s widely used in high-performance industries, including aerospace and medical implants. しかし, titanium is difficult to machine due to its toughness, so specialized tooling and machining processes are required.

マグネシウム

Magnesium is one of the lightest metals, making it a suitable choice for applications that require reduced weight, 自動車や航空宇宙など. Magnesium’s properties also make it excellent for high-temperature applications. しかし, its flammability during machining poses a challenge.

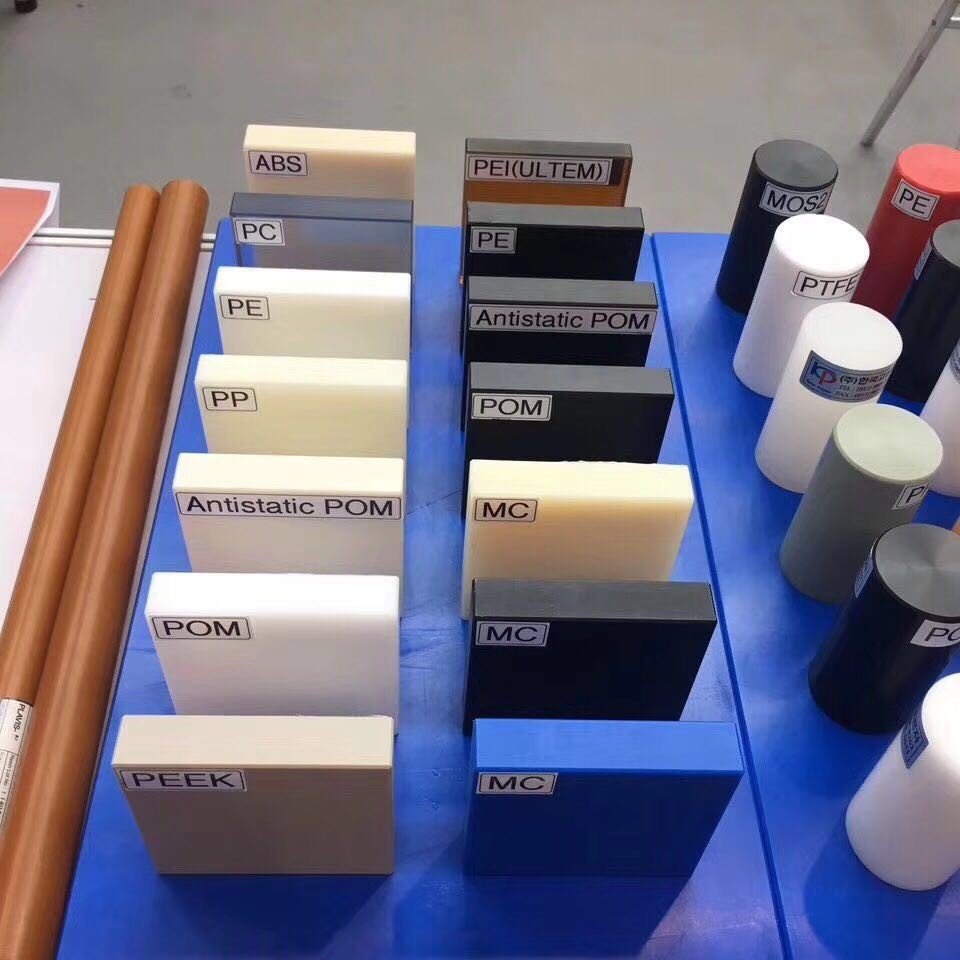

Types of Plastic Materials for CNC Machining and Examples

While metals dominate CNC machining, plastics are gaining traction, especially for applications where lightweight, 耐久性, and flexibility are necessary. The following plastics are frequently used in CNC machining:

アクリル (PMMA)

アクリル, or PMMA, is widely used for its optical clarity and rigidity. It is often used as a substitute for glass in applications such as windows, ディスプレイ, and signage. Acrylic is versatile but prone to cracking, especially under high stress, which must be considered during machining.

