A impressão UV em metal é uma tecnologia inovadora que revolucionou a indústria gráfica, particularly in the fabrication and customization of metal parts. This advanced digital printing process uses ultraviolet (ultravioleta) light to cure ink onto the metal surface, resulting in sharp, durável, and high-quality prints. Whether for industrial parts, marca, or artistic applications, UV printing offers a versatile and efficient solution for various metal surfaces.

This article provides a comprehensive guide to understanding UV printing on metal, including the process, benefícios, limitações, and common applications.

1. What is UV Printing?

UV printing is a form of digital printing where ultraviolet light is used to cure or dry the ink as it is applied to the printed surface. This method is different from traditional printing methods because the ink is immediately dried by the UV light, rather than by heat or air drying. This makes UV printing particularly effective on non-porous surfaces such as metals, plásticos, e vidro.

The UV ink used in this process is specially formulated to bond tightly to metal surfaces, ensuring long-lasting, high-quality prints. The curing process enhances the durability and resistance of the printed design to wear, arranhões, e desaparecendo.

2. Benefits of UV Printing on Metal

UV printing on metal has become increasingly popular due to its numerous advantages over traditional printing methods. Here are some key benefits:

Econômico: Although the initial investment in UV printing equipment can be high, it ultimately saves money due to lower operational costs. The process is faster, which reduces labor costs, and there is less waste as no setup time or printing plates are required.

Ecologicamente correto: UV printing is a greener option compared to other methods. The inks used are free from volatile organic compounds (VOCs), which makes the process safer and more environmentally responsible.

Rápido e eficiente: The immediate curing of UV inks speeds up the printing process, resulting in faster turnaround times. Adicionalmente, the prints require no further drying time, enabling quicker production schedules.

Flexibilidade: UV printing allows for printing on a wide range of materials, incluindo metais, plásticos, madeira, leather, and textiles. This flexibility makes it ideal for manufacturers needing to print on different substrates.

