Achieving precise hole sizes and exceptional surface finishes is critical—especially in industries such as aerospace, автомобилен, medical device production, and heavy machinery manufacturing. One of the most effective methods to meet these demands is boring machining.

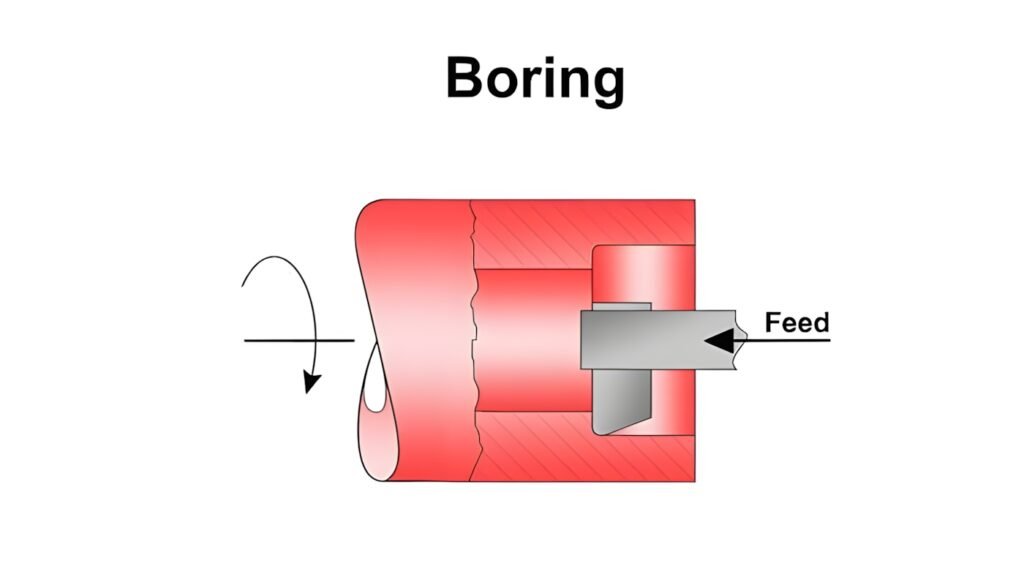

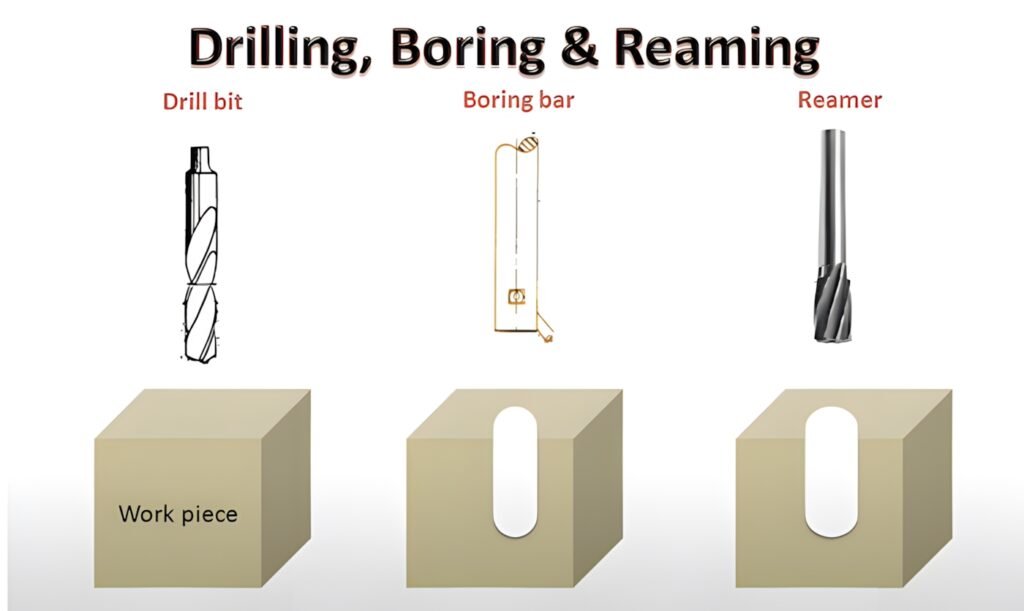

Unlike drilling, which creates a new hole from scratch, boring is the process of enlarging and refining an existing hole that was originally drilled, гласове, or forged. This secondary machining process allows manufacturers to achieve micron-level accuracy, improve concentricity, and produce superior surface finishes.

