Пробиването на дълбоки дупки може да звучи като високо специализиран процес, И това е така, защото е. За разлика от стандартното сондиране, където дълбочината на дупката е сравнително плитка, Пробиването на дълбоки дупки е предназначено за създаване на дупки с a Съотношение дълбочина към диаметър на 10:1 или по -голямо. Тази техника се използва широко в индустриите, където точността, сила, и надеждността са критични - като аерокосмическото, автомобилен, масло & газ, И дори медицински изделия.

В тази статия, Ще се потопим Какво е сондиране на дълбоки дупки, Защо е важно, Използваните различни методи, предизвикателствата, свързани с това, и практически решения. До края, Ще имате пълно разбиране за това как този процес захранва някои от най -модерните технологии в света.

Какво е сондиране на дълбоки дупки?

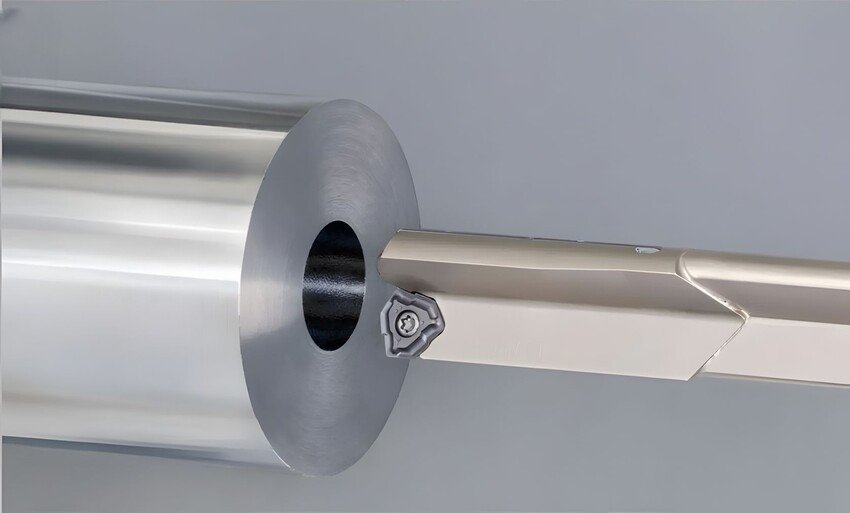

В основата си, Пробиването на дълбоки отвори е процес на обработка, предназначен да произвежда прецизен, направо, и чисти дупки които са значително по -дълбоки, отколкото са широки.

Определение: Дупката се счита за „дълбока дупка“, когато дълбочината му е поне 10 пъти диаметърът му (10:1 съотношение).

Произход: Исторически, Процесът започна с производството на пистолети, което изискваше дълго, направо, и високо точни отвори. Ето защо пробиването на пистолети все още е една от най -често срещаните техники.

Съвременна употреба: Днес, Същите принципи се прилагат за индустрии като аерокосмическото (компоненти на двигателя), автомобилен (Инжектори за гориво, колянови валове), и масло & газ (инструменти за пробиване и тръбопроводи).

Дълбокото сондиране гарантира структурна цялост, Гладка производителност, и висока точност където нормалните методи за сондиране не достигат.

Значение на сондажа на дълбоки дупки в съвременните индустрии

Космонавтика и отбрана

В космонавтиката, Леките, но силни материали са от решаващо значение. Пробиването на дълбоки дупки се използва за производство на компоненти като колесник, Хидравлични системи, и дори оръжейни системи. Прецизността не се договаря, тъй като дори незначителните грешки могат да повлияят на производителността и безопасността.

Автомобилна индустрия

Автомобилите разчитат на сондиране на дълбоки дупки за компоненти като:

Инжектори за гориво (мъничко, Прецизни дупки за поток на гориво)

Коляни & Касферни валове (маслени проходи за смазване)

Хидравлични цилиндри (Използва се в системите за управление и спирачки)

Тук, Издръжливостта и точността влияят пряко върху ефективността на двигателя и надеждността на превозното средство.

Масло & Газова промишленост

При изследване и сондиране на нефт, Инструментите и тръбите често се нуждаят дълги сондажи които могат да издържат на тежки условия. Дълбокото сондиране гарантира сила, надеждност, и устойчивост на износване В компоненти като сондажни глави и петролни инструменти.

Инженерство & Медицински приложения

в Хидравлични системи, дълго, Необходими са прави дупки за контрол на налягането и гладкия поток на течността.

в медицински изделия, като хирургически инструменти, Дълбокото пробиване на дупки гарантира, че компонентите са и двете Малки и високо точни За безопасни операции.

Основни предимства на пробиването на дълбоки дупки

Висока точност - Способността за пробиване направо, Точни дупки на дълги дълбочини.

