Aluminum bending is a critical manufacturing process that involves transforming straight aluminum profiles or sheets into specific shapes through mechanical force. Porque alumínio possesses a unique crystal structure, achieving a perfect bend without cracking requires a deep understanding of material science and mechanical techniques.

EU. Critical Factors Affecting the Bending Process

Successful aluminum bending depends on more than just the machine; it depends on the physics of the material:

Formabilidade: This is the inherent ability of an alloy to undergo plastic deformation without fracturing. Factors like grain structure and chemical composition determine if a metal will “flow” or “snap” during a bend.

Alongamento: Measured as a percentage during tensile testing, elongation indicates how much the metal can stretch before it breaks. High-elongation alloys are far more forgiving during tight radius bending.

Bend Radius vs. Grossura: The “Minimum Bend Radius” is the smallest radius to which a sheet can be bent without failing. Geralmente, thicker materials require larger bend radii to prevent the outer surface from exceeding its ultimate tensile strength.

II. Best Aluminum Alloys for Bending

Not all aluminum is created equal. The alloying elements (Manganês, Magnésio, Silício) drastically change how the metal reacts to stress:

1. 3003 Series (Liga de Manganês)

This is arguably the best “general-purpose” bending alloy. It is highly workable and offers moderate strength.

Características: Alta ductilidade, excelente resistência à corrosão.

Formulários: Chemical equipment, cobertura, e trocadores de calor.

2. 5052 Series (Liga de magnésio)

Stronger than the 3003 série, 5052 is a favorite for structural sheet metal work.

Características: Excellent fatigue strength and resistance to marine environments. It retains its shape well after bending.

Formulários: Hardware marítimo, hydraulic tubes, e equipamentos médicos.

3. 6061 Series (Magnesium and Silicon Alloy)

Enquanto 6061 is the most common “structural” aluminum, it is notoriously difficult to bend. It is prone to cracking unless specific tempers or pre-heating methods are used.

Formulários: Aerospace structures, quadros automotivos, and heavy-duty bridges.

III. Understanding Tempers and Preventing Failure

O Temperamento (the hardness or state of the metal) is just as important as the alloy itself.

Ó (Recozido): The softest state, easiest to bend but offers low structural strength.

T4/T6 (Heat Treated): Provides high strength but makes the material brittle and prone to cracking during bending.

Tips to Prevent Cracking:

Bend Across the Grain: Like wood, aluminum has a “grain” direction from the rolling process. Bending perpendicular to the grain reduces the chance of failure.

Use lubrificação: Reduces friction between the metal and the die, preventing surface marring.

Pre-heating: For high-strength alloys like 6061, heating the material to a specific temperature can increase ductility temporarily.

IV. Industrial Bending Methods Comparison

Depending on the geometry of the part (sheet vs. tube), different mechanical approaches are required:

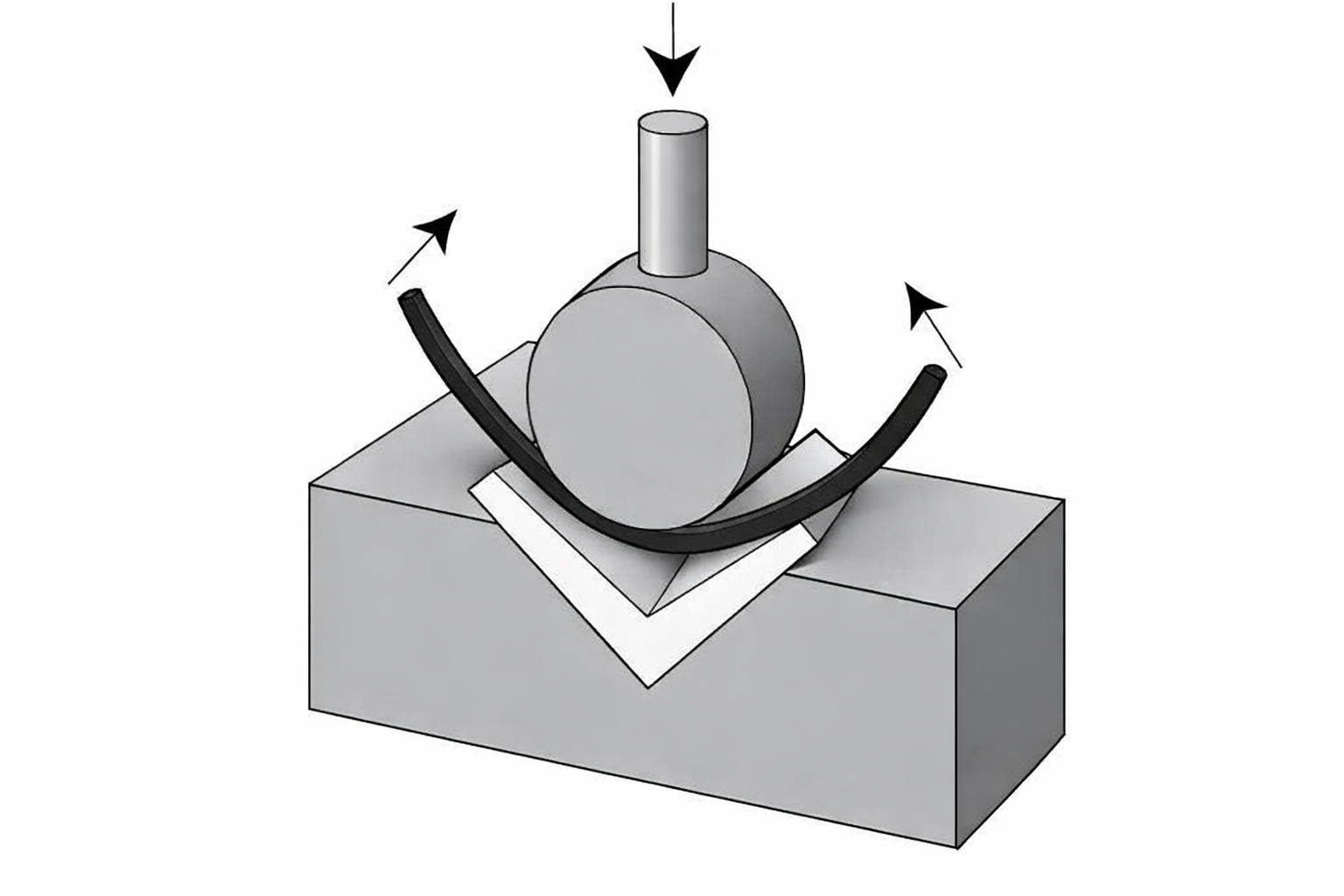

| Método | How it Works | Melhor para |

| Press Brake | A punch forces the sheet into a V-shaped die. | Large sheets, high-precision angles. |

| Dobragem de rolo | Aluminum passes through three rotating rollers. | Large radius curves, cilindros, and hoops. |

| Rotary Draw | The metal is clamped to a rotating die and drawn around it. | Tight-radius tubing (escapamentos, handrails). |

| Stretch Forming | The part is gripped and stretched over a form block. | Grande, complex curves with minimal springback. |

| Compression | A wiper shoe wraps the material around a stationary die. | Producing identical bends on both ends of a part. |

V. Key Applications of Bent Aluminum

Automotivo: Body panels and structural frames rely on bent aluminum to keep vehicles lightweight and fuel-efficient.

Aeroespacial: Fuselage ribs and wing spars are often created using stretch forming to ensure high precision.

Construção: Window frames and architectural cladding utilize three-roller bending for aesthetic curves.

Eletrônicos: Heat sinks and enclosures are often fabricated via press brake bending.

Perguntas frequentes

1. Why does aluminum “spring back” after I bend it?

Springback occurs because all metals have some degree of elasticity. When the bending force is released, the internal elastic stress causes the part to partially return to its original shape. To compensate, operators must “over-bend” the part by a few degrees.

2. Can I bend 6061-T6 aluminum without it cracking?

It is difficult. 6061-T6 is very brittle. To bend it successfully, you usually need a much larger bend radius (at least 3 times to 6 times the thickness) or you must anneal it to a “W” or “O” temper before bending.

3. What is the advantage of Rotary Draw Bending over Roll Bending?

Rotary draw bending uses a mandril (a solid insert inside the tube) which prevents the tube from collapsing or wrinkling. It is much better for tight, precise bends in tubing, whereas roll bending is better for large, sweeping arcs.

4. Does bending aluminum make it weaker?

Bending actually causes “work hardening” at the bend site, which increases the hardness and tensile strength in that specific area. No entanto, if the bend is too sharp, it can introduce micro-cracks that compromise the structural integrity.

5. How do I know the “Grain Direction” of an aluminum sheet?

On most cold-rolled sheets, the grain runs parallel to the direction in which the sheet was rolled. You can often see faint longitudinal lines on the surface. For the strongest bend, you should orient your bend line at 90° to these lines.