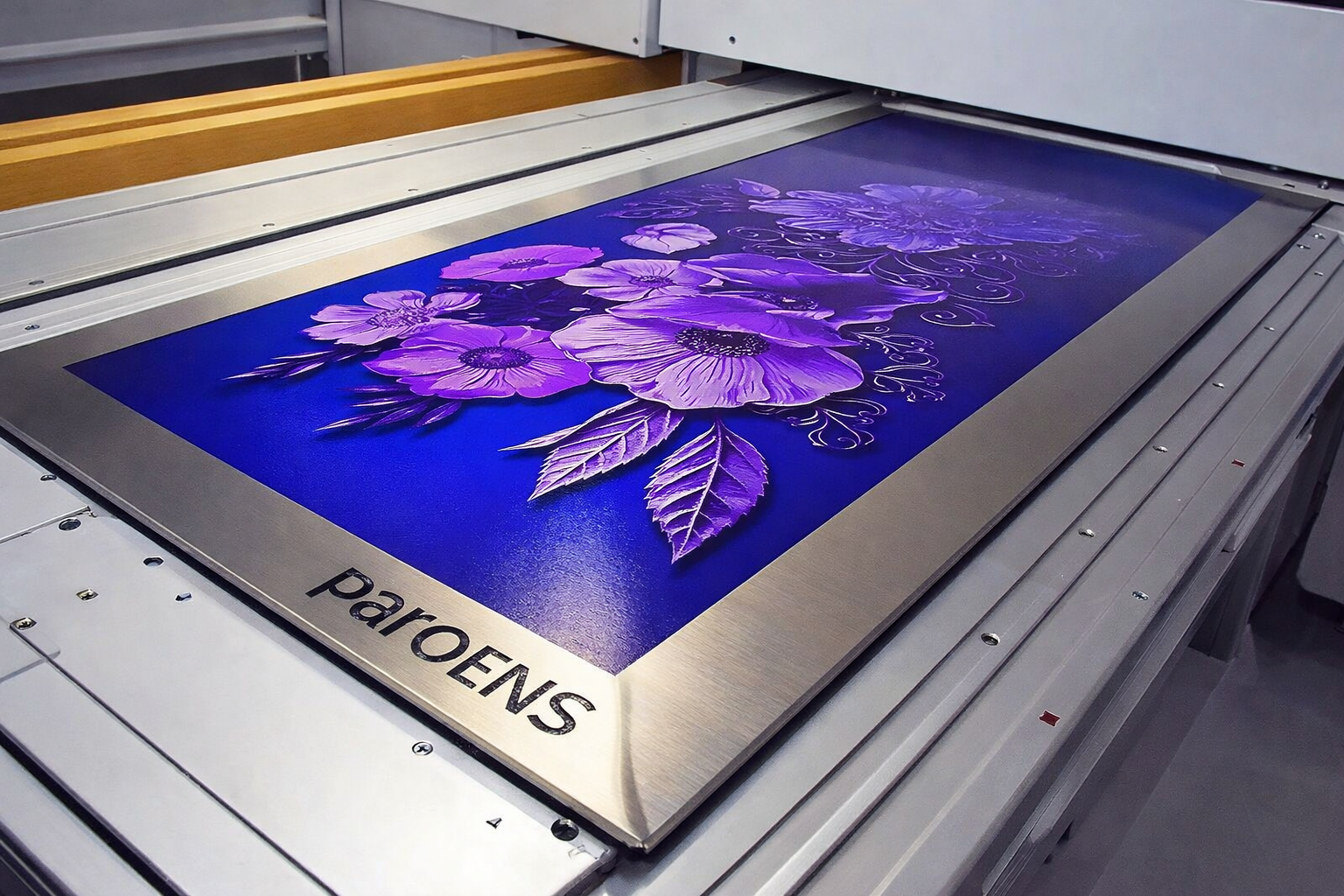

High-Quality Prints: UV printing produces vibrant, high-resolution, and sharp prints on metal surfaces. The colors are crisp and bright, offering full-color capability that meets the highest standards for industrial and artistic applications.

Durabilidade: The UV ink bonds well to metal surfaces, creating prints that are highly resistant to fading, arranhando, e danos ambientais, making them suitable for both indoor and outdoor applications.

3. Limitations of UV Printing on Metal

While UV printing offers many benefits, there are a few limitations to consider:

High Initial Investment: The upfront cost of UV printers and equipment can be high, which may be a barrier for small businesses or those just entering the industry.

Limited Color Range: While UV printing supports full-color prints, the range of colors available may be limited compared to other printing methods such as screen printing.

UV Light Exposure: UV inks require UV light to cure, which may pose health risks if not handled properly. Extended exposure to UV light can cause skin irritation and damage, so adequate safety measures must be in place.

Ink Drying Process: While UV ink cures rapidly, the ink needs to be exposed to UV light, which could require special handling and equipment in certain work environments.

Despite these challenges, UV printing remains a highly effective and popular choice for metal fabrication and decoration.

4. Step-by-Step Metal UV-Printing Process

The UV printing process on metal is relatively straightforward but requires attention to detail. Here’s a step-by-step guide:

Etapa 1: Prepare Tools and Accessories

The first step is to choose the material to print on. Metals like stainless steel and aluminum are common choices for UV printing, but each material requires different preparation:

Para aço inoxidável, a surface treatment such as flame treatment or applying a primer is necessary to enhance the adhesion of the UV ink.

Para alumínio, special care must be taken to choose an appropriate UV ink that bonds well with its surface.

It’s also crucial to have a high-quality UV printer capable of printing on metal surfaces. Adicionalmente, ensure that the printer uses durable, high-performance inks for optimal results.

Etapa 2: Design the Pattern

Before you start printing, design the pattern you wish to print. This could be logos, graphics, or text. Ensure that the dimensions of the design are accurate and that the file is saved in a format compatible with the UV printer. Many printers require files in formats like PDF, PNG, or TIFF.

Etapa 3: Prepare the Metal Surface

Proper surface preparation is key to achieving the best results. Clean the metal thoroughly to remove any dust, graxa, or contaminants that could interfere with the ink’s ability to cure. Por esta, you can use alcohol or a mild cleaner. Depois da limpeza, apply a surface promoter (such as a primer) to ensure strong adhesion of the UV ink. This step may require testing to ensure the compatibility of the promoter and the metal surface.

Etapa 4: Begin the UV Printing Process

Once the design is ready and the metal surface is prepped, it’s time to start the printing process. Begin with a test print to check the print quality, alinhamento, and overall appearance. Adjust parameters such as ink density, printing speed, and resolution as needed.

Once you are satisfied with the test print, proceed with the full printing process. Be sure to maintain quality control throughout production, checking the prints at regular intervals to ensure consistent results.

5. Best Metals for UV Printing

UV printing works well on a variety of metals. Some of the most common metals used for UV printing include:

Aço inoxidável: Popular due to its durability, resistência à corrosão, and smooth surface.

Alumínio: A lightweight material with a smooth finish, ideal for UV printing.

Latão: Known for its distinctive appearance and durability, often used in signage.

Copper and Bronze: Used for artistic and decorative applications.

