Motorcycles are more than just machines—they are a blend of engineering, изпълнение, and personal expression. Behind every smooth ride and powerful acceleration lies a collection of precisely engineered parts, many of which are produced with ЦПУ (Компютърно цифрово управление) механична обработка.

CNC machining has revolutionized motorcycle manufacturing by offering несравнима точност, скорост, и гъвкавост. Whether it’s replacing worn-out components, upgrading performance, or adding custom styling, CNC technology provides a reliable solution for riders and manufacturers alike.

В това ръководство, we’ll take a closer look at why CNC machining is so important for motorcycle parts, what components are commonly made this way, the materials and processes used, finishing options, and the overall benefits it brings to the motorcycle industry.

Why CNC Machining for Motorcycle Parts?

CNC machining has become the go-to method for producing motorcycle parts because of its точност, многофункционалност, and customization potential. Here are the key reasons:

Replacement of Damaged Parts

Motorcycles experience high wear due to constant exposure to heat, вибрация, and friction. С обработка на ЦПУ, damaged parts such as pistons, валове, or wheels can be reproduced quickly and accurately, ensuring riders can get back on the road without long delays. Even discontinued or rare parts can be recreated with a proper CAD design.

Upgraded & Stylish Appearance

Riders often want to add a personal touch to their bikes. CNC обработката позволява custom-designed wheels, Покрития, и декоративни елементи that not only improve performance but also enhance the bike’s look. The cost of customization has also become more affordable in recent years.

Прецизност & точност

За разлика от ръчната обработка, CNC is automated and follows digital designs with incredible accuracy. Това означава тесни допустими отклонения, Повтарящи се резултати, and minimal defects. For parts like camshafts and pistons, this precision directly impacts engine performance.

Quick Production

CNC machines run continuously and can switch between designs with minimal downtime. За производители, this means faster lead times and the ability to quickly correct design errors without starting from scratch.

Custom Motorcycle Parts Made with CNC Machining

Many motorcycle parts—both functional and aesthetic—can be crafted with CNC machining. Below are the most common examples:

Колела

Motorcycle wheels are often CNC-machined from алуминиеви сплави because they need to be lightweight yet strong. CNC milling makes it possible to create intricate spoke designs and customized finishes that combine performance with visual appeal.

Компоненти на двигателя

The heart of every motorcycle is its engine, and CNC machining plays a major role in its construction.

Cylinder Head: Controls fuel combustion and airflow; CNC ensures exact dimensions for efficient operation.

Касферни валове: Control valve timing; CNC turning allows for precision profiles that can even be tuned for better power output.

Pistons: High-performance pistons must withstand heat and stress. CNC machining allows for custom designs that improve durability and engine response.

Lights and Lenses

CNC machining is also used for light covers and lenses, often made from plastics or aluminum. These parts can be customized to meet safety regulations while adding a unique style.

Aesthetic and Body Parts

Beyond performance, many riders invest in customized body covers, seat bases, и декоративни елементи. С 5-ОСС ОБРАЗОВАНЕ НА CNC, complex curves and artistic designs can be produced with ease.

Materials Used for Custom Motorcycle Parts

Алуминий – Lightweight but strong. It’s easy to machine and polish, which makes it a favorite for custom wheels, рамки, and handlebars. плюс, it doesn’t rust easily.

Неръждаема стомана – Known for its strength and shiny finish. Stainless steel is heavier than aluminum, but it’s great for exhaust systems, крепежни елементи, and parts that need to handle stress without corroding.

Въглеродни влакна – Ultra-light and modern-looking. Carbon fiber is often used for high-performance bikes where weight reduction is key. Think body panels, fairings, and sometimes even wheels.

Титан – A premium choice. Titanium is strong like steel but much lighter. It’s perfect for high-end exhausts and performance parts, though it’s usually more expensive.

Пластмаси and Composites – Materials like ABS or fiberglass are often used for bodywork, fairings, or covers because they’re light, moldable, and can be painted easily.

Месинг и Мед (for details) – These aren’t for the main structure, but builders love using them for accents, фитинги, or custom touches that add a retro or vintage vibe.

Machining Processes for Motorcycle Parts

Different machining processes are chosen based on part geometry and function:

CNC струговане:

Used for cylindrical components such as camshafts, бутала, и валове. Provides smooth, precise rotational symmetry.

CNC фрезоване:

Ideal for wheels, custom brackets, and asymmetrical parts. 3-axis and 5-axis milling can handle both simple and highly complex shapes.

