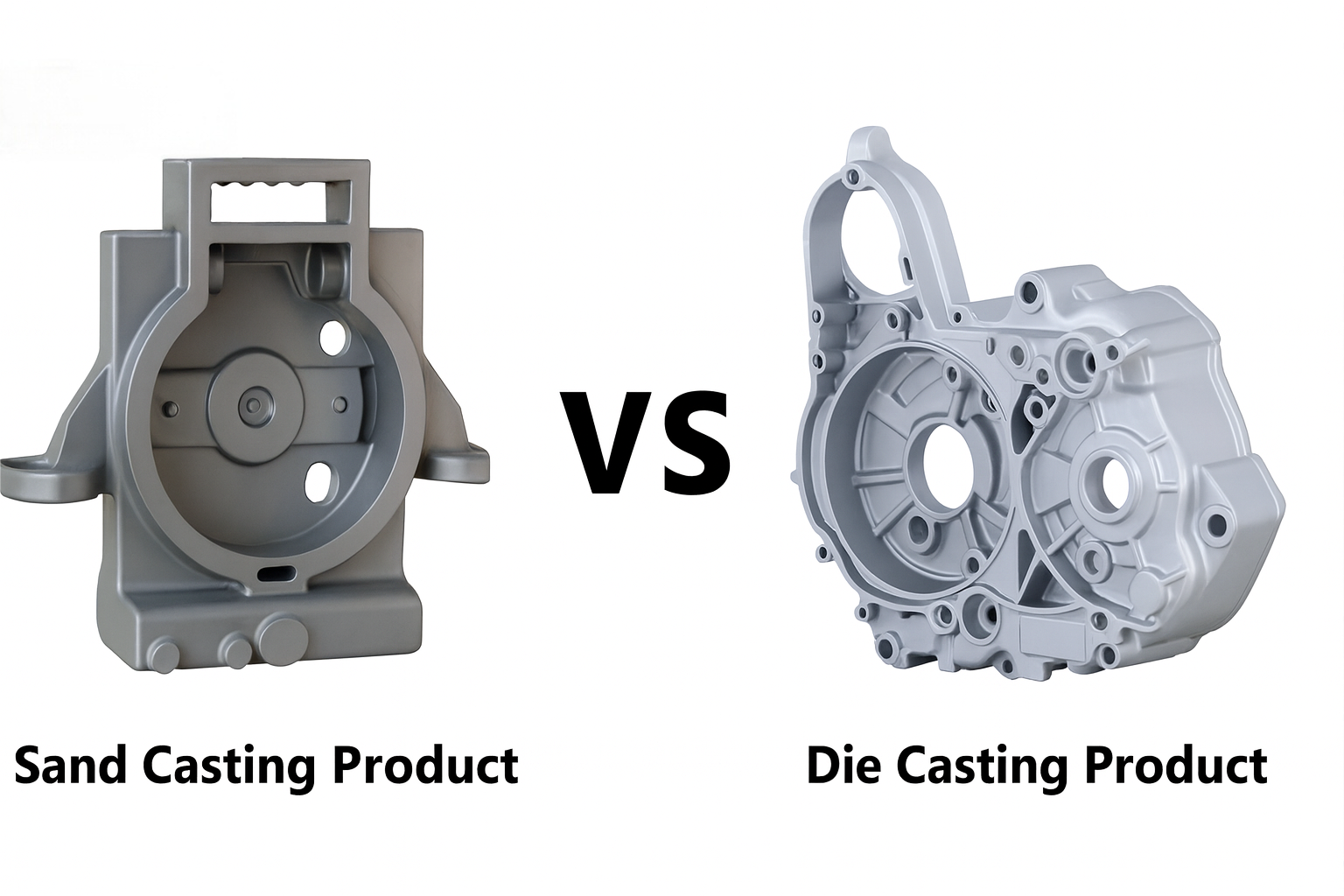

Choosing the right casting method is a critical decision that dictates a product’s final quality, 料金, and feasibility. 両方 ダイカスト そして 砂型鋳造 are fundamental processes in metal manufacturing, but they operate under vastly different principles and cater to separate industrial requirements. While both achieve the basic goal of forming molten metal into a desired shape, understanding their distinct mechanisms and trade-offs is essential for product engineers and procurement specialists.

