O que é moldagem por injeção de nylon?

O que é moldagem por injeção de nylon

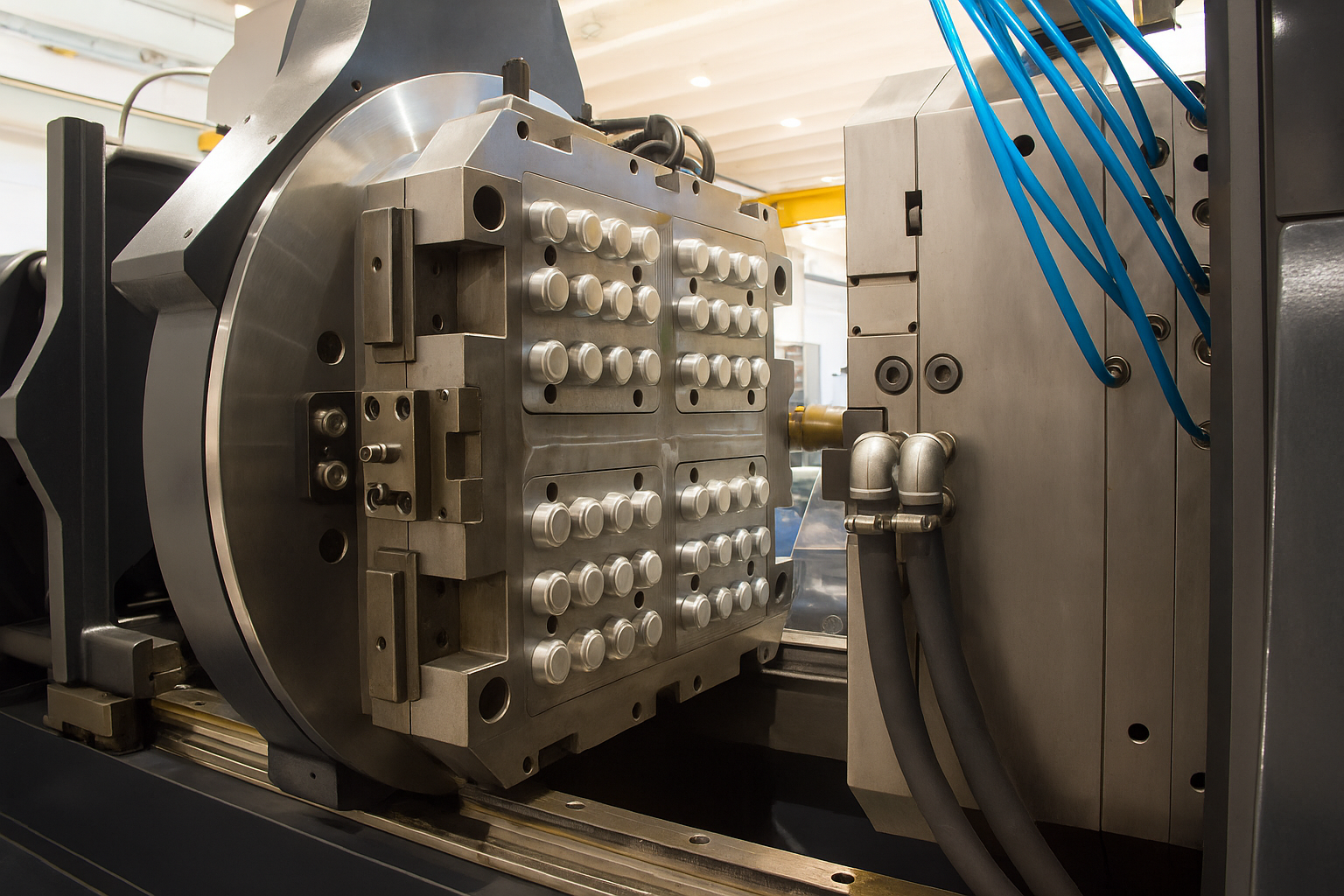

Nylon injection molding is a manufacturing process that uses molten nylon — a type of engineering thermoplastic — to produce durable, leve, and high-strength components. Nylon, Também conhecido como poliamida (PA), is a semi-crystalline polymer characterized by excellent mechanical strength, resistência ao desgaste, and chemical stability.

Devido ao seu high crystallinity, nylon exhibits superior toughness, resistência à fadiga, and thermal performance. It can withstand demanding environments and often replaces metal in applications such as engrenagens, fixadores, cable ties, fan blades, e peças da bomba.

The most common nylons used in injection molding include:

Nylon 6 (PA6)

Nylon 66 (PA66)

Nylon 12 (PA12)

Glass-fiber reinforced nylon (PA-GF)

Each grade has distinct mechanical and processing characteristics, allowing engineers to balance força, flexibilidade, and moisture resistance for specific end uses.

