Politetrafluoretileno (PTFE), mais conhecido por sua marca Teflon, é um dos plásticos mais quimicamente resistentes e termicamente estáveis do mundo. Este fluoropolímero oferece desempenho excepcional em setores exigentes, desde aeroespacial e farmacêutico até processamento de alimentos e eletrônicos. Embora suas propriedades mecânicas possam não rivalizar com outros plásticos de engenharia, Usinagem de teflon é uma solução prática para a fabricação de componentes personalizados que exigem baixo atrito, alta resistência ao calor, e inércia.

Este guia fornece uma análise detalhada das propriedades do PTFE, as vantagens e desafios de usiná-lo, aplicações adequadas, dicas de ferramentas, e alternativas materiais.

O que é teflon (PTFE)?

Teflon é um fluoropolímero sintético produzido pela polimerização de tetrafluoroetileno (TFE). Descoberto pela primeira vez acidentalmente em 1938 da DuPont, é quimicamente composto por átomos de carbono e flúor, formando uma das ligações mais fortes da química orgânica. Esta estrutura única é o que confere ao PTFE a sua impressionante resiliência química e térmica.

Propriedades principais:

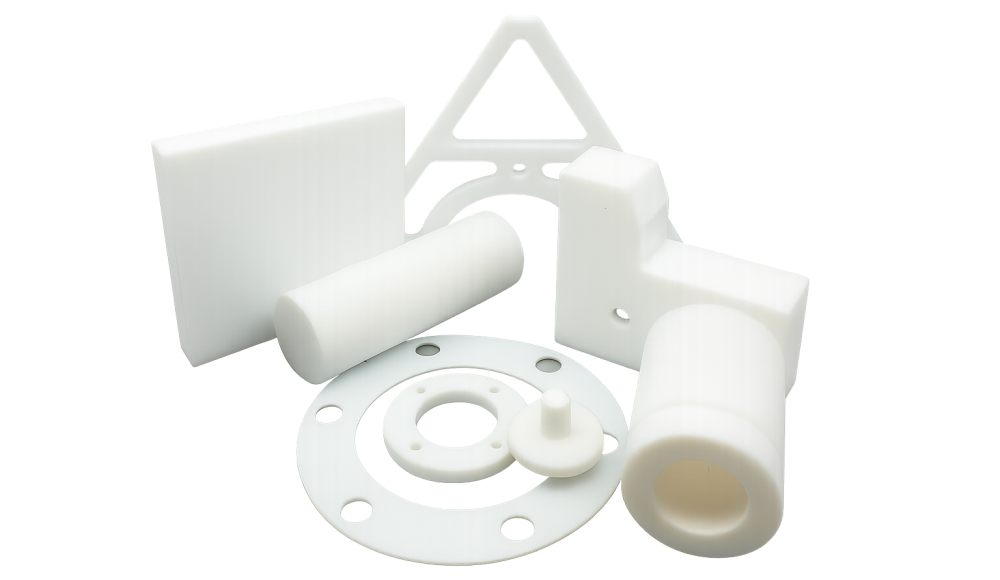

Aparência: Branco, sólido ceroso

Ponto de fusão: ~327°C (621°F)

Fórmula Química: (C₂F₄)ₙ

Estrutura: Cadeia linear de átomos de carbono rodeados por átomos de flúor

Teflon é:

Hidrofóbico: Repele a água e a maioria das substâncias

Não reativo: Extremamente resistente a ácidos, bases, e solventes

Baixa fricção: Entre os coeficientes de atrito mais baixos de qualquer sólido

Termicamente estável: Pode operar de -260°C a 260°C sem degradação

Vantagens da usinagem de Teflon

Vantagens materiais

As características do material do Teflon são o que o torna tão útil na usinagem CNC de precisão:

Resistência química: Inerte para quase todos os produtos químicos industriais

Resistência UV e às intempéries: Mantém propriedades sob exposição externa

Resistência à água: Naturalmente hidrofóbico, tornando-o ideal para sistemas de fluidos

Isolamento Elétrico: Excelente rigidez dielétrica em uma ampla faixa de temperatura

Estabilidade térmica: Pode operar em ambientes criogênicos e de alta temperatura

Baixo atrito: Ideal para peças deslizantes ou rotativas

Qualidade Alimentar: Compatível com FDA e fácil de esterilizar

Resistência à chama: Inflamabilidade muito baixa

Vantagens do processo

A usinagem de PTFE oferece vantagens adicionais devido à sua suavidade e usinabilidade:

Facilmente Usinável: Corta facilmente com força mínima

Sem deformação térmica: Permanece dimensionalmente estável durante a usinagem a seco ou a úmido

Não é necessário endurecimento: Não há necessidade de tratamento térmico pós-usinagem

Ótimo para protótipos: Rápido para produzir componentes personalizados ou de baixo volume