Смилане:

Applied to shafts, лагери, and other parts requiring extremely smooth surfaces. Improves dimensional accuracy.

Пробиване:

Necessary for holes used in assembly, крепежни елементи, and cooling channels in engine parts.

Лазерно рязане:

Used for lightweight covers, windscreens, and decorative parts with fine details.

Surface Finishes for Motorcycle Parts

След обработка, surface finishing improves durability, устойчивост на корозия, и външен вид:

Анодиране: Creates a hard, protective oxide layer, often with a colored finish for aesthetics.

Прахово боядисване: Provides a thick, durable coating resistant to chips and scratches.

Бластиране на мъниста: Improves fatigue strength and gives a matte, uniform appearance.

Галванопластика: Adds a protective and decorative metal layer (напр., хром).

Полиране: Delivers a shiny, mirror-like surface—popular for visible motorcycle parts.

Benefits of CNC Machined Motorcycle Parts

Висока точност – Critical for engine performance and safety.

Lightweight yet Strong – Better fuel efficiency and handling.

Бързо производство – Reduces downtime for repairs and upgrades.

Customizable – Riders can personalize designs for style and performance.

Great for Prototyping – Manufacturers can test new designs quickly before mass production.

How Much Do CNC Motorcycle Parts Really Cost?

Избор на материали

The type of material has a big impact on price. например, aluminum is usually cheaper and easier to machine than titanium or carbon fiber. Stainless steel sits somewhere in the middle—it’s strong and durable but a bit tougher (and costlier) до машина.

Сложност на частта

A simple bracket or spacer? That’s going to be relatively cheap. A custom engine cover with detailed cuts, криви, and logos? That takes longer to machine, which means higher costs. The more complicated the design, the more expensive the part.

Количество

Making one part is always more expensive per piece than making 50. If you’re ordering in bulk, the cost per unit drops significantly. But for unique, one-off custom builds, expect to pay a premium.

Finishes and Extras

Raw parts cost less, but if you want anodizing, полиране, прахово боядисване, или гравиране, those finishing touches add to the final bill. These details can really make a bike stand out, but they’re not free.

Machine Time and Labor

CNC машините се зареждат до часа. The longer your part takes to cut, Колкото по -висока е цената. Complex 5-axis machining is usually pricier than basic 3-axis work.

Location and Shop Rates

A CNC shop in the U.S. or Europe will likely charge more than one in Asia, simply because of labor and overhead differences.

💡 Quick Tip: If you’re on a budget, stick to simpler designs, use aluminum, and limit special finishes. If you’re going for a high-end showpiece, be prepared to pay more for premium materials and intricate designs.

