No moldagem por injeção indústria, precision molds are the foundation of high-quality part production. Ao longo do tempo, no entanto, even the most well-crafted molds experience wear, damage, or the need for design changes. No Precisão máxima, our expert toolmakers specialize in comprehensive mold repair and modification services that restore tool performance, prolongar a vida útil do molde, and enhance production efficiency.

Whether it’s fixing a damaged core, improving cooling efficiency, or altering a cavity design for new product requirements, Tops Precision provides complete in-house solutions with the highest attention to detail and customer collaboration.

Our Mold Repair Process

Our Mold Repair Process

When a mold requires repair, Tops Precision follows a structured and transparent workflow to ensure accuracy, eficiência, and quality restoration.

Etapa 1: Initial Problem Identification

The repair process begins when an issue is identified—either by our production team during regular maintenance or by customers who notice part defects or operational inconsistencies.

We immediately notify the customer, document the problem with detailed images, and provide a preliminary assessment.

For customers outside our facility, we also accept molds from other manufacturers, accompanied by a report or instructions describing the problem.

Etapa 2: Inspection and Root Cause Analysis

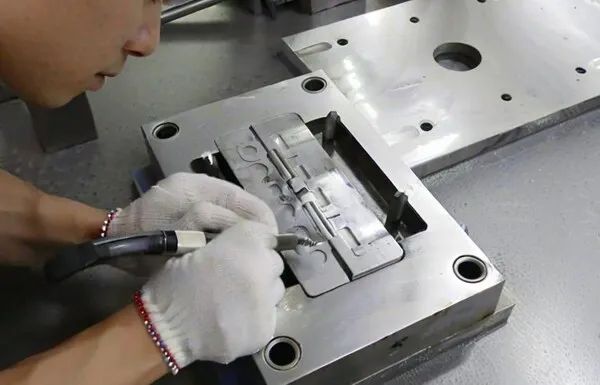

Once received, our toolmakers carefully open and disassemble the mold to evaluate all functional components—such as cores, cavidades, deslizamentos, pinos ejetores, and cooling lines.

We analyze the root cause of the issue, which may include:

Metal fatigue or wear from prolonged use

Corrosion in cooling channels

Misalignment due to improper clamping

Cracks or parting line damage

This diagnostic phase ensures that we address not just the visible damage but the underlying causes as well.

Etapa 3: Proposal and Cost Estimate

After our analysis, we prepare a detailed proposal that outlines:

Recommended repair procedures

Replacement components (se necessário)

Estimated cost and lead time

Optional performance improvements

This proposal is shared with the customer for review. We always ensure full transparency before any work begins.

