A criação de jóias percorreu um longo caminho de escultura à mão e fundição. Hoje, CNC (Controle Numérico Computadorizado) A usinagem está transformando a indústria, tornando -a mais rápido, mais preciso, E incrivelmente criativo. Com usinagem CNC, Os designers podem transformar suas visões mais complexas em realidade, produzindo impecável, peças de jóias personalizadas com precisão notável. Neste artigo, Exploraremos os meandros da usinagem CNC, suas vantagens na produção de jóias, Materiais adequados, considerações de design, e técnicas de acabamento,Para garantir que cada peça seja uma obra -prima.

Entendendo a usinagem CNC em jóias

O que é usinagem CNC?

Usinagem CNC é a Processo de fabricação controlado por computador que usa ferramentas automatizadas para cortar com precisão, forma, e materiais gravados. Em vez de confiar em técnicas manuais de manutenção, As máquinas CNC seguem Designs digitais pré-programados Para criar componentes de jóias altamente detalhados.

Como o CNC difere da fabricação de jóias tradicionais?

Ao contrário dos métodos tradicionais que envolvem escultura manual, fundição, ou estampagem, A usinagem CNC fornece:

- Precisão superior- Cada corte e gravação são executados com extrema precisão.

- Maior eficiência- Designs complexos podem ser produzidos mais rapidamente do que manualmente.

- Reprodutibilidade- Peças idênticas podem ser criadas em lotes grandes sem variações.

- Versatilidade- Funciona com uma ampla gama de metais e permite formas complexas.

Para joalheiros, A usinagem CNC abre inúmeras possibilidades, permitindo que eles produzam designs impressionantes e intrincados com consistência inigualável.

Benefícios da usinagem CNC para jóias

Insanamente preciso & Altamente detalhado 🎯

A usinagem CNC pode esculpar os menores detalhes com precisão absoluta. Seja Filigrana delicada, padrões complexos, ou micro-gravação, Máquinas CNC podem cortar designs que são quase impossível de fazer manualmente.

🔹 Por que isso importa:

✔ Simetria perfeita e execução impecável.

✔ Detalhes ultrafinos que parecem impressionantes sob ampliação.

✔ Ideal para logotipos personalizados, nomes, e texturas complexas.

💡 Exemplo: Imagine a anel com uma gravura microscópica das iniciais de um cliente ou uma pulseira com Padrões florais complexos- A usinagem do CNC torna possível!

Produção mais rápida, Menos tempo de espera ⏳

As jóias feitas à mão tomam semanas ou até meses para concluir, Mas as máquinas CNC podem produzir um lote de anéis ou pingentes em horas. Este é um Casador de jogos Para empresas de jóias que desejam ampliar.

🔹 Por que isso importa:

✔ Tempos de resposta mais rápidos para clientes.

✔ Produção mais eficiente sem sacrificar a qualidade.

✔ Mais fácil de produzir em massa designs personalizados.

💡 Exemplo: Um joalheiro pode cortar 50 pingentes idênticos em um dia usando o CNC, comparado à escultura manual de cada um ao longo de várias semanas!

Funciona com uma ampla gama de materiais 🌎

A usinagem CNC não se limita a apenas ouro e prata- Funciona platina, titânio, aço inoxidável, latão, alumínio, e até metais exóticos. Isso significa que os designers podem experimentar diferente materiais, cores, e acabamentos.

🔹 Por que isso importa:

✔ Mais opções de materiais para designs exclusivos.

✔ Capacidade de criar peças ultra-leves ou extremamente duráveis.

✔ Pode misturar e combinar metais para uma aparência moderna.

💡 Exemplo: Você poderia criar um pingente de dois tons com uma base de platina e detalhes em ouro - todos usinados com perfeição!

Perfeito para o costume & Jóias personalizadas 🛠️

Os clientes de hoje querem jóias que exclusivo para eles- A usinagem da CNC faz personalização mais fácil do que nunca. Seja iniciais gravadas, símbolos únicos, ou designs completamente sob medida, CNC permite a personalização em escala.

🔹 Por que isso importa:

✔ Os clientes recebem um de cada tipo pedaços.

✔ Mais fácil de modificar os designs existentes sem começar do zero.

✔ Cria a luxo, feito para você experiência.

