O cenário ferozmente competitivo da produção moderna exige inovação contínua para reduzir os tempos de ciclo e diminuir os custos de produção. No moldagem por injeção de plástico setor, o sistema de câmara quente emergiu como uma tecnologia crítica, oferecendo soluções sofisticadas para esses desafios. Eliminando resíduos plásticos solidificados e otimizando o controle térmico, as câmaras quentes proporcionam uma vantagem competitiva substancial em relação às metodologias tradicionais de câmaras frias. Os fabricantes devem compreender as várias estruturas – pré-fabricadas, ajustável, e personalizado – para selecionar a solução mais econômica para suas necessidades exclusivas.

Este guia fornece uma visão geral abrangente da tecnologia de câmara quente, detalhando seu funcionamento, componentes essenciais, vantagens, armadilhas potenciais, e os diferentes tipos disponíveis no mercado hoje.

O que é um sistema de moldagem por injeção de câmara quente?

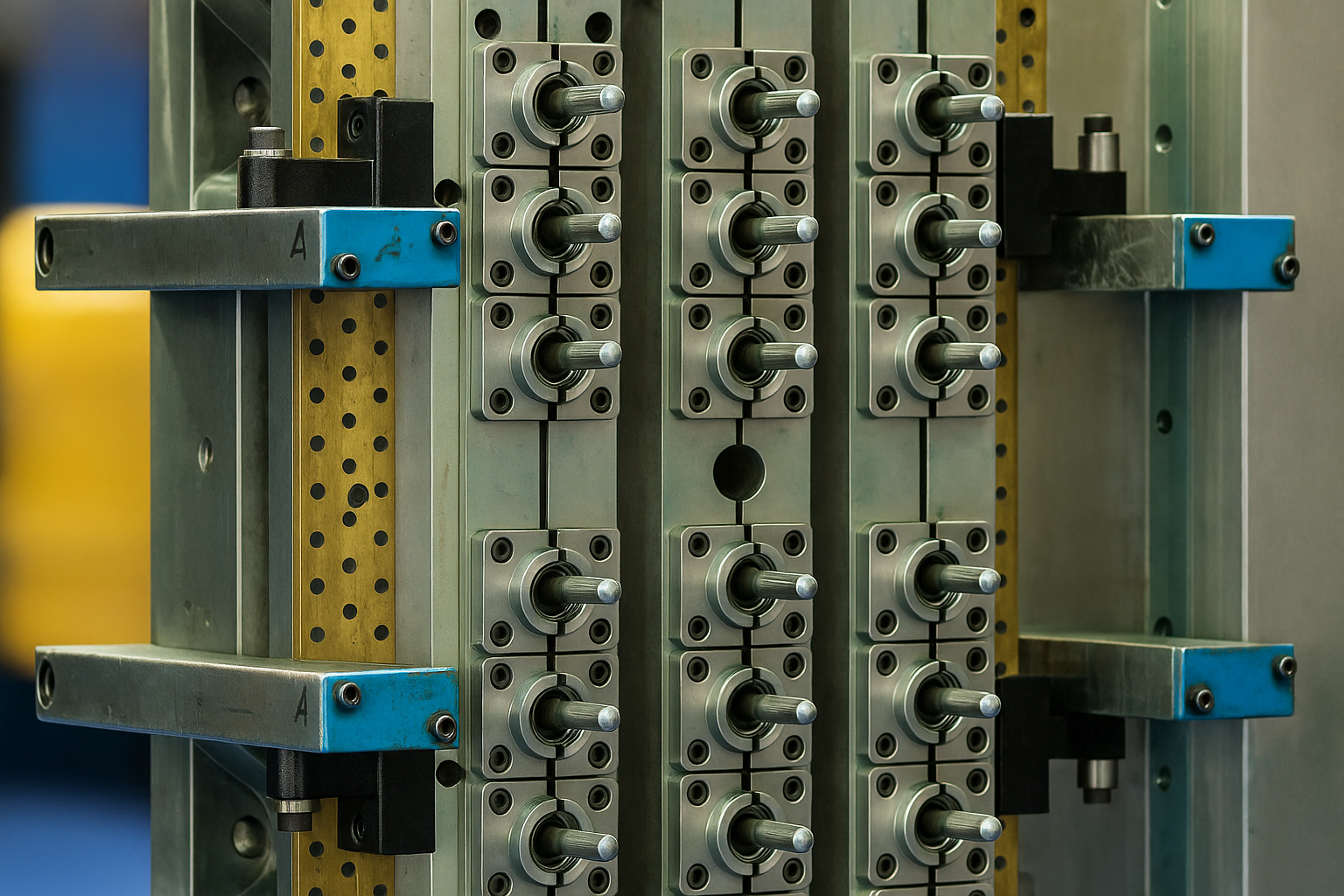

Um sistema de moldagem por injeção de câmara quente é um conjunto de componentes aquecidos projetados para manter o material termoplástico em estado fundido desde o bico da unidade de injeção até a entrada da cavidade do molde. (o portão). Ao contrário dos corredores frios, que permitem que o material solidifique nos canais de alimentação, o sistema de câmara quente derrete continuamente o plástico, garantindo um fluxo consistente e rápido para ciclos de injeção subsequentes. Este sistema é integrado diretamente na máquina de corte e na estrutura da ferramenta de molde.

Corredor Quente vs.. Sistemas de moldagem por injeção de câmara fria

A escolha entre sistemas de câmara quente e fria impacta fundamentalmente a eficiência da produção, uso de materiais, e qualidade da peça.

| Recurso | Sistema de Câmara Quente | Sistema de câmara fria |

| Estado material no canal | Sempre Derretido (Aquecido) | Solidifica (Resfriado) |