ポリプロピレン (PP)

Polypropylene is known for its chemical resistance and fatigue strength. It’s commonly used in medical applications and consumer goods. しかし, its tendency to soften at high temperatures makes it challenging to machine in some cases.

アセタール (POM/Delrin)

Acetal is known for its superior strength, moisture resistance, and excellent machinability. It’s frequently used in precision components like gears and bearings due to its ability to maintain its shape even under heavy loads.

ナイロン

Nylon is a strong, 耐久性のある, and impact-resistant material used in numerous applications, including bearings, 歯車, および電気コンポーネント. It also has low friction, making it a common choice for parts exposed to wear.

ABS

ABS is an affordable plastic with good machinability, 抗張力, そして耐衝撃性. It’s used in producing automotive parts, 保護エンクロージャー, and prototypes. ABS is also highly colorable, making it a good choice for aesthetic applications.

UHMW-PE

Ultra-high-molecular-weight polyethylene (UHMW-PE) is highly resistant to wear and abrasion, making it suitable for applications like bearings, 歯車, および滑り面. Although it can be difficult to machine, its exceptional properties make it a valuable material for high-stress environments.

ポリカーボネート (パソコン)

Polycarbonate is known for its excellent impact resistance and optical clarity. It is often used in high-temperature applications, as well as in the production of electronic components, 医療機器, および自動車部品.

ポリエーテルケトン (ピーク)

PEEK is a high-performance plastic with outstanding chemical resistance, 機械的強度, 寸法安定性, making it ideal for use in extreme environments such as aerospace, 食品加工, そして石油とガス.

ポリ塩化ビニル (PVC)

PVC is a low-cost plastic with excellent machinability. It’s used in applications requiring resistance to chemicals and high impact, such as plumbing systems, electrical fittings, および自動車コンポーネント.

Quick View: CNC Machining Material Chart

Here’s a quick overview of common CNC materials, their key properties, and some examples of where they’re used.

| 材料の種類 | 材料 | 主要なプロパティ | 一般的なアプリケーション | グレード & Codes |

| 金属 | アルミニウム | 軽量, 耐食性, 優れた加工性 | Aerospace frames, 自動車部品, エレクトロニクス, 工事 | アル 1050, アル 6061, アル 7075 |

| ステンレス鋼 | 強い, 耐食性, 耐熱性 | Medical equipment, 海洋, outdoor enclosures | SS 303, SS 304, SS 316 | |

| 炭素鋼 | 高強度, 優れた加工性 | Mechanical fasteners, 構造コンポーネント | 1018, 4130, 4140 | |

| 銅 | Great thermal/electrical conductivity, 順応性のある, 耐食性 | Electrical wire, magnetic devices, ジュエリー | 銅, 銅 + 亜鉛, 銅 + Be | |

| チタン | 高い強度重量比, 耐食性 | 航空宇宙, 軍隊, biomedical parts | Ti Grade 1, Ti Grade 2 | |

| マグネシウム | ライト, excellent thermal properties | エンジンコンポーネント, 自動車, 航空宇宙 | マグネシウム, マグネシウム合金 | |

| プラスチック | アクリル (PMMA) | High optical clarity, 硬い, 耐久性のある | 看板, light fixtures, 自動車部品, 消費財 | PMMA-Acrylic, PMMA-High Temp |

| ナイロン (PA6) | 強い, 耐久性のある, 耐衝撃性, good for wear-resistance | 歯車, ベアリング, 自動車部品 | PA6, PA66, ナイロン 6-6 | |

| ポリカーボネート (パソコン) | Shatter-resistant, 耐熱性, 光学的透明度 | 医療機器, 自動車部品, electronic components | パソコン, パソコン + Glass Fill | |

| ピーク | 高い耐薬品性, maintains stiffness at high temperatures | 航空宇宙, 医療機器, 半導体成分 | ピーク | |

| ABS | 良好な機械加工性, 耐衝撃性, 抗張力 | エンクロージャー, ラピッドプロトタイピング, 自動車部品 | ABS, ABS-High Temp | |

| Composite | カーボンファイバー | 高強度, 軽量, high stiffness | 航空宇宙, 自動車, スポーツ用品 | CFRP, CRP, CFRTP |

What Is the Most Used Machining Material?