Limitações da usinagem de Teflon

Apesar de seus muitos benefícios, usinar Teflon apresenta alguns desafios únicos:

Alto Coeficiente de Expansão Térmica: As peças podem expandir ou contrair mais do que outros plásticos

Deformação de fluência: Tende a deformar-se lentamente sob estresse mecânico de longo prazo

Difícil manter tolerâncias: Especialmente em recursos finos ou pequenos

Fraca estabilidade dimensional: Sujeito a empenamento durante a usinagem ou pós-processamento

Material macio: Pode deixar rebarbas ou marcas de ferramentas, exigindo acabamento extra

Para minimizar problemas:

Use ferramentas afiadas

Evite projetos com tolerâncias apertadas

Empregue técnicas eficazes de resfriamento e rebarbação

Aplicações comuns de peças de Teflon usinadas CNC

Usinagem CNC é um método preferido para fabricar componentes sólidos de PTFE usados em diversas indústrias. Algumas peças típicas incluem:

| Aplicativo | Exemplos |

| Válvulas & Acessórios | Vedações de tubos, arruelas, peças de controle de fluxo |

| Rolamentos & Buchas | Componentes resistentes ao desgaste de baixo atrito |

| Isolamento | Isoladores elétricos, espaçadores de cabos |

| Componentes de Laboratório | Conectores resistentes a produtos químicos, porta-amostras |

| Peças de qualidade alimentar | Lâminas raspadoras, bocais, placas de vedação |

| Dispositivos médicos | Implantes, conectores de tubos biocompatíveis |

| Aeroespacial | Juntas e vedações leves |

| Semicondutor | Componentes inertes do caminho do fluido |

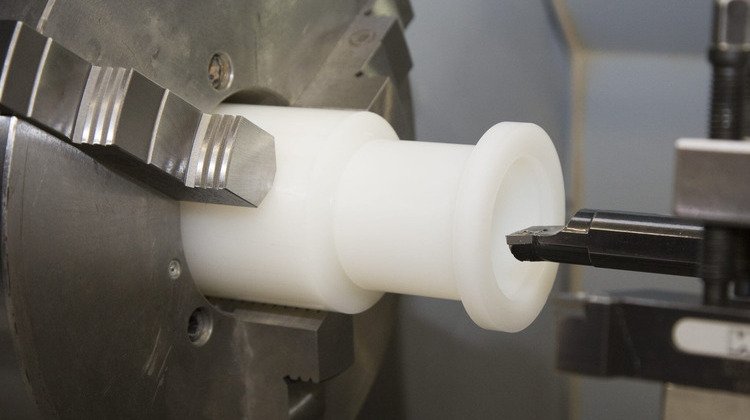

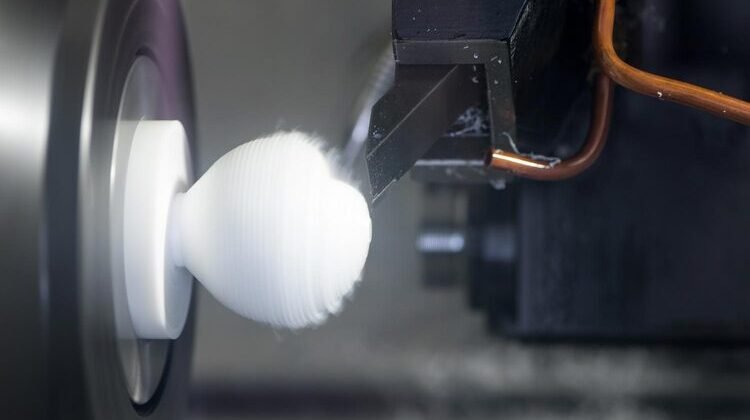

Dicas de usinagem e melhores práticas para Teflon

Para obter os melhores resultados na usinagem CNC de PTFE, Considere o seguinte:

Ferramentas

Usar carboneto ou Ferramentas HSS com bordas extremamente afiadas

Ferramentas de canal único ou polido reduzem rebarbas e melhoram o acabamento

Coolidor e lubrificação

Aplicar não aromático, refrigerantes solúveis em água

Névoas de pulverização ou ar comprimido funcionam bem para remoção de cavacos e gerenciamento de calor

Velocidades e feeds

Use velocidades de corte moderadas e altas taxas de avanço para evitar o derretimento do material

Evite pressão excessiva da ferramenta ou acúmulo de calor

Rebarbação e Acabamento

Usar lixamento, congelamento criogênico, ou rebarbação química para remover rebarbas macias

Congelar a peça antes do acabamento pode reduzir a maciez e a deformação

Considerações de projeto

Planeje para tolerâncias mais flexíveis (~±0,13 mm) a menos que a peça seja aliviada de tensão

