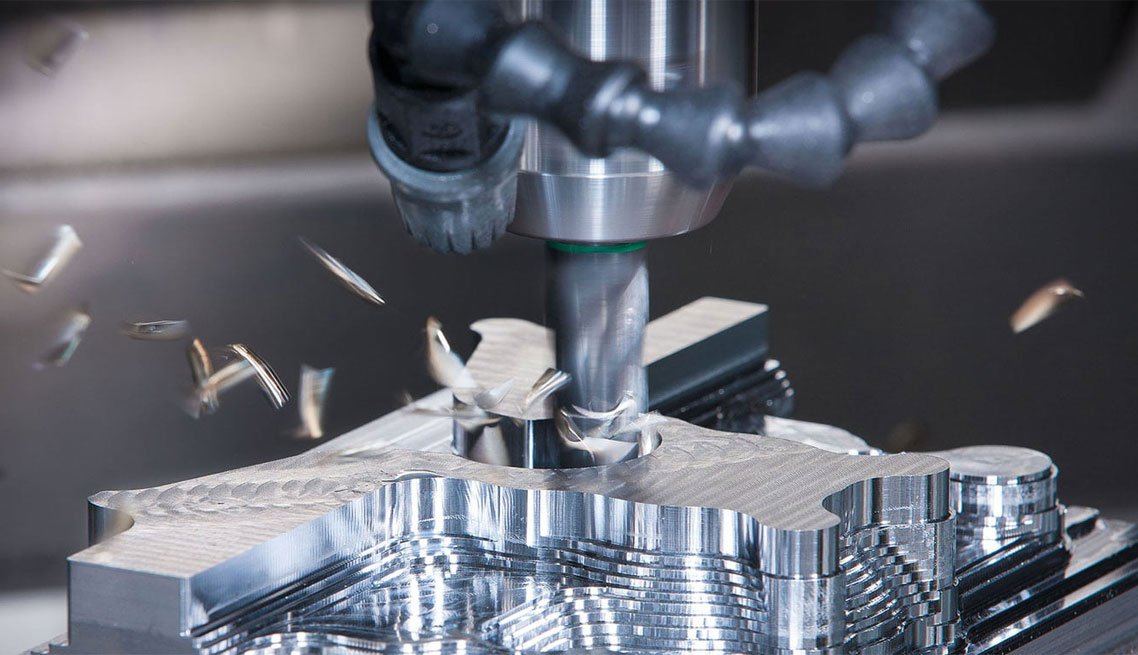

Entender a usinabilidade é essencial para engenheiros, maquinistas, e fabricantes Para otimizar os processos de produção, Selecione os materiais certos, e garantir produtos finais de alta qualidade. Este artigo explorará a maquiagem aprofundada, incluindo o seu fatores -chave, Classificações de maquinabilidade, Técnicas de medição, e maneiras de melhorar a usinabilidade Para uma melhor eficiência e economia de custos.

O que é máquinabilidade?

Machinabilidade refere -se a quão facilmente um material pode ser cortado, em forma, ou usinado Ao manter a alta qualidade de peça. Isso é Não apenas sobre velocidade de corte- Também envolve acabamento superficial, precisão dimensional, Desgaste da ferramenta, e eficiência geral.

Um material com Alta máquinabilidade pode ser processado rapidamente, Com o mínimo de desgaste da ferramenta, Menos força de corte, e um acabamento superficial liso. Por outro lado, um material com Máquina de baixa maquiagem requer mais força de corte, gera calor excessivo, Usar ferramentas mais rápido, e pode resultar em baixa qualidade da superfície.

No entanto, A maquinabilidade é frequentemente um troca na seleção de material. Enquanto metais macios como alumínio e latão tem excelente máquinabilidade, eles podem falta força e durabilidade. Em contraste, Materiais mais difíceis como titânio e aço inoxidável são mais difíceis de usinar, mas oferecem maior resistência, resistência à corrosão, e durabilidade.