Това ръководство предоставя a comprehensive, engineer-focused deep dive into boring machining—its advantages, ограничения, процеси, equipment types, предизвикателства, and expert tips for success.

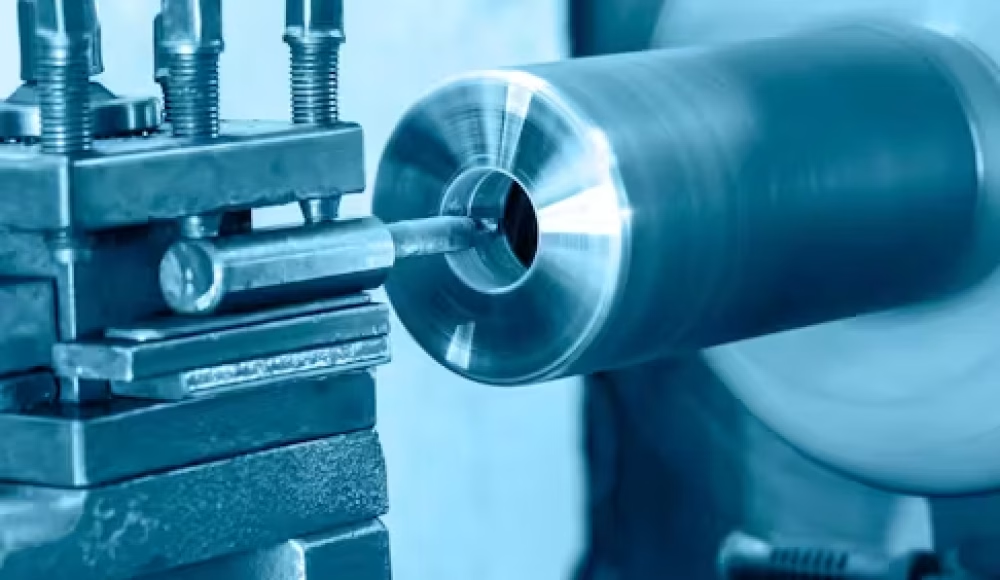

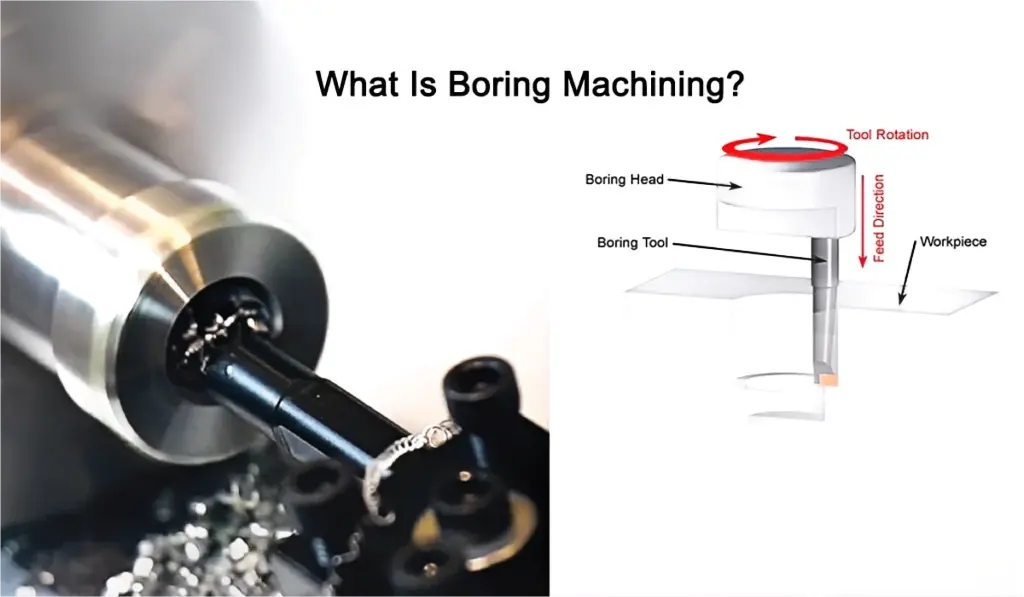

What is Boring Machining?