💡 Exemplo: Um casal quer Anéis de casamento correspondentes com eles impressões digitais gravadas dentro- A usinagem do CNC faz acontecer com Precisão incrível!

Menos resíduos materiais, Mais economia 💰

A criação de jóias tradicionais geralmente resíduos Muito metal caro por causa da corte e arquivamento manual. Usos de usinagem CNC Ferramentas de corte de precisão para minimizar o desperdício, fazendo isso mais econômico e sustentável.

🔹 Por que isso importa:

✔ economiza dinheiro em matérias -primas.

✔ Menos resíduos de metal = mais ecológico.

✔ Designs otimizados com eficiência máxima.

💡 Exemplo: Em vez de esculpir manualmente um pingente de ouro e perder metal no processo, Máquinas CNC Corte apenas o que é necessário, reduzindo o excesso de sucata.

Sem erros humanos = menos erros ❌

Até os joalheiros mais qualificados podem fazer pequenos erros Ao criar joias. Com usinagem CNC, Cada peça é idêntica, garantindo zero defeitos e consistência perfeita.

🔹 Por que isso importa:

✔ Sem pequenas diferenças de forma, tamanho, ou gravação.

✔ Não há necessidade de retrabalho ou retoques.

✔ Cada peça encontra padrões de alta qualidade.

💡 Exemplo: Se você está produzindo um conjunto de abafas idênticas, CNC garante que eles sejam 100% o mesmo, eliminando o risco de variações.

Replicação mais fácil de designs 🔄

Se você criar um anel mais vendido ou design pendente, A usinagem CNC faz isso cópias fáceis de produzir mais idênticas- Se você precisa 10, 100, ou até 1,000 pedaços.

🔹 Por que isso importa:

✔ Torna mais as empresas de jóias escalável.

✔ garante que cada peça corresponda ao Design original perfeitamente.

✔ Ideal para Coleções de marca e Ordens de atacado.

💡 Exemplo: Uma marca de jóias lança um Coleção de edição limitada- A usinagem do CNC permite que eles produzir peças idênticas de alta qualidade sem inconsistências manuais.

Opções de acabamento avançadas para uma aparência luxuosa ✨

Após a usinagem do CNC, As peças de jóias podem ser terminadas com polimento, gravação, jato de areia, e anodizando Para alcançar uma aparência diferente - de Glamour de alto e-brilho à elegância do metal escovado.

🔹 Por que isso importa:

✔ mais Opções de estilo sem trabalho extra.

✔ pode alcançar fosco, espelho, ou acabamentos texturizados.

✔ O acabamento sofisticado faz jóias Sinta -se luxuoso.

💡 Exemplo: Um CNC-MACHINED pulseira de ouro pode ser polido para um brilho semelhante ao espelho ou dado a Acabamento de cetim fosco- tudo com controle preciso.

Compatível com software CAD para designs perfeitos 🖥️

A usinagem CNC funciona diretamente com cafajeste (Design auxiliado por computador) programas, o que significa que os designers de jóias podem criar, Tweak, e visualizar suas peças antes que elas sejam feitas.

🔹 Por que isso importa:

✔ Veja o design em 3D antes de cortar.

✔ Faça alterações facilmente sem desperdiçar materiais.

✔ Ajuda designs perfeitos antes da produção.

💡 Exemplo: Um designer de jóias pode Ajuste o tamanho ou a espessura de um anel no arquivo CAD antes de ser usinado - consultando o ajuste perfeito!

Tecnologia à prova de futuro para a indústria de jóias 🚀

A usinagem CNC está na vanguarda de Modia de joias e continuará evoluindo com Design orientado a IA, 3D Digitalização, e corte a laser ultra preco. Marcas de jóias que adotam o CNC agora ficará à frente da competição.

🔹 Por que isso importa:

✔ acompanha Tendências modernas de jóias.

✔ funciona com inovações de ponta Como a digitalização em 3D.

✔ Garante sucesso a longo prazo em um mercado competitivo.

💡 Exemplo: Algumas marcas de luxo já estão usando a usinagem CNC para criar complexo, Jóias geométricas únicas isso seria impossível com métodos tradicionais.

