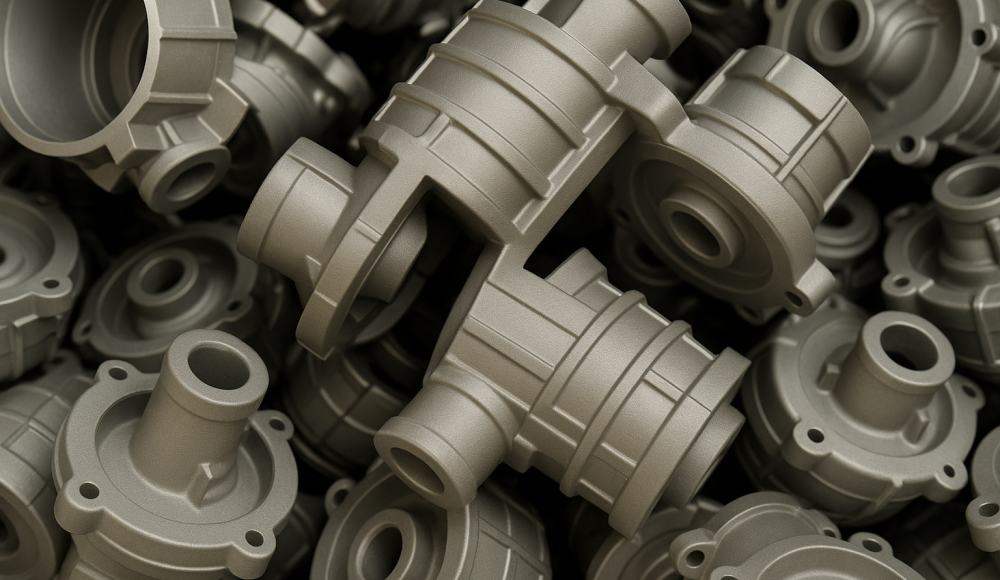

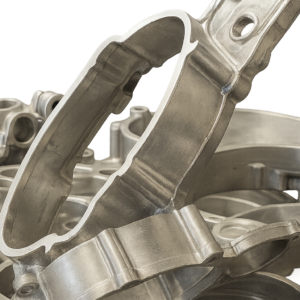

Кастинг на алуминиев матрица е един от най -съществените производствени процеси в днешния индустриален пейзаж. Комбиниране на леките свойства на алуминия с прецизността на формоването с високо налягане, Тази техника произвежда сложна, Ефективно и в мащаб части с висока якост.

Това ръководство предоставя изчерпателен преглед на процеса на леене на алуминий, включително ключови сплави, повърхностни покрития, Дизайнерски съображения, и приложения в основните индустрии.

Въведение

Алуминият е лек, устойчив на корозия метал с висока термична и електрическа проводимост. Тези свойства го правят идеален за производство на сложни компоненти с тесни допустими отклонения чрез леене на матрици. Сред всички формиращи процеси, Алуминиевата леене на матрици се откроява заради повторяемостта си, размерна точност, и ефективност на разходите, особено за производството с голям обем.

Какъв е процесът на леене на алуминиев матрица?

Определение

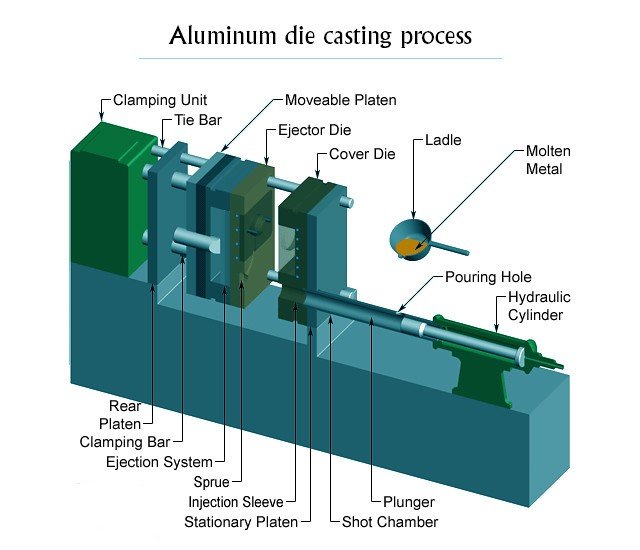

Алуминиевото леене на матрици е метод за производство на високо налягане, който инжектира разтопен алуминий в стоманена форма (Умира) за производство на комплекс, Точни метални части. Той се провежда предимно с помощта на Машини за леене на студена камера Поради високата точка на топене на алуминий (~ 660 ° C или 1220 ° F.), което би повредило потопените компоненти в машина за гореща камера.