Boring machining is a precision machining method used to enlarge, align, или завърши an existing hole to meet exact specifications.

Key purposes include:

Increasing hole diameter to match design tolerances

Correcting misaligned or imperfectly drilled holes

Improving surface finish for better component performance

Ensuring concentricity with other features in the part

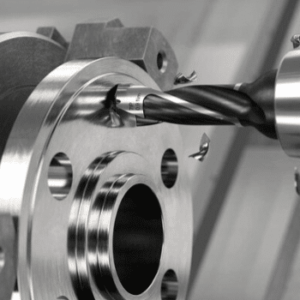

The operation is typically carried out using a режещ инструмент с една точка called a boring bar, mounted on equipment such as a струг, CNC Milling Machine, или specialized boring machine.

Advantages of Boring Machining

Exceptional Accuracy

Boring can achieve tolerances as tight as ± 0,0005 инча (± 0,0127 mm)—up to 40 times more precise than standard drilling.

Превъзходно покритие на повърхността

With the right tooling and cutting parameters, boring can produce finishes of 32 micro inches Ra or better, improving sealing surfaces and wear resistance.

Универсалност

Works on a wide range of materials—стомана, алуминий, титан, месинг, пластмаси, композити—and can create features beyond circular holes, като например слотове, бразди, and keyways.

Custom Hole Sizes

Not restricted to standard drill diameters—ideal for parts requiring non-standard or oversize holes.

Efficiency in Mass Production

CNC-controlled boring machines can process multiple parts with Постоянна повторяемост, reducing scrap rates and increasing throughput.

Limitations of Boring Machining

Въпреки предимствата си, boring machining has several drawbacks:

High Equipment Cost – Precision boring machines and CNC centers require significant capital investment.

Skilled Operator Requirement – Precision setup and tool alignment are critical for accuracy.

Only Works on Existing Holes – Requires a pre-drilled or cast hole before boring begins.

Setup Time for Small Runs – May not be cost-effective for one-off jobs.

Tool Deflection Risk – Especially in deep hole boring, leading to diameter variations.

How Boring Machining Works

Make a pilot hole

Drill or cast a hole slightly undersize (so there’s material left to clean up).

Deburr/chamfer the entrance so the boring bar enters cleanly.

Set up and align

Струг: Indicate the part so the existing hole runs true; mount the boring bar as short and rigid as possible.

Мелница: Locate the hole center with a probe/edge finder; fit a boring head or boring toolholder in the spindle.

Rough bore

Take a few larger radial steps (bigger depth of cut) to remove most of the stock quickly.

Оставете 0.10–0.30 mm (0.004–0.012″) per side for finishing (varies by material/size).

Semi-finish (optional but smart)

Reduce depth of cut and feed to stabilize size and improve roundness.

Re-measure; compensate for any thermal drift or tool deflection.

Finish bore

Вземете one or two light passes (напр., 0.02–0.08 mm / 0.001–0.003″ per side).

Use consistent coolant/air and steady feed to hit size and surface finish.

Add a spring pass (same size, no offset) if the part/material “springs back.”

Measure and verify

Използвайте a bore gauge, air gauge, или telescoping gauge + mic for size and roundness.

Проверете concentricity и позиция to the datum (CMM if critical).

Deburr the entrance/exit; add a small chamfer if specified.

Types of Boring Machines

Horizontal Boring Machine

Какво е: The spindle (the part holding the cutting tool) is mounted horizontally.

When to use it: Перфектен за long parts or when you need to bore holes deep into the side of a large workpiece.

Typical jobs: Двигателни блокове, machine bases, large plates.

Защо е страхотно:

Handles big, heavy workpieces С лекота.

Excellent for precision on large-scale industrial components.

Vertical Boring Machine

Какво е: The spindle is mounted vertically, and the workpiece usually sits flat on a rotating table.

When to use it: Идеален за големи, тежък, and awkwardly shaped parts that are easier to handle lying flat.

Typical jobs: Turbine casings, big flanges, large valves.

Защо е страхотно:

Gravity helps keep the part stable.

Easier to load and unload heavy parts.

Floor Boring Machine

Какво е: A massive machine with a moving column and spindle, designed for very large components placed directly on the shop floor or a heavy-duty table.

When to use it: За huge industrial parts that don’t fit on standard machine tables.

Typical jobs: Shipbuilding parts, wind turbine hubs, large gear housings.