Melhores materiais para jóias usinadas em CNC

Alguns metais são fáceis de cortar e polir, enquanto outros são mais difíceis, mas mais duráveis. Esteja você está fazendo Brincos delicados, Anéis de declaração em negrito, ou pingentes intrincados, Escolher o metal certo vai afetar a aparência, sentir, e longevidade da sua peça.

Ouro - o clássico atemporal ✨

O ouro tem sido usado em jóias para séculos, E por um bom motivo - é lindo, de valor, e fácil de trabalhar com. A usinagem CNC pode cortar ouro em detalhes finos sem danificar sua estrutura.

🔹 Por que é ótimo para jóias CNC:

✔ Macio e fácil de máquina, tornando -o perfeito para desenhos complexos.

✔ Não enferruja ou manchas, Então dura para sempre.

✔ Disponível em cores diferentes: ouro amarelo, ouro branco, Rose Gold.

🔹 Coisas a considerar:

✔ porque o ouro é macio, peças muito finas ou delicadas podem dobrar facilmente.

✔ Gold mais alto de Karat (18K ou 24k) é mais suave do que Karat inferior (10K ou 14k).

✔ Mais caro do que outros metais - então você quer acertar o design da primeira vez!

💡 Melhor para: Anéis, pingentes, relógios de luxo, jóias finas com gravuras complexas.

Prata - Elegante & Acessível 🩶

Prata é uma escolha popular para jóias porque parece luxuoso, mas custa menos do que ouro. É também fácil de usinar, tornando -o ideal para Designs de jóias CNC personalizados.

🔹 Por que é ótimo para jóias CNC:

✔ Soft, Como ouro, Portanto, é fácil moldar em detalhes finos.

✔ Pifres para um Alto brilho, Dando a jóias uma aparência luxuosa.

✔ Mais acessível do que ouro e platina.

🔹 Coisas a considerar:

✔ Prata manchas com o tempo, Portanto, precisa de limpeza regular.

✔ pode ser arranhado facilmente, especialmente em Jóias de alto contato (como anéis).

✔ pode ser um pouco macio demais para Peças finas ou delicadas.

💡 Melhor para: Colares, Brincos, Peças gravadas, Designs artísticos.

Platina-ultra durável & Luxuoso 🤍

Platinum é um dos mais metais duráveis usado em jóias finas. Isso é mais denso e mais forte do que ouro ou prata, tornando -o perfeito para peças que precisam durar a vida inteira.

🔹 Por que é ótimo para jóias CNC:

✔ Muito forte e resistente a arranhões, Ótimo para desgaste diário.

✔ Naturalmente branco, Então isso não precisa de ródio como ouro branco.

✔ Hipoalergênico, tornando -o ideal para a pele sensível.

🔹 Coisas a considerar:

✔ Mais difícil de máquina do que ouro ou prata, Então o corte do CNC leva mais tempo.

✔ Mais caro do que prata, mas não tão caro quanto o ouro de alto karat.

✔ mais pesado do que outros metais, o que pode fazer Peças maiores parecem pesadas.

💡 Melhor para: Alianos de casamento, Anéis de noivado, Jóias de ponta.

Titanium - Moderno, Leve & Super forte 🔩

O titânio se tornou o favorito para moderno, Designs de jóias nervosos. Isso é leve, forte, e resistente a arranhões, tornando -o perfeito para estilos de vida ativos.

🔹 Por que é ótimo para jóias CNC:

✔ Muito forte e leve, Ótimo para desgaste confortável.

✔ Não enferruja ou manchas, Então parece ótimo por anos.

✔ pode ser anodizado para criar cores frias (azul, roxo, ouro, etc.).

🔹 Coisas a considerar:

✔ Mais difícil de máquina do que metais moles como ouro ou prata.

✔ Difícil de redimensionar ou reparar Depois que as jóias são feitas.

✔ Não é tão flexível, então Não é ideal para intrincado, Designs delicados.

💡 Melhor para: Anéis masculinos, peças de declaração modernas, jóias minimalistas.

Aço inoxidável-amigável ao orçamento & Difícil 🛠️

Se você está procurando acessível, jóias duráveis, Aço inoxidável é uma opção fantástica. Tem um elegante, Look industrial, tornando -o popular para audacioso, Designs modernos.