Стъпка по стъпка процес:

Топене: Алуминиевите блокове се разтопят в отделна пещ.

Намаляване: Разтопеният метал е ръчно или роботично натоварен в ръкава на изстрела.

Инжектиране: Буталото принуждава разтопения алуминий в кухината на формата при високо налягане (10–175 MPa).

Втвърдяване: Металът се охлажда и се втвърдява вътре в матрицата, обикновено в рамките на секунди.

Изтласкване: Мухълът се отваря и частта се изхвърля, често с автоматизирани изхвърлящи щифтове.

Подстригване и довършителни работи: Излишен материал (светкавица) се отстранява, и се прилага незадължително покритие на повърхността.

Умиращите умиращи могат да се използват повторно хиляди пъти, Осъществяване на този метод идеален за производствени работи с голям обем.

Предимства на кастинга на алуминиев матрица

Кастингът на алуминиевите матрици предлага няколко технически и икономически ползи:

✅ Превъзходно покритие на повърхността: Гладки повърхности, които изискват малко до никаква след обработка.

✅ Висока точност на размерите: Допустимите отклонения, колкото ± 0,1 mm са постижими.

✅ Високо съотношение на якост към тегло: Частите са както леки, така и структурно здрави.

✅ Отличен термичен & Електропроводимост: Идеален за радиаторни минки и заграждения.

✅ Минимална порьозност: Усъвършенствани вентилации и гейтинг намаляват вътрешните празнини.

✅ Гъвкавост на дизайна: Поддържа сложни геометрии и секции с тънки стени (<1.5 мм).

✅ Ефективност на разходите: Форми за многократна употреба, Бързи времена на цикъл, и автоматизацията намалява разходите за част.

✅ устойчивост: Алуминият е 100% рециклируема без загуба на производителност.

Обикновени алуминиеви леящи сплави

Изборът на правилната сплав е от решаващо значение за производителността, издръжливост, и леярство. Ето най-използваните степени на умиране:

| Сплав | Ключови характеристики | Приложения |

| A380 | Отлична леярска способност, сила, устойчивост на корозия | Скоби на двигателя, електроинструменти, Електронни заграждения |

| A390 | Висока твърдост, устойчивост на износване, ниска пластичност | Цилиндрови блокове, Хидравлични компоненти |

| A360 | Стягане под налягане, Превъзходна устойчивост на корозия | 5G корпуси, черупки на контролера |

| A413 | Добра плавност, стягане под налягане | Сложни тънкостенни части |

| ADC-12 | Японски стандарт; Подобно на A383 | Автомобилни и индустриални компоненти |

| ADC-1 | Подобрена сила, по -малко свиване | Отливки с висока точност |

Всяка сплав се различава в механичните свойства, термично поведение, обработваемост, и устойчивост на корозия или напукване.

Основни характеристики на алуминиевите сплави

Алуминиевите сплави, които са подредени, предлагат мощна комбинация от механични и функционални свойства:

Лек: Намалява общата маса и подобрява енергийната ефективност.

Устойчив на корозия: Образува естествен оксиден слой, за да се предпази от ръжда.

Термично ефективен: Отлично разсейване на топлина за електронни заграждения.

Електрически проводим: Идеален за EMI/RFI екраниране.

Високо якост на опън и добив: Надежден за структурни товари.

Напълно рециклируем: Екологично устойчиво с минимално деградация.

Опции за довършване на повърхността за алуминий с изтичане

Въпреки че алуминиевите кастинги често имат гладък завършек, Повърхностните обработки се прилагат за подобряване на външния вид или функционалната ефективност.

Анодиране

Преобразува повърхността в алуминиев оксиден слой.

Подобрява износването и устойчивостта на корозия.