Overview and Core Principles

ダイカスト (High-Pressure Process)

Die casting utilizes durable, precisely machined metal molds (死ぬ). Molten metal is injected into these molds at extremely high pressure (まで 4,500 psi) and high speed. This pressure forces the metal into every cavity of the mold, creating highly defined features. 固まったら, the die opens, and the part (the casting) is ejected.

砂型鋳造 (Atmospheric Process)

Sand casting, the oldest form of casting, uses molds created from a mixture of 砂, 粘土, and water (or chemical binders). The molten metal is poured into the mold cavity under atmospheric pressure (gravity alone). The sand mold is destroyed to retrieve the finished part, and a new mold must be prepared for the next cycle.

Key Differences in Detail

The selection often hinges on a deep comparison across seven key parameters:

あ. Tooling Material and Durability

ダイカスト: The metal molds (死ぬ) are made from hardened tool steel, designed to withstand thousands of cycles. This high durability is the foundation of the process’s efficiency for mass production.

砂型鋳造: Molds are ephemeral and made of compacted sand, designed for a single use. The pattern (used to create the cavity in the sand) can be wood, プラスチック, または金属, offering lower initial costs.

B. Production Volume and Tooling Costs

| パラメータ | 砂型鋳造 | ダイカスト |

| ツーリングコスト (Initial) | 低い (通常 $500 に $8,000) | 高い (通常 $8,000 に $80,000 それ以上) |

| サイクル時間 | 遅い (includes 5–10 minutes for mold preparation/destruction) | 速い (cycles measured in seconds/minutes) |

| Ideal Volume | Low-to-Medium (プロトタイプ, 1 に 500 単位) | High-Volume Mass Production (Thousands to Millions) |

| 部品あたりのコスト | より高い | Very Low (due to fast cycle time) |

C. Dimensional Accuracy and Precision

The high pressure used in die casting is crucial for precision.

ダイカスト: Achieves superior dimensional accuracy (tolerances often within ± 0.05 mm to ± 0.15 んん. This precision often minimizes or eliminates the need for expensive post-machining.

砂型鋳造: Lower accuracy (tolerances typically ± 0.8 mm to ± 1.5 んん). The process results in a looser fit and requires larger machining allowances (extra material added for subsequent CNC machining).

D. Surface Finish and Wall Thickness

表面仕上げ:

ダイカスト: Produces an excellent, 滑らかな仕上げ (できるだけ低い 1 μm) right out of the mold, often requiring no finishing.

砂型鋳造: 去るa coarse, rough surface due to the texture of the sand mold, requiring extensive cleaning, 研削, or shot blasting.

肉厚:

ダイカスト: Capable of producing very 薄い壁 (as thin as 0.5 んん), enabling lightweight designs.

砂型鋳造: Limited to thicker walls (通常 3 mm or more) to ensure proper flow and prevent solidification defects.

E. Internal Quality and Strength

ダイカスト: The high-pressure injection minimizes internal porosity (air gaps). This results in a denser, stronger part with superior mechanical properties and a more consistent internal structure.

砂型鋳造: Since metal is poured under gravity, air pockets and porosity are common. While the overall material strength may be comparable, the risk of internal defects is higher, which can affect consistency and fatigue life.

F. Material Selection and Size Constraints

材料の制限 (Alloy Friendliness):

ダイカスト: Primarily limited to low-melting-point alloys such as Aluminum (アル), 亜鉛 (亜鉛), マグネシウム (マグネシウム), and Copper (銅) 合金. High-melting-point ferrous metals (like steel) are generally incompatible because they would rapidly damage the metal die.

砂型鋳造: Highly versatile and alloy-friendly. It can be used for almost any metal, including high-temperature ferrous alloys like steel and cast iron, as the sand mold is destroyed after one use.

Size Constraints:

ダイカスト: Usually limited to smaller-to-medium-sized parts (例えば, エンジンブロック, トランスミッションのケース, ハウジング).

砂型鋳造: に最適です very large components (例えば, massive pump casings, large machine bases, 船のプロペラ), as mold size is easily scaled.