🔹 Por que é ótimo para jóias CNC:

✔ Muito forte e resistente a arranhões.

✔ Acessível e amplamente disponível.

✔ Hipoalergênico, Então é ótimo para pele sensível.

🔹 Coisas a considerar:

✔ Mais difícil de máquina do que ouro ou prata.

✔ Não pode ser facilmente redimensionado ou ajustado após a usinagem.

✔ Não tem o mesmo apelo de luxo como ouro, prata, ou platina.

💡 Melhor para: Jóias masculinas, Designs minimalistas, peças de declaração.

Latão & Cobre - quente & Visualização vintage 🟠

Brass e cobre são frequentemente usados para artístico, Jóias de estilo vintage. Eles desenvolvem um único pátina ao longo do tempo, dando -lhes um envelhecimento, visual antiga.

🔹 Por que eles são ótimos para jóias CNC:

✔ Acessível e fácil de máquina.

✔ Pifres para um esquentar, brilho dourado.

✔ Ótimo para audacioso, Designs artísticos.

🔹 Coisas a considerar:

✔ Ambos os metais oxidar e desenvolver uma pátina (que algumas pessoas amam!).

✔ pode causar Descoloração da pele Se usado por longos períodos.

✔ Não é tão valioso quanto o ouro, prata, ou platina.

💡 Melhor para: Jóias Bohemianas, peças de declaração artística, Designs gravados.

Alumínio-Ultra-Lightweight & Personalizável ⚪

Alumínio é não tão comum em jóias finas, Mas é perfeito para personalizado, Peças leves. É também fácil de colorir através da anodização, dando aos designers a chance de criar exclusivo, jóias coloridas.

🔹 Por que é ótimo para jóias CNC:

✔ Super leve, tornando -o confortável para peças grandes.

✔ pode ser anodizado em muitas cores, De blues profundos a vermelhos brilhantes.

✔ Muito acessível e fácil de máquina.

🔹 Coisas a considerar:

✔ Não é assim forte ou valioso como metais preciosos.

✔ arranhões mais facilmente do que metais mais difíceis.

✔ não tem o visual tradicional de "luxo" de ouro, prata, ou platina.

💡 Melhor para: Moderno, jóias coloridas, Designs leves, peças de declaração criativa.

Escolhendo o material certo para o seu design de jóias

Então, Como você Escolha o melhor metal para suas jóias usinadas com CNC? Aqui está um guia rápido:

🔹 Vá para ouro ou prata Se você quiser tradicional, jóias elegantes.

🔹 Escolha platina para soft-end, peças duradouras.

🔹 Escolha titânio ou aço inoxidável para forte, Designs modernos.

🔹 Use latão ou cobre Se você gosta de jóias vintage e antigas.

🔹 Experimente o alumínio por diversão, colorido, e designs leves.

Não importa qual metal você escolher, A usinagem CNC permite que você crie esplêndido, preciso, e peças de jóias exclusivas Isso vai durar a vida inteira. 💎✨

Dicas importantes de design para jóias usinadas em CNC

Criar jóias com usinagem CNC abre inúmeras possibilidades para intrincados, Designs personalizados. Mas antes de você começar a cortar metais preciosos, Há algumas coisas importantes a serem lembradas para garantir que sua peça final pareça impressionante e funcione perfeitamente.

Mantenha -o detalhado - mas não muito complicado

Uma das maiores vantagens da usinagem CNC é sua capacidade de criar Designs altamente detalhados e precisos. No entanto, Há um bom equilíbrio - você não quer que seu design seja também intrincado, ou pode ser difícil usinar adequadamente.

🔹 O que considerar:

✔ pequenos detalhes, como gravuras finas ou trabalho de filigra, Mas linhas extremamente finas ou cortes profundos podem ser complicados.

✔ Evite formas excessivamente complexas com recursos desnecessários que podem diminuir a produção ou aumentar os custos.

✔ Se um design tiver elementos super pequenos, Teste primeiro em uma peça de amostra antes de usinar materiais caros, como ouro ou platina.

💡 Pense nisso como projetar jóias de renda - os padrões de elicados são lindos, Mas eles precisam ser fortes o suficiente para manter sua forma.