Електрически непроводимо, Добър за изолация.

Прахово боядисване

Добавя дебел, Цветно, и траен защитен слой.

Драскотина, UV, и устойчив на корозия.

Естетична гъвкавост: матова, гланц, или текстурирани облицовки.

Chem Film (Хроматно преобразуващо покритие)

Осигурява устойчивост на корозия, като същевременно поддържа електрическа проводимост.

Идеален за аерокосмически и военни части.

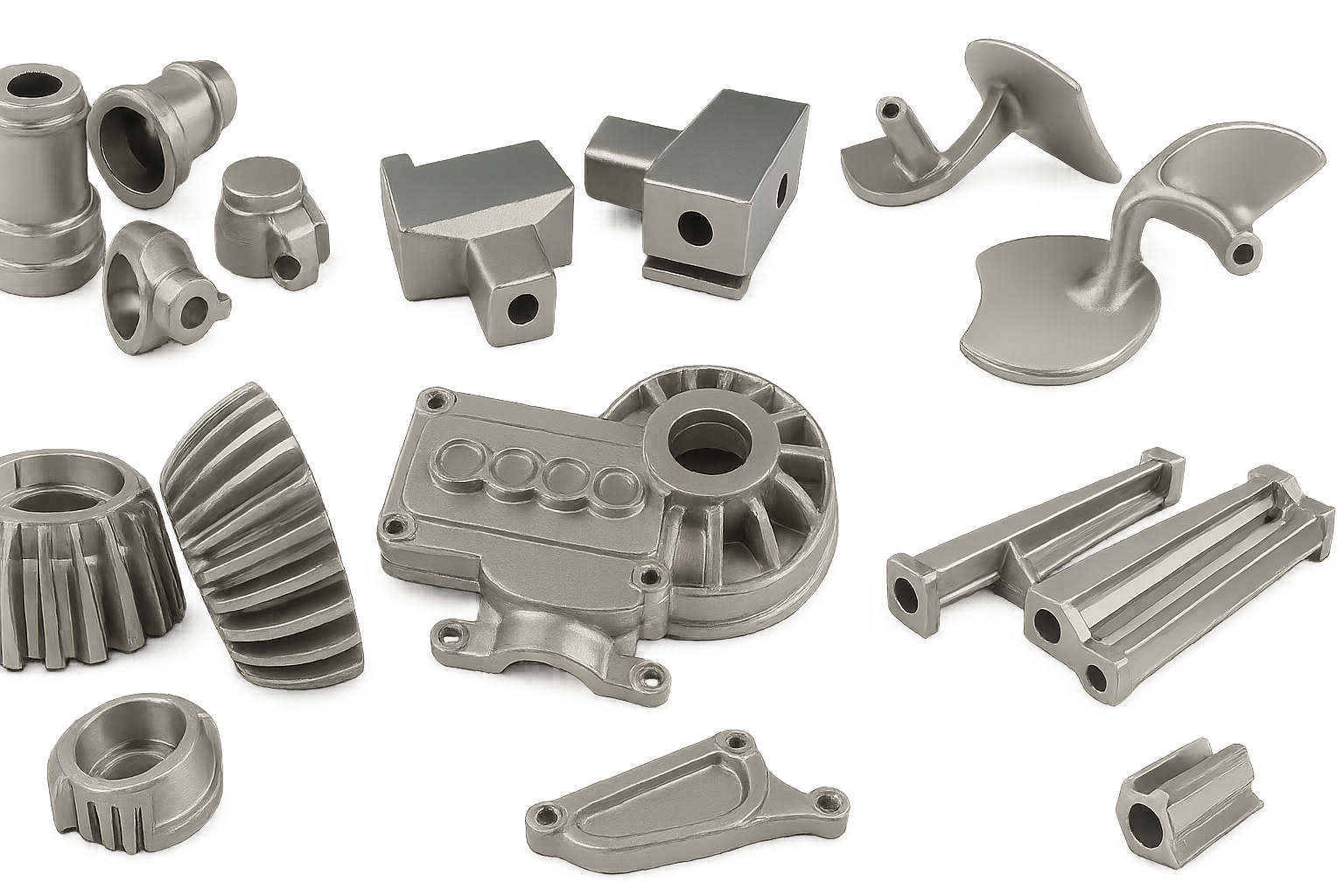

Приложения на кастинга на алуминиев матрица

Строителство

Рамки за прозорци, Строли за завеси, Поддържащи структури.