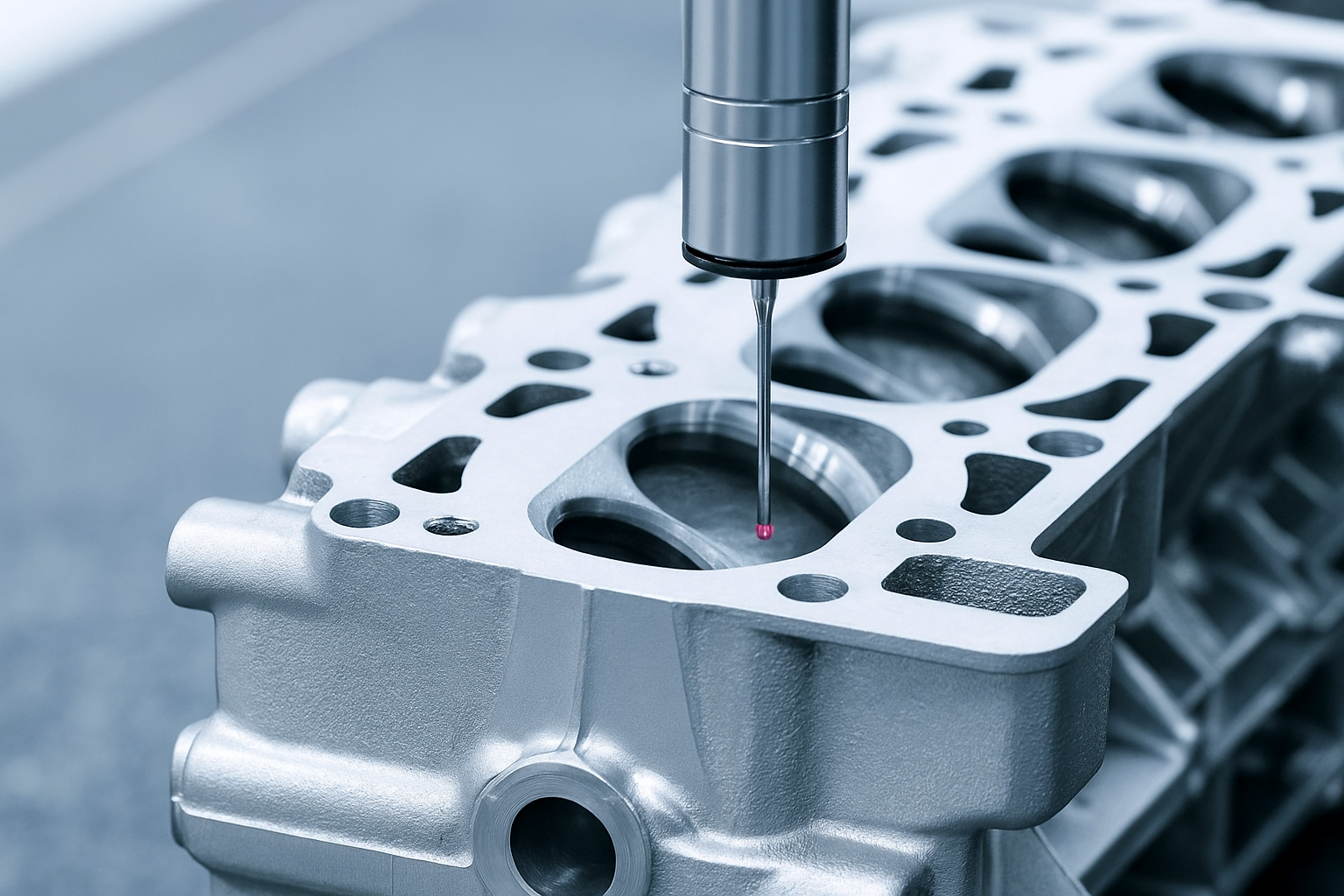

Quality Control in CNC Motorcycle Parts

Precision and Fit

Every part has to match the design down to a fraction of a millimeter. Imagine ordering a custom brake lever and it doesn’t line up with your bike’s mounting point—frustrating, точно? CNC machining ensures parts are cut with extreme accuracy, and quality checks confirm that everything fits perfectly before shipping.

Material Checks

Not all metals or plastics are created equal. Good CNC shops test materials before machining to make sure they’re strong, издръжлив, and right for the job. например, aluminum alloys are checked for hardness, while stainless steel is checked for corrosion resistance.

Повърхностно покритие

Rough edges or scratches can ruin both the performance and appearance of a motorcycle part. Quality control includes checking for smooth surfaces, sharp detailing, and even finishes (whether it’s polished, anodized, или прахообразно покритие).

Stress and Durability Testing

Motorcycle parts take a beating—heat, вибрация, and heavy loads. Some high-end shops even test parts under simulated conditions to make sure they won’t fail when you’re out on the road.

Consistency for Multiple Parts

If you’re ordering a batch of parts—say, 20 footpegs—they all need to be exactly the same. Quality control checks for consistency so you don’t end up with mismatched pieces.

Final Inspection Before Delivery

Before a part leaves the shop, it usually goes through a final round of inspections. That might include measuring dimensions again, checking finishes, and making sure the part matches the original CAD design.

Tips for Custom CNC Machining Motorcycle Parts

Start with a Clear Design

The more details you provide, the better. A solid CAD drawing or even a well-thought-out sketch helps the machinist understand exactly what you need. Don’t leave anything vague—dimensions, ъгли, and special features should be crystal clear.

Pick the Right Material

Different parts need different materials. например, aluminum is lightweight and great for bodywork, while stainless steel is stronger and ideal for brackets or structural parts. Talk with your machinist if you’re unsure—they can suggest what works best.

Think About Function, Not Just Looks

A part that looks amazing but doesn’t hold up on the road isn’t worth it. Always balance style with strength, издръжливост, и изпълнение.

Check Tolerances

Motorcycles are machines with lots of moving parts, and small mistakes can cause big problems. Make sure your parts are designed with the right tolerances (how much “wiggle room” they can have) so they fit correctly.

Work with an Experienced Shop

Not all CNC shops are the same. Look for one that has experience with automotive or motorcycle parts. They’ll already know the common issues and can help avoid mistakes.