Fatores que afetam a usinabilidade

Propriedades dos materiais: O núcleo da usinabilidade

Todo material tem propriedades únicas que determinam o quão fácil (ou difícil) é para máquina.

🔩 dureza - mais difícil é, O mais difícil é

- O que isso significa: Dureza é o quão resistente é um material para cortar, arranhando, ou dente.

- Impacto na usinabilidade: Quanto mais difícil o material, quanto mais difícil é a máquina.

- Exemplo:

- Alumínio (metal macio)🟢: Fácil de cortar, acabamento suave, Desgaste com baixa ferramenta.

- Aço ou titânio endurecido🔴: Difícil de cortar, usa ferramentas rapidamente, requer velocidades lentas de usinagem.

💡 Regra simples: Mais difícil = Máquina mais baixa (mas partes mais fortes!).

🔨 Trento - absorve choque ou quebre facilmente?

- O que isso significa: Tonalidade é o quão bem um material absorve o impacto sem quebrar.

- Impacto na usinabilidade: Materiais difíceis criam longo, chips pegajosos, que ficam emaranhados em ferramentas e desacelerando o corte.

- Exemplo:

- Latão (Metal quebradiço)🟢: Quebra em curto, fichas fáceis de remover = boa usinabilidade.

- Aço inoxidável (metal resistente)🔴: Produz longos, chips pegajosos que entupirem ferramentas.

💡 Regra simples: Mais resistência = Mais difícil de máquina (Mas melhor para fortes, partes resistentes ao impacto!).

🌡️ Condutividade térmica - isso lida bem com o calor?

- O que isso significa: Alguns materiais transferem o calor rapidamente, enquanto outros prendem.

- Impacto na usinabilidade: Má condução de calor = Ferramentas superaquecidas, Expansão térmica, e mau acabamento superficial.

- Exemplo:

- Alumínio (alta condutividade)🟢: O calor se dissipa rapidamente, Reduzindo o desgaste da ferramenta.

- Titânio (baixa condutividade)🔴: O calor permanece na zona de corte, causando ferramentas a se desgastar mais rápido.

💡 Regra simples: Melhor transferência de calor = Usinagem mais fácil, Vida de ferramenta mais longa.

🧑🔬 Composição química-é ilícita livre ou não?

- Alguns materiais Naturalmente, corte melhor por causa de sua composição química. Outros precisam aditivos para melhorar a usinabilidade.

- Exemplo:

- Aço de corte livre contém enxofre ou chumbo Para ajudar a quebrar batatas fritas e reduzir o atrito.

- Cobre puro é difícil de máquina porque é macio e gomoso.

💡 Regra simples: Alguns materiais são projetado Para uma melhor usinabilidade!

Condições de corte: O plano de jogo de usinagem

Até os materiais mais difíceis podem ser usinada com mais eficiência com as condições de corte certas.

🔄 Velocidade de corte - quão rápido é a ferramenta em movimento?

- O que isso significa: Velocidade em que a ferramenta de corte se move sobre o material.

- Impacto na usinabilidade:

- Muito lento = superfície áspera, bordas construídas.

- Muito rápido = excesso de calor, Desgaste da ferramenta.

- Exemplo:

- O alumínio pode lidar com alta velocidade(melhor dissipação de calor).

- Titânio precisa de velocidades mais lentas(evita superaquecimento).

💡 Regra simples: Encontrando o velocidade perfeita continua usinando eficientes e ferramentas em boa forma.

📏 Taxa de alimentação - quanto material é cortado por passagem?

- O que isso significa: A taxa de alimentação é a rapidez com que a ferramenta de corte se move para o material.

- Impacto na usinabilidade:

- Maior taxa de alimentação = corte mais rápido, Mas mais desgaste de calor e ferramenta.

- Menor taxa de alimentação = corte mais lento, Mas melhor acabamento superficial.

💡 Regra simples: O equilíbrio é fundamental—Poo de resíduos lentos, ferramentas de danos rápidos demais!

🔍 Profundidade de corte - quão profundo é cada passagem?