Advantages of Nylon Injection Molding

Nylon is one of the most popular engineering plastics for moldagem por injeção because it combines moldabilidade, desempenho, e eficiência de custos. Below are its major benefits explained in detail.

1. Low Melt Viscosity

Nylon melts easily and flows smoothly within the mold, even through thin sections or complex geometries.

Enables the production of peças de paredes finas (tão baixo quanto 0.7 milímetros).

Reduces injection pressure and ensures complete mold filling.

Shortens cycle times for high-volume production.

2. Excellent Chemical and Abrasion Resistance

Nylon resists a wide range of chemicals, Incluindo:

Dilute acids and alkaline solutions

Hydrocarbons, combustíveis, and oils

Organic solvents like alcohols and halogenated hydrocarbons

Isso é baixo coeficiente de atrito and high wear resistance make it ideal for parts that experience sliding or rotational motion, como engrenagens, buchas, e rolamentos.

3. Resistência de alta temperatura

Nylon maintains mechanical integrity at elevated temperatures.

Standard nylon grades can operate continuously up to 120–150°C.

Glass-filled nylons withstand even higher temperatures before softening.

This property makes nylon suitable for automotive engine compartments and industrial machinery.

4. Fatigue and Impact Resistance

Nylon’s semi-crystalline molecular structure gives it excellent resistência à fadiga, allowing it to endure repeated stress cycles without cracking or breaking.

Designing parts with generous corner radii further improves performance under cyclic loads.

5. Mechanical Strength Comparable to Metal

Nylon exhibits high tensile and flexural strength, enabling it to replace metal in many load-bearing applications.

Reinforcing nylon with glass fibers or mineral fillers increases rigidity and dimensional stability while reducing creep under load.

Nylon Injection Molding Design Guidelines

Proper part design ensures both precisão dimensional e eficiência de produção. Below are nylon-specific design considerations.

1. Espessura da Parede

Recomendado: 0.030–0.115 in (0.76–2.92 mm)

Maintain uniform wall thickness to prevent sink marks and warping.

Gradual transitions (≤15%) between adjacent walls are ideal.

Avoid walls thicker than 6 milímetros, as they increase cooling time and may trap voids.

Nylon’s low melt viscosity allows thinner walls than many other thermoplastics while maintaining part strength.

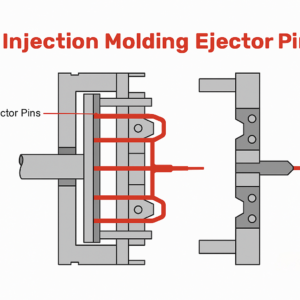

2. Radii and Corners

Avoid sharp corners that create stress concentrations.

Minimum radius: 0.5 milímetros.

Optimal radius: ≈75% of nominal wall thickness for best fatigue performance.

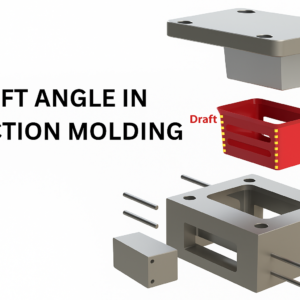

3. Ângulos de inclinação

Nylon’s smooth surface and low friction allow for minimal draft.

0.5°–1° per side is recommended to ease ejection and shorten cycle times.

Superfícies planas (por exemplo., engrenagens) can sometimes be molded with no draft.

4. Part Tolerances

Nylon has a higher shrinkage rate (0.5%–2%) than many plastics, making dimensional control challenging.

Accurate mold temperature management reduces variation.

Glass-filled grades exhibit lower shrinkage and improved stability.

Controlled moisture conditioning post-molding ensures long-term precision.

Nylon Material Properties

Nylon Material Properties

The following are typical material properties for several nylon grades:

| Propriedade | Nylon 11 | Nylon 12 | Nylon 46 | Nylon 66 | Nylon 66 30% GF |

| Densidade (g/cm³) | 1.04 | 1.31 | 1.20 | 1.17 | 1.38 |

| Linear Shrinkage (cm/cm) | 0.0083 | 0.0069 | 0.019 | 0.0139 | 0.0044 |

| Rockwell Hardness (R) | 107 | 98 | 95 | 114 | 117 |

| Resistência à tracção (MPa) | 37.1 | 46.1 | 73.9 | 72.5 | 155 |

| Alongamento no intervalo (%) | 119 | 67 | 43 | 47 | 4 |

| Flexural Modulus (GPa) | 0.95 | 5.66 | 2.64 | 3.09 | 7.96 |

| Drying Temperature (°C) | 90 | 93 | 94 | 81 | 82 |

| Temperatura de fusão (°C) | 261 | 224 | 303 | 279 | 285 |

| Mold Temperature (°C) | 49 | 71 | 103 | 75 | 86 |

Takeaway -chave: Nylon’s balance of high tensile strength, dureza, e flexibilidade makes it ideal for load-bearing components. No entanto, devido ao seu hygroscopic nature, nylon must be dried thoroughly before processing.