Escolha o metal certo para o seu design

Nem todos os metais se comportam da mesma maneira durante a usinagem do CNC. Alguns são macio e fácil de cortar, enquanto outros são difícil e requer um planejamento mais cuidadoso.

🛠 Melhores metais para jóias CNC:

- Ouro & Prata- Macio, fácil de usinar, e ótimo para detalhes bons.

- Platina- forte e durável, mas requer lento, usinagem precisa.

- Titânio & Aço inoxidável- Mais difícil de cortar, mas perfeito para moderno, Estilos de jóias ousados.

🔹 Coisas a considerar ao escolher um metal:

✔ Metais macios (ouro, prata) são ótimos para uma bela gravura, mas podem ser arranhados mais facilmente.

✔ Metais rígidos (aço inoxidável, titânio) são duráveis, mas podem levar mais tempo para a máquina e exigir ferramentas mais fortes.

✔ A espessura do seu design é importante -Peças mais grossas funcionam melhor para metais duráveis, Enquanto desenhos delicados teram mais macios.

💡 Escolha o seu metal com base na aparência que você deseja e como você precisa de suas jóias para ser.

Planeje a espessura da parede direita

As peças de jóias devem ser magro o suficiente para se sentir leve e elegante, mas grosso o suficiente para permanecer forte e evitar quebrar.

🔹 Guia de espessura ideal:

✔ Anéis e pingentes: Pelo menos 0.8mm - 1,2 mm espesso.

✔ Brincos e encantos: Em volta 0.6mm - 1,0 mm para durabilidade.

✔ pulseiras e pulseiras: Pelo menos 1.5mm - 2,0 mm para evitar dobrar.

💡 Pense na espessura da parede como o esqueleto do seu design - muito fino, E pode se encaixar; Muito grosso, E pode parecer volumoso.

Garanta conexões suaves & Articulações fortes

Se o seu design tiver várias partes - como um pingente com um loop ou um anel com um ambiente anexo - você precisa Pontos de conexão fortes e suaves Então tudo fica junto com segurança.

🔹 Como fazer articulações fortes:

✔ Evite fazer pontas finas ou pequenos pontos de conexão- Eles podem enfraquecer com o tempo.

✔ Verifique se os pontos de fixação para pedras preciosas ou fechos são resistente e bem apoiado.

✔ Bordas redondas Em vez de cortes nítidos para acabamento mais suave e melhor durabilidade.

💡 Pense nisso como construir uma ponte - se os pontos de conexão são fracos, toda a estrutura pode entrar em colapso!

Design para acabamento pós-formação

Folhas de usinagem CNC Pequenas marcas de ferramentas na superfície das jóias, o que significa que a maioria das peças precisa de polimento e acabamento extras. Planeje seu design Saber que o polimento vai mudar um pouco a aparência final.

🔹 O que considerar para terminar:

✔ Se você quiser um Acabamento de alto brilho, Deixe espaço extra para polimento para que os detalhes não sejam apagados.

✔ Se o seu design incluir gravação ou textura, verifique se eles são profundos o suficiente para ainda serem visíveis após o polimento.

✔ Considere adicionar um camada de revestimento (ouro, ródio, ou óxido preto) Para aprimorar a aparência e a durabilidade da peça.

💡 É como pintar uma obra -prima - você precisa preparar a tela antes de adicionar os toques finais!

Otimizar para conforto & Desgaste

As jóias não devem apenas parecer incríveis, mas também se sentirem confortáveis em usar. Desenhos que são muito volumosos, pesado, ou afiado pode tornar uma peça desconfortável e menos prática.

🔹 Como tornar as jóias mais vestíveis:

✔ Sujeito todas as bordas afiadas Então eles não arranham a pele.

✔ Mantenha Bandas de anel confortáveis- não muito grosso ou muito fino.

✔ Verifique se os brincos e pingentes são leve o suficiente Então eles não puxam as orelhas ou o pescoço.

💡 Se parece lindo, mas se sente desconfortável, As pessoas não querem usá -lo!

Planeje as configurações de pedra preciosa (Se necessário)

Se você está projetando uma peça que segure pedras preciosas, o Configuração usinada por CNC precisa ser perfeitamente medido para que as pedras se encaixem em segurança.

🔹 Dicas de configuração de pedras preciosas:

✔ Uso CNC para cortar com precisão pontas ou molduras Para um ajuste confortável.