Защо е страхотно:

Can machine parts so big they have to stay in one place.

Handles heavy-duty, high-precision work.

Jig Boring Machine

Какво е: A super-precise machine designed to produce exact hole locations и завършва, often used to make jigs, приспособления, и прецизно инструменти.

When to use it: Кога tolerances are extremely tight and accuracy is the top priority.

Typical jobs: Аерокосмически компоненти, high-end molds, Умиращи комплекти.

Защо е страхотно:

Incredibly accurate positioning.

Perfect for work that can’t afford even a tiny alignment error.

CNC Boring Machine

Какво е: A computer-controlled boring machine that automates movement, скорост, and tool adjustments.

When to use it: За производство в голям обем or parts with complex boring requirements.

Typical jobs: Компоненти за автомобилни двигатели, хидравлични цилиндри, industrial machinery parts.

Защо е страхотно:

Highly repeatable results.

Can handle complicated programs and multi-step boring in one setup.

Line Boring Machine

Какво е: A portable or stationary machine that bores a straight, perfectly aligned hole through multiple surfaces in a single setup.

When to use it: To repair or machine bores in place without moving the part to a big machine.

Typical jobs: Repairing large equipment like excavators, boring through bearing housings, gearbox bores.

Защо е страхотно:

Saves time and money on heavy equipment repairs.

Ensures perfect alignment between multiple bores.

Types of Boring Processes

Line Boring

Aligns bores in components like двигателни блокове, турбини. Tool supported at both ends for rigidity.

Back Boring

Enlarges a hole from the opposite side—used in firearm manufacturing and hydraulic components.

Blind Boring

Creates a hole that does not pass completely through the workpiece—common in hydraulic manifolds.

Micro Boring

Използва се за мъничко, точни дупки in medical devices and aerospace parts, often requiring tolerances within микрони.

Вертикална & Horizontal Boring

Choice depends on workpiece size, форма, and weight.

Common Challenges in Boring Machining

Вибрация – Caused by long boring bars; leads to chatter marks.

Tool Deflection – Affects diameter accuracy.

Maintaining Concentricity – Especially in deep holes.

Machine Wear – Can cause accuracy loss over time.

Surface Finish Control – Requires precise cutting parameters.

Генериране на топлина – Must be managed with coolants to prevent dimensional distortion.

Expert Tips for Better Boring Machining

Use the Right Tool Material & Геометрия – Carbide inserts for harder metals; high-speed steel for softer materials.

Оптимизиране на параметрите на рязане – Adjust скорост, фураж, и дълбочина на рязане for material type.

Keep Boring Bars Short & Твърд – Reduces vibration and deflection.

Perform Regular Machine Maintenance – Prevents performance drop.

Use High-Quality Coolants – Improves finish and extends tool life.

Boring vs Other Machining Processes

| Процес | Прецизност | Повърхностно покритие | Цел | Типична толерантност |

| скучно | Много високо | 32 μin Ra | Enlarge/refine existing holes | ±0,0005 инча |

| Пробиване | Среден | 125 μin Ra | Create new holes | ±0.02 in |

| Разширяване | високо | 63 μin Ra | Slightly refine holes | ± 0,001 инча |

| Фрезоване | Променлива | 125 μin Ra | Create holes/features | ±0.01 in |

Applications of Boring Machining

Автомобилна индустрия 🚗

Където се използва: Двигателни блокове, cylinder bores, crankshaft housings, and gearbox cases.

Why boring matters here: Engines need holes that are perfectly round and aligned to keep everything running smoothly and reduce wear. Even a tiny misalignment can cause vibration or damage over time.

Аерокосмическа индустрия ✈

Където се използва: Jet engine housings, Компоненти на предавката за кацане, и структурни рамки.

Why boring matters here: В космонавтиката, weight and precision are critical. Boring helps achieve тесни допустими отклонения and smooth finishes that ensure safe, reliable performance at extreme speeds and temperatures.

Heavy Machinery and Construction Equipment 🚜

Където се използва: Excavator arms, loader joints, Корпуси на лагери, and gearboxes.

Why boring matters here: These parts take a lot of stress, so the bores must be силен, aligned, and able to handle heavy loads without failure.

Масло, Газ, and Energy Sector ⚙

Където се използва: Турбинни корпуси, pump casings, and drill components.

