PEIとは (ポリエーテルイミド)?

PEIとは (ポリエーテルイミド)

ポリエーテルイミド (PEI) 優れた耐熱性で知られる高性能エンジニアリング熱可塑性プラスチックです。, 寸法安定性, および電気絶縁性. それは同じポリマーファミリーに属します ポリエーテルエーテルケトン (ピーク) しかし、要求の厳しい環境において、よりコスト効率の高いパフォーマンスと製造可能性のバランスを提供します。.

PEIの最も有名なブランドは、 ウルテム®, によって開発された SABICグローバルテクノロジーズ, これにはほぼ含まれます 100 異なるグレード—未充填からガラスまで- およびカーボンファイバー強化バージョン - 機械的強度が必要な用途に合わせて調整, 熱抵抗, そして難燃性.

その多用途性にも関わらず、, PEIは 比較的高価な そして持っています 耐摩耗性が低い のような素材よりも ピーク, PTFE, または UHMWPE. また、必要です 非常に高い処理温度 そして経験するかもしれない 環境応力亀裂 塩素系溶剤にさらされた場合, 強アルカリ, または連続負荷下の濃酸.

そのコストとユニークな特性により、, PEI は通常、次のような用途で使用されます。 致命的, 高価値アプリケーション どこの強さ, 絶縁, 耐熱性も重要です.

PEI射出成形の応用例

PEI射出成形の応用例

PEI 射出成形は部品の抵抗が必要な箇所に使用されます 極度の暑さ, 繰り返しの滅菌, または 激しい電気的ストレス.

一般的なアプリケーションには次のものがあります。:

医療機器: 輸液ポンプ, 手術器具, 繰り返しオートクレーブ滅菌サイクルを受ける呼吸器装置.

電気 & 電子部品: コネクタ, ソケット, スイッチ, 高電圧下でも絶縁を維持する必要がある回路ハウジング.

航空宇宙部品: 難燃性が要求される内装部品, 軽量設計, 高温でも安定した性能を発揮.

自動車システム: 熱や振動にさらされるボンネット下のセンサーと電気モジュール.

産業機器: テストフィクスチャ, ポンプハウジング, および高性能絶縁体.