✔ Considere o profundidade e largura de pedra Ao planejar a configuração.

✔ Certifique -se de As bordas de metal não arranham as pedras mais macias Como opalas ou esmeraldas.

💡 Pense nisso como colocar um diamante em um anel - precisa ser apertado o suficiente para permanecer seguro, mas não muito apertado, que danifique a pedra.

Preparação antes da formação

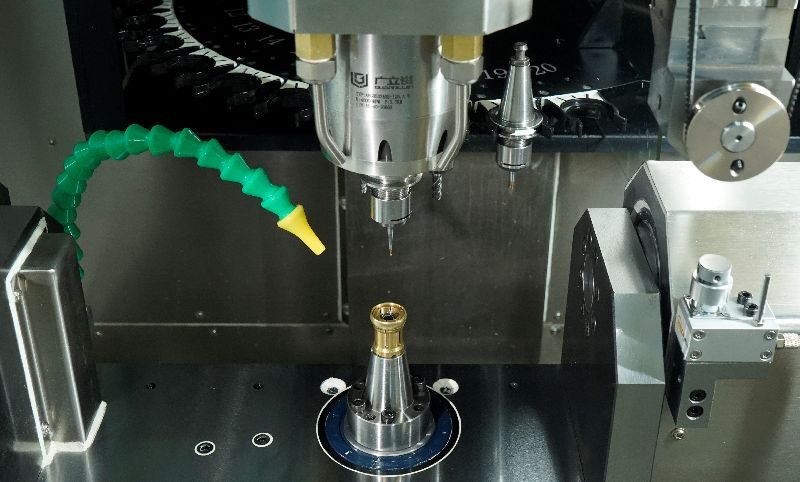

Escolhendo a máquina CNC certa para o trabalho

Diferentes máquinas CNC são especializadas em diferentes tipos de jóias. A escolha depende do design e do tipo de metal que está sendo usado.

🛠 Máquinas CNC comuns usadas para jóias:

- Fresadoras CNC- Ótimo para esculpir padrões complexos, gravação, e esculpindo formas únicas.

- Tornos CNC- Ideal para fazer peças simétricas como alianças ou pulseiras.

- Máquinas de gravura a laser- usado para gravar detalhes finos, nomes, ou logotipos na superfície do metal.

💡 Imagine um escultor escolhendo o cinzel perfeito para uma obra -prima - é isso que a seleção da máquina CNC certa faz para jóias!

Protegendo o metal no lugar

Antes do início da usinagem, o bloco de metal ou folha deve estar devidamente seguro. A última coisa que você quer é que o material se mova enquanto é cortado!

🔹 Como isso é feito?

✔ Um vício ou grampo mantém o metal estável dentro da máquina CNC.

✔ A máquina verifica o alinhamento para garantir que o corte seja.

✔ as ferramentas certas (cortadores, exercícios, ou bits de gravação) são escolhidos com base no design.

💡 Esta etapa é como segurar um pedaço de madeira estável antes de esculpir - garante limpo, cortes precisos!

Processo de usinagem CNC para jóias

A usinagem começa: Corte, Modelagem, e gravura

Uma vez que tudo estiver definido, A máquina CNC segue o Instruções pré-programadas para cortar, forma, e gravar a peça de joalheria.

🔹 O que acontece durante a usinagem?

✔ A máquina move a ferramenta de corte com extrema precisão, removendo pequenos pedaços de metal.

✔ Se o design incluir gravação, A máquina esculpe nomes cuidadosamente, padrões, ou texturas.

✔ Para designs com configurações de pedra preciosa, A máquina perfura buracos ou cria pontas para segurar as pedras.

💡 Imagine um joalheiro de robô trabalhando com precisão incrível - a usinagem do CNC garante que todos os detalhes sejam perfeitos!

Verificando o primeiro corte

Depois que a usinagem inicial está completa, Os joalheiros verificam a peça para garantir que ela corresponda ao design digital.

🔹 O que foi verificado nesta etapa?

✔ são todos os cortes e gravuras corretos?

✔ Faça as medidas correspondam ao design CAD original?

✔ são quaisquer ajustes necessários antes de continuar?