| Desperdício (Corredor) | Mínimo a Nenhum (Corredor é eliminado) | Alto (Requer remoção e reafiação) |

| Tempo de ciclo | Significativamente reduzido (Sem tempo de resfriamento para o corredor) | Mais longo (Requer tempo de resfriamento e desativação) |

| Aparência do portão | Pequeno local de injeção; acabamento suave e detalhado. | Vagas maiores (Portões); requer aparar/desgastar. |

| Custo | Maior custo inicial de ferramentas | Menor custo inicial de ferramentas |

| Eficiência Operacional | Excelente para grandes volumes, produção automatizada. | Adequado para produção de pequenos volumes ou peças grandes. |

A vantagem mais convincente do sistema de câmara quente é a sua capacidade de injetar diretamente o plástico fundido na cavidade do produto., garantindo que apenas a peça moldada seja removida durante cada ciclo. Isto praticamente elimina o desperdício do corredor e a operação secundária de desgaseificação, traduzindo-se em economias de custos significativas, especialmente ao processar resinas caras ou especiais.

Como funciona um sistema de moldagem por injeção de câmara quente?

O mecanismo operacional de um sistema de câmara quente é baseado em um rigoroso gerenciamento térmico. O plástico é mantido fundido dentro dos tubos do corredor por elementos de aquecimento controlados com precisão incorporados no coletor e nos bicos. Este estado líquido contínuo garante que o material esteja sempre pronto para injeção.

O sistema ignora o canal de canal e canal frio tradicional, permitindo a suavidade, material fundido flua diretamente para as cavidades do molde com perda mínima de pressão. Ao eliminar o sistema de sprue, o produto acabado requer menos cortes e aparas, levando a superfícies mais lisas e melhorando a estética e a tolerância do componente final. O processo de injeção mais rápido é facilitado pelo menor volume de plástico líquido, o que também ajuda na recuperação mais rápida do parafuso de injeção, reduzindo ainda mais o tempo de ciclo geral.