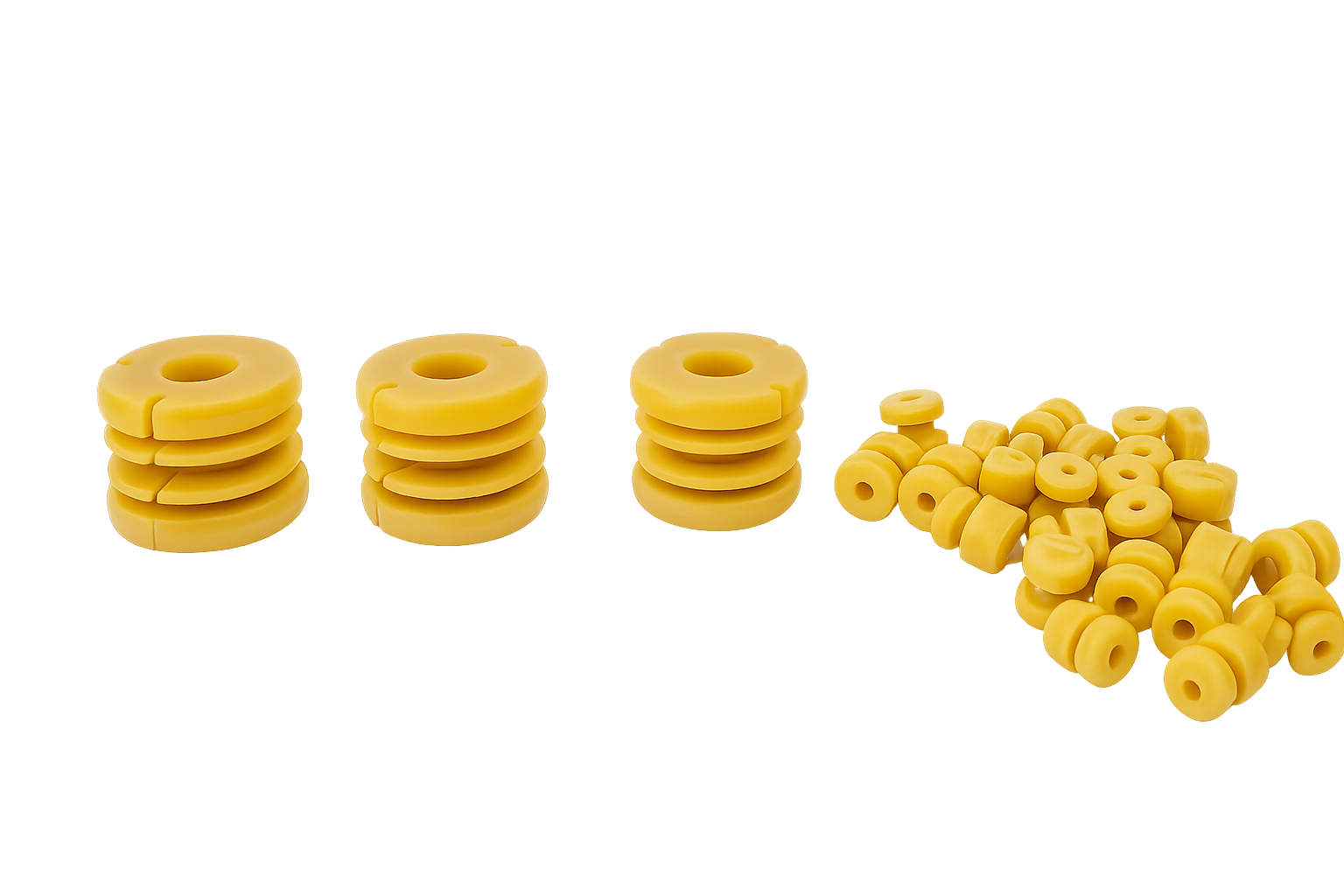

成形 PEI 部品には通常、 半透明の琥珀色, ただし、美観や識別のニーズを満たすために着色剤を追加することもできます。.

PEI射出成形の利点

PEI射出成形の利点

温度抵抗

PEI は次の条件で連続的に動作できます。 170℃まで そして耐える 熱たわみ温度 (HDT) 間 200℃と210℃ 負荷がかかっている. これにより、多くの高温環境で金属や熱硬化性樹脂の代替が可能になります。. 210℃を超える, 長期にわたるストレスにより変形し始める.

耐クリープ性

クリープとは、一定の荷重下で材料が変形する傾向のことです. PEIの 優れた耐クリープ性 そして 寸法安定性 長年の熱サイクルの後でも厳しい公差を維持する必要がある精密部品に適しています。. その 均一な熱膨張係数 (CTE) 熱にさらされたときの寸法変化を確実に予測可能.

滅菌能力

射出成形PEIは耐久性があります 蒸気オートクレーブ, エチレンオキサイドガス, そして ガンマ線—医療分野で一般的なすべての滅菌方法. この耐性により、医療コンポーネントを劣化や変色なく繰り返し再利用できます。.

耐環境性

PEI は以下の条件下で良好なパフォーマンスを発揮します 紫外線への曝露, 高湿度, そして 熱応力. 安定剤を使用すると耐紫外線性をさらに高めることができます, それを実行可能な選択肢にする 屋外アプリケーション のような 電気エンクロージャ, パワーメーター, そして センサーハウジング.

誘電強度

エンジニアリングプラスチックの中でも, PEI はそのうちの 1 つを展示します。 最高の絶縁耐力-その周り 25 kV/mmで 1.6 mmの厚さ. これにより、次のような用途に最適です。 電気絶縁体, コンデンサハウジング, そして 高電圧コネクタ. 誘電限界を超えると, しかし, 材料は 絶縁破壊, 絶縁ではなく導電性になる, したがって、適切な設計が不可欠です.

PEI 射出成形の設計ガイドライン

適切な設計手法に従うことで、一貫した部品品質と効率的な成形性が確保されます。.

肉厚

推奨範囲: 0.060–0.100インチ (1.5–2.5mm)

壁が厚いと流れの長さが短くなります, 不完全な充填の危険性がある.

壁の厚さを維持する ユニフォーム; 変動は以下を超えてはなりません ±25%, 応力の蓄積やヒケを防ぐために、移行は段階的に行う必要があります。.

半径

応力集中を引き起こす鋭い角を避けてください.

最小内径: >0.015 で (0.38 んん)

より大きな半径を優先する, 理想的には 25壁厚の –50%, 改善する 流れ力学 そして 部品の耐久性.

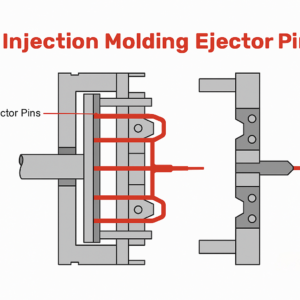

抜き勾配角度

部品の取り出しを容易にするには:

標準抜き勾配角度: 1片側あたり°.

テクスチャーのある表面の場合, ドラフトを増やす 1.5°ごとに 0.001 テクスチャ深度の.

より滑らかな仕上げには必要な抜き勾配が少なくなる場合があります.

部品の公差

PEI は許可します 厳しい許容範囲 ±0.001インチ, 標準的な製造公差は次のようになりますが、 ±0.003~0.005インチ. 公差が厳しくなると製造コストが大幅に増加するため、設計者は精度と工具コストのバランスを取る必要があります。.