Selecting the Right Process

The optimal choice is determined by prioritizing the key requirements of the final component:

| If Your Primary Requirement Is… | Choose… | Rationale |

| 高い生産量 | ダイカスト | Fastest cycle time (highest throughput). |

| Low Tooling Budget / Quick Start | 砂型鋳造 | Minimal initial investment and rapid pattern creation. |

| 優れた表面仕上げ / Thin Walls | ダイカスト | Pressure injection creates smooth surfaces and allows for thinner designs. |

| Casting Steel or Cast Iron | 砂型鋳造 | Can handle the high melting temperature of ferrous alloys. |

| Very Large Part Size | 砂型鋳造 | Scalable mold size and lower cost per unit volume for massive components. |

| 厳しい公差 & Minimal Machining | ダイカスト | Inherently higher precision and excellent repeatability. |

代表的なアプリケーション

Die Casting Applications: 自動車 (エンジンブラケット, トランスミッションハウジング, ピストン), エレクトロニクス (ヒートシンク, エンクロージャ), 電動工具, 医療機器, and Toys.

Sand Casting Applications: Large valves, エンジンブロック, agricultural equipment frames, machine tool bases, and any specialized or プロトタイプ part needed quickly and cheaply.

要約すれば, Die Casting is a high-speed, high-precision solution for high-volume, small-to-medium parts, その間 Sand Casting is a flexible, lower-cost option for prototypes, 低容量の実行, and very large components made from any alloy.

よくある質問

1. Why is Die Casting generally limited to low-melting-point alloys like Aluminum and Zinc?

Die casting uses metal dies made of hardened steel. If high-melting-point metals (like steel or cast iron) 使用されました, the extreme heat would cause the metal dies to erode rapidly (a process called thermal fatigue or “heat checking”), dramatically reducing the die’s lifespan and increasing maintenance costs. したがって, die casting is cost-effective only with alloys that have lower melting temperatures, such as Aluminum (アル), 亜鉛 (亜鉛), and Magnesium (マグネシウム).

2. Can sand castings achieve the same precision as die castings if post-machining is performed?

While post-machining (例えば, using CNC) can correct the dimensional inaccuracies and rough surface finish of sand castings, achieving the same level of precision as an as-cast die-cast part is often impractical and expensive. Sand castings require a large machining allowance (extra material) to compensate for casting variations. Removing this material through CNC adds significant time and cost, often negating the initial savings of the sand casting process.

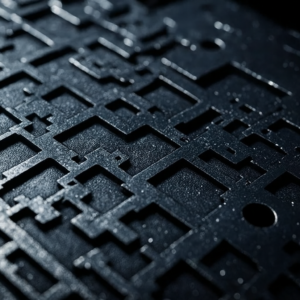

3. What is the main cause of the rough surface finish in sand casting?

The roughness in sand casting is caused by the mold material itself. The sand particles used to create the cavity are relatively coarse. When the molten metal fills the cavity, its surface texture mirrors the coarse texture of the sand grains, resulting in a matte, granular, and uneven surface.

4. Why are internal defects (気孔率) more common in sand casting than die casting?

砂型鋳造では, metal is poured under gravity (atmospheric pressure). During solidification, gas bubbles can become trapped, or shrinkage cavities can form relatively easily, につながる 気孔率. で ダイカスト, の extremely high injection pressure compacts the metal as it solidifies, forcing air and gases out and resulting in a much denser, more structurally sound internal structure with minimal porosity.

5. For low-volume production of a large part, what factor makes sand casting cheaper despite its slow cycle time?

For low-volume runs of large parts, the high cost of creating a durable, 精度 metal die for die casting becomes the overwhelming expense. Sand casting is cheaper because the tooling (の pattern used to make the sand mold) is often made from inexpensive materials like wood, プラスチック, or foam, representing a minimal capital investment compared to the massive steel die required for the alternative process.

6. How does the cooling rate differ between the two processes, and why does it matter?

ダイカスト: The molten metal contacts a cold, 密集 metal mold, resulting in very rapid cooling. This rapid cooling often produces a finer grain structure near the surface (a “chill zone”), which can enhance surface hardness and strength.

砂型鋳造: The molten metal is surrounded by porous, 絶縁 砂, resulting in a much slower cooling rate. The slow cooling leads to a coarser grain structure and can increase the risk of internal defects.

7. When considering sustainability, which process is more environmentally friendly?

Both processes have environmental factors:

ダイカスト: Is highly energy-intensive due to the need to keep large metal dies hot and the high-pressure system. しかし, the metal dies are reusable for hundreds of thousands of parts.

砂型鋳造: The primary waste is the large volume of spent, used sand that must be disposed of or recycled.

一般的に, Die Casting is considered more sustainable for mass production because the extremely low material waste, high repeatability, and long tool life result in less overall waste per part produced compared to the continuous consumption of sand in the alternative process.