Principais componentes dos sistemas de câmara quente

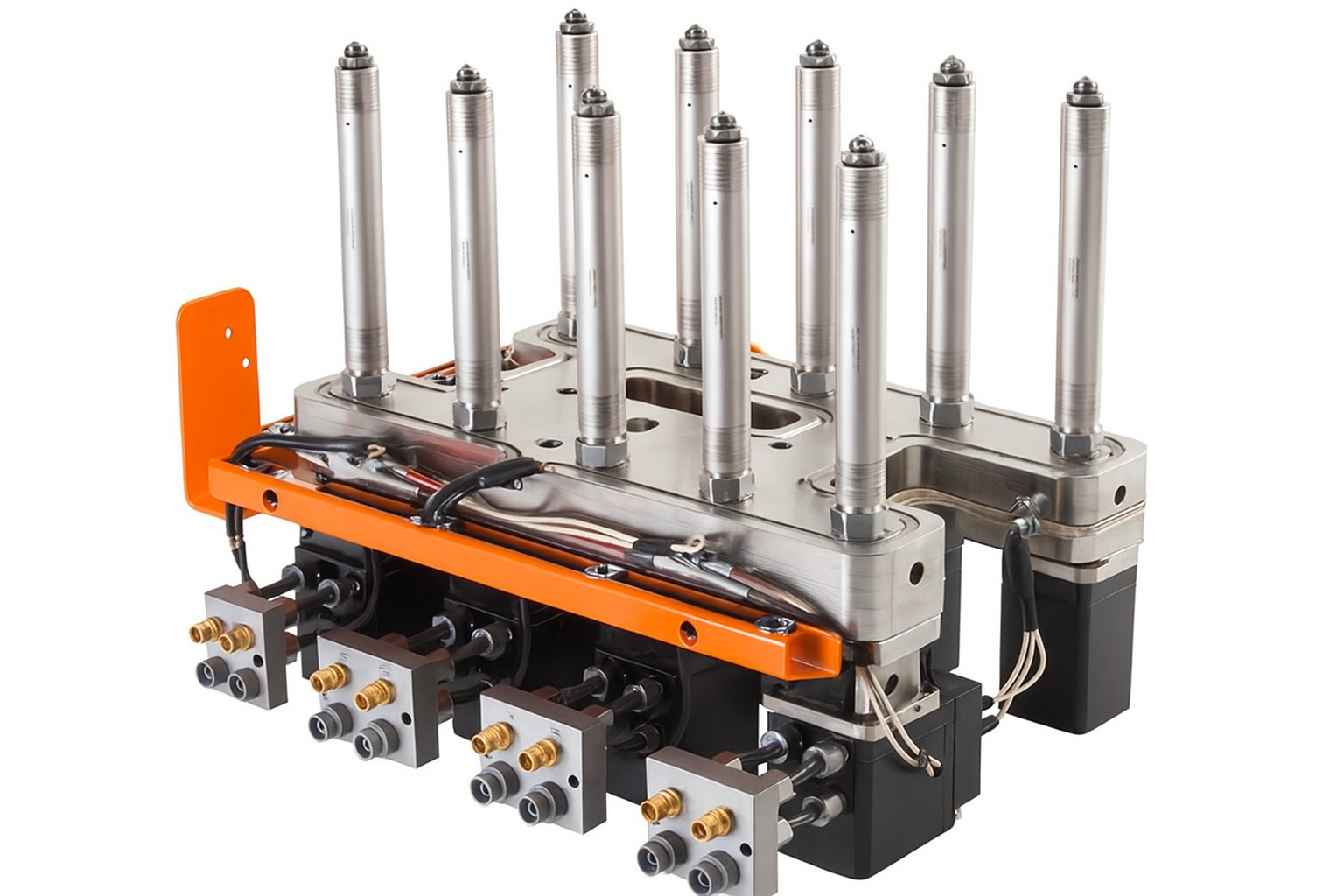

Um sistema de câmara quente é uma montagem complexa que compreende vários, componentes com temperatura controlada:

Bicos ou Bicos: Estes são componentes projetados com precisão que ligam o manifold à porta da cavidade do molde. Eles controlam o fluxo de plástico no ponto de injeção e determinam o estilo da comporta (por exemplo., dica quente, borda, ou portão valvulado). Eles devem manter uma temperatura extremamente consistente até a abertura da cavidade.

Variedades: São ferramentas projetadas para receber o plástico derretido da unidade de injeção e distribuí-lo uniformemente pelas múltiplas aberturas dos bicos.. Os coletores são projetados sob medida, muitas vezes com passagens internas complexas, para garantir caminhos de fluxo idênticos e quedas de pressão para todas as cavidades simultaneamente, o que é fundamental para alcançar uma qualidade consistente das peças.