PEI グレードと材料特性

PEI には、フィラー含有量と性能レベルが異なる複数のグレードがあります。. 以下の表は、いくつかの主要なデータをまとめたものです。 一般的な Ultem® および RTP グレード:

| 財産 | ウルテム® 1000 | ウルテム® 2200 (20% GF) | ウルテム® 2300 (30% GF) | RTP 2100 LF |

| 密度 (g/cm3) | 1.27 | 1.42 | 1.51 | 1.27 |

| 収縮率 (%) | 0.5-0.7 | 0.3-0.5 | 0.2-0.4 | 0.8 |

| ロックウェル硬度 (M) | 106 | 114 | 114 | — |

| 抗張力 (MPa) | 110 @ 収率 | 131 @ 壊す | 175 @ 壊す | 105 @ 収率 |

| 破断伸び (%) | 50 | 4 | 2.4 | 60 |

| 曲げ弾性率 (GPa) | 3.3 | 6.89 | 9.6 | 3.31 |

| 誘電強度 (KV/mm) | 25 | 26.3 | 26 | 19.7 |

| 体積抵抗率 (ああ・cm) | 1×10¹⁵ | 7×10¹⁶ | 1×10¹⁵ | 1×10¹² |

| 乾燥温度 (℃) | 150 | 150 | 150 | 149 |

| 溶融温度 (℃) | 350–410 | 350–400 | 350–410 | 354–399 |

| 金型温度 (℃) | 135–180 | 135–165 | 135–180 | 135–177 |

ガラス入りグレード (20–30%) 優れた剛性と寸法安定性を提供します, しかし、彼らはそうです 延性が低い. 非充填PEIはより優れた衝撃強度と透明性を提供します, 視覚的または機械的なテスト用途に最適です.

PEI 材料処理ガイドライン

湿気のコントロール

PEI は吸湿性があるため、吸湿を防ぐために完全に乾燥させる必要があります。 泡, ボイド, そして 表面欠陥.

未充填PEI: 4 150℃で時間.

強化PEI: まで 6 150℃で時間.

水分レベルは以下でなければなりません 0.02% 成形前.

温度制御

PEI の要求 非常に高い処理温度:

溶融温度: 350℃~410℃.

金型温度: 135℃~180℃.

ご了承ください 色素沈着PEI 382℃を超えると変色する可能性があります. 金型全体で一貫した温度制御を維持することで、適切な流動と結晶化が保証されます。.

射出圧力

一般的な射出圧力: 70–150MPa.

圧力が高いほど改善される 金型充填 そして 収縮を減らす, ただし、過剰な圧力は反りやバリを引き起こす可能性があります.

収縮

未充填PEI: 等方性収縮 (ユニフォーム).

ガラス入りPEI: 異方性 (方向性のある), 不均一な寸法変化を引き起こす.

収縮を最小限に抑えるには:

金型温度を下げる.

射出圧力と保圧時間を増やす.

フローのバランスを保つために適切なゲート位置を使用する.

PEI 射出成形を成功させるためのベスト プラクティス

経験豊富なスタッフと連携 射出成形機 高性能熱可塑性プラスチックに精通している.

使用 精密工具 温度制御システム付き.

埋め込む 製造可能性のための設計 (DFM) デザインとコストのバランスを早めに決める.

プロセスの変動を避けるために、乾燥機と温度コントローラーを定期的にメンテナンスします。.

行為 モールドフロー解析 (MFA) 最適なゲートとベントの配置のために.

結論

PEI射出成形 強力な製品の生産を可能にします, 耐熱性, 医療分野の重要な用途向けの電気絶縁コンポーネント, 航空宇宙, そしてエレクトロニクス産業.

PEI は一般的なプラスチックよりもコストが高く、加工が困難ですが、, その 熱耐久性, 絶縁耐力, そして 寸法安定性 パフォーマンスを犠牲にすることができない要求の厳しい環境には不可欠です.

適切な金型設計と組み合わせると, 処理パラメータ, 熟練したエンジニアリング制御, PEI—特に ウルテム®—優れた長期信頼性を実現.

よくある質問

- PEIとPEEKの主な違いは何ですか?

PEI は安価ですが、PEEK に比べて耐摩耗性と耐薬品性が低くなります。. PEEK は 250°C 以上での連続使用に優れています, 一方、PEI は約 170°C までが理想的です. - PEIは医療用インプラントに使用できますか?

いいえ, PEI は生体吸収性ではないため、長期の移植には適していません。. しかし, で広く使用されています 滅菌可能な体外医療機器. - ガラスフィラーはPEIの特性にどのような影響を与えるのか?

ガラス繊維が剛性を高める, 抗張力, 耐熱性は高いが、柔軟性と耐衝撃性は低下する. - PEI樹脂の理想的な乾燥条件は何ですか??

水分含有量が以下になるまで 150°C で 4 ~ 6 時間乾燥します。 0.02%. 広がりや脆さを防ぐには、適切な乾燥が重要です. - PEI は屋外の電気用途に適していますか?

はい. UV安定剤入り, PEI は、日光や高温にさらされる屋外環境でも優れた性能を発揮します。.

続きを読む:

ナイロン射出成形: デザイン, プロセス, およびエンジニア向けの材料ガイド