Evite paredes finas ou geometrias delicadas propensas a deformações

Materiais Alternativos ao Teflon

Para projetos onde as limitações do Teflon são inaceitáveis, as seguintes alternativas oferecem benefícios semelhantes com maior resistência ou processabilidade:

| Material | Vantagem Principal | Marca Comum |

| PFA (Perfluoroalcóxi) | Melhor antiaderente, mais flexível | Teflon PFA |

| Pctfe (Policlorotrifluoroetileno) | Menor transmissão de vapor de água | Kel-F |

| ECTFE (Etileno Clorotrifluoroetileno) | Excelente resistência à corrosão | Presença |

Cada um desses materiais pode ser usinado CNC, mas pode ter diferentes requisitos de ferramentas e manuseio..

Conclusão: Serviços de usinagem de PTFE de precisão feitos por especialistas

Teflon (PTFE) é um material ideal para ambientes exigentes que exigem resistência química, estabilidade térmica, e baixo atrito. No entanto, sua suavidade e instabilidade dimensional significam que usinagem de PTFE de precisão requer uma abordagem cuidadosa e operadores experientes.

Se você deseja criar protótipos ou produzir em massa componentes de Teflon personalizados, faça parceria com um fabricante familiarizado com plásticos de engenharia. No Precisão máxima, oferecemos usinagem CNC PTFE avançada com suporte especializado - desde assistência no projeto até inspeção de qualidade final.

Contate nossa equipe hoje para obter um orçamento gratuito ou saber como podemos ajudar em seu próximo projeto.

Perguntas frequentes

1. What makes Teflon (PTFE) the preferred material for low-friction applications?

Teflon (PTFE) has one of the lowest coefficients of friction of any solid material, comparable to wet ice sliding on wet ice. This unique property stems from the uniform blanket of fluorine atoms surrounding the carbon backbone. This structure prevents other molecules from forming strong bonds with the PTFE surface, making it extremely “slippery” and ideal for rolamentos, buchas, vedações, and sliding surfaces where wear resistance and minimal energy loss are critical.

2. Is PTFE the same as the non-stick coating found on cookware?

Sim, chemically, it is the same material. PTFE is the base ingredient for most high-quality non-stick cookware coatings. No entanto, in cookware, the PTFE is applied as a afinar, high-temperature-cured coating. Em Usinagem CNC, PTFE is worked as a solid block (often referred to as billet or rod) to produce thick, estrutural, custom parts like gaskets, isoladores, or pump components.

3. What is “Creep Deformation,” and why is it a significant limitation for machined PTFE parts?

Creep is the tendency of a solid material to slowly and permanently deform or flow under mechanical stress below its yield strength. Since PTFE is a relatively soft material with a low glass transition temperature, it is highly susceptible to creep, especially under continuous load or at slightly elevated temperatures. This means that PTFE gaskets or seals under constant compression may eventually lose their thickness and fail to seal properly over time.

4. Why is cryogenic deburring often used for finishing machined PTFE parts?

Because PTFE is very soft, traditional mechanical deburring (scraping or sanding) can easily smear the material, damage the surface finish, or cause slight dimensional changes. Cryogenic deburring involves freezing the PTFE part using liquid nitrogen or carbon dioxide until it becomes temporarily hard and brittle. The soft burrs then become brittle and are easily removed by tumbling or light blasting without damaging the underlying, tougher material.

5. What is the biggest machining challenge when holding tight tolerances on PTFE?

The biggest challenge is PTFE’s Alto Coeficiente de Expansão Térmica (CTE). A small change in temperature (even from ambient heat or machine friction) causes the part to expand or contract significantly more than other plastics or metals. Além disso, the material’s inherent poor dimensional stability and tendency to stress-relieve and warp after material removal make achieving and holding tolerances tighter than $\PM 0.13 \texto{ milímetros}$ difficult without specialized stress-relieving procedures.

6. When should PFA or PCTFE be used as an alternative instead of standard PTFE?

The alternatives are chosen to overcome PTFE’s specific limitations:

-

PFA (Perfluoroalcóxi): Used when melt processability é necessário (for complex molding) while maintaining PTFE’s low friction and chemical resistance.

-

Pctfe (Policlorotrifluoroetileno): Used when the key requirement is the lowest possible water vapor transmission rate (impermeability) and higher mechanical strength, making it ideal for pharmaceutical packaging or cryogenic seals where moisture must be absolutely excluded.

7. Why is a high feed rate sometimes beneficial when machining PTFE despite its softness?

Using a high feed rate (the speed at which the tool advances into the material) can be beneficial because it allows the tool to make a thicker, limpador chip. This action rapidly removes the material and helps prevent the tool from simply rubbing or smearing the soft plastic. A thicker chip also carries heat away more efficiently and helps reduce the formation of soft, difficult-to-remove burrs.