CNC加工に関しては, metal and plastic are the most commonly used materials. しかし, if we had to pick one, アルミニウム takes the top spot.

Why Is Aluminum So Popular?

- 機械加工が容易– It cuts smoothly without excessive wear on tools.

- Lightweight yet strong– Ideal for industries like aerospace and automotive.

- 耐食性– Great for outdoor and high-moisture applications.

- 手頃な価格– Compared to titanium or stainless steel, aluminum is budget-friendly.

- リサイクル可能– Eco-friendly and widely available.

Other Popular Materials for CNC Machining:

- 鋼鉄– Strong, 耐久性のある, and used in heavy-duty applications.

- 真鍮– Excellent for precision parts and electrical components.

- プラスチック (ABS, POM, ナイロン) - 軽量, 手頃な価格, and great for prototypes.

What Material Is Easiest to Machine?

If you’re looking for a material that cuts like butter, 真鍮 is one of the easiest to machine.

Why Is Brass So Easy to Machine?

- Soft and smooth– It cuts cleanly without chipping.

- 低摩擦– Reduces heat buildup, so it doesn’t damage tools.

- Great surface finish– Needs little to no post-processing.

- Doesn’t work-harden– Unlike stainless steel, brass stays easy to machine.

Other Easy-to-Machine Materials:

- アルミニウム– Almost as easy as brass but stronger.

- プラスチック (ABS, POM, ナイロン)– These cut quickly and don’t dull tools.

- 軟鋼– Softer than stainless steel and easier to cut.

Which Material Is Difficult to Machine?

いくつかの材料 eat up cutting tools, cause excessive heat, or require special techniques 機械に. の most challenging materials to work with include チタン, インコネル, そして硬化した鋼.

Why Are These Materials Hard to Machine?

- チタン– High strength-to-weight ratio makes it tough, but it also generates a lot of heat, causing tool wear.

- インコネル (ニッケル合金)– Used in aerospace and high-heat applications, this metal is extremely hard and resists cutting.

- 硬化鋼– It’s great for durability but requires slow speeds, 特殊工具, and coolant to machine effectively.

- カーボンファイバー & 複合材料– These can fray, 割れ目, or produce harmful dust when machined.

Tips for Machining Hard Materials:

✔使用します carbide or diamond-coated tools for longer tool life.

✔ Apply クーラント to prevent overheating.

✔使用します slow speeds and proper feed rates to reduce tool wear.

✔ Consider specialized CNC machines designed for hard metals.

If your project requires ultra-durable 部品, these materials are worth the challenge, しかし be prepared for longer machining times and higher costs.

Key Factors for CNC Machining Materials Selection

How do you make sure you’re choosing the best material? There are several important factors to consider, and understanding these can help you make more informed decisions.

Part Applications

The first thing to think about is what your part will actually be used for. Different materials are better suited to different applications. 例えば, if you’re creating parts for the aerospace industry, you’ll need materials that are lightweight yet strong, のように チタン または アルミニウム. 一方で, if you’re making parts for a food processing system, you might need a material that’s resistant to high temperatures and harsh chemicals, のような ステンレス鋼 または ピーク プラスチック.

Each material has its strengths and weaknesses, and you want to match the material’s properties to the demands of the application. Understanding the environment your part will function in—whether it will face high pressure, 極端な温度, or constant wear and tear—can guide you to the right material choice.

部品重量

The weight of your part plays a significant role in material selection. For parts that need to be light and easy to handle (like components in the 自動車 または 航空宇宙 産業), you’ll need materials with a low density, のような アルミニウム または チタン. These materials are not only lightweight but also durable and strong.