Controle de Fluxo: Esta função essencial, normalmente gerenciado por tecnologia de portão valvulado, controla o tempo preciso do fluxo de plástico para fora do bico. Usando pinos acionados mecanicamente, o fluxo pode ser iniciado ou interrompido instantaneamente, controlando a vedação do portão e evitando baba ou amarração.

Conexões ou Links: O sistema depende de várias conexões especializadas, incluindo ligações elétricas para elementos de aquecimento, termopares para feedback de temperatura, e linhas para resfriamento (água ou ar) e atuação de portão valvulado.

Benefícios dos moldes de câmara quente

A tecnologia de câmara quente oferece inúmeras vantagens que a tornam a escolha preferida para a fabricação de moldes plásticos de alto volume e alta precisão:

Flexibilidade no Design: As câmaras quentes acomodam várias técnicas de gating – edge gating, portão de ponta quente, ou válvula de passagem - permitindo que os engenheiros coloquem a comporta no melhor local para preenchimento ideal do molde e aparência cosmética. Essa flexibilidade simplifica o projeto do molde para resfriamento e melhora o processo geral de corte.

Controle aprimorado do sistema de moldagem: O sistema permite uma inicialização mais rápida e uma operação simplificada, uma vez que não há corredores solidificados para remover após disparos curtos. Isso permite um melhor desempenho ao injetar materiais com menos estresse, minimizando empenamento e flexão da placa causados pela expansão do material.

Automatizando o Processo: A produção impecável, componentes sem flash auxiliam na automação de moldes. O tamanho consistente da peça e a ausência de guias evitam que as ferramentas fiquem presas, agilizando o processo de montagem realizado pela robótica.

Economia de custos a longo prazo: Embora o investimento inicial seja maior, o sistema se mostra barato no longo prazo, reduzindo a duração do ciclo de produção e a quantidade de resíduos plásticos, levando a um aumento direto na produtividade.

Alta qualidade das peças: Ao eliminar a câmara fria, o sistema melhora a embalagem e o enchimento do material. Mantém condições térmicas consistentes desde a abertura principal até a extremidade do molde, garantindo pressão e enchimento uniformes. Isto é fundamental para alcançar tolerâncias rigorosas e alta precisão nos componentes finais.

Tempo de ciclo reduzido: A eliminação do rotor – que muitas vezes tem uma massa de resfriamento maior que a própria peça – encurta significativamente a fase de resfriamento. Este fator, combinado com tempos mais rápidos de injeção e recuperação do parafuso, acelera o ciclo geral de produção.

Eliminação de corredor: Isto é vital para eliminar os custos associados à reafiação, armazenar, e reprocessar o excesso de material. Para materiais especiais, como aqueles usados em aplicações médicas ou sensíveis, onde a reafiação não é permitida, câmaras quentes são a única solução viável.

Brechas (Desvantagens e Desafios) de sistemas de câmara quente

Apesar de seus benefícios, os sistemas de câmara quente apresentam desafios específicos que os fabricantes de moldes devem enfrentar:

Ótimo cuidado e manutenção: As câmaras quentes são sistemas complexos que exigem manutenção e atenção meticulosas. O manuseio incorreto ou cuidados incorretos podem levar a falhas graves dos componentes, resultando em tempo de inatividade dispendioso e possíveis perdas financeiras.

Necessidade de equipamento avançado: Os requisitos operacionais do sistema são altamente rigorosos, necessitando de máquinas de alta precisão que devem estar perfeitamente sincronizadas. Qualquer mau funcionamento, como uma tampa de plástico colocada incorretamente, pode levar a vazamentos e danos aos transportadores de fusão. A localização precisa do bocal e da comporta é fundamental para evitar defeitos.

Expansão térmica & Contração: As diferenças substanciais de temperatura entre o coletor aquecido e a placa de molde resfriada causam expansão e contração térmica. Os engenheiros devem projetar a ferramenta para compensar precisamente esse movimento para manter a integridade da vedação da comporta. Controlar a emissão de calor durante todo o processo é um desafio.