Titânio: Offers strength and resistance to corrosion, making it a premium choice for specialized printing.

6. Applications of Metal UV Printing

UV printing on metal has a wide range of applications, Incluindo:

Branding: Companies use UV printing to create high-quality branded signage, logotipos, and labels on metal products.

Warning Signs: UV printing is commonly used to produce durable, weather-resistant warning signs for hazardous areas.

Artistic Decor: Artists and designers use UV printing to create intricate artwork on metal surfaces.

Barcoding: UV printing allows manufacturers to print barcodes and QR codes directly onto metal parts for traceability.

Peças da máquina: UV printing is frequently used in the industrial sector to print serial numbers, números de peça, and other details on machine components.

Embalagem: Printing on metal packaging, such as cans or containers, is often done using UV printing due to its durability.

7. Comparação: UV Printing vs. Sublimation Printing on Metal

While both UV printing and sublimation printing are used for printing on metal, they differ significantly in their approach:

UV Printing: Uses UV light to cure ink directly onto the metal surface, resulting in sharp, vibrant prints that are long-lasting.

Sublimation Printing: Involves turning the ink into a gas and bonding it with the metal surface. This method works best on light-colored metals and produces less crisp images compared to UV printing.

UV printing is generally faster, produces more durable prints, and offers superior color vibrancy compared to sublimation printing.

8. Comparação: UV Printing vs. Screen Printing on Metal

Screen printing is a traditional method of printing on metal, and it involves using stencils (screens) to transfer ink to the metal surface. While UV printing offers more versatility and higher-quality prints, screen printing is often preferred for high-volume production due to its speed and lower cost per unit.

UV Printing: Provides higher-quality, waterproof, and durable prints with a wide range of colors.

Impressão da tela: More cost-effective for large volumes, but the colors fade more quickly and the process is slower.

9. Common Problems and Solutions in Metal UV Printing

During the metal UV printing process, common issues may arise. Here are some problems and their solutions:

Color Deviation: Ensure the design is in the correct color mode and file format.

Scattered Ink Dots: Check the ink cartridges and printhead for any issues, and perform a cleaning cycle.

Print Drips: Look for air leaks or clogs in the nozzle.

Blurry Prints: Increase the image resolution to ensure sharp, clear prints.

Horizontal Lines: Clean the printhead to avoid clogging.

10. Conclusão

UV printing on metal has quickly become one of the most popular and reliable methods for high-quality printing on a variety of metal surfaces. Its advantages, including speed, durabilidade, and color accuracy, make it an excellent choice for a range of industrial, commercial, and artistic applications. Despite a few limitations, the technology offers numerous benefits that are hard to match with traditional printing techniques.

For anyone looking to produce vibrant, long-lasting prints on metal, UV printing is the ideal choice.

Perguntas frequentes

- What is the main difference between UV printing and sublimation printing on metal?

UV printing uses UV light to cure ink onto metal, producing vibrant and long-lasting prints. Sublimation printing dyes the ink into the metal, which works best on light metals but may not provide ascrisp or durable prints as UV printing. - Can UV printing be done on any type of metal?

UV printing can be done on various metals, incluindo aço inoxidável, alumínio, latão, cobre, e titânio. No entanto, surface preparation is crucial for adhesion, especially with metals like stainless steel, which may require additional treatments. - What kind of inks are used in UV printing on metal?

The best inks for UV printing on metal include water-based inks for vibrant finishes, curable inks for durability, and solvent-based inks for strong surface adhesion. The choice of ink depends on the specific metal and the desired outcome. - Is UV printing on metal environmentally friendly?

Sim, UV printing is environmentally friendly as it uses inks free from volatile organic compounds (VOCs), making it safer for both workers and the environment compared to other printing methods. - How long does a UV print on metal last?

UV prints on metal are highly durable and resistant to fading, arranhando, e danos ambientais. They can last for years, making them ideal for both indoor and outdoor applications. - What types of designs can be printed using UV printing on metal?

UV printing on metal can handle a wide range of designs, from simple text and logos to complex graphics and photographs. The technology supports full-color prints, making it suitable for various industrial, marca, and artistic applications. - Do I need to do anything special to the metal before UV printing?

Sim, metal surfaces typically require cleaning and sometimes pretreatment (such as flame treatment or applying a primer) to ensure proper adhesion of the UV ink. Surface preparation is key to achieving high-quality results. - What are the common problems in UV printing on metal?

Common issues include color deviation, scattered ink dots, blurry prints, print drips, and horizontal lines. These can often be fixed by ensuring proper file format, maintaining the printhead, and regularly cleaning the machine.