対照的に, if your part will need to support heavy loads, you’ll want a material that is denser and stronger, のような 鋼鉄. Understanding the weight requirements of your part helps ensure that it performs as expected without unnecessary material costs or processing time.

Part Accuracy and Tolerance

Accuracy is often one of the most critical aspects when choosing a material. Some materials are easier to machine to precise dimensions than others. 例えば, アルミニウム is generally easier to machine to tight tolerances compared to tougher materials like チタン または 炭素鋼. The more difficult a material is to machine, the higher the cost and time it will take to achieve the desired precision.

If your part requires high accuracy and tight tolerances, be prepared to work with materials that are harder to machine or that may require additional processes (like heat treatment or specialized tooling). Make sure to factor in the level of precision required when choosing a material, as it will directly affect your machining costs and timelines.

Part Properties

Think about the properties your part needs to have. 例えば:

- 強さ: Does your part need to withstand heavy loads? Materials like 鋼鉄または チタン provide excellent strength.

- 耐食性: Will your part be exposed to moisture or chemicals? 考慮する ステンレス鋼または アルミニウム.

- 熱安定性: Is your part going to be exposed to high temperatures? セラミックスそして チタン are great for heat resistance.

Each material has specific properties that make it ideal for particular environments and uses. 素材を選択するとき, consider how these properties will help your part function well in its intended application.

Product Aesthetics

時々, the way a part looks is just as important as how it performs. 例えば, で 消費財 または エレクトロニクス, the appearance of the part can play a major role in consumer acceptance. Materials like プラスチック (例えば, ABS または ポリカーボネート) can be easily molded and colored to meet design specifications.

一方で, 金属 のように ステンレス鋼 そして アルミニウム can also provide a sleek, modern look. If aesthetics are a big concern, make sure to choose materials that can either be easily finished or already have the look you’re aiming for.

Surface Finish Options

When machining a part, the surface finish is important for both its appearance and functionality. いくつかの材料, のように アルミニウム または ステンレス鋼, are easier to polish and finish, 他の人が, のように 炭素鋼 or certain plastics, may require additional finishing steps to achieve the desired look or smoothness.

Surface finishes also play a role in the performance of the part. 例えば, parts that will be used in high-friction environments (such as gears or bearings) will need a finish that reduces wear, while parts used in medical or aerospace applications may require a smooth, polished surface for functionality and aesthetic reasons.

被削性

Some materials are easier to machine than others, which can affect both the cost and the time it takes to produce the part. Softer materials like アルミニウム そして プラスチック are easier to machine and can reduce tooling wear and overall production time. 一方で, harder materials like チタン または タングステン are more difficult to machine, 特殊なツールが必要です, additional time, and potentially higher costs.

If your project has strict deadlines or budget constraints, it’s important to consider the machinability of the material, as choosing a material that’s too difficult to machine can significantly increase the time and cost of production.

料金

Cost is always a factor in material selection. While it’s tempting to go for the highest-performance material, it may not always be the most cost-effective choice. Materials like アルミニウム are generally more affordable and offer a good balance between machinability, 強さ, そして耐久性, making them a popular choice. しかし, high-performance materials like チタン または ピーク can be much more expensive, both in terms of material costs and machining time.

Before deciding on a material, make sure you balance performance with cost. 時々, a less expensive material will perform just as well for your application, allowing you to save on both material costs and machining expenses.

Tips When Using CNC Processes to Machine Different Materials

Choose the Right Tools for the Job

Not all cutting tools are created equal. Different materials require different types of tools to achieve the best results. 例えば, harder metals like チタン そして ステンレス鋼 will need carbide or ceramic tools because they can withstand the heat and stress of cutting harder materials. For softer materials like アルミニウム または プラスチック, you can often get away with using high-speed steel tools.

- ヒント: Always match your tool material to the material you’re machining. This helps in reducing tool wear and ensures smoother cuts.