💡 É como experimentar um traje personalizado pela primeira vez-pequenos ajustes podem ser necessários para obter o ajuste perfeito!

Termo toques antes do polimento

Nesta fase, A peça de joalheria tem sua forma básica, Mas pode ter bordas ou pequenas imperfeições da usinagem. Antes de polir, A peça é submetida:

✔ Deburrendo - Removendo bordas afiadas deixadas cortando.

✔ Suavização - Usando ferramentas finas para refinar detalhes e texturas.

✔ Inspeção final -verificando duas vezes se tudo está correto antes de passar para a próxima etapa.

💡 Pense nesta etapa como lixar uma escultura de madeira antes de adicionar tinta - isso torna a superfície lisa e impecável!

Pronto para a próxima etapa: Polimento e revestimento

Depois que a usinagem é feita, as jóias passam para polimento, revestimento, e configuração de pedra preciosa Para completar sua transformação.

✔ Um esmalte de alto brilho traz à tona a beleza do metal.

✔ Se necessário, um arremesso de ouro ou ródio é aplicado para maior durabilidade.

✔ Se as pedras preciosas fazem parte do design, Eles são cuidadosamente definidos nas configurações usinadas.

💡 De uma peça de metal de corte áspero a um impressionante, jóia polida - a usinagem do CNC facilita a criação de jóias, mais rápido, e mais preciso do que nunca!

Conclusão

A usinagem CNC tem transformou a indústria de jóias, possibilitando criar peças com precisão incomparável, personalização, e eficiência. Esteja você criando uma faixa de ouro simples ou um anel de noivado altamente complexo, Tecnologia CNC garante a perfeição em todos os detalhes.

Para fabricantes de joias que procuram abraçar artesanato moderno, mantendo a beleza do metaljamento tradicional, A usinagem CNC é a solução final.

✨ O futuro das jóias está aqui - onde a arte encontra precisão. ✨

OK,Para TOPS Sobre o uso $\texto{CNC}$ Conteúdo do artigo sobre processamento de joias de metais preciosos,Eu escrevi para você 5 chegar 8 Perguntas frequentes detalhadas e altamente relevantes em inglês。

Perguntas frequentes

1. Quais vantagens específicas a usinagem CNC oferece em relação aos métodos tradicionais de fabricação de joias, como fundição ou fabricação manual de metais preciosos (Ouro, Platina)?

A usinagem CNC oferece qualidade superior precisão e eficiência de materiais.

-

Precisão: Permite a criação de intrincados, geometrias não prismáticas, simetria perfeita, e recursos repetíveis (como configurações complexas de pinos ou furos de micro-pavimentação) com extrema precisão (PM 0.01 milímetros), garantindo uma fixação perfeita da pedra e o ajuste dos componentes.

-

Eficiência: Ao contrário do elenco, que envolve perda de material através de sprues e oxidação, CNC a usinagem gera cavacos de metal precisos que são altamente recicláveis, minimizando o desperdício de materiais caros.

2. Como o TOPS gerencia a dureza desafiadora e o alto valor de materiais como platina e ouro de alto quilate durante o processo de fresamento CNC?

Usinagem desses itens de alto valor, materiais difíceis requerem parâmetros altamente controlados:

-

Ferramentas: Utilizamos equipamentos especializados, ferramentas de corte de alta resistência ao desgaste (frequentemente carboneto revestido de diamante) projetado para difícil, metais não ferrosos para manter arestas vivas e prolongar a vida útil da ferramenta.

-

Recuperação de Materiais: Devido ao alto custo do material, implementamos protocolos rigorosos de coleta de cavacos e poeira ao longo de todo o processo para garantir a recuperação quase total da sucata de metais preciosos para reciclagem.

-

Rigidez da Máquina: Alta rigidez CNC máquinas (frequentemente 5 eixos) são usados para amortecer vibrações, o que é crítico para obter acabamentos superficiais finos em superfícies macias, materiais pegajosos como ouro puro.

3. Qual o papel da usinagem multieixos (4-eixo ou 5 eixos) brincar na criação de componentes complexos de joias, como configurações complexas ou anéis curvos?