Подобрено повърхностно покритие - Гладките стени намаляват триенето и износване в критични приложения.

Ефективност & Животът на инструмента - Специализиран дизайн на свредлото и доставка на охлаждаща течност удължават живота на инструмента и намаляват разходите.

Универсалност - Може да се справи с широк спектър от материали, От стомани до суперансали.

Общи техники при сондиране на дълбоки дупки

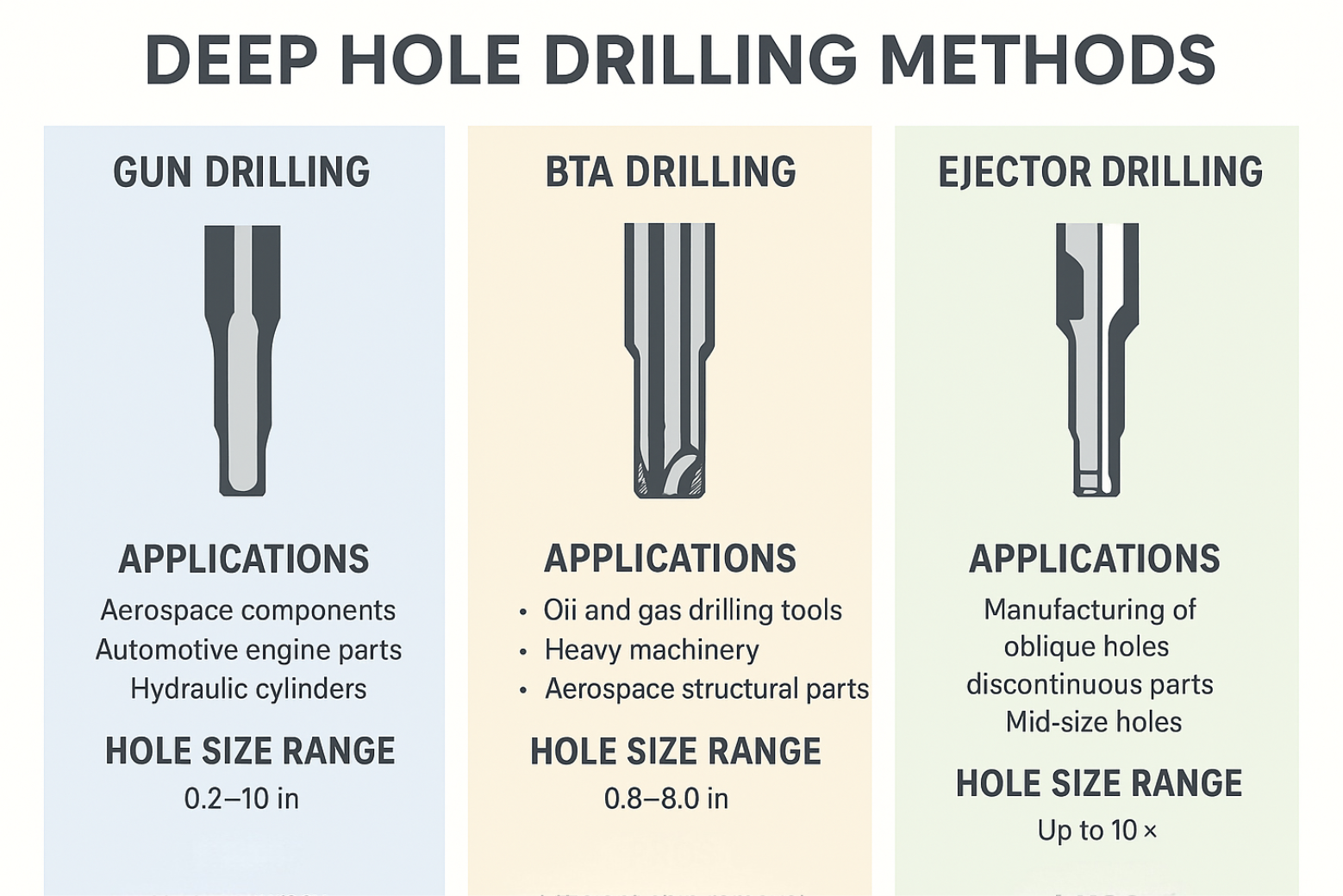

Пробиване на пистолет

Най-доброто за малък диаметър, прави дупки.

Произвежда отлична точност и повърхностно покритие.

Често срещано при производството на огнестрелно оръжие, Аерокосмически части, и автомобилни горивни системи.

BTA (Скучна и трепанинг асоциация) Пробиване

Използва се за по -големи диаметри на дупките.

Системата с една тръба премахва чиповете ефективно през центъра.

Идеален за масло & газ, тежки машини, и аерокосмически структурни части.