Увеличаване на употребата в мостове и модулни строителни системи.

Автомобилна

Корпути на предаване, двигателни блокове, скоби, маслени тигани.

Помага за намаляване на теглото и емисиите на превозното средство.

електроника

Топлоотводи, заграждения, Рамки за смартфони, 5G корпуси на антената.

Комбинира термичното управление с EMI Sheling.

Мебели

Трайни, но елегантни компоненти като бази на стола, дръжки, и брави.

Космонавтика

Бутални глави, корпуси на предавките, Заграждения за осветление, части на двигателя.

Комбинира ниско тегло с висока производителност на опън.

Дизайнерски съображения за алуминиеви части на заливане

Дизайн на мухъл

Оптимизирайте за гладък метален поток и лесно изхвърляне.

Определете ясни линии за разделяне и добавете ъгли на черновата.

Точка на инжектиране

От решаващо значение за намаляване на хванатия въздух и осигуряване на пълно запълване.

Може да са необходими множество порти за сложни части.

Дебелина на стената

По -тънките стени намаляват теглото, но трябва да поддържат структурната цялост.

Целете еднаква дебелина на стената, за да се избегнат горещи точки и изкривяване.

Алуминиеви фактори за разходи за леене

Алуминиевата леене на матрици е най-рентабилен в мащаб. Основните променливи за ценообразуване включват:

Разходи за инструменти: Обикновено 7 000 - 75 000 долара в зависимост от сложността.

Обем: Високите обеми намаляват разходите за единица поради повторната употреба на плесени.

Геометрия на част: Сложните форми изискват по -сложни инструменти и по -дълги времена на цикъл.

Материал & Машинно време: Тип на сплав и част от масовото въздействие Продължителност на цикъла и разходи за материали.

Труд: Настройка, Подрязване, и времето за проверка допринася за разходите за труд.

Услуги за кастинг на алуминиева матрица - пример за бързо показване

Топ прецизни оферти:

Допустими отклонения като ± 0,004 ” (0.1 мм)

ISO 9001:2015 Сертифицирани процеси

DFM обратна връзка и бързи цитати от CAD модели

Пълно прототипиране на възможностите за масово производство

Ползи:

До 30% спестяване на разходи

Персонализирани завършвания и спецификации

Контрол на качеството от край до край

Заключение

Кастингът на алуминиева матрица е с висока точност, мащабируем, и рентабилен метод за производство. Той е особено идеален за приложения, изискващи леки, но силни компоненти с тесни допустими отклонения и чисти облицовки. Когато работите с по -големи обеми на производство, Die Casting предлага несравнима стойност в производителността, скорост, и повторяемост.

Независимо дали изграждате автомобилни компоненти, електроника, или архитектурни части, Избор на правилната сплав, Дизайнерска стратегия, и партньорът за обслужване може значително да повлияе на успеха на вашия проект.

Често задавани въпроси

Q1: Как се различава леенето на алуминиевите матрици от пясъчното леене?

Кастингът използва стоманени форми за прецизност; Пясъчното леене използва разходни пясъчни форми.

Кастингът на матрици има по -добра точност на размерите и повърхностно покритие, но по -високи разходи за инструменти.

Пясъчни кастинг костюми с нисък обем, Производство с големи части; Кастингът на матрица се отличава в писти с голям обем.

Q2: Е алуминиев кастинг скъпо?

Инструментариумът е скъпо предварително, Но процесът става много рентабилен за големи партиди.

Q3: Колко бързо е кастингът на умира?

След като се настрои инструментариума, цикъла на цикъла варира от 30 секунди до няколко минути на част.

Свързани статии:

Умираща кастинг срещу. CNC обработка

Леене под налягане срещу леене по инвестиция

Обработен алуминий срещу лят алуминий

1 мисъл за "Пълно ръководство за кастинг на алуминиев матрица: Процес, Сплави, Довършителни работи & Приложения”