Cuidado extra com resina sensível ao calor: O processamento de resinas sensíveis ao calor requer conhecimento especializado e extremo cuidado. Se não for gerenciado adequadamente, a exposição prolongada ao calor pode levar à degradação do material, resultando em mudanças de cor ou quebra da cadeia molecular, comprometendo a integridade estrutural do material.

Alto custo inicial: A complexidade dos componentes torna os sistemas de câmara quente inerentemente caros. Este elevado investimento de capital pode não ser justificado para empresas com baixos volumes de produção ou em regiões onde o custo do equipamento inicial supera as poupanças de materiais a longo prazo..

Preço e tipos de sistemas de câmara quente

A. Divisão de custos

O alto custo é impulsionado principalmente pela engenharia de precisão do coletor. Um coletor típico de câmara quente pode variar de $20,000 para $30,000, com um adicional $5,000 ou mais necessário para a unidade controladora de temperatura. A despesa global é diretamente proporcional ao número de gotas ou zonas (cavidades) o sistema é projetado para preencher simultaneamente.

B. Tipos por mecanismo de portão

Dica quente: A configuração de câmara quente mais comum e simples. Baseia-se em uma ponta aquecida que fica diretamente no portão, mantendo o plástico fundido. Geralmente é mais barato que o sistema de bico valvulado e é ideal para produção rápida de itens simples..

Válvula Valvulada: Apresenta um pino mecânico que se move para dentro e para fora do local do portão. Fecha instantaneamente após a injeção, garantindo uma limpeza, acabamento superficial sem marcas. Os bicos valvulados são mais caros, mas são usados para produtos estéticos exigentes e com alta perfeição.

C. Tipos por método de aquecimento

Aquecido Internamente: O calor é gerado de dentro do canal de fluxo, oferecendo controle localizado sobre o movimento do material. No entanto, sistemas aquecidos externamente os substituíram em grande parte devido à melhor distribuição e controle de calor.

Aquecido Externamente: Os elementos de aquecimento são colocados ao redor dos canais de fluxo (placas coletoras). Esses sistemas fornecem transmissão térmica superior e melhor controle de calor do que corredores isolados, embora envolvam um design mais complicado e caro.

D. Corredores Isolados

Esses corredores são mais simples e baratos de construir. Eles não possuem elementos de aquecimento externos, mas dependem das propriedades isolantes do polímero e da alta velocidade do ciclo para manter o núcleo interno fundido. No entanto, eles sofrem de problemas como enchimento não uniforme, congelamentos de portão, e longos períodos de estabilização.

Conclusão

A tecnologia de câmara quente representa um avanço significativo na moldagem por injeção, entregando peças de qualidade superior, aumento do rendimento da produção, e economias substanciais de custos de materiais a longo prazo. Fornecendo controle preciso sobre a entrega do fundido e eliminando o desperdício do canal, os sistemas de câmara quente atendem efetivamente à necessidade da indústria de custos mais baixos e tempos de ciclo mais rápidos. À medida que os produtos se tornam mais complexos e os custos dos materiais continuam a aumentar, a adoção de sistemas avançados de câmara quente se tornará cada vez mais vital para manter a excelência competitiva no cenário moderno de fabricação de plástico.

Perguntas frequentes

1º trimestre: O que é ‘Babar’ ou ‘Encordoamento’ e como os Hot Runners evitam isso?

A: Babar ou Amarrar refere-se ao vazamento de plástico derretido da porta entre os ciclos de injeção. Isso geralmente ocorre porque a pressão plástica dentro do bocal é maior que a pressão exercida pelo molde frio na comporta.. Sistemas de válvulas (Seção VII.B) são a solução mais eficaz: o pino mecânico sela instantaneamente a comporta depois que a pressão de retenção é liberada, parando fisicamente qualquer vazamento, garantindo assim uma limpeza, componente sem flash e evitando tempo de inatividade para limpeza.

2º trimestre: Como o Manifold atinge temperatura uniforme e fluxo equilibrado para todas as cavidades?

A: O principal objetivo do projeto do coletor é o equilíbrio térmico e hidráulico.