Изхвърляне на пробиване

Работи с Система с двойна тръба.

Предлага гъвкавост и може да се използва в стандартните центрове за обработка.

Перфектен за дупки със среден размер, където скоростта на производството е важна.

Съображения за инструменти и оборудване

За постигане на най -добри резултати, Няколко фактора се нуждаят от внимание:

Избор на бормашина: Избор на правилния бит (Свредла с пистолет, BTA, или изхвърляне) За размера на материала и дупката.

Охлаждащи системи: Течените охлаждания с високо налягане са от съществено значение за отстраняването на чипове и предотвратяване на износване на инструмента.

Възможности на машината: Често се изискват специализирани машини с твърди настройки, за да се предотврати вибрацията и несъответствието.

Какъв тип свредло е подходящ за пробиване през метал?

Когато става въпрос за пробиване в метал, Не всички свредла са създадени равни. Използването на грешен тип може да накара работата да се разочарова и дори да повреди вашите инструменти или детайла. Ето защо избирането на дясна тренировка е толкова важно.

Бързорежеща стомана (HSS) Свредла

Това са най -често срещаните и достъпни битове за тренировки. Те работят добре за по -меки метали като алуминий, месинг, и мека стомана. Ако просто се нуждаете от основен вариант, HSS обикновено е достатъчен.

Кобалтово свредло

По -силен от HSS, Кобалтовите битове за свредло са идеални за по -твърди метали като неръждаема стомана или чугун. Те могат да се справят с по -голяма топлина, Което е чудесно, защото пробиването през по -строги метали създава повече триене.

Карбидни свредла

Това са тежкотоварните шампиони. Карбидните битове са изключително трудни и могат да се режат през наистина трудни метали, Но те също са крехки, което означава, че могат да щракнат, ако не се използват внимателно. Те често се използват в индустриални настройки, където прецизността и издръжливостта са ключови.

Свредла с титан

Това са HSS пробивни парчета с титаново покритие. Покритието ги кара да издържат по -дълго чрез намаляване на триенето и топлината. Те са приятна средна основа, ако искате по -добра производителност от обикновените HSS, без да плащате високата цена на кобалт или карбид.

Предизвикателства и решения при сондиране на дълбоки дупки

Недоставка и счупване на инструменти

Проблем: Лекото несъответствие може да причини отклонение или счупване на инструмента.

Решение: Използвайте прецизно тегло, стабилни почивки, и системи за наблюдение в реално време.

Стабилност на детайла

Проблем: Дългите детайли могат да вибрират или да се движат по време на сондиране.

Решение: Сигурно затягане и настройка за потискане на вибрациите.

Специфични за материалите предизвикателства

Проблем: Твърди сплави или топлинно устойчиви метали причиняват прекомерно износване.

Решение: Използвайте сондажни битове с покритие (карбид, TiN, и т.н.) и оптимизирайте параметрите на подаване/скоростта.

Защо да изберете Най-висока точност За сондиране на дълбока дупка?

Не всеки магазин за машини е оборудван за сондиране на дълбоки дупки. Tops Precision осигурява:

Експертиза - Години опит със сложни проекти за сондиране.

Висока точност - Разширено оборудване и строг контрол на качеството.

Ефективност на разходите - Конкурентни цени, без да се компрометира качеството.

Надеждно партньорство - Ангажимент за предоставяне на време и спазване на индустриалните стандарти.

Заключение

Пробиването на дълбоки дупки е нещо повече от просто да се направи дупка - става въпрос за създаване прецизен, надежден, и високоефективни компоненти които захранват всичко - от реактивни двигатели до медицински инструменти. С правилните методи, инструменти, и експертиза, тя отваря вратата към безкрайни възможности в индустриите.

Ако вашият проект изисква Услуги за пробиване на дълбоки дупки, Партньорството с квалифициран производител гарантира, че получавате необходимата точност и производителност.

Често задавани въпроси

Q1: Каква е разликата между сондирането на дълбоки дупки и нормалното сондиране?

Дълбока дупка се справя с много по-високи съотношения на дълбочина и диаметър (10:1 или повече), докато стандартното сондиране обикновено остава под 3:1.

Q2: Какви сондажни парчета са най -подходящи за дълбоки дупки в дърво?

Специализирани изключително продължителни тренировки или тренировки с пистолети, предназначени за дървообработка.

Q3: Какво е стандартното съотношение дълбочина и диаметър за сондиране на дълбоки дупки?

10:1 или по -голямо, макар и в някои случаи, Може да отиде доста отвъд 100:1 с усъвършенствано оборудване.

Прочетете повече:

CNC фрезови услуги (За сравнение на методите за приготвяне на дупки)

Повърхностно покритие за обработени части

Обработка на неръждаема стомана / Обработка на титан