Plan Ahead for Finishing

Don’t forget about the final touches like anodizing, полиране, или покритие. A raw part may work fine, but a proper finish can improve both the look and the lifespan of the part.

Communicate Clearly

Stay in touch with your machinist throughout the process. Ask for updates, request photos if needed, and make sure you’re both on the same page before production begins.

Test and Adjust

Even with perfect machining, sometimes a custom part needs a little tweaking during installation. Be prepared to test-fit and make small adjustments if needed.

Заключение

CNC machining has transformed the motorcycle industry by combining engineering precision, creative freedom, и ефективно производство. от engine components that demand high accuracy да се customized wheels and body parts that reflect personal style, CNC machining provides solutions for both performance and aesthetics.

As motorcycles continue to evolve, CNC machining will remain at the forefront of innovation—helping riders enjoy smoother, по-бързо, and more reliable machines.

Често задавани въпроси

1. Why is maintaining tight tolerances (прецизност) so critical for motorcycle engine components?

Maintaining tight tolerances (± 0.05 мм or less) is absolutely critical because engine components operate under extreme heat, high speed, and tremendous stress. Parts like бутала, цилиндрови глави, и разпределителни валове must fit together precisely to ensure proper sealing, efficient combustion, and accurate valve timing. Any deviation can lead to excessive friction, преждевременно износване, power loss, and catastrophic engine failure.

2. Which materials are best for achieving a lightweight performance part versus a strong structural part?

-

For Lightweight Performance: Алуминиеви сплави (като 6061 или 7075 серия) are the top choice for components like wheels, triple clamps, and non-structural covers, offering an excellent strength-to-weight ratio and good machinability. Въглеродни влакна is the ultimate choice for minimal weight in fairings and body panels.

-

For Strong Structural Parts: Неръждаема стомана is preferred for brackets, крепежни елементи, and exhaust components where maximum strength, твърдост, and corrosion resistance are needed, despite its higher weight. Титан is the premium alternative, offering steel’s strength at half the weight.

3. What is the difference between 3-axis and 5-axis CNC machining for motorcycle parts?

-

3-Обработка на оси: Moves the cutting tool along the X, Y, и Z оси. It is cost-effective and suitable for flat parts, simple brackets, and basic contours (напр., footpegs, simple covers).

-

5-Обработка на оси: Allows the tool to also pivot on two rotational axes (A and C). This is essential for creating комплекс, contoured surfaces like intricate wheel spokes, ergonomically curved seat bases, and complex engine cylinder heads in a single setup, improving precision and surface finish.

4. How does anodizing improve the performance and appearance of aluminum motorcycle parts?

Anodizing is an electrochemical process that creates a трудно, protective oxide layer on the surface of aluminum. This layer offers three main benefits:

-

Устойчивост на корозия: Protects the aluminum from weathering, road salts, и влага.

-

Устойчивост на износване: Makes the surface significantly harder and more scratch-resistant.

-

Естетика: Allows the part to be dyed in various colors (черен, червен, син, и т.н.), providing a durable, stylish finish favored by custom builders.

5. Can CNC machining be used to recreate discontinued or vintage motorcycle parts?

да, this is one of CNC machining’s key advantages. If an original part is damaged or no longer available, a machinist can use reverse engineering техники (like 3D scanning or precise measurements) За да създадете a CAD model. This digital model is then used to program the CNC machine to reproduce the part with the exact original dimensions and often with superior modern materials.

6. Why is prototyping crucial before mass-producing custom motorcycle parts?

Прототипиране (making one or a few initial parts) is essential because motorcycles are complex assemblies. A prototype allows the designer and builder to:

-

Test Fit: Ensure the part mounts correctly without interference (напр., a brake lever clearing a throttle housing).

-

Test Function: Verify that the part performs its mechanical or aerodynamic function under real-world stress.

-

Finalize Aesthetics: Confirm the finish, цвят, and design are exactly what the customer desires before committing to an expensive, large-volume production run.

7. What factors cause the biggest variation in the final cost of a CNC motorcycle part?

The largest cost drivers are:

-

Материал: Using Titanium or Carbon Fiber instead of standard Aluminum.

-

Complexity/Time: Requiring high-precision 5-Обас на ос for intricate shapes versus simple 3-axis cutting.

-

Завършете: Adding premium treatments like custom твърдо анодиране или mirror polishing rather than leaving a raw machined finish.

-

Количество: The cost per unit drops significantly when ordering in large batches (икономии от мащаба).

Прочетете повече:

CNC Milling vs CNC Turning Explained