Why boring matters here: The bores in these parts often carry high-pressure fluids or gases, so they need to be accurately machined to prevent leaks and withstand extreme conditions.

Морска индустрия 🚢

Където се използва: Ship propeller shafts, опори на двигателя, and large gearbox housings.

Why boring matters here: Marine parts are exposed to harsh saltwater environments, so boring helps ensure proper fit and alignment, reducing wear and corrosion over time.

Медицинско оборудване 🏥

Където се използва: Хирургически инструменти, ортопедични импланти, and diagnostic devices.

Why boring matters here: In the medical world, Прецизността е всичко. Holes must be гладко, burr-free, и перфектно оформен to avoid complications or damage during use.

Изработка на матрици и матрици 🛠

Където се използва: Injection mold bases, Умиращи комплекти, и джигове.

Why boring matters here: Perfectly bored holes ensure that molds align correctly, producing consistent, high-quality parts every time.

Заключение

Boring machining remains one of the most reliable and precise methods for achieving perfect hole geometry in manufacturing. While it requires specialized equipment, квалифицирани оператори, and careful setup, the results—high accuracy, отлично покритие на повърхността, and repeatability—make it indispensable in many industries.

Често задавани въпроси

1. What is the fundamental difference in function between drilling, скучно, и пробиване?

-

Пробиване: The primary process of creating a new hole from solid material, offering moderate accuracy.

-

скучно: The process of enlarging and correcting an existing hole to achieve high precision in diameter, закръгленост, и местоположение (concentricity).

-

Разширяване: A finishing process used to slightly refine an existing drilled or bored hole, improving its size tolerance and surface finish, but only removing a very small amount of material.

2. Why is the “boring bar overhang” such a critical factor in the success of the operation?

The boring bar overhang (the length the bar extends from the holder) directly impacts твърдост. Because the tool is only supported at one end, excessive overhang causes the boring bar to vibrate severely (бърборене) when cutting. Chatter leads to poor surface finish, inaccurate dimensions (hole size variation), and rapid tool wear. The general rule is to keep the bar overhang as short as possible.

3. What is a “spring pass” in finish boring, and why is it used?

A spring pass is a final, light cut taken with zero additional offset or change in cutting depth. Its purpose is to compensate for the slight elastic deflection or “springing” of the boring bar or the workpiece during the previous cut. By running the tool through the same path again without changing the setting, it cleans up any minor material left behind due to deflection, ensuring the final hole size is precisely what was programmed.

4. How does a Line Boring Machine differ from a standard Horizontal Boring Machine?

-

Standard Horizontal Boring Machine: Използва се за обработка големи, heavy components in a controlled machine shop environment. The boring bar is supported at one end by the spindle.

-

Line Boring Machine: Designed specifically to machine a perfectly straight and aligned series of bores through multiple separate mounting points (like bearing housings on an engine block). Critically, the boring bar is typically supported at both ends of the bore series for maximum rigidity, often used for repair work in situ (on-site).

5. What is the primary cause of poor surface finish in a bored hole?

The most common cause of poor surface finish in boring is vibration or chatter, usually resulting from excessive boring bar overhang or insufficient machine rigidity. Other contributing factors include:

-

Dull Tooling: The cutting edge pushing material rather than cleanly slicing it.

-

Improper Feed Rate: Too high of a feed rate leaves deep spiral marks on the surface.

-

Insufficient Coolant: Allowing heat to build up, causing the material to deform.

6. When should Micro Boring be used, and what level of accuracy can it achieve?

Micro boring is reserved for extremely small holes (typically less than 1 мм или 0.04 инча in diameter) or applications requiring the absolute highest precision. It uses specialized, tiny tools and is capable of achieving accuracy within микрони (thousandths of a millimeter), making it essential for medical devices, Инжектори за гориво, and high-end aerospace instrumentation.

7. Why is heat generation a major concern in precision boring, even with coolant?

While coolant helps, heat is a concern because it causes термично разширение of both the workpiece and the boring bar. Even a tiny temperature increase can temporarily change the diameter of the part or the length of the tool, което води до грешки в размерите. This requires machinists to monitor temperature closely and use a consistent flow of coolant during the finishing pass to stabilize the dimensions.

Прочетете повече:

CNC фрезоване: A Complete Guide to Precision Machining

CNC струговане: Principles and Applications