A usinagem multieixos é essencial para complexidade e consistência:

-

5-Eixo: Necessário para esculpir complexo, superfícies de forma livre (como formas estilizadas de animais ou desenhos de bandas torcidas) sem interromper o caminho de corte. Ele permite que a ferramenta alcance recursos de vários ângulos em uma configuração.

-

4-Eixo: Ideal para peças cilíndricas ou rotativas (como anéis ou pulseiras) que exigem que os recursos sejam usinados em torno da circunferência, garantindo simetria e detalhes consistentes em toda a banda. Isso minimiza a refixação manual e possíveis erros de alinhamento.

4. Como as joias exigem um alto acabamento cosmético, quais etapas de acabamento pós-usinagem CNC são normalmente necessárias para obter um polimento espelhado em uma peça Gold ou Platinum?

Enquanto CNC pode conseguir um acabamento mecânico fino (Rá 0.8 \mãe), um verdadeiro polimento espelhado requer mais etapas:

-

Preparação: A suavização inicial geralmente é feita usando um passe de usinagem fino.

-

Jateamento/Tombamento Abrasivo: A peça pode passar por um movimento controlado da mídia para remover pequenas marcas de ferramentas e bordas lisas.

-

Polimento Manual: Para acabamento espelhado da mais alta qualidade, a peça muitas vezes requer final polimento manual usando uma série de discos abrasivos finos e compostos, como CNC não é possível replicar totalmente o alto brilho, alto brilho exigido por joias de luxo.

5. Como ocorre o uso CNC a usinagem auxilia especificamente na cravação subsequente de pedras preciosas, particularmente em configurações de micro-pavimentação ou canal?

CNC a usinagem fornece a base perfeita para a cravação da pedra:

-

Assentos Consistentes: A máquina fresa com precisão e consistência, furos e assentos precisos para pedras, garantindo profundidade e diâmetro uniformes em centenas de configurações.

-

Pontas Otimizadas: Pontas e paredes são usinadas em dimensões e ângulos exatos, permitindo que a incubadora trabalhe com material de espessura e altura conhecidas, o que é crucial para configurações de micropavimentação e canais seguras e esteticamente agradáveis, minimizando o risco de perda de pedra.

6. É CNC usinagem usada para criar moldes (padrões de cera/resina) para fundição tradicional por cera perdida, ou a TOPS usina a peça de metal final diretamente?

TOPS normalmente usa CNC para usinar o peça de metal final diretamente.

-

Enquanto CNC pode ser usado para moer padrões de cera ou resina para fundição de precisão, usinar a peça de metal final oferece precisão dimensional e integridade superiores, especialmente para metais duros e projetos complexos que sofreriam distorção ou degradação da superfície durante o processo de fundição.

7. Quais são as restrições de material em relação ao tamanho ou complexidade da peça ao usar CNC para ouro de alto quilate, dada a sua relativa suavidade?

As principais restrições estão relacionadas à estabilidade do material e às características finas:

-

Pressão da ferramenta: Ouro de alto quilate é macio, então o CNC O processo deve usar baixa pressão da ferramenta e altas velocidades do fuso para evitar acúmulo de material pegajoso na ferramenta ou deformação material (manchando) em vez de corte limpo.

-

Paredes Finas: Recursos muito finos (como faixas afiadas ou pontas finas) em ouro macio pode facilmente vibrar ou quebrar durante a usinagem, exigindo designs de fixação e métodos de resfriamento específicos para suportar rigidamente o material durante o corte.

Links externos

Para enriquecer ainda mais sua compreensão da usinagem CNC na fabricação de jóias, Aqui estão três recursos externos respeitáveis:

- Como a usinagem CNC é usada para joias de metal precioso: Este artigo investiga as vantagens de usar a usinagem CNC para metais preciosos como ouro e prata, destacando sua precisão e eficiência. com

- 8 As maneiras pelas quais a usinagem leva a fabricação de jóias a um nível totalmente novo: Este guia discute como a usinagem CNC aprimora os recursos de design de jóias, reduz os custos de produção, e introduz técnicas inovadoras que são desafiadoras para alcançar através dos métodos tradicionais. com

- Usinagem CNC na fabricação de jóias - o que é e como funciona: Este recurso fornece uma visão geral abrangente da usinagem CNC na fabricação de jóias, incluindo seus benefícios, como o design versatilidade, diversidade material, e eficiência de custos. com