Nylon Injection Molding Process Parameters

Controlling processing parameters ensures consistent part quality and dimensional accuracy.

1. Viscosity

Nylon has low melt viscosity, enabling fast mold filling through thin or intricate channels.

This reduces cycle times but requires careful pressure and speed control to prevent flashing.

2. Moisture Control

Nylon easily absorbs atmospheric moisture.

Excessive moisture causes vazios, jogar, and brittleness.

Optimal moisture content: 0.15–0.20%.

Dry nylon at 80–90°C for 3–6 hours before molding.

3. Temperature Control

Higher mold temperature → increased crystallinity and strength.

Muito alto (acima 330°C) → risk of degradação térmica and discoloration.

Typical processing range:

Barrel temperature: 260–290°C

Mold temperature: 70–90°C

4. Injection Pressure

Typical range: 700–1400 bar (10,000–20,000 psi).

Low pressure → short shots, knit lines, acabamento superficial ruim.

High pressure → flash, warpage, or dimensional distortion.

Proper pressure profiling ensures uniform density and minimal internal stress.

5. Injection Speed

High injection speeds reduce cycle time and weld lines.

No entanto, excessive speed can cause shear heating e Marcas de queimadura.

Controlled ramp-up of speed is best for thin-walled nylon parts.

6. Gassing and Venting

Nylon molding generates gases during melt injection.

Poor venting causes vazios, burns, and incomplete filling.

Provide vent depths around 0.02–0.04 mm near cavity edges.

7. Encolhimento

Typical range: 0.5–2%, depending on grade and cooling rate.

Controlled by:

Higher mold temperatures (reduce shrinkage).

Uniform wall thickness.

Glass reinforcement (minimizes warping).

Common Nylon Injection Molding Defects and Solutions

| Defeito | Possible Cause | Recommended Solution |

| Splay marks | Excess moisture | Pre-dry material properly |

| Flashing | Excess pressure or low clamp force | Adjust injection pressure, inspect mold fit |

| Deformação | Uneven cooling or wall thickness | Optimize mold design and cooling layout |

| Short shots | Low injection speed or venting issue | Increase speed, melhorar a ventilação |

| Discoloration | Overheating or degradation | Lower melt temperature, ensure material purity |

Applications of Nylon Injection Molding

Nylon molded parts are used across numerous industries due to their combination of força, dureza, e resistência ao calor.

Automotivo: Engrenagens, buchas, radiator fans, fuel line connectors

Elétrica & Eletrônicos: Cable ties, isoladores, terminal housings

Bens de consumo: Power tool housings, appliance components

Equipamento industrial: Rolamentos, rolos, mechanical fasteners

Aeroespacial: Lightweight interior fittings, colchetes, clipes

Best Practices for Successful Nylon Injection Molding

Store nylon pellets in airtight containers to prevent moisture absorption.

Sempre dry material before molding.

Maintain uniform cooling to minimize warping.

Usar glass-filled grades for high-strength or precision applications.

Aplicar controlled temperature and pressure profiles during molding.

Conclusão

Nylon injection molding combines the strength of engineering plastics with the versatility of thermoplastics. When processed correctly, nylon delivers exceptional performance, durabilidade, e precisão, making it a preferred material for both industrial and consumer applications.

Proper control of umidade, temperatura, and pressure, along with intelligent design practices, ensures high-quality nylon parts that can even replace metal components.

Perguntas frequentes

- What is the best type of nylon for injection molding?

Nylon 6 e nylon 66 are the most commonly used types. Nylon 66 offers higher strength and temperature resistance, while Nylon 6 provides better surface finish and flexibility. - Why must nylon be dried before injection molding?

Because nylon is hygroscopic, it absorbs moisture from the air. Moisture in the resin can cause bubbles, jogar, and degradation during molding. - Can nylon replace metal parts in mechanical assemblies?

Sim. With glass-fiber reinforcement, nylon can achieve tensile strength comparable to aluminum, making it a cost-effective lightweight alternative. - What are the common challenges when molding nylon?

Key challenges include moisture absorption, encolhimento, deformação, and maintaining tight tolerances due to high shrinkage rates. - How do you reduce shrinkage in nylon injection molding?

Use higher mold temperatures, uniform wall thickness, and glass-filled grades. Controlled cooling also helps prevent warpage.

Leia mais:

Dicas para projetar clipes para peças de plástico

5 Coisas que você precisa saber sobre moldagem por injeção de plástico

Tudo sobre o básico da moldagem por injeção plástica

Tudo o que você precisa saber sobre moldagem por injeção de policarbonato?

1 pensei em “Moldagem por injeção de náilon: Projeto, Processo, e guia de materiais para engenheiros”