- O que isso significa: A profundidade de corte é a quantidade de material removida em uma passagem.

- Impacto na usinabilidade:

- Cortes rasos = forças inferiores, melhor qualidade da superfície.

- Cortes profundos = remoção de material mais rápida, mas maior tensão da ferramenta.

💡 Regra simples: Vá mais fundo para a eficiência, Mas não tão profundo que as ferramentas quebram!

Ferramentas de corte: A ferramenta certa para o trabalho

Mesmo um material bem machinável causará problemas se o ferramenta de corte errada é usado.

⚙️ Material da ferramenta - Força vs. Resistência ao desgaste

- Diferentes ferramentas de corte funcionam melhor para diferentes materiais.

- Materiais de ferramentas comuns:

- Aço de alta velocidade (HSS): Bom para metais moles, mas se desgasta em mais difíceis.

- Carboneto: Mais difícil e dura mais, mas custa mais.

- Cerâmica & Ferramentas de diamante: Usado para Materiais super duros Como titânio.

💡 Regra simples: Materiais mais difíceis precisam de ferramentas de corte mais fortes!

🛠️ Geometria da ferramenta - os assuntos de ponta

- Ângulo de ancinho: Controla como a ferramenta se envolve com o material.

- Ângulo de ancinho positivo = corte mais fácil, melhor fluxo de chip.

- Ângulo de ancinho negativo = mais força da ferramenta, Melhor para metais duros.

- Ângulo de folga: Evita esfregar e melhora a vida da ferramenta.

💡 Regra simples: A forma certa da ferramenta torna o corte mais suave e fácil!

Resfriamento e Lubrificação: Mantendo as coisas frias & Suave

Usando refrigerantes e lubrificantes reduz o calor, atrito, e desgaste da ferramenta.

💦 Coolentes (Controle de calor)

- Ajuda a remover excesso de calor Da zona de corte.

- Impede superaquecimento da ferramenta e expansão térmica.

🛢️ Lubrientes (Reduzindo o atrito)

- Reduz o atrito, prevenindo quebra de ferramentas e rugosidade da superfície.

- Ajuda com Remoção de chip, especialmente para materiais pegajosos como alumínio.

💡 Regra simples: Resfriamento = vida útil mais longa da ferramenta, cortes mais suaves!

Condição da máquina -ferramenta: Old vs.. Novas máquinas

Mesmo com o Melhor material, ferramentas, e condições de corte, um máquina desgastada ou instável pode causar problemas.

- Máquinas mais antigas vibrar mais, causando baixa precisão.

- Máquinas CNC mais recentes oferecer melhor precisão, estabilidade, e acabamentos mais suaves.

💡 Regra simples: Uma boa máquina = melhor máquinabilidade!

Qual é a classificação de máquinabilidade?

A classificação de maquiagem é uma maneira simples de comparar como os diferentes materiais se comportam durante a usinagem. Ajuda os fabricantes a escolher os materiais certos, Configure as condições de corte certas, e evite desgaste desnecessário de ferramentas ou atrasos na produção. Vamos dividi-lo em termos fáceis de entender!

Por que precisamos de uma classificação de maquiagem? 🚀

Imagine que você é um maquinista trabalhando em um novo projeto. Você precisa escolher entre aço inoxidável e alumínio para uma peça. O aço inoxidável é forte, Mas máquinas de alumínio muito mais rápidas. Como você decide qual é melhor para usinagem?

É aí que as classificações de maquiagem ajudam! Eles dão a cada material uma pontuação com base em como é fácil cortar, forma, e terminar. Classificações mais altas significam usinagem mais fácil, Enquanto as classificações mais baixas significam mais dificuldade.

✅ Ajuda a comparar diferentes materiais rapidamente

✅ Guia seleção de ferramentas e velocidade de corte

✅ Melhora a eficiência da produção

✅ Reduz o desgaste e os custos da ferramenta

Como é calculada a classificação de maquiagem? 📊

A classificação de maquiagem geralmente é baseada em um material de referência. A referência mais usada é C36000 Brass, que recebe uma classificação de 100% Porque as máquinas de TI com muita facilidade.

Todos os outros materiais são comparados a este padrão. É assim que funciona:

🔹 Se um material for mais fácil de máquina do que o latão → recebe uma classificação mais alta do que 100%

🔹 Se for mais difícil fazer a máquina → recebe uma classificação abaixo 100%

Por exemplo:

- Alumínio (6061-T6):90–95% 🟢 (Quase tão fácil quanto bronze!)

- Aço inoxidável (304):30–40% 🔴 (Muito mais difícil de cortar!)

- Titânio (Nota 5):20–25% 🚨 (Muito difícil de máquina!)

💡 Regra simples: Mais alto % = Mais fácil de máquina, Mais baixo % = Mais difícil de máquina

Métodos para melhorar a usinabilidade

Fabricantes com frequência Modificar materiais ou condições de usinagem para melhorar a usinabilidade. Algumas estratégias comuns incluem:

Tratamento térmico 🔥

- Suaviza metais como Aço e alumínio, reduzindo forças de corte.

- anelamento reduz a dureza e alivia as tensões internas.

Aditivos materiais ⚗️

- Adicionando chumbo ou enxofre Melhora a formação de chips e reduz o atrito.

- Exemplo: Aço de formação livre (11L17) contém enxofre para um corte mais fácil.

Coolentes & Lubrificantes 💦

- Reduz acúmulo de calor, Desgaste da ferramenta, e forças de corte.

- Melhora Acabamento de superfície e evacuação de chips.

Otimizando parâmetros de corte 🔧

- Ajuste velocidade, taxa de alimentação, e profundidade de corte Melhora a eficiência da usinagem.

- Impede conversa, dano de ferramenta, e geração excessiva de calor.

Como a usinabilidade é medida?

Não há uma maneira única de medir a máquinabilidade, Mas métodos comuns incluem:

| Método | Descrição | Exemplo |

| Teste de vida da ferramenta 🛠️ | Mede quanto tempo dura uma ferramenta antes de se desgastar. | Vida de ferramenta mais longa = melhor máquinabilidade. |

| Análise de acabamento da superfície ✨ | Avalia a suavidade da superfície usinada. | Má máquina = acabamento mais áspero. |

| Consumo de energia ⚡ | Maior força de corte requer mais energia. | Menor potência = usinagem mais fácil. |

| Formação de chip 🔄 | Curto, Cascas quebradas indicam melhor máquinabilidade. | Chips pegajosos = usinagem mais dura. |

Materiais CNC comuns e sua usinabilidade

Metais: De fácil de cortar a difícil de máquina ⚙️

🟢 Brass (C36000) - o metal mais fácil de máquina

Classificação de maquinabilidade: 100% (Padrão)

✔ Extremamente fácil de cortar, deixando um acabamento suave.

✔ Produz curto, Fichas limpas (Sem bagunça emaranhada).

✔ Baixo desgaste da ferramenta = Vida de ferramenta mais longa e custos mais baixos.

💡 Melhor para: Peças de precisão, acessórios, componentes elétricos.

🟢 Alumínio (6061-T6) - leve e fácil de máquina

Classificação de maquinabilidade: 90–95%

✔ Máquinas rápido e com eficiência Com o mínimo de desgaste da ferramenta.

✔ Ótimo para moagem de CNC e girar.

✔ produz superfícies lisas com necessário pós-processamento mínimo necessário.

💡 Melhor para: Aeroespacial, automotivo, eletrônicos, peças personalizadas.

🟡 Aço macio (AISI 1018) - um equilíbrio entre força e máquinabilidade

Classificação de maquinabilidade: 70%

✔ Mais fácil de cortar do que o aço inoxidável, mas não tão fácil quanto o alumínio.

✔ Produz Acabamentos de superfície decentes mas pode precisar de polimento.

✔ mais forte que o alumínio, mas propenso a ferrugem se não for revestido.

💡 Melhor para: Componentes estruturais, peças de máquinas, engrenagens.

🟡 Aço inoxidável (304) -resistente e resistente à corrosão

Classificação de maquinabilidade: 30–40%

✔ forte, durável, e resistente à ferrugem.

✔ O trabalho endurece (fica mais difícil ao cortar).

✔ pode causar desgaste da ferramenta e requer velocidades de corte mais lentas.

💡 Melhor para: Ferramentas médicas, equipamento de processamento de alimentos, Aplicações marítimas.

🔴 Titanium (Nota 5, Ti-6Al-4V) - forte, mas difícil de cortar

Classificação de maquinabilidade: 20–25%

✔ Super forte, leve, e resistente ao calor.

✔ Baixa condutividade térmica = estadia de calor na zona de corte 🔥.

✔ Difícil em ferramentas de corte, exigindo revestimentos especializados.

💡 Melhor para: Aeroespacial, implantes médicos, peças de alto desempenho.

🔴 Inconel (Liga de níquel) - um dos mais difíceis de máquina

Classificação de maquinabilidade: 10–15%

✔ Resistência extrema de calor e corrosão.

✔ Produz Muito calor enquanto corta, que pode danificar as ferramentas.

✔ Requer velocidades lentas e ferramentas de corte especializadas.

💡 Melhor para: Motores a jato, Reatores nucleares, ambientes extremos.

Plásticos: Fácil de cortar, mas com considerações especiais 🛠️

Os plásticos são geralmente mais fácil de máquina do que metais, Mas eles vêm com seus próprios desafios. Alguns podem derretem ou distorcem em calor alto, enquanto outros podem chip ou crack se cortado muito agressivamente.

🟢 Polietileno (PEAD) - macio e fácil de cortar

✔ Muito fácil de máquina com ferramentas CNC padrão.

✔ Não produz muito calor ou desgaste da ferramenta.

✔ pode se dobrar um pouco em vez de quebrar sob pressão.

💡 Melhor para: Recipientes de comida, componentes mecânicos, peças leves.

🟢 Policarbonato - forte, Transparente, e Machinable

✔ pode ser cortado com alta velocidade e produz bordas lisas.

✔ pode derreter ou deformar Se as velocidades de corte forem muito altas.

💡 Melhor para: Peças ópticas, janelas de segurança, Componentes resistentes ao impacto.

🟡 PVC (Cloreto de Polivinila) - Máquina moderada

✔ Rígido e durável, mas pode ficar quebradiço sob estresse.

✔ O corte pode produzir partículas de poeira fina que requerem ventilação adequada.

💡 Melhor para: Peças de encanamento, Componentes resistentes a produtos químicos, Aplicações médicas.

Compósitos & Outros materiais difíceis de máquinas 🛠️

Os compósitos são difíceis de fazer a máquina porque geralmente contém uma mistura de materiais, fazendo -os Hard to Cutting Tools.

🔴 Polímero reforçado com fibra de carbono (PRFC) - Difícil em ferramentas

✔ Extremamente forte e leve.

✔ Produz poeira fina em vez de batatas fritas, que pode ser perigoso.

✔ Ferramentas de corte de amortecimento rapidamente Devido a fibras abrasivas.

💡 Melhor para: Aeroespacial, automotivo, equipamento esportivo.

🔴 Polímero reforçado com fibra de vidro (PRFV) - ainda mais difícil que a fibra de carbono

✔ Semelhante à fibra de carbono, mas mais abrasivo em ferramentas.

✔ Requer ferramentas revestidas de diamante ou carboneto Para evitar o desgaste.

💡 Melhor para: Marinho, Lâminas de turbinas eólicas, componentes industriais.

🔴 Cerâmica-Ultra-Hard, Mas quebradiço

✔ Extremamente resistente ao desgaste e resistente ao calor.

✔ Requer Ferramentas de diamante especializadas e baixas taxas de alimentação.

💡 Melhor para: Aplicações de alta temperatura, implantes médicos, instrumentos de precisão.

Madeira & Materiais orgânicos: Surpreendentemente bom para usinagem CNC 🌳

A madeira é comumente usada em Roteadores CNC em vez de Mills de metal. Alguns bosques são macios e fácil de cortar, enquanto outros são denso e resistente.

🟢 madeira macia (Pinho, Cedro) - Fácil e rápido de máquina

✔ Corta de maneira rápida e fácil com roteadores CNC padrão.

✔ pode ser esculpido em Designs intrincados com acabamentos suaves.

💡 Melhor para: Mobília, esculturas, Projetos de bricolage.

🟡 Madeira de lei (Carvalho, Bordo) - Mais resistente, mas mais durável

✔ Mais denso e mais difícil de cortar do que madeira macia.

✔ pode causar Marcas de queimadura Se as velocidades de corte forem muito altas.

💡 Melhor para: Fazendo o gabinete, móveis finos, criação de instrumentos.

Comparando classificações de máquinas 📊

Aqui está uma comparação rápida dos materiais CNC comuns e como são fáceis de fazer a máquina:

| Material | Classificação de maquinabilidade (%) | Facilidade de usinagem |

| 🟢 Brass de corte livre (C36000) | 100% | Muito fácil |

| 🟢 Alumínio (6061-T6) | 90–95% | Fácil |

| 🟡 Aço macio (1018) | 70% | Moderado |

| 🟡 Aço inoxidável (304) | 30–40% | Duro |

| 🔴 Titanium (Nota 5, Ti-6Al-4V) | 20–25% | Muito difícil |

| 🔴 Inconel (Liga de níquel) | 10–15% | Extremamente difícil |

| 🟢 Polietileno (PEAD) | 90% | Muito fácil |

| 🟡 Policarbonato | 80% | Moderado |

| 🔴 Fibra de carbono (PRFC) | 40–50% | Resistente a ferramentas |

| 🔴 Fibra de vidro (PRFV) | 30–40% | Muito difícil |

Conclusão

Entender a usinabilidade é essencial para Fabricantes, engenheiros, e maquinistas Para otimizar a seleção de material, reduzir os custos de produção, e melhorar a eficiência.

Considerando cuidadosamente propriedades dos materiais, Condições de usinagem, e estratégias de corte, A maquinabilidade pode ser melhorada, resultando em produção mais rápida, custos mais baixos, e componentes de maior qualidade.

Para empresas que procuram soluções de usinagem CNC, selecionando Materiais de alta máquina e otimizando parâmetros de corte pode fazer uma diferença significativa no sucesso da produção. 🚀

Perguntas frequentes

- Qual é a diferença entre a usinabilidade e a trabalhabilidade?

Maquinabilidade refere -se a Cortando e moldando um material, enquanto trabalhabilidade refere -se a formação, flexão, ou forjamento.

- Como a usinabilidade afeta o custo?

MACHINABILIDADE MAIOR = Menos desgaste da ferramenta, menor uso de energia, e produção mais rápida = custos mais baixos.

- A usinabilidade pode ser melhorada?

Sim! Usando tratamento térmico, Coolentes, velocidades de corte otimizadas, e melhor ferramentas Melhora a usinabilidade.

Links externos recomendados 🔗

Aqui estão três recursos úteis relacionados à usinabilidade e usinagem CNC:

1️⃣ Classificações de maquinabilidade de materiais (Gráfico abrangente de máquinabilidade)

🔗 https://www.engineersedge.com/manufacturing/machinability-rating-chart.htm

2️⃣ Guia para materiais de usinagem CNC (Comparação de diferentes materiais para usinagem)

🔗 https://www.protolabs.com/resources/design-tips/cnc-machining-material-selection-guide/

3️⃣ Seleção de ferramentas de corte para usinar diferentes materiais

🔗 https://www.sandvik.coromant.com/en-us/knowledge/materials

5 pensamentos "MACHINABILIDADE DE MATERIAIS: Entendimento, Fatores, e classificações”