Uniformidade Térmica: Os coletores de alta qualidade utilizam aquecedores internos localizados com precisão e múltiplas zonas térmicas, monitorado por termopares, para manter exatamente a mesma temperatura de fusão em todo o bloco.

Equilíbrio de Fluxo (Balanço Hidráulico): Os canais internos são projetados de modo que o comprimento e a geometria do caminho de fluxo do ponto de injeção central até cada ponta do bico sejam idênticos. Isso garante queda de pressão e velocidade de enchimento iguais em todas as cavidades, o que é crítico para dimensões consistentes das peças.

3º trimestre: O que é ‘aquecimento por cisalhamento’ e por que é uma preocupação em câmaras quentes?

A: O aquecimento por cisalhamento é o calor gerado dentro do próprio plástico devido ao atrito à medida que o material flui rapidamente através de canais estreitos ou cantos afiados.. Em corredores quentes, isso pode ser problemático porque o calor intencional do coletor combina com o calor friccional, potencialmente aumentando a temperatura do material acima de seu limite seguro. Isto pode levar a localização degradação térmica do plástico, causando descoloração ou comprometimento da resistência da peça (Seção VI).

4º trimestre: Qual é a principal desvantagem de usar Câmaras Quentes para mudanças frequentes de cores ou materiais?

A: O principal desafio é o Tempo de purga. Como todo o volume interno do coletor está preenchido com material fundido, mudar de uma cor ou tipo de material para outro requer a eliminação completa do material antigo. Este processo, conhecido como purga, pode consumir tempo significativo e resina cara, compensando alguns dos benefícios da redução de resíduos. Sistemas projetados com volume mínimo de canal de fluxo são preferidos para aplicações que exigem mudanças frequentes.

Q5: Qual a importância da Unidade Controladora de Temperatura (TCU)?

A: O TCU é absolutamente vital. É o ‘cérebro’ do sistema de câmara quente, usando sofisticadas derivadas proporcionais-integrais (PID) algoritmos de controle para monitorar constantemente as leituras do termopar e regular com precisão a energia fornecida aos elementos de aquecimento. Sem controle preciso de temperatura (até $mathbf{\pm 0,5^circ C}$), a consistência do derretimento do plástico irá flutuar, levando a defeitos como tiros curtos, queimando, ou congelamento do portão, inutilizando os benefícios da câmara quente.

Q6: O que é um ‘Gate Vestige’ e como o sistema Hot Runner o minimiza?

A: Um vestígio de portão é o pequeno remanescente de material deixado na peça após o portão ser quebrado ou cortado. Sistemas de câmara quente, especialmente aqueles que usam Dica quente ou Válvula Valvulada projetos, criar portas que são inerentemente menores do que aquelas em moldes de câmara fria. Em um sistema valvulado, o pino mecânico veda o plástico nivelado com a superfície da peça, deixando um vestígio praticamente invisível, muitas vezes eliminando a necessidade de qualquer operação de corte secundária.

Q7: Por que é difícil usar Câmaras Quentes com certos materiais termofixos?

A: As câmaras quentes são projetadas principalmente para termoplásticos. Materiais termofixos (como epóxi ou silicone) sofrer uma reação química irreversível (cura) quando aquecido, transformando-se de um líquido viscoso em um infusível, massa sólida. Se um material termofixo fosse usado em uma câmara quente padrão, curaria dentro do coletor e bloquearia permanentemente os canais, destruindo a ferramenta cara. Especializado, muitas vezes descartável, sistemas de câmara fria ou ligação adesiva são usados para termofixos.

P8: O que é ‘Pin Sticking’ em um sistema Valve Gate?

A: O pino preso ocorre quando o pino da válvula mecânica não se move livremente ou não veda corretamente. A principal causa geralmente é o superaquecimento da ponta do pino, fazendo com que o plástico solidifique e adira ao pino, ou ligeiro desalinhamento entre o pino e a bucha do bico. Este problema pode causar baba (se o pino não conseguir selar) ou abertura incompleta do portão (restringindo o fluxo), que requer manutenção e recalibração imediata do sistema de atuação pneumático/hidráulico.