Etapa 4: Customer Approval and Repair Execution

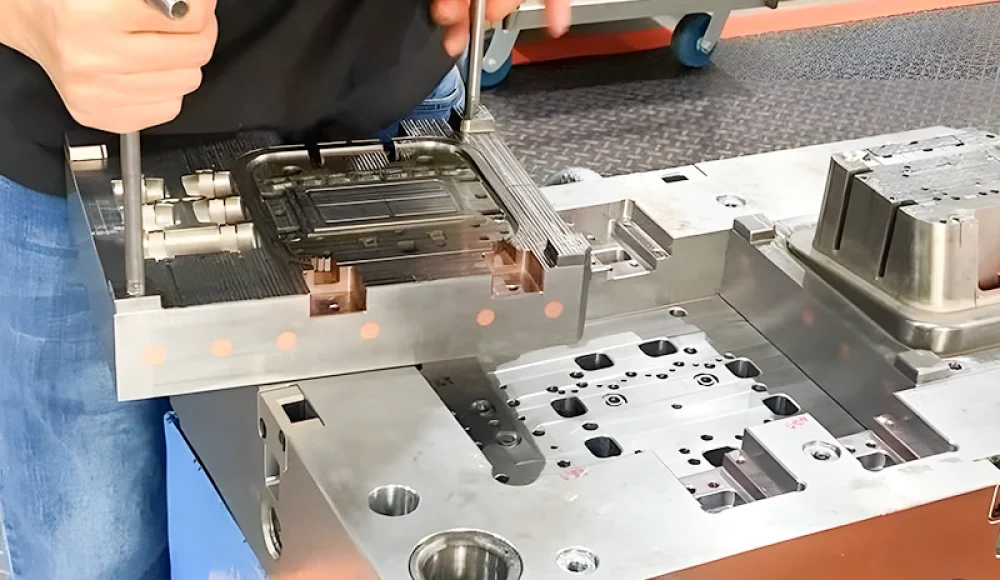

Once the customer approves the proposal and necessary paperwork is completed, our skilled technicians proceed with the repair.

Typical repair work includes:

Welding and re-machining worn surfaces

Replacing broken or worn inserts and pins

Reworking damaged shut-offs or gate areas

Cleaning and polishing to restore mold finish

All repairs are performed with precision to OEM standards or better, ensuring that the mold returns to production-ready condition.

Etapa 5: Quality Verification and Testing

Before returning the mold to the customer, we perform test runs and dimensional inspections to verify performance.

Our goal is to ensure the mold produces parts with consistent dimensions, qualidade da superfície, and cycle times equivalent to or better than its original condition.

Perguntas frequentes

1º trimestre: Are mold repairs and modifications the same as maintenance?

Not exactly. Manutenção is preventive and focuses on cleaning, lubrificação, and part replacement before failure occurs.

Repairs address actual damage or malfunction, enquanto modifications involve design changes to improve or alter mold performance.

2º trimestre: What causes molds to require repair or modification?

Most mold damage results from normal wear and tear, especially in high-volume production environments. Continuous metal-to-metal contact, resin buildup, or improper cooling can accelerate degradation.

Modifications typically stem from part redesigns or process optimization precisa.

3º trimestre: How long does a typical repair or modification take?

Lead times vary depending on the extent of damage, complexidade, and current workload.

Tops Precision always specifies lead times in our proposals and communicates proactively if delays occur. We maintain strict capacity control to ensure entrega no prazo sem comprometer a qualidade.

4º trimestre: Pode Precisão máxima repair molds made by other companies?

Absolutamente. Many manufacturers and even competitors send us their molds for repair or modification.

Due to the shortage of experienced toolmakers in Southern California, Tops Precision’s fully equipped tool room was established specifically to support regional mold maintenance and repair needs.

Q5: What types of molds can Precisão máxima handle?

Tops Precision services a wide range of molds including:

Thermoplastic injection molds

Multi-cavity production molds

Hot runner and cold runner systems

Large automotive and industrial tooling

Our facilities are equipped to handle small precision tools as well as large, complex molds.

Por que escolher Precisão máxima for Mold Repairs and Modifications

Experienced Toolmakers: Our technicians have decades of combined experience in tool repair, soldagem, usinagem, e design.

In-House Capabilities: Full-service tool room equipped with CNCs, EDMs, grinders, and polishing stations.

Resposta rápida: Efficient scheduling and transparent lead-time communication.

Garantia da Qualidade: Every repaired or modified mold undergoes comprehensive testing before delivery.

Customer-Centric Process: We collaborate closely with customers to ensure results meet performance expectations.

Get a Mold Repair or Modification Quote

If your mold needs professional attention—whether it’s repair, design modification, or preventive maintenance—Precisão máxima is ready to help.

We’ll provide a detailed analysis, cost estimate, and turnaround plan tailored to your production needs.

📞 Contato Precisão máxima hoje to discuss your mold repair and modification requirements or request a free consultation and quotation.

Leia mais:

Tipos de moldes de injeção: Categorias, Características, e aplicações industriais

Guia de seleção de materiais para moldagem por injeção

Projeto de sistema de resfriamento de molde de injeção: Um guia completo

Defeitos cosméticos comuns na moldagem por injeção e como consertá -los