Control Cutting Speed and Feed Rate

Cutting speed and feed rate are crucial to achieving the desired results. If the cutting speed is too fast for a certain material, it can cause the tool to wear out faster, overheat, or even break. 一方で, if the feed rate is too slow, it can lead to inefficient machining and increased production time.

- ヒント: For softer materials like アルミニウム, use faster cutting speeds and higher feed rates. For harder materials like チタン または 鋼鉄, reduce the cutting speed and feed rate to avoid excessive heat buildup and tool wear.

適切なクーラントを使用します

Using coolant during CNC machining is essential to reduce heat buildup and prevent damage to both the tool and the workpiece. Different materials generate different levels of heat, so the type of coolant and the amount used can vary.

- ヒント: 使用 water-based coolants for softer materials like アルミニウム そして プラスチック, as they can help prevent thermal damage. For harder materials like ステンレス鋼 そして チタン, you might want to use oil-based coolants for better cooling and lubrication.

Pay Attention to Material Thickness

The thickness of the material you’re machining affects how quickly and efficiently your CNC machine can cut through it. Thicker materials, especially metals like 炭素鋼 そして ステンレス鋼, will require more powerful machines and stronger tools to get through them. 一方で, thinner materials like プラスチック または aluminum sheets will require less power and can be machined more quickly.

- ヒント: Always adjust your cutting depth and tool paths depending on the material thickness. For thicker materials, reduce the depth of each cut to avoid straining the machine and tooling.

Consider Material Properties Before Choosing a Machining Strategy

Each material has its own set of characteristics—some are more brittle, others are more flexible, and some can expand or contract when exposed to heat. Understanding these properties will help you determine the best machining strategy for the material.

- ヒント: For materials prone to warping, のような プラスチック のように PVC または アセタール, use lower cutting speeds and avoid deep cuts to minimize the material’s movement. For materials like チタン, which expand due to heat, use a slower feed rate and ensure your machine is well-calibrated to avoid any distortions.

適切な作業を確認してください

Holding your material securely in place is critical, especially when machining complex shapes. If the workpiece is not properly held, it can move during machining, leading to poor tolerances, surface imperfections, or even damaged parts. Some materials are more prone to deformation or shifting, so they need extra care.

- ヒント: Use strong and reliable workholding fixtures, のような クランプ または vacuum chuck systems, to hold your parts in place securely. For softer materials like プラスチック, use softer workholding methods to avoid damaging the part.

Choose the Right CNC Machine

Not every CNC machine is suitable for every material. より柔らかい素材, のように アルミニウム, can be easily machined with standard 3-axis CNC machines. しかし, harder materials, のような チタン または 鋼鉄, may require 5-軸CNCマシン for more flexibility and better precision.

- ヒント: For intricate or highly detailed cuts in tough materials, consider using 5-軸CNC加工. This type of machine will allow for more angles of attack and better control of the cutting process.

Surface Finish Matters

The finish on the surface of your machined part can make a huge difference, both in terms of aesthetics and functionality. いくつかの材料, のように アルミニウム そして ステンレス鋼, will have a naturally smooth surface finish after machining, 他の人が, のように プラスチック または チタン, may require additional post-machining processes like 研磨 または 陽極酸化処理 to achieve the desired finish.

- ヒント: Always keep the desired surface finish in mind when selecting a material. If a shiny or smooth finish is needed, ensure that the material you choose is conducive to that kind of finish. いくつかの材料, のように 真鍮 または ステンレス鋼, can be polished easily, 他の人が, のように ブロンズ, might require extra steps.

Account for Material Cost and Availability

Material cost is always a key consideration. チタン そして ステンレス鋼, while excellent for certain applications, can be much more expensive than materials like アルミニウム または 真鍮. さらに, some materials are more readily available than others, which could affect lead times.

- ヒント: Choose materials that fit within your project budget. もし ステンレス鋼 is over your budget, 考慮する アルミニウム または 炭素鋼 as alternatives for less critical parts.

Understand the Environmental Impact

Some materials have a significant environmental impact, either through mining, 処理, or disposal. Materials like プラスチック, if not recycled properly, can contribute to waste. しかし, metals like アルミニウム そして ステンレス鋼 are often highly recyclable.

- ヒント: 可能な場合はいつでも, choose materials that are recyclable or have a minimal environmental impact. アルミニウム, 例えば, is widely recycled and has a lower environmental footprint compared to materials like プラスチック.

Get the Right CNC Machining Material for Your Projects

Choosing the right material is crucial for your CNC machining project. If you are unsure which material is best suited for your needs, consider seeking professional advice from CNC machining service providers who offer extensive material options and expertise.

What Are the Cost Implications of Different Machining Materials?

Choosing the right material for CNC machining isn’t just about strength and performance—it also affects your budget. Some materials are cheap and easy to machine, while others are expensive and require special tools or extra processing time.

What Drives the Cost of Machining Materials?

- Raw Material Price - 一部の材料, like aluminum, are widely available and affordable, 他の人が, チタンのように, are much more expensive.

- 被削性– Softer materials (like brass and aluminum) machine faster, reducing labor and tool wear. 硬質材料 (like stainless steel or Inconel) require slower machining and special tools, increasing costs.

- 工具の摩耗– Some materials dull cutting tools quickly, leading to higher tooling costs.

- Scrap and Waste– Harder materials may result in more waste due to tool breakage or machining errors.

- Finishing Requirements– Some metals, like brass, naturally look great, 他の人が, like carbon steel, require coatings or polishing, adding extra cost.

Cost Comparison of Common Machining Materials

| 材料 | Raw Material Cost | 加工費 | Total Cost Impact | ベストユースケース |

| アルミニウム | 低い | 低い | $$ | 航空宇宙, 自動車, エレクトロニクス |

| 真鍮 | 中くらい | Very Low | $$ | 精密部品, 配管, 電気 |

| ステンレス鋼 | 中くらい | 高い | $$$ | 医学, 食品加工, 腐食耐性部品 |

| チタン | 非常に高い | 非常に高い | $$$$$ | 航空宇宙, 医療用インプラント |

| 炭素鋼 | 低い | 中くらい | $$ | 構造部品, ツール |

| プラスチック (ABS, POM, ナイロン) | 低い | Very Low | $ | プロトタイプ, 軽量コンポーネント |

| インコネル (ニッケル合金) | Extremely High | Extremely High | $$$$$$ | ジェットエンジン, extreme heat applications |

How to Balance Cost and Performance

✅ Go for aluminum or brass あなたが望むなら 手頃な価格, easy-to-machine materials.

✅ Use plastics for low-cost prototypes that don’t need high strength.

✅ Consider stainless steel when corrosion resistance is crucial, but be prepared for higher machining costs.

✅ Titanium and Inconel は premium materials—use them only when absolutely necessary due to their high price and machining difficulty.

💡 プロのヒント: If your part doesn’t need extreme strength or heat resistance, stick with aluminum or mild steel to save on both material and machining costs.

結論

CNC machining is an incredibly versatile manufacturing process that accommodates a wide range of materials. Whether you’re working with metals, プラスチック, or composites, the key to success is selecting the right material based on the part’s application, プロパティ, and machining requirements. By understanding the material properties and machining challenges, you can optimize the material selection process, コストを削減します, and achieve high-quality parts.

よくある質問

- What are the factors to be considered when selecting a CNC material?

Consider part application, 重さ, 正確さ, プロパティ, そしてコスト.

- Which aluminum alloy is best for CNC machining?

Aluminum 6061-T6 is commonly used for CNC machining due to its excellent machinability and strength.

- Which plastics are most machinable?

アセタール, ピーク, and PVC offer great machinability and dimensional stability.

- What is the hardest metal to mill?

Titanium is one of the hardest metals to mill, often requiring specialized tooling and techniques.

1 「」について考えましたCNC加工材